Winter equipment that has withstood the test of time continues to be a valuable asset for those facing harsh conditions. Understanding the intricate connections and layouts of these reliable machines can be key to maintaining their performance. Each component plays a role in delivering the efficiency and power needed to clear paths and driveways, making proper maintenance essential for continued use.

For enthusiasts and repairers, having a clear understanding of the inner structure is crucial. By examining the layout and placement of each mechanism, it becomes easier to identify what needs attention during routine servicing or

Overview of Classic Ariens Snowblower Components

The mechanical structure of these reliable machines is built to withstand tough conditions, ensuring efficient performance during harsh winters. Each element has a specific role, contributing to the overall effectiveness of the equipment. From the power unit that drives the entire operation to the intricate mechanisms that control direction and movement, these components work in harmony to clear paths and driveways with precision.

Engine Assembly: The heart of the machine, this unit generates the power needed to handle varying levels of snow. Its robust design allows for consistent operation even in low temperatures, making it a crucial part of the system.

Understanding the Key Mechanical Parts

In this section, we will explore the fundamental components that drive functionality and efficiency in outdoor machinery. These elements play a crucial role in ensuring smooth operation, providing durability and reliable performance through various tasks.

Main Drive System

The drive mechanism is the heart of any outdoor equipment. It transfers power from the engine to the wheels, ensuring consistent movement across different terrains. Key elements in this system include:

- Transmission: Regulates speed and direction, offering control for varying conditions.

- Belts and Chains: Essential for linking power between the engine and moving parts, providing a

Identifying Essential Engine Components

Understanding the fundamental elements of a machine’s power unit is crucial for maintenance and repairs. Recognizing each component allows for accurate diagnostics and ensures that the system runs smoothly and efficiently.

Cylinder Block serves as the backbone of the mechanism, housing several vital moving parts. Its sturdy construction provides support and alignment for other key elements, ensuring proper function.

The carburetor plays a pivotal role in mixing air and fuel, creating an optimal blend for combustion. This mixture is vital for the performance and efficiency of the engine.

Flywheel helps maintain balance and store kinetic energy during operation, aiding in consistent speed regulation. It also assists in cooling by circulating air over other nearby parts.

Maintenance Tips for Vintage Models

Ensuring the smooth operation of older machines requires attention to detail and consistent upkeep. Regular care helps to extend the lifespan of equipment, ensuring it remains reliable even after years of use. By focusing on specific areas, owners can keep their machines running efficiently.

- Lubrication: Frequent application of grease or oil to moving parts prevents friction and wear. Pay close attention to joints, axles, and rotating components.

- Inspect Belts and Chains: Check

Replacement Options for Discontinued Parts

As components for older equipment become unavailable, it can be challenging to maintain the functionality of reliable machines. Seeking alternatives for those hard-to-find elements ensures that your device continues to operate smoothly. Below are some of the most effective methods to find suitable substitutes

Locating Hard-to-Find Mechanical Pieces

Finding elusive components for vintage machinery can be a challenging endeavor. Many enthusiasts encounter difficulties when seeking specific elements that are no longer in production or readily available in standard retail outlets. However, with a strategic approach and resourcefulness, it is possible to track down these hard-to-find items effectively.

One of the most effective methods is to engage with specialized forums and communities dedicated to machinery restoration. Members often share valuable insights, and some may have spare parts available for trade or sale. Additionally, reaching out to local repair shops that focus on vintage equipment can yield surprising results. These establishments may have connections or inventory that isn’t listed online.

Resource Type Description Online Marketplaces Websites like eBay and Craigslist often feature listings for rare components from individual sellers. Specialized Retailers Stores that focus on vintage machinery may stock or be able to order specific parts. Local Classifieds Community boards or local publications can have ads for parts being sold or swapped. Salvage Yards Visiting salvage yards that deal with machinery can provide unexpected finds. By exploring these avenues, enthusiasts can enhance their chances of locating those elusive mechanical pieces and keep their beloved machinery running smoothly.

Exploring Common Wear and Tear Areas

Understanding the typical areas that experience deterioration is crucial for maintaining optimal performance of your equipment. Identifying these regions can help prevent significant issues and extend the lifespan of the machine.

Blades and Cutting Edges: The most noticeable components are often the blades. Continuous exposure to harsh conditions can lead to dullness and damage. Regular inspection and timely replacement are essential to ensure efficient operation.

Belts and Cables: These components endure substantial stress during use. Fraying or breaking can cause operational failures. It is advisable to routinely check for signs of wear and replace them as needed to maintain functionality.

Fuel and Oil Systems: Regular maintenance of these systems is vital. Clogged filters or stale fuel can significantly impair performance. Keeping these areas clean and ensuring proper fluid levels can prevent breakdowns.

Wheels and Tracks: The movement mechanisms are subject to wear from rough surfaces. Inspecting for cracks or uneven wear can help identify when replacement is necessary, ensuring safe and smooth operation.

Chassis and Frame: Over time, exposure to the elements can lead to rust and structural weaknesses. Regularly checking the integrity of the frame will help avoid critical failures and ensure stability.

By focusing on these common areas of deterioration, you can effectively plan maintenance and address issues before they escalate, ultimately enhancing the reliability of your machine.

Upgrading Old Snowblower Systems

Enhancing the functionality of aged machinery can significantly improve efficiency and performance. With advancements in technology, many components can be replaced or upgraded to extend the lifespan of older models, making them more reliable and effective for winter tasks. By integrating modern features, operators can enjoy improved operation and user experience.

First, consider upgrading the engine. Replacing the original unit with a more powerful, fuel-efficient alternative can provide greater output and reduce operational costs. Additionally, newer engines often come equipped with better emissions control, contributing to a cleaner environment.

Another area to focus on is the auger assembly. A robust, high-performance auger can enhance the ability to clear heavy snowfall. Upgrading to a multi-stage system can further improve efficiency by breaking down compacted snow more effectively.

Lastly, examine the controls and electronics. Upgrading to electronic controls can simplify operation and provide features such as electric start or variable speed settings. Implementing improved safety features, like enhanced lighting or improved ergonomics, can also contribute to a more pleasant user experience during harsh weather conditions.

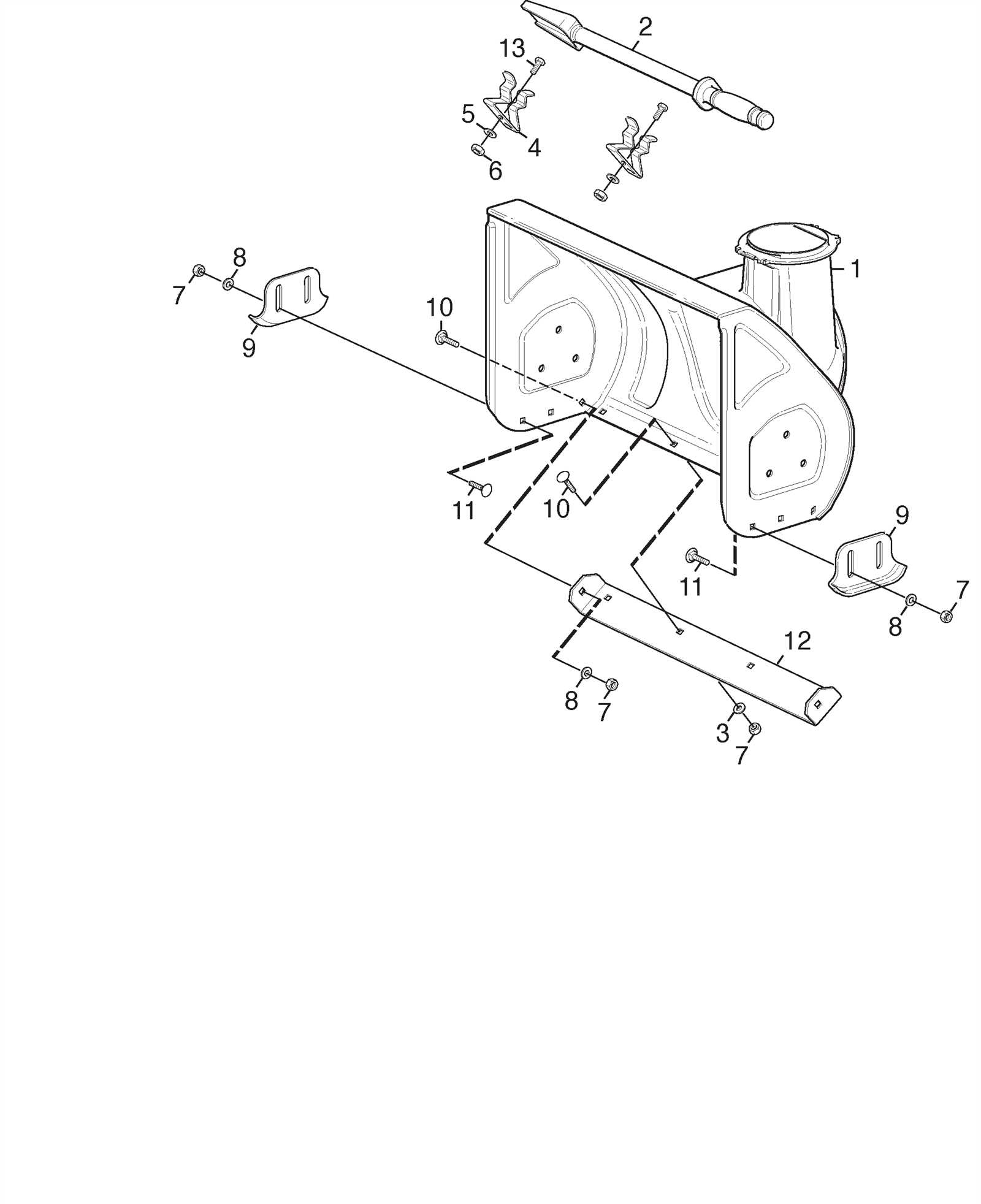

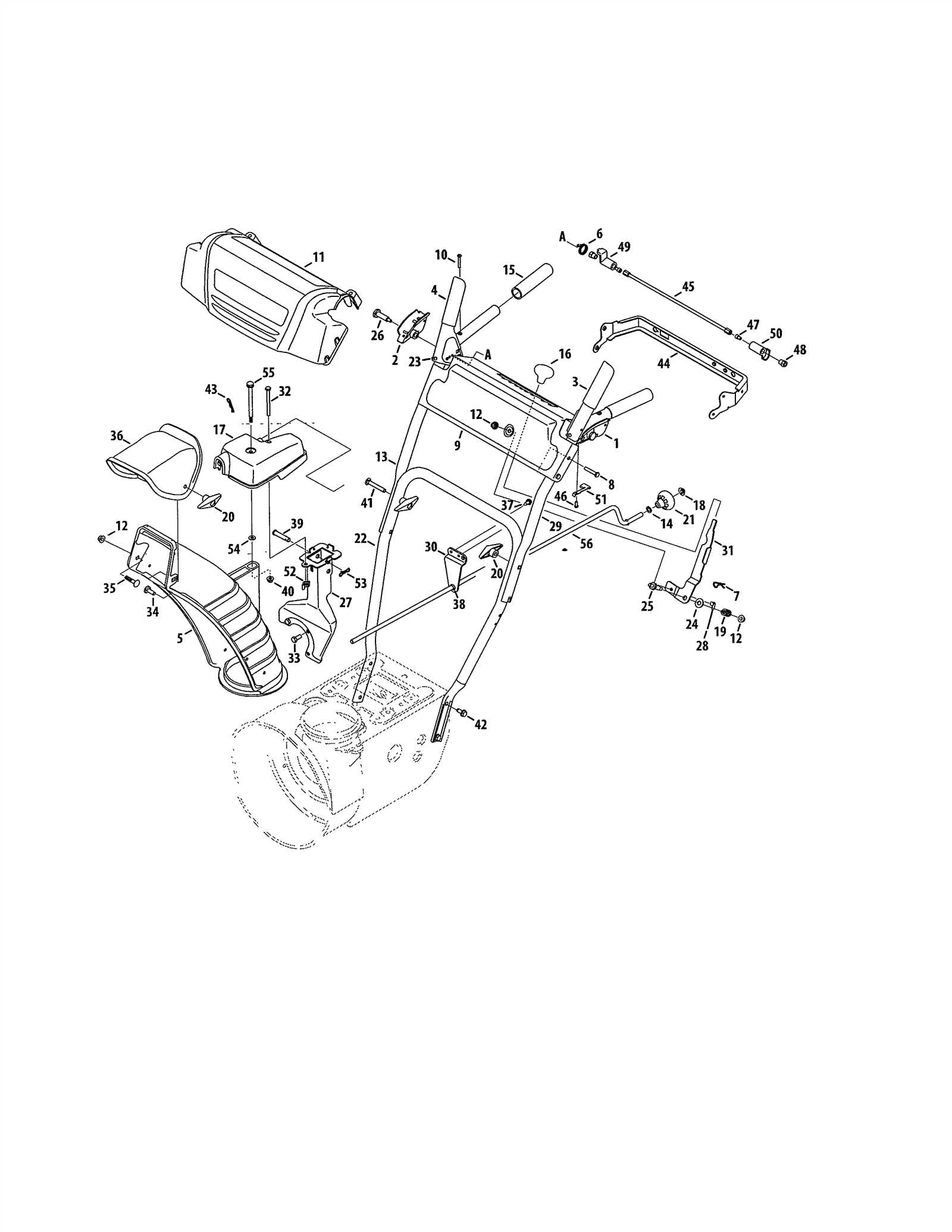

Visual Guide to the Component Layout

This section provides a comprehensive overview of the arrangement and configuration of essential elements within the equipment. Understanding the layout can significantly enhance troubleshooting, maintenance, and overall functionality. By familiarizing yourself with each component’s position and relation to others, you can effectively manage repairs and modifications.

Key Elements and Their Functions

Every element plays a crucial role in the overall performance. Components are strategically positioned to optimize operation and accessibility. For instance, the engine unit is typically at the core, surrounded by various controls and support structures. Recognizing how these parts interact can help in diagnosing issues quickly and efficiently.

Identifying Components with Ease

To assist users in identifying and understanding each element’s purpose, visual references and labeling are crucial. Utilizing clear illustrations or color-coded markings can aid in quick recognition and enhance the learning process. Knowing where each component is located and its specific function allows for more confident handling of maintenance tasks.