In the realm of power tools, the functionality and efficiency of a chainsaw are significantly influenced by its intricate assembly of elements. Each component plays a vital role in ensuring optimal performance, and familiarity with these parts can greatly enhance maintenance and repair processes. This exploration delves into the intricate layout of a well-known chainsaw, providing insights into its various segments.

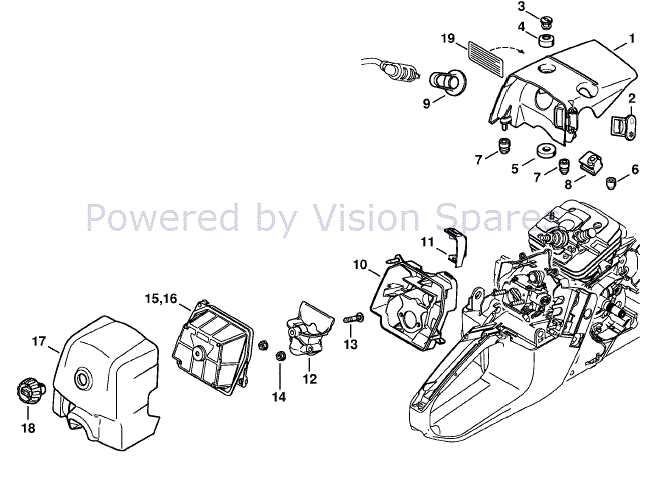

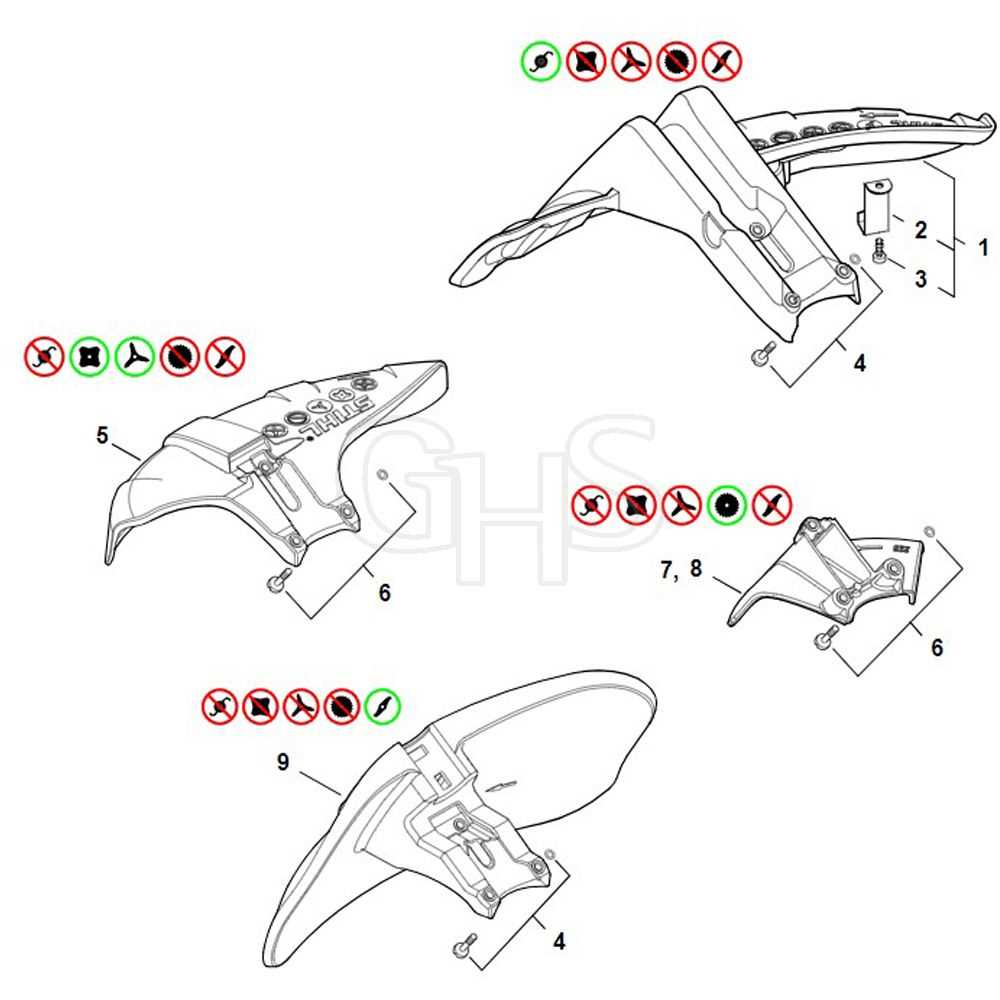

When addressing any mechanical device, visual aids can prove invaluable. A detailed representation of the assembly not only aids in identification but also streamlines troubleshooting efforts. Understanding how each piece interrelates fosters a greater appreciation for the engineering behind these robust machines.

Furthermore, knowing the specifics of each component enables users to make informed decisions regarding upgrades and replacements. Whether one is a seasoned professional or a hobbyist, being well-versed in the structure of such equipment empowers individuals to maximize their tool’s longevity and efficiency.

Understanding the Stihl MS 361

This section explores the features and functionalities of a popular model in the world of outdoor power equipment. Designed for efficiency and durability, this tool is favored by both professionals and enthusiasts alike. Understanding its components can significantly enhance maintenance and performance.

Key Features

- Powerful engine for demanding tasks

- Lightweight design for ease of use

- Advanced safety mechanisms

- Ergonomic handle for comfortable grip

Maintenance Tips

- Regularly check the air filter for clogs.

- Ensure the chain is properly lubricated.

- Inspect spark plugs periodically.

- Clean the housing to prevent debris buildup.

Key Components of the Chainsaw

The functionality of a cutting tool relies on several crucial elements that work in harmony to deliver efficient performance. Understanding these components is essential for maintenance and effective operation, ensuring that users can achieve optimal results while minimizing risks.

Power Unit

The power unit serves as the heart of the cutting apparatus, providing the necessary energy to drive the chain. Typically, this unit can be powered by either gasoline or electricity. A well-maintained engine ensures reliable performance, allowing for sustained cutting operations.

Guide Bar and Chain

The guide bar is the elongated metal piece that supports the cutting chain, providing stability and direction during use. The chain, which is equipped with sharp teeth, rotates around the guide bar, enabling efficient slicing through wood and other materials. Regular inspection and proper tensioning of these components are vital for safe and effective operation.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for both professionals and enthusiasts, allowing for a clearer grasp of how each element fits into the overall system. This knowledge not only enhances the efficiency of repairs but also extends the lifespan of the equipment.

Facilitating Troubleshooting

When issues arise, having a visual guide helps identify the root cause swiftly. With a detailed overview of each section, users can pinpoint malfunctioning elements, reducing downtime and ensuring a quick return to optimal functionality.

Enhancing Assembly and Disassembly

Accurate visual references streamline the processes of putting together and taking apart machinery. By providing clear instructions on where components are situated and how they connect, these resources minimize the risk of errors and prevent potential damage during handling.

In summary, visual aids are essential for anyone looking to maintain or repair their equipment effectively. They empower users with the knowledge needed to address issues confidently and improve the overall performance of their machinery.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair equipment. This visual guide provides an organized view of components, enabling users to identify and locate each part quickly. By familiarizing yourself with the layout and symbols used, you can streamline the process of reassembly and troubleshooting.

Key Elements of an Assembly Illustration

- Numbering System: Each item typically has a unique identifier that corresponds to a list of parts.

- Component Groups: Parts are often grouped by function, making it easier to understand how they interact.

- Reference Points: Look for arrows or lines that indicate connections and relationships between components.

Tips for Effective Use

- Begin by identifying the section relevant to your repair or maintenance task.

- Cross-reference numbers with the accompanying list to ensure you have the correct items.

- Take note of any specific assembly instructions or warnings highlighted in the guide.

- Consult additional resources if any component appears unclear or unfamiliar.

Common Replacement Parts for MS 361

Regular maintenance of your equipment is crucial for optimal performance. Knowing the essential components that often need replacement can enhance efficiency and prolong the lifespan of your tool.

- Chain: Ensures cutting precision and should be replaced when dull or damaged.

- Bar: The guiding element of the chain, it can wear down over time.

- Air Filter: Keeps the engine clean and should be replaced regularly for better airflow.

- Spark Plug: Vital for ignition; a worn spark plug can affect starting and performance.

- Fuel Filter: Prevents debris from clogging the fuel system; replace it to maintain engine health.

By keeping these components in check, you can ensure that your tool runs smoothly and effectively for years to come.

Where to Find Genuine Stihl Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is crucial for optimal performance and longevity. Fortunately, there are several reliable avenues to explore when seeking quality replacements.

- Authorized Dealers: Start by visiting local authorized retailers that specialize in outdoor machinery. These establishments typically carry a comprehensive range of genuine components and provide expert assistance.

- Official Website: The manufacturer’s official site often features an online store where you can conveniently browse and purchase authentic items directly.

- Reputable Online Retailers: Several well-known e-commerce platforms specialize in outdoor equipment. Ensure they offer verified components and check customer reviews for credibility.

- Service Centers: Many service centers that perform repairs also sell genuine components. Consulting with a technician can provide insights into what you need.

- Local Hardware Stores: Some hardware stores carry a selection of authentic items. It’s advisable to confirm their reliability and authenticity before purchasing.

By utilizing these resources, you can ensure that your equipment remains in peak condition and continues to operate safely and efficiently.

Maintenance Tips for Stihl Chainsaws

Proper upkeep of your cutting tool is essential for ensuring its longevity and optimal performance. Regular maintenance can prevent issues, enhance efficiency, and ensure safety while operating. Here are some practical tips to keep your device in excellent condition.

- Regular Cleaning: After each use, clean the exterior and the air filter. Remove any debris that may accumulate, especially around the chain and bar.

- Check the Chain Tension: Always inspect the tension of the chain before use. A properly tensioned chain will improve cutting efficiency and reduce the risk of accidents.

- Sharpen the Chain: Dull chains can cause excessive wear on the bar and increase the risk of kickback. Sharpen the chain regularly or replace it when necessary.

Additionally, consider the following aspects:

- Inspect the Bar: Examine the guide bar for any signs of wear or damage. Rotate it periodically to ensure even wear.

- Oil the Chain: Ensure the chain is well-lubricated. Use the appropriate oil to maintain optimal performance and prevent overheating.

- Check Fuel and Oil Levels: Always use high-quality fuel and maintain proper oil levels for efficient operation.

By following these guidelines, you can prolong the life of your equipment and ensure safe, effective operation every time you use it.

Troubleshooting Common Issues

When using a power tool, encountering problems can be frustrating, but many issues can be resolved with some basic troubleshooting techniques. Understanding common malfunctions and their potential solutions can help ensure that your equipment operates efficiently and safely.

One frequent concern is difficulty starting the engine. This may stem from an empty fuel tank, a clogged air filter, or an improperly adjusted choke. Checking these components can often lead to a quick resolution.

Another typical issue is reduced cutting performance. This may be caused by a dull blade, incorrect chain tension, or even improper lubrication. Regular maintenance, including sharpening the blade and checking the tension, can greatly enhance performance.

Overheating is also a common problem. This can occur if the tool is being used continuously without breaks, or if the cooling system is obstructed. Ensuring proper airflow and taking breaks during extended use can mitigate this issue.

Lastly, vibrations and unusual noises can indicate underlying problems. Loose bolts or worn parts may be responsible, and addressing these immediately can prevent further damage and ensure safe operation.

Upgrading Your Chainsaw’s Performance

Enhancing the efficiency of your cutting tool can significantly improve your overall experience, whether for professional use or personal projects. By focusing on specific components and their functionality, you can achieve remarkable results and extend the lifespan of your equipment.

Start with the Engine: Upgrading the power unit can lead to better torque and cutting speed. Consider options such as high-performance air filters and carburetors that optimize fuel flow.

Improve the Bar and Chain: Investing in a premium bar and chain combination can drastically affect cutting performance. Look for options designed for speed and durability, which can reduce friction and increase efficiency.

Enhance Safety Features: Adding advanced safety mechanisms not only protects the user but also ensures smooth operation. Features like chain brakes and vibration dampening can improve handling and control.

By thoughtfully selecting enhancements, you can transform your cutting tool into a more powerful and reliable asset for any task.