The intricacies of machinery often lie in their individual elements, each playing a crucial role in overall functionality. By exploring the various components that make up a specific model of compact loaders, operators and technicians can enhance their understanding and maintenance practices. This knowledge is essential for ensuring optimal performance and longevity of the equipment.

In the realm of heavy machinery, knowing how each part interacts with others can lead to better troubleshooting and repair strategies. A detailed exploration of these segments allows users to identify potential issues and streamline their maintenance routines. Moreover, familiarizing oneself with the configuration of these elements is key to achieving the ultimate operational efficiency.

For those invested in the performance of their equipment, visual aids that illustrate the assembly of various parts can be invaluable. Such resources enable a deeper insight into the mechanical relationships within the loader, empowering users to make informed decisions. Ultimately, this understanding fosters a more proficient handling of machinery, paving the way for enhanced productivity and reduced downtime.

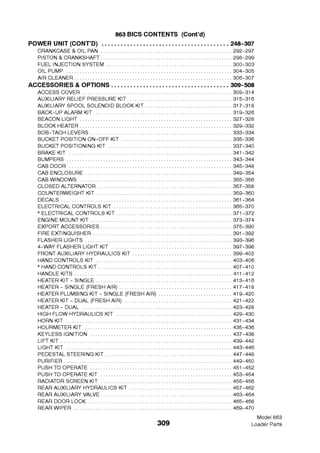

Understanding Bobcat 863 Parts

Familiarizing oneself with the components of a specific machinery model is essential for effective maintenance and operation. Recognizing how each element functions and interacts with others can significantly enhance performance and longevity. This knowledge empowers users to troubleshoot issues, ensure timely replacements, and optimize functionality.

Key Components Overview

The various elements of heavy machinery can be categorized based on their roles and importance. Here is a summary of some crucial components:

| Component | Function |

|---|---|

| Engine | Provides power for operation. |

| Hydraulic System | Facilitates movement and lifting capabilities. |

| Transmission | Transmits power from the engine to the wheels. |

| Chassis | Supports all components and provides stability. |

| Operator Controls | Allows the operator to control movement and functions. |

Importance of Regular Inspection

Routine checks of the individual elements can prevent unexpected failures and costly repairs. Understanding how each part operates can lead to better care and informed decisions regarding service and maintenance schedules. This proactive approach not only extends the machinery’s lifespan but also enhances overall efficiency.

Key Components of Bobcat 863

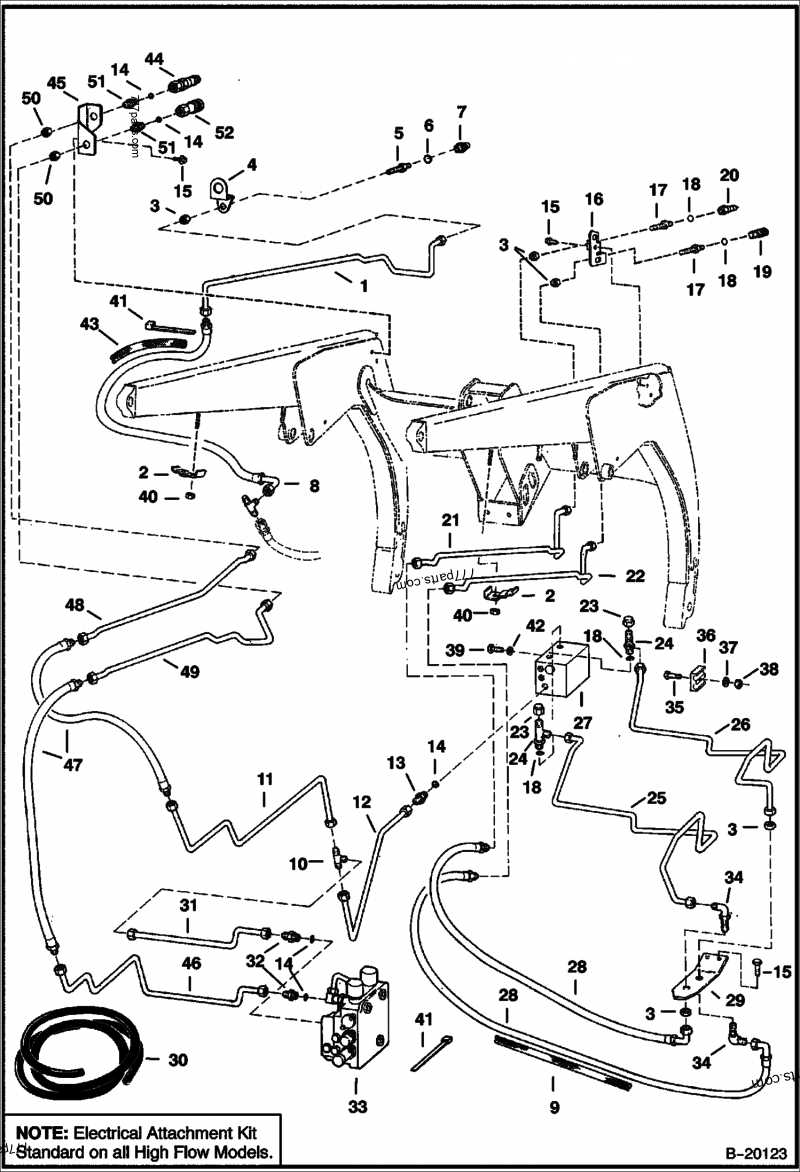

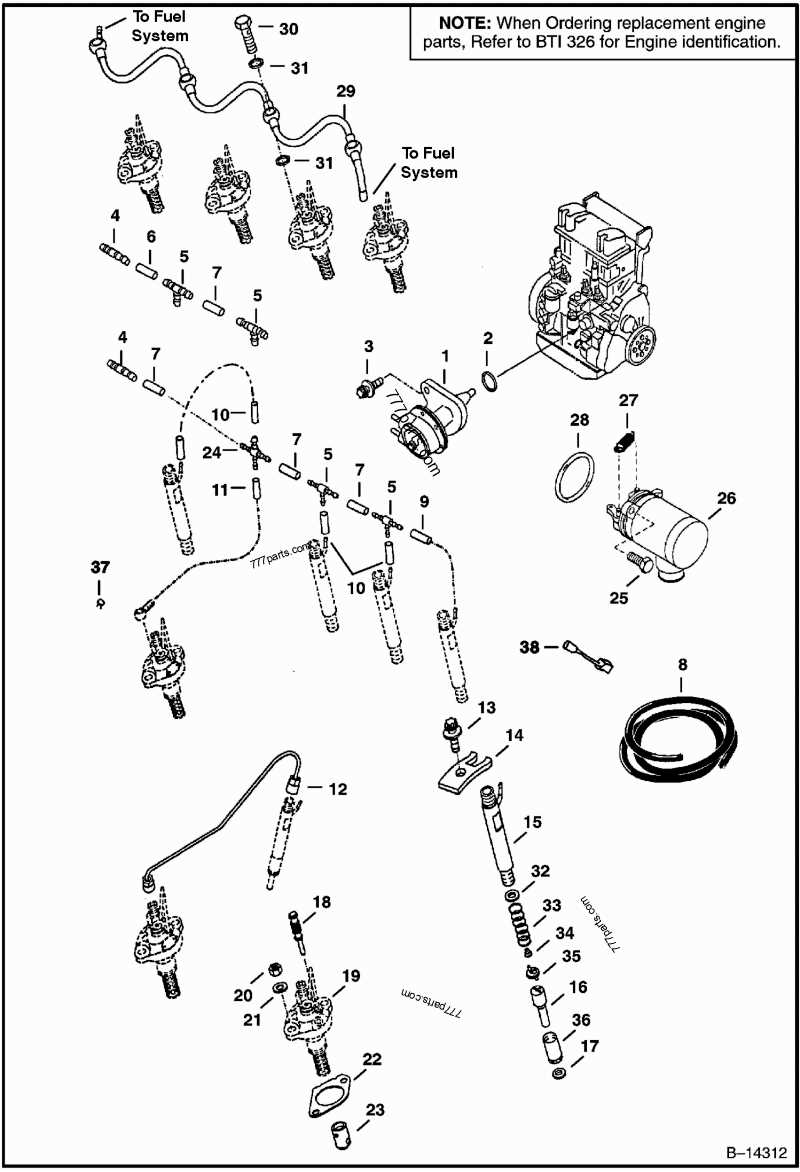

The functionality of any compact loader relies heavily on its essential elements. Understanding these key components is crucial for maintaining performance and ensuring efficient operation. Each part plays a significant role in the overall effectiveness and reliability of the machine.

Engine: The heart of the machinery, the engine provides the necessary power for all operations. Its efficiency directly impacts fuel consumption and output capacity.

Hydraulic System: This system facilitates movement and operation of attachments. It consists of pumps, cylinders, and valves, all working in harmony to ensure smooth and responsive control.

Transmission: A vital component that transfers power from the engine to the wheels or tracks. It affects speed and maneuverability, playing a key role in the machine’s performance in various terrains.

Chassis: The structural framework that supports the entire loader. A robust chassis enhances stability and durability, allowing the machine to handle heavy loads.

Electrical System: Responsible for powering the machine’s various electronic components, this system ensures reliable operation of lights, ignition, and other critical features.

Cooling System: Essential for preventing overheating, this system maintains optimal operating temperatures, ensuring the longevity and efficiency of the engine.

Understanding these fundamental components is vital for effective maintenance and operation, allowing users to maximize the capabilities of their equipment.

Common Issues with Bobcat 863 Parts

When it comes to heavy machinery, understanding potential problems is crucial for maintaining optimal performance. Operators often encounter various challenges that can hinder efficiency and increase downtime. Recognizing these common issues can help in proactive maintenance and timely repairs.

One prevalent concern involves hydraulic system failures. Leaks or pressure drops can lead to reduced lifting capacity and slower response times. Regular inspections and timely replacements of seals and hoses can mitigate these problems.

Another frequent issue is related to the drive components. Worn-out tracks or wheels can affect maneuverability and stability. Ensuring proper alignment and replacing components at the first sign of wear can prevent more significant complications.

Electrical system malfunctions are also notable. Faulty wiring or failing sensors can disrupt operations, leading to unpredictable performance. Regular checks and proper diagnostics are essential to keep the electrical systems functioning smoothly.

Lastly, the cooling system often requires attention. Overheating engines can result from blocked radiators or faulty thermostats. Maintaining clean cooling components and monitoring temperatures can help avoid severe engine damage.

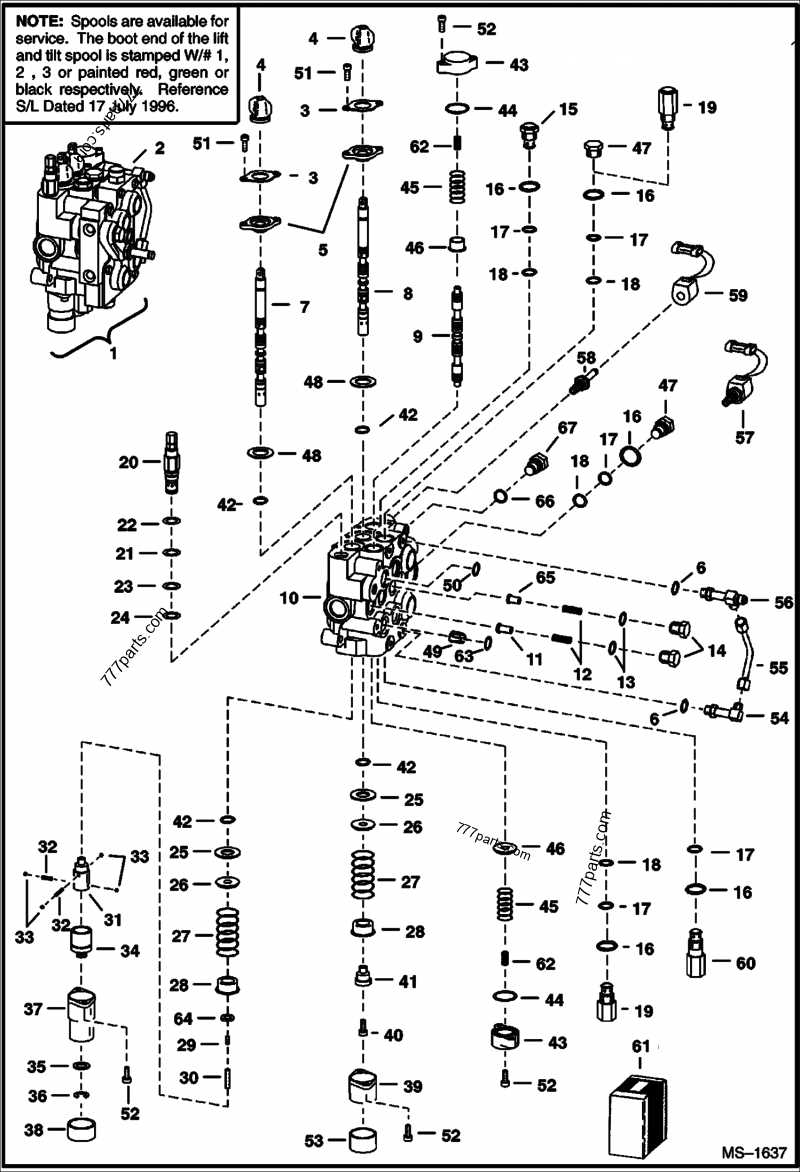

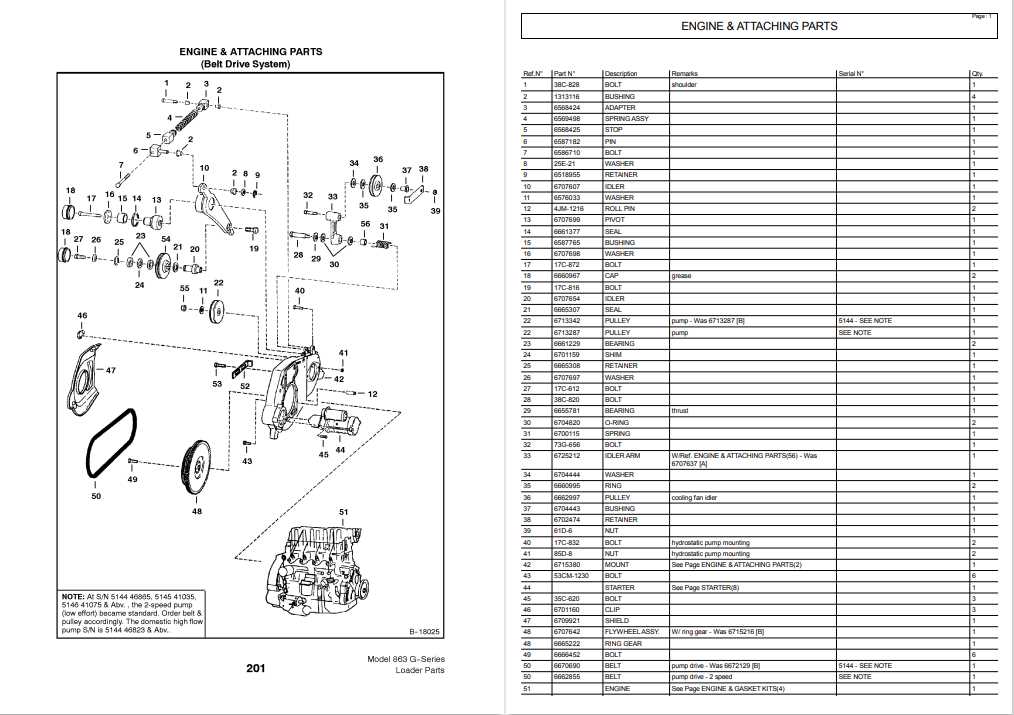

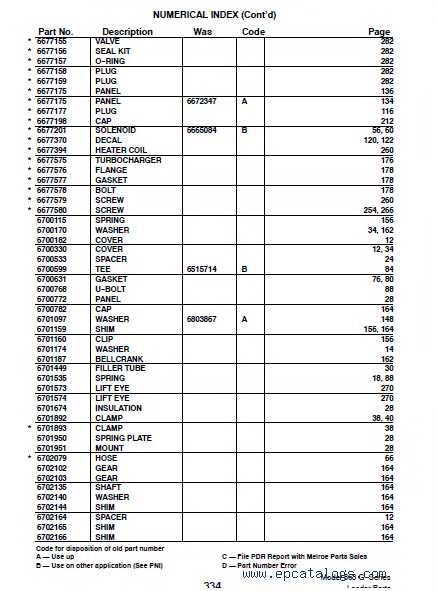

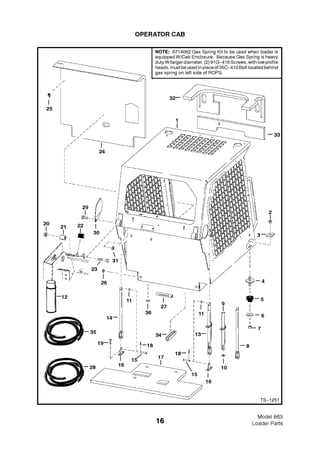

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide crucial information about the components of a machine and their interconnections, making it easier to identify what is needed for service or replacement.

Key Components of Schematics

Familiarize yourself with the various symbols and notations used in these visuals. Each symbol represents a different element, and knowing these can help you navigate the layout with confidence.

Steps for Interpretation

Follow these steps to effectively interpret these visual representations:

| Step | Description |

|---|---|

| 1 | Identify the main assembly or system being illustrated. |

| 2 | Locate the individual components and their corresponding labels. |

| 3 | Cross-reference with a parts list if available for specific details. |

| 4 | Check for any accompanying notes or specifications. |

Essential Maintenance Tips for Longevity

Regular upkeep is crucial for ensuring the durability and performance of machinery. By adopting proactive measures, operators can extend the lifespan of their equipment and minimize costly repairs. Focus on routine inspections, proper lubrication, and timely replacements of worn components to maintain optimal functionality.

Establish a schedule for checking vital systems and addressing any signs of wear or damage. Keeping the equipment clean not only enhances efficiency but also prevents premature deterioration. Using high-quality fluids and filters will contribute significantly to the overall health of the machine.

Additionally, ensure that operators are well-trained in proper usage techniques to avoid unnecessary strain on mechanical parts. Engaging in periodic training sessions can help reinforce best practices and encourage awareness of potential issues before they escalate.

Where to Find Replacement Parts

Finding high-quality components for machinery can be a challenging task, but numerous resources are available to help streamline the process. Whether you need an essential element for routine maintenance or a specific item for repairs, understanding where to search is crucial for ensuring optimal performance and longevity of your equipment.

Online Retailers

The internet is a treasure trove of options for sourcing components. Various online stores specialize in heavy machinery supplies, offering a vast selection of items. Sites like e-commerce platforms and specialized retailers provide user-friendly search tools to locate specific components easily. Additionally, reading customer reviews can guide you in choosing reputable suppliers.

Local Dealers and Distributors

For those who prefer in-person shopping, visiting local dealers is an excellent choice. Authorized distributors often carry genuine items and can provide expert advice on the best options for your machinery. Furthermore, building relationships with local suppliers can lead to better service and potential discounts.

Regardless of the source, ensuring compatibility and quality is paramount when seeking replacements. By utilizing both online and local resources, you can efficiently find the necessary components to keep your equipment running smoothly.

Aftermarket vs. OEM Parts Explained

The choice between different components can significantly impact performance, durability, and cost. Understanding the distinctions between various types of replacements is essential for making informed decisions. This section delves into the nuances of alternatives and original options, providing insight into their respective advantages and potential drawbacks.

Understanding OEM Components

Original Equipment Manufacturer items are created by the same company that produced the original machinery. These options are often regarded as the gold standard due to their high level of compatibility and reliability. Users can expect a seamless fit and consistent performance, as these items are designed specifically for the equipment in question.

Exploring Aftermarket Alternatives

Aftermarket offerings are produced by third-party manufacturers. While they can often be more affordable, the quality and fit may vary significantly. Some alternatives provide excellent performance and longevity, while others might not meet the same standards. It’s crucial to research and choose reputable brands to ensure that the equipment remains operational and safe.

Ultimately, the decision between these options should consider factors such as budget, performance requirements, and long-term goals for the machinery.

Safety Considerations for Repairs

When engaging in maintenance tasks, ensuring safety is paramount. Proper precautions not only protect the individual performing the repairs but also contribute to the longevity of the equipment. Adopting a systematic approach to safety can prevent accidents and facilitate a smoother repair process.

Essential Safety Practices

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-ventilated to minimize exposure to fumes and dust.

- Keep the area tidy to reduce the risk of tripping or other hazards.

- Use tools that are in good condition and suited for the task at hand.

Equipment Precautions

- Before starting any work, disconnect the power source to avoid accidental activation.

- Utilize lockout/tagout procedures to secure equipment during repairs.

- Consult the manufacturer’s guidelines for specific safety recommendations related to the equipment.

- Be aware of weight limits and use proper lifting techniques or assistance when handling heavy components.

By prioritizing safety, individuals can ensure that repair tasks are conducted efficiently and with minimal risk, leading to better outcomes and a safer working environment.

Resources for Bobcat 863 Owners

For those who own this compact machinery, having access to reliable resources is essential for maintenance and operation. Whether you’re looking for manuals, community support, or replacement components, a variety of options can enhance your ownership experience.

Manuals and Documentation

- Owner’s manuals for operational guidance

- Service manuals for detailed maintenance procedures

- Technical specifications sheets for quick reference

Community and Support

- Online forums for troubleshooting and advice

- Social media groups for connecting with other enthusiasts

- Local workshops and training sessions for hands-on learning