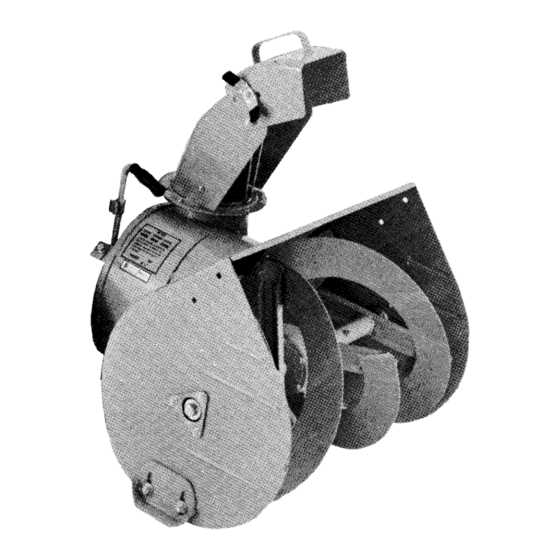

When it comes to maintaining and repairing heavy-duty machines designed for clearing winter debris, having a clear understanding of each individual component is crucial. These machines consist of various parts that work together to ensure optimal performance during harsh conditions. Familiarizing oneself with the layout and functions of each element can make troubleshooting, repairs, and replacements significantly easier.

For those who prefer to handle repairs on their own, access to clear and detailed layouts of the machine’s internal structure is invaluable. Such visual guides provide insight into where specific parts are located, how they interact, and the best way to approach maintenance tasks. Knowing how all pieces fit together not only aids in improving the lifespan of the equipment but also in enhancing its efficiency.

In this section, we will explore a comprehensive guide to the key components of these winter machines. By understanding the setup and role of each part, you can approach repair work with confidence, ensuring that the equipment stays in top condition throughout the season. Whether you’re replacing a worn-out component or simply conducting routine checks, having this knowledge will allow for quicker and more accurate fixes.

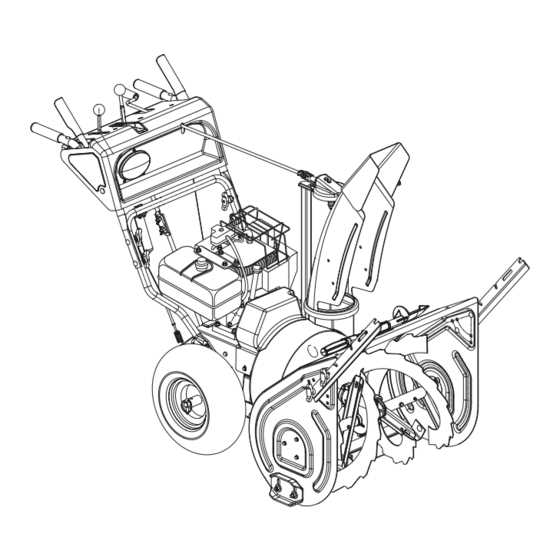

Ariens Snowblower Parts Overview

Understanding the essential components of a winter clearing machine is crucial for maintaining its efficiency and longevity. Each part plays a specific role in ensuring smooth operation, and knowing how they work together can help users troubleshoot issues and perform regular maintenance. In this section, we will explore the primary components that make up the equipment, their functions, and the importance of keeping them in optimal condition for peak performance during heavy snowfall.

Key Components

The main elements of the machine are designed to facilitate movement, propulsion, and clearing tasks. The engine serves as the power source, while the drive mechanism connects the wheels to the engine, enabling movement across the ground. The auger system is responsible for gathering and lifting the snow, while the chute directs it away from the path. These parts are interconnected, meaning that an issue with one can often affect the overall functionality of the equipment.

Maintenance Tips

Regular inspection and proper care of each component can significantly extend the machine’s lifespan. Ensuring that the engine is free from debris, lubricating moving parts, and checking for wear and tear in key areas like belts and cables are essential tasks. Replacing worn components promptly can prevent further damage and ensure that your equipment performs at its best during the snow season. Always consult the user manual for specific maintenance instructions tailored to your model.

Understanding Snowblower Components

When tackling winter weather challenges, a thorough grasp of machinery elements is essential. Each component plays a vital role in ensuring efficiency and functionality. By familiarizing yourself with these elements, you can enhance performance and address any issues that may arise during operation.

Power Source: At the heart of any effective machine lies the power source, which drives all operations. This can be a gas engine or an electric motor, each offering unique advantages in terms of performance and maintenance.

Auger: The rotating mechanism responsible for gathering snow is crucial for efficient clearing. Its design determines how effectively snow is pulled in and directed for discharge.

Chute: This component controls the direction in which the snow is expelled. Adjustability is key; a well-designed chute allows the operator to maneuver snow precisely where it’s needed.

Impeller: Once snow is collected, the impeller plays a critical role in propelling it out of the chute. The efficiency of this part directly impacts the machine’s overall performance.

Skid Shoes: These attachments determine the height at which the machine operates above the ground. Proper adjustment ensures optimal performance on various surfaces, preventing damage and enhancing efficiency.

Controls: Intuitive controls allow the operator to manage speed, direction, and other functionalities with ease. A well-designed control system is vital for safety and comfort during use.

Understanding these essential components empowers users to maintain their machinery effectively and troubleshoot issues as they arise. Regular inspection and knowledge of each part’s function will contribute to prolonged life and improved performance of the equipment.

Common Issues with Snowblower Parts

When operating winter machinery, users often encounter a range of challenges that can affect performance and reliability. Understanding these common problems can help in diagnosing and resolving issues more effectively, ensuring that equipment functions smoothly during critical times.

Wear and Tear: Over time, components can experience significant degradation due to continuous use and exposure to harsh conditions. Common signs include cracks, fraying, and corrosion, which can lead to reduced efficiency.

Clogging: Debris accumulation is a frequent issue that can impede functionality. Materials such as ice, snow, and dirt may block essential mechanisms, causing the machine to underperform or stall entirely.

Fuel Issues: Inadequate fuel quality or supply can result in poor engine performance. Users may notice difficulties in starting the machinery or irregular operation, often linked to stale fuel or blockages in the fuel line.

Electrical Failures: Wiring and connections are susceptible to damage from cold temperatures and moisture. This can lead to malfunctioning ignition systems or issues with lights and controls, which are crucial for safe operation.

Blade Deterioration: The cutting edges of equipment can dull over time, resulting in ineffective performance. Regular inspections and maintenance can help maintain their sharpness and efficiency, preventing unnecessary strain on the engine.

Addressing these common challenges promptly can significantly enhance the longevity and effectiveness of winter machinery, ensuring it is ready for any snow-related task.

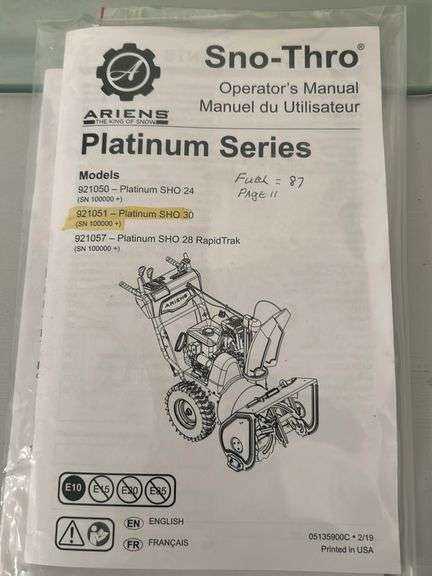

How to Identify Your Model

Knowing the exact model of your equipment is crucial for effective maintenance and repair. Identifying the correct version ensures you acquire the right components and understand the functionality of your machine. Here’s how to determine your model accurately.

Follow these steps to pinpoint your specific version:

- Check the User Manual: The manual typically contains detailed information about the model number and specifications.

- Locate the Identification Tag: Most machines have a metal or plastic tag that includes vital information such as the model number. Common locations for this tag include:

- On the frame, near the engine.

- Under the handle or along the side.

- On the rear of the unit.

By following these guidelines, you can easily determine the specifics of your equipment, ensuring that you have the right information for any repairs or maintenance tasks.

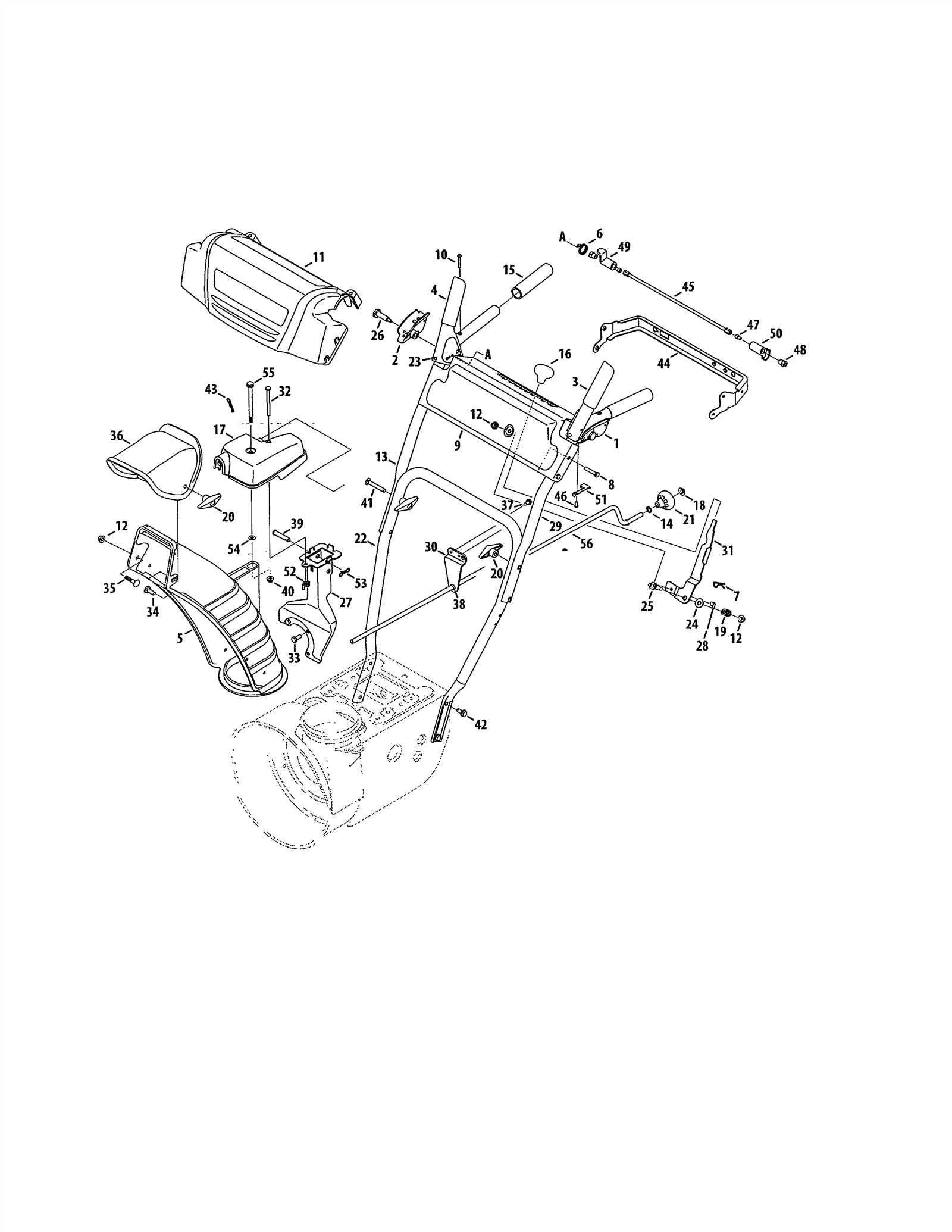

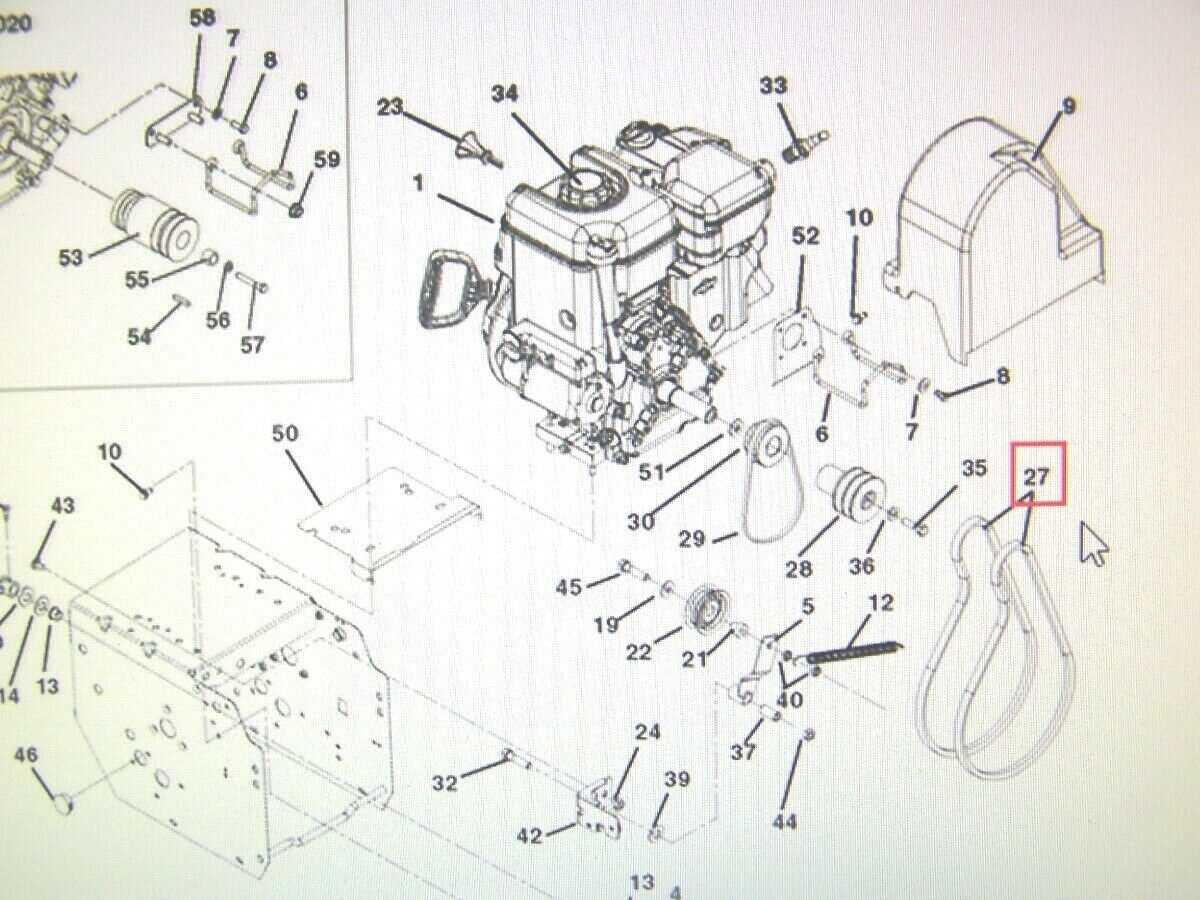

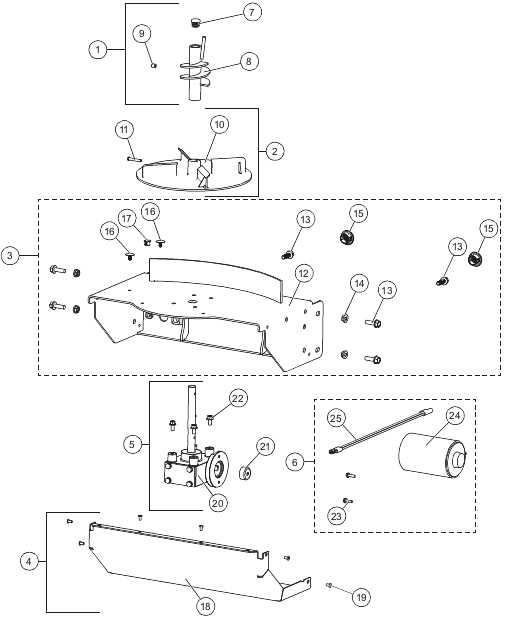

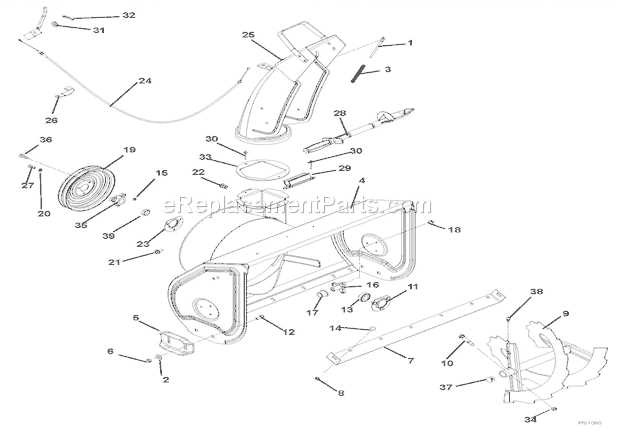

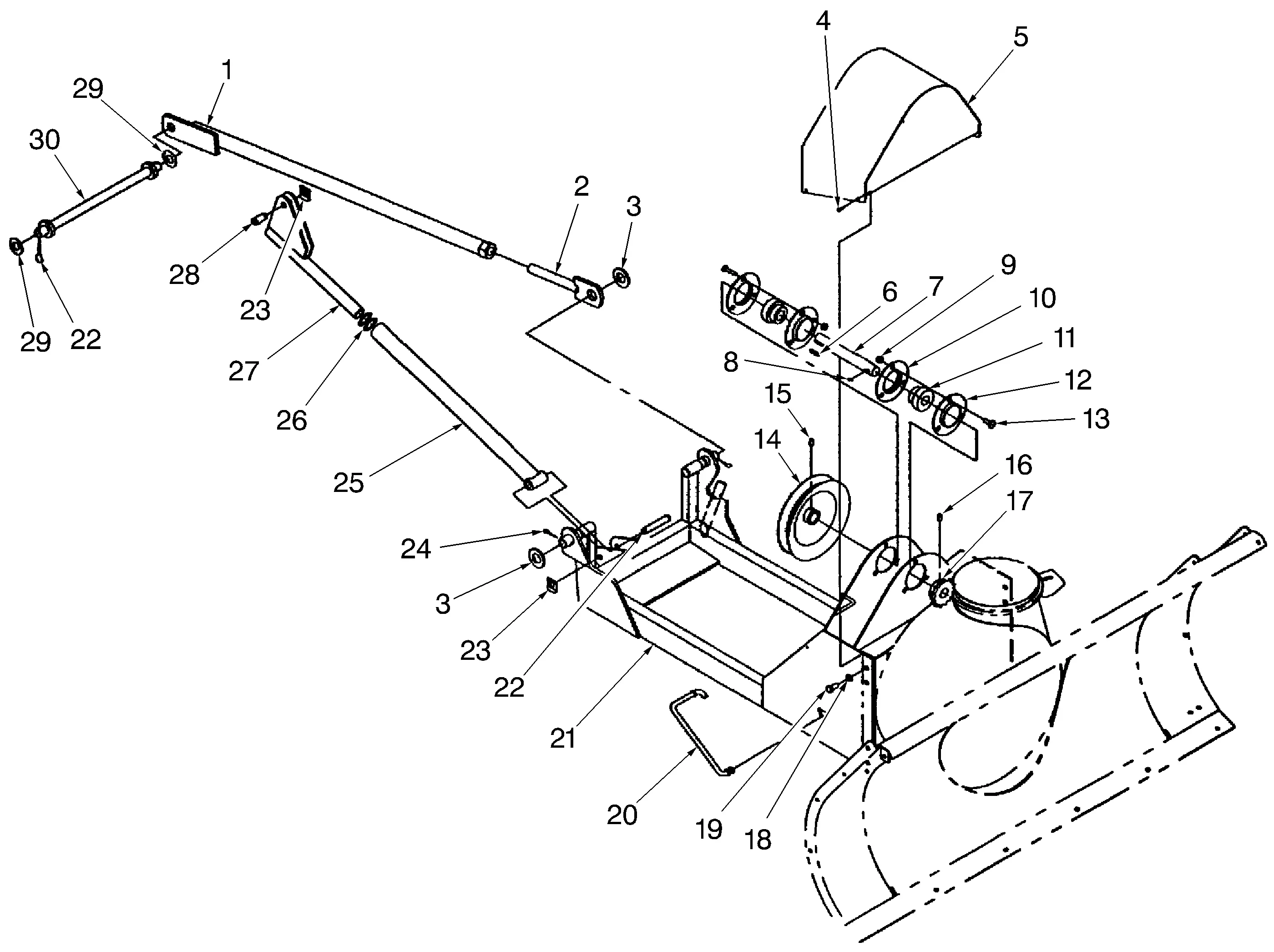

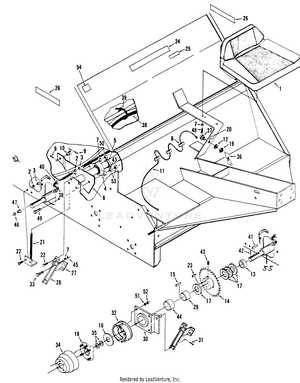

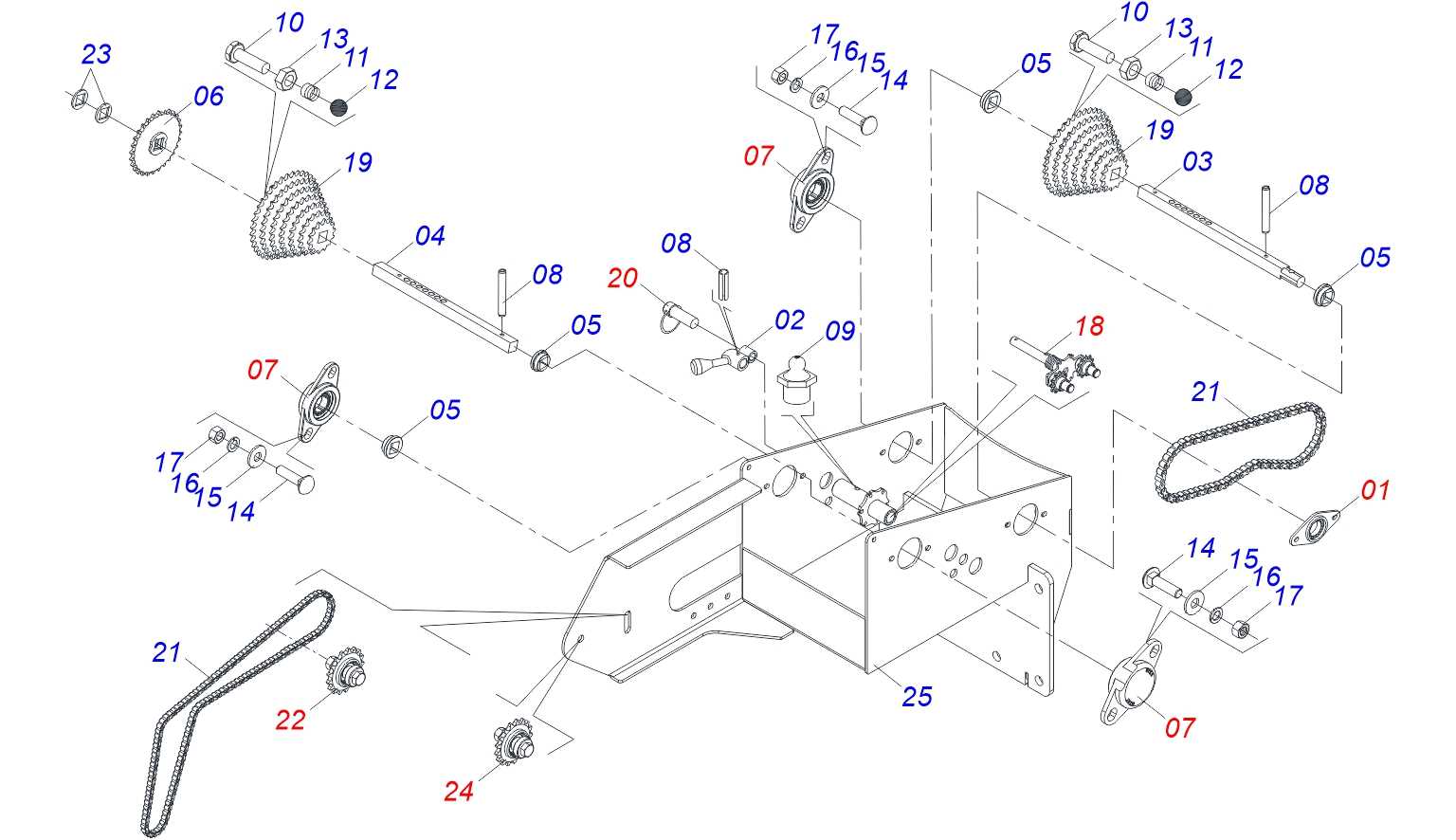

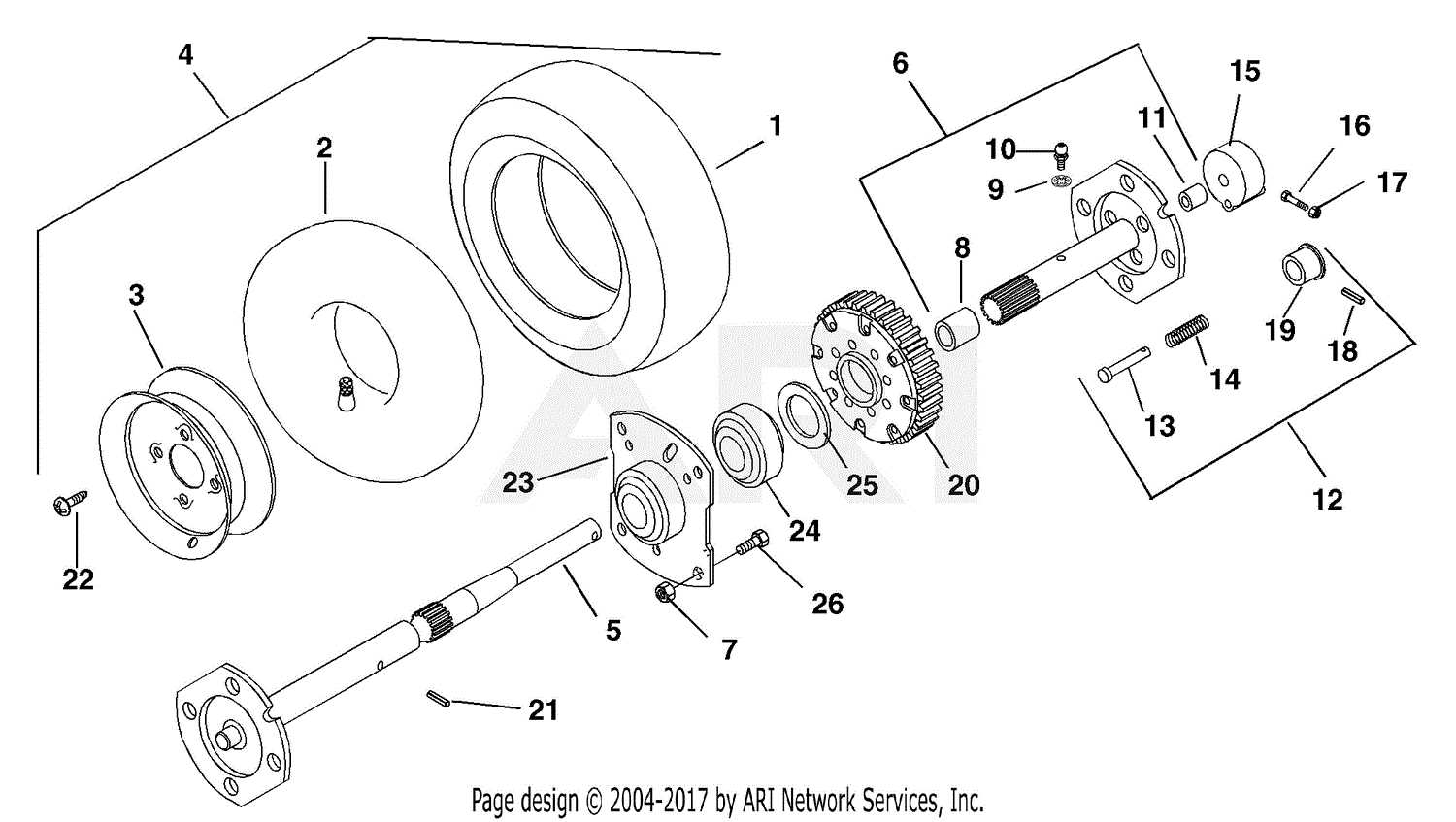

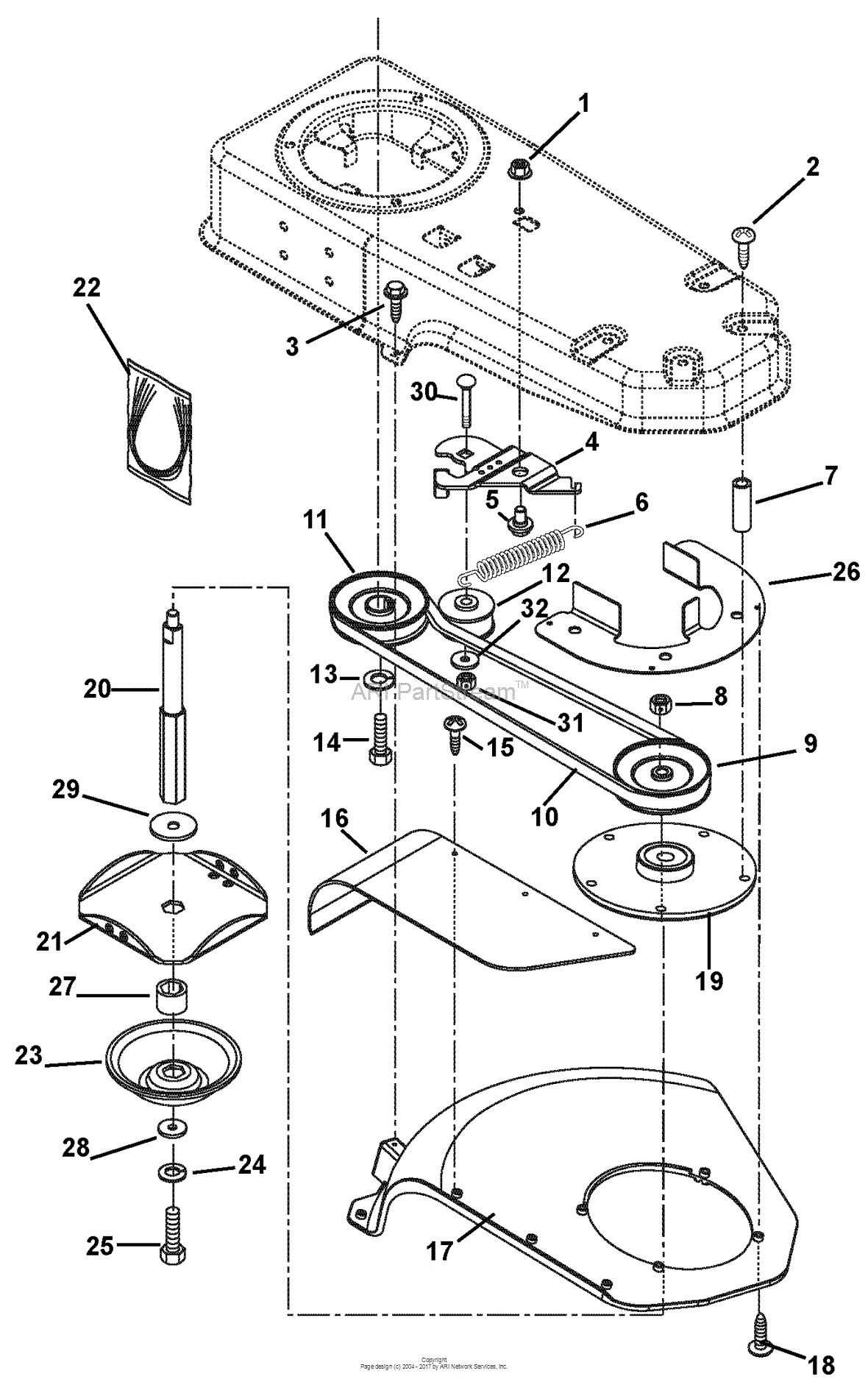

Parts Diagram: A Visual Guide

Understanding the components of complex machinery becomes significantly easier when you have a clear visual representation of each individual element and how they interact. This guide offers a detailed look at the various elements, helping you quickly identify and troubleshoot any issues. By having a visual reference at hand, you’ll be better equipped to recognize parts, understand their function, and carry out repairs or maintenance with confidence.

Why Visual References Are Essential

When dealing with intricate equipment, it’s not always easy to remember every component’s exact name or location. A visual guide can simplify this process by providing an easy-to-follow overview, making it easier to locate specific pieces. Whether you’re replacing a damaged item or performing regular upkeep, having a visual guide allows for quick identification and ensures that the proper procedures are followed.

Key Features of a Comprehensive Visual Guide

- Clear illustrations with labeled components

- Easy-to-understand breakdown of each part’s role

- Identification of both major and minor elements

- Helpful reference for troubleshooting common issues

- Step-by-step guides for replacement or repairs

With these features in place, the visual guide serves as an indispensable tool for anyone looking to maintain or fix their equipment. The clarity provided by these diagrams helps prevent errors and saves time during any repair or maintenance tasks.

Where to Find Replacement Parts

Finding components for your outdoor equipment can be a straightforward process if you know where to look. Numerous resources are available to help you locate the necessary items, ensuring your machinery operates efficiently once again.

Online Retailers

The internet is a treasure trove for sourcing various components. Many websites specialize in providing a wide range of options, allowing you to compare prices and availability. Here are some popular online platforms:

| Website | Description |

|---|---|

| Amazon | Offers a vast selection of components with customer reviews and fast shipping. |

| eBay | Great for finding both new and used items, often at competitive prices. |

| Manufacturer’s Website | Provides original components directly from the source, ensuring compatibility. |

Local Retailers

Your local hardware or specialty stores may carry essential components as well. Building a relationship with these retailers can often lead to personalized service and advice, helping you find exactly what you need. Don’t hesitate to ask for assistance, as many staff members are knowledgeable about the products they sell.

Maintenance Tips for Longevity

Regular care and upkeep are essential to ensuring the long-term performance and reliability of your outdoor equipment. Proper maintenance not only helps prevent breakdowns but also extends the lifespan of the machine, allowing it to operate efficiently through many seasons. Following a consistent maintenance schedule can save both time and money, while keeping your device in peak condition for years to come.

Routine Inspections

Performing regular inspections is the first step in maintaining the efficiency of your equipment. Check for signs of wear and tear, and ensure that all components are functioning properly. Identifying potential issues early can prevent costly repairs down the road.

- Inspect belts and cables for damage or wear.

- Ensure all bolts and screws are tightly fastened to avoid loose parts.

- Look for any signs of leaks or cracks that could indicate a problem.

- Check the fuel and oil levels, and ensure they are clean and free of contaminants.

Storage and Seasonal Maintenance

Proper storage plays a significant role in preserving your equipment. Whether it’s off-season storage or just a temporary break, following these steps will help protect the internal components and keep everything running smoothly when you need it most.

- Drain any remaining fuel before storing the machine to prevent clogging in the fuel system.

- Store the equipment in a dry, cool place to avoid rust and damage from the elements.

- Lubricate moving parts to ensure smooth operation when the equipment is next used.

- Cover the device with a weatherproof tarp to protect it from dust, debris, and moisture.

DIY Repair: Tools You Need

When tackling repairs on outdoor equipment, having the right tools can make the job easier and more efficient. Whether you are fixing a mechanical issue or performing maintenance, certain instruments are essential for disassembling, diagnosing, and reassembling the machine. In this guide, we’ll highlight the tools you should have on hand to ensure a successful DIY repair project.

Essential Tools for the Job

To begin any repair or maintenance task, you need to be well-equipped. The following tools are commonly used for most mechanical projects and will help you perform tasks ranging from simple adjustments to more complex fixes:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts of various sizes. |

| Wrenches | For gripping and turning bolts or nuts that may be too tight for your hands to turn. |

| Screwdrivers | Needed for removing screws, often for cover plates or smaller components. |

| Pliers | Helps with gripping, bending, or cutting wires and components. |

| Lubricant | Essential for maintaining moving parts and preventing rust or wear. |

| Rubber Mallet | Used to tap parts into place without damaging them. |

Additional Considerations

While the basic set of tools covers most tasks, there may be specific equipment required for specialized repairs. Be sure to check the condition of your tools regularly, as worn-out equipment can hinder progress. Also, keep safety gear such as gloves and eye protection on hand to avoid accidents during your repair work.

When to Seek Professional Help

Understanding the intricacies of your equipment can sometimes be overwhelming. While regular maintenance and troubleshooting can often resolve minor issues, there are specific situations where enlisting the help of an expert becomes essential. Recognizing these moments can save time, prevent further damage, and ensure your machinery operates safely and efficiently.

Here are some key indicators that professional assistance may be necessary:

- Persistent Issues: If problems recur despite your best efforts to fix them, it might be time to consult a specialist.

- Unusual Noises: Strange sounds during operation can indicate deeper mechanical issues that require professional attention.

- Physical Damage: Visible damage to components often requires expert assessment to avoid exacerbating the issue.

- Electrical Problems: If you’re experiencing wiring or electrical faults, it’s safer to seek help from a qualified technician.

- Warranty Concerns: Attempting repairs on equipment still under warranty can void coverage; professionals can help maintain that warranty.

By recognizing these signs, you can make informed decisions and ensure your equipment remains in optimal condition. Professional expertise can not only resolve existing problems but also extend the lifespan of your machinery.