The efficient operation of a brushcutter relies on the intricate assembly of various elements that work in harmony. Each component plays a vital role in ensuring the machine performs optimally, making it essential for users to familiarize themselves with these parts. Gaining insight into the structure and function of each piece can significantly enhance maintenance and troubleshooting efforts.

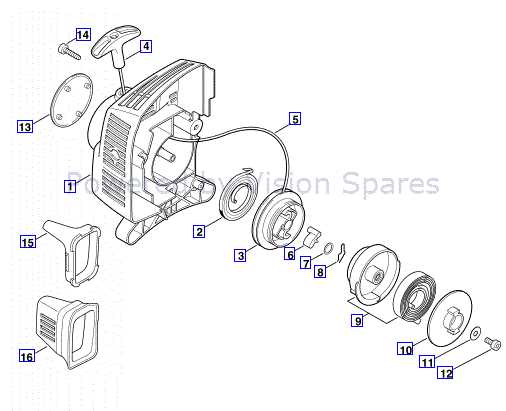

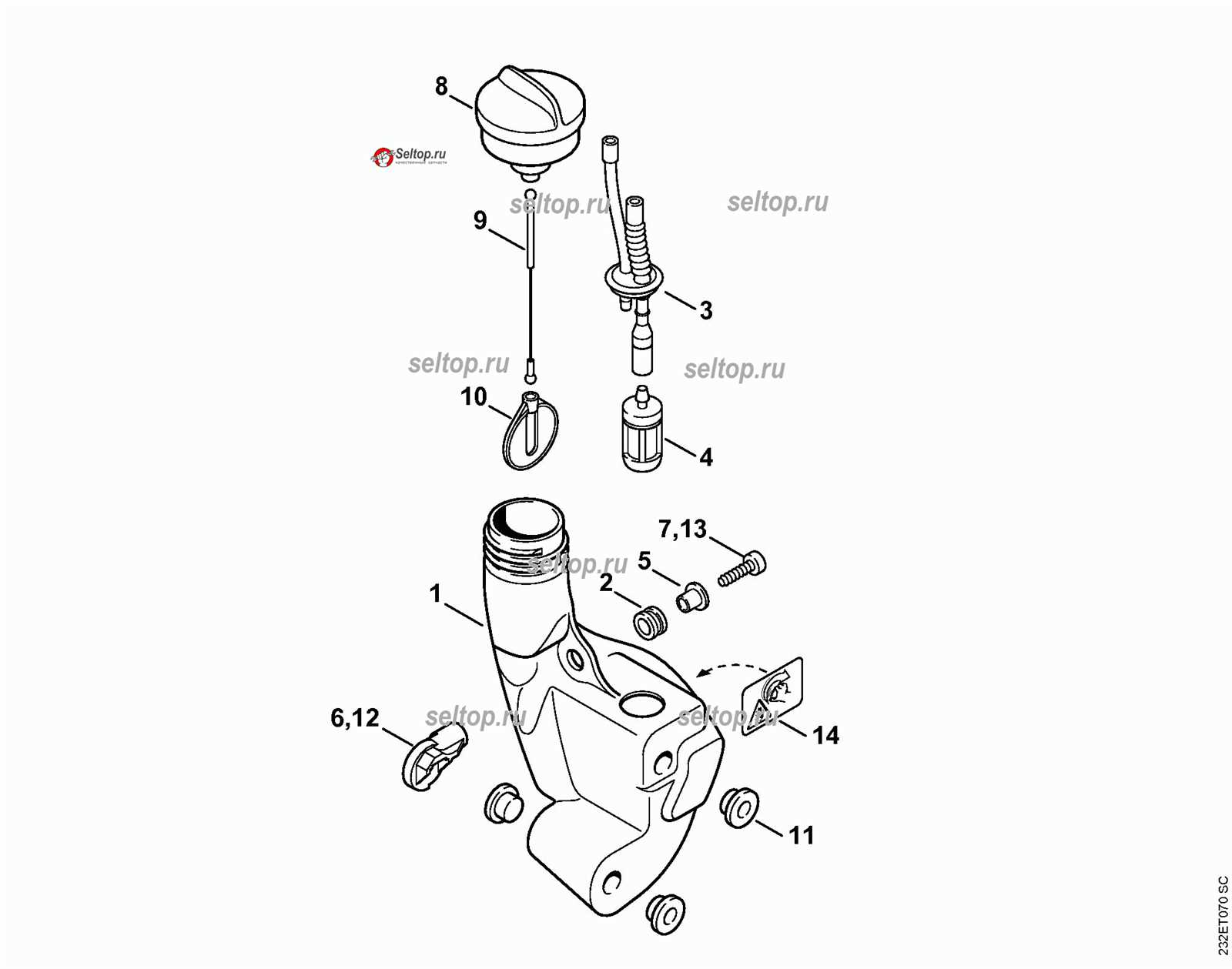

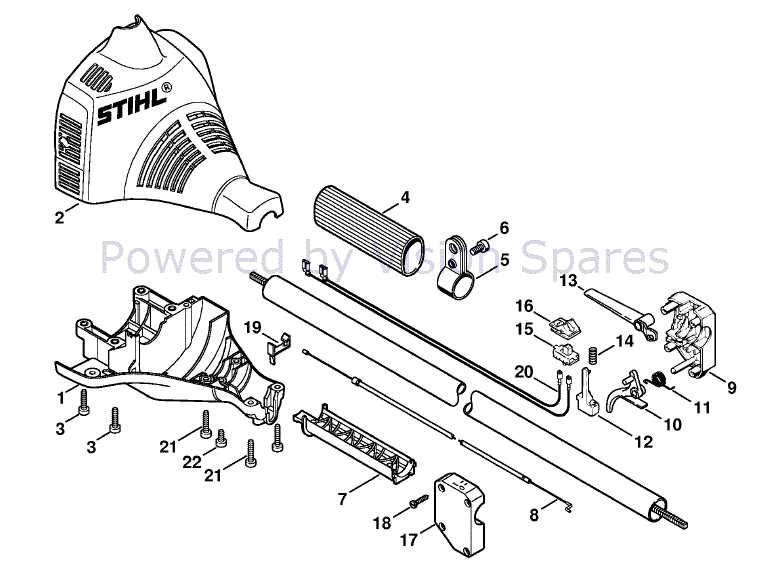

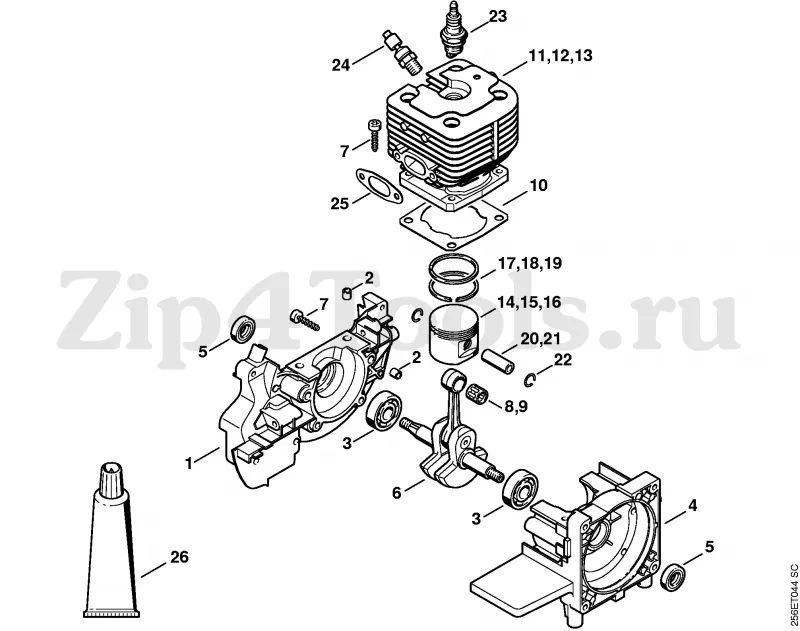

Users often seek visual references to identify and comprehend the relationships between the different components. Such illustrations serve as valuable guides, offering clarity on how each part contributes to the overall functionality of the equipment. This knowledge empowers users to make informed decisions regarding repairs and replacements, ultimately prolonging the lifespan of their tools.

Moreover, understanding the layout of these elements fosters greater confidence in handling the machinery. Familiarity with each segment allows for efficient operation and helps in recognizing signs of wear or malfunction. A well-informed user can swiftly address issues before they escalate, ensuring the equipment remains reliable for tackling even the toughest tasks.

Overview of Stihl FS 55 Components

The efficient operation of outdoor power equipment relies heavily on its individual elements, each designed to perform specific functions. Understanding the various components of a particular model can significantly enhance maintenance practices and troubleshooting efforts.

Key Elements

- Engine: The heart of the machine, responsible for converting fuel into mechanical energy.

- Fuel System: Comprising the tank and delivery mechanisms, this system ensures a steady flow of fuel to the engine.

- Cutting Head: The primary component for trimming and mowing, featuring blades or lines suited for various applications.

- Handle and Controls: Designed for comfort and ease of use, these components allow the operator to maneuver the equipment effectively.

- Chassis: The framework that supports all other parts, providing stability and protection.

Maintenance Considerations

- Regularly check and clean the engine to ensure optimal performance.

- Inspect the fuel system for leaks or blockages that may hinder functionality.

- Examine the cutting head for wear and replace components as necessary to maintain cutting efficiency.

- Keep the handles and controls free from debris to ensure safe operation.

- Periodically assess the chassis for damage to prolong the lifespan of the equipment.

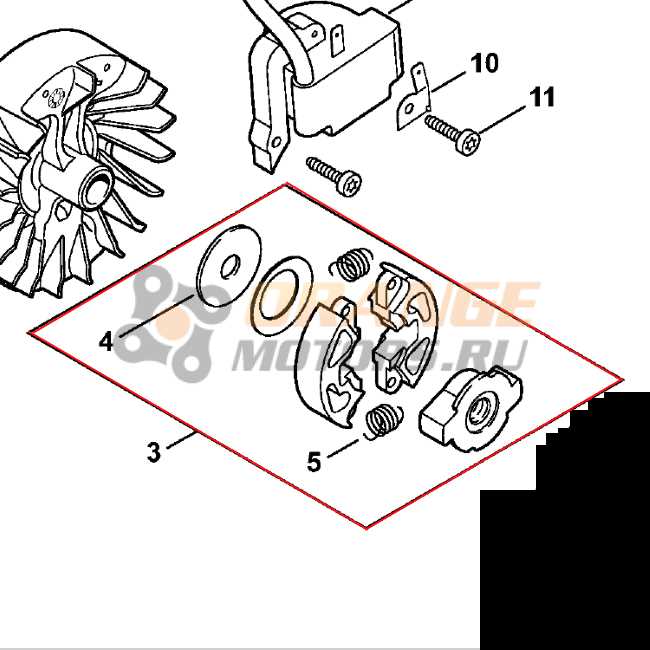

Understanding the Parts Diagram

Grasping the layout of an equipment assembly is essential for effective maintenance and repair. A visual representation of components provides clarity on how individual elements interact within the machinery. This can enhance troubleshooting skills and streamline the repair process, ensuring optimal performance of the device.

Key aspects to consider when examining the visual representation include:

- Component Identification: Recognizing each individual part and its function within the system is crucial. This knowledge aids in understanding how to replace or repair specific elements.

- Assembly Order: Understanding the sequence in which components are assembled can prevent issues during reassembly and ensure that everything fits correctly.

- Connection Points: Familiarizing yourself with how parts connect to one another helps in identifying potential wear areas and points of failure.

- Maintenance Areas: Some components may require regular upkeep. Recognizing these parts allows for timely maintenance, prolonging the life of the equipment.

Utilizing this visual guide effectively enables users to maintain their machinery in peak condition, ultimately leading to better efficiency and performance.

Common Issues with FS 55 Parts

The efficient functioning of garden equipment is crucial for maintaining outdoor spaces. However, various components may experience issues over time, affecting performance and usability. Understanding these common problems can aid in proper maintenance and timely repairs, ensuring the longevity of the device.

Frequent Challenges

- Fuel System Failures: Clogged fuel lines and dirty filters can impede the flow of fuel, leading to starting issues or reduced power.

- Ignition Problems: Defective spark plugs or faulty ignition coils may cause misfiring or prevent the engine from starting altogether.

- Cutting Mechanism Malfunctions: Worn blades or improperly adjusted cutting heads can result in ineffective trimming, requiring frequent replacements.

Maintenance Tips

- Regularly check and clean the fuel lines and filters to ensure proper fuel flow.

- Inspect and replace spark plugs periodically to maintain optimal ignition performance.

- Sharpen or replace cutting blades as needed to ensure efficient operation.

By addressing these common challenges, users can enhance the reliability and efficiency of their garden equipment, promoting a more enjoyable and effective gardening experience.

How to Use the Parts Manual

Utilizing a manual for components is essential for effective maintenance and repair of equipment. This resource serves as a comprehensive guide, offering clear visuals and references that assist in identifying each element within the assembly. By familiarizing yourself with the contents, you can ensure proper handling and replacement of components when necessary.

Understanding the Layout is crucial when navigating this manual. Typically, it includes various sections dedicated to different assemblies, allowing you to quickly locate the information you need. Each section is usually accompanied by labeled illustrations that correspond to the respective parts, making identification straightforward.

To effectively reference specific components, start by identifying the section that corresponds to the area of your interest. Take note of the part numbers and descriptions provided alongside the visuals. This will aid in acquiring the correct replacements or accessories without confusion.

Moreover, always keep the manual handy during maintenance tasks. Whether you are assembling or disassembling parts, having this reference nearby can streamline the process, reducing the likelihood of errors. By following the guidance outlined within this resource, you can enhance your overall experience and ensure your equipment operates efficiently.

Replacing Components on the FS 55

Maintaining the functionality of your outdoor equipment involves the timely replacement of worn or damaged elements. Ensuring that all parts operate efficiently not only enhances performance but also extends the lifespan of the unit. This guide provides an overview of how to effectively replace components, focusing on critical areas that require attention during routine maintenance.

Identifying Worn Components

Before proceeding with replacements, it is essential to accurately identify components that show signs of wear. Look for indicators such as unusual noises, vibrations, or decreased performance. Regular inspections can help pinpoint issues early, allowing for prompt intervention.

Step-by-Step Replacement Process

Once you have identified the components in need of replacement, follow these steps:

- Gather Required Tools: Assemble all necessary tools and replacement parts for the task.

- Power Off the Equipment: Always ensure that the equipment is powered down to prevent any accidental starts during maintenance.

- Carefully Disassemble: Follow the manufacturer’s instructions to carefully disassemble the necessary sections of the unit.

- Replace Components: Install the new parts, ensuring they are securely fitted and aligned correctly.

- Reassemble and Test: Once all replacements are complete, reassemble the equipment and perform a test run to confirm everything is functioning properly.

By following these guidelines, you can ensure that your outdoor equipment remains in top condition, ready to tackle any task with efficiency and reliability.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment is crucial for ensuring longevity and optimal performance. Having the right tools on hand can make routine maintenance tasks straightforward and efficient. This section outlines the indispensable instruments that every owner should consider for effective servicing of their machinery.

Basic Hand Tools

Essential hand tools such as wrenches, screwdrivers, and pliers form the backbone of any maintenance toolkit. These instruments allow for easy adjustments and repairs. A quality set of wrenches, including both metric and imperial sizes, is particularly beneficial for loosening and tightening various components. Additionally, a selection of screwdrivers, both flat and Phillips, is necessary for accessing different fasteners throughout the equipment.

Specialized Maintenance Equipment

In addition to basic hand tools, specialized equipment can enhance maintenance efforts. Items such as spark plug wrenches, fuel line tools, and air filter cleaning kits are invaluable for targeted tasks. Spark plug wrenches simplify the removal and replacement of ignition components, while fuel line tools aid in servicing the fuel system. Maintaining clean air filters is equally important, and dedicated cleaning kits ensure optimal airflow and performance.

Finding Genuine Replacement Parts

When maintaining outdoor equipment, ensuring the quality of components is paramount. Authentic components not only enhance the performance of your tools but also prolong their lifespan. This section delves into the importance of sourcing reliable replacements and offers guidance on how to find them effectively.

Understanding the Importance of Authentic Components

Utilizing original components guarantees compatibility and reliability. Imitations may seem appealing due to lower costs, but they often lead to performance issues and can even damage your equipment in the long run. Authentic components are engineered to meet specific standards, ensuring optimal operation and safety during use.

Where to Find Quality Replacements

To locate reliable components, begin by visiting authorized dealers or reputable online retailers. Many manufacturers provide resources on their official websites, including lists of certified distributors. Additionally, engaging with local service centers can provide insights into trusted sources. Always verify the authenticity of the product by checking for serial numbers or other identifiers that signify originality.

Tips for Efficient Repairs

Effective maintenance of outdoor power equipment requires a methodical approach. Understanding the internal mechanisms and utilizing proper techniques can significantly enhance the repair process. By following specific strategies, you can minimize downtime and ensure your tools operate at peak performance.

1. Gather Necessary Tools and Supplies: Before beginning any repair, collect all required instruments and materials. Having everything on hand reduces interruptions and allows for a smoother workflow.

2. Consult Reliable Resources: Refer to authoritative manuals or online resources for guidance on your equipment’s components and assembly. This information can provide valuable insights into troubleshooting and part identification.

3. Document the Disassembly Process: As you take apart the equipment, make notes or take photos of each step. This documentation can serve as a useful reference during reassembly, ensuring nothing is overlooked.

4. Organize Components: Keep all removed elements sorted and labeled. This practice prevents confusion and helps streamline the reinstallation process, saving both time and effort.

5. Test After Repairs: Once the repair is complete, perform a thorough check to ensure everything is functioning correctly. This final assessment helps identify any lingering issues and confirms that the equipment is ready for use.