The intricate structure of a telescopic cutting tool can be overwhelming, especially for those unfamiliar with its functionality. Each element plays a crucial role in ensuring efficient operation and optimal performance. By familiarizing oneself with these components, users can better maintain and troubleshoot their equipment.

Within this guide, we will explore the essential components that comprise this specialized tool. Highlighting the individual pieces will provide insight into their specific functions and interrelationships, allowing for a more profound appreciation of the overall design. Understanding these aspects not only enhances user experience but also extends the longevity of the equipment.

Moreover, having a clear representation of the various elements assists in identifying potential issues and determining appropriate solutions. This knowledge empowers users to take charge of their maintenance practices and ensures that their cutting device remains in peak condition for years to come.

When it comes to maintaining trees and shrubs, a versatile cutting tool is essential. This type of equipment is designed to offer enhanced reach and efficiency, making it a valuable asset for both professional landscapers and homeowners. Here are some notable characteristics that set this tool apart from others.

Durability and Build Quality

The construction of this cutting tool ensures long-lasting performance, capable of withstanding rigorous tasks in various conditions. Key elements include:

- Robust Materials: Made from high-quality metals and composites, these tools resist wear and tear.

- Weather Resistance: Engineered to endure harsh environments, protecting internal components from moisture and corrosion.

Enhanced Functionality

This tool features advanced mechanisms to maximize usability and effectiveness. Its design incorporates:

- Adjustable Length: Users can customize the tool’s reach, making it easier to tackle higher branches.

- Interchangeable Blades: Different blade options are available, allowing for varied cutting tasks, from trimming to more substantial removals.

- Lightweight Design: Despite its strength, the tool remains easy to handle, minimizing user fatigue during prolonged use.

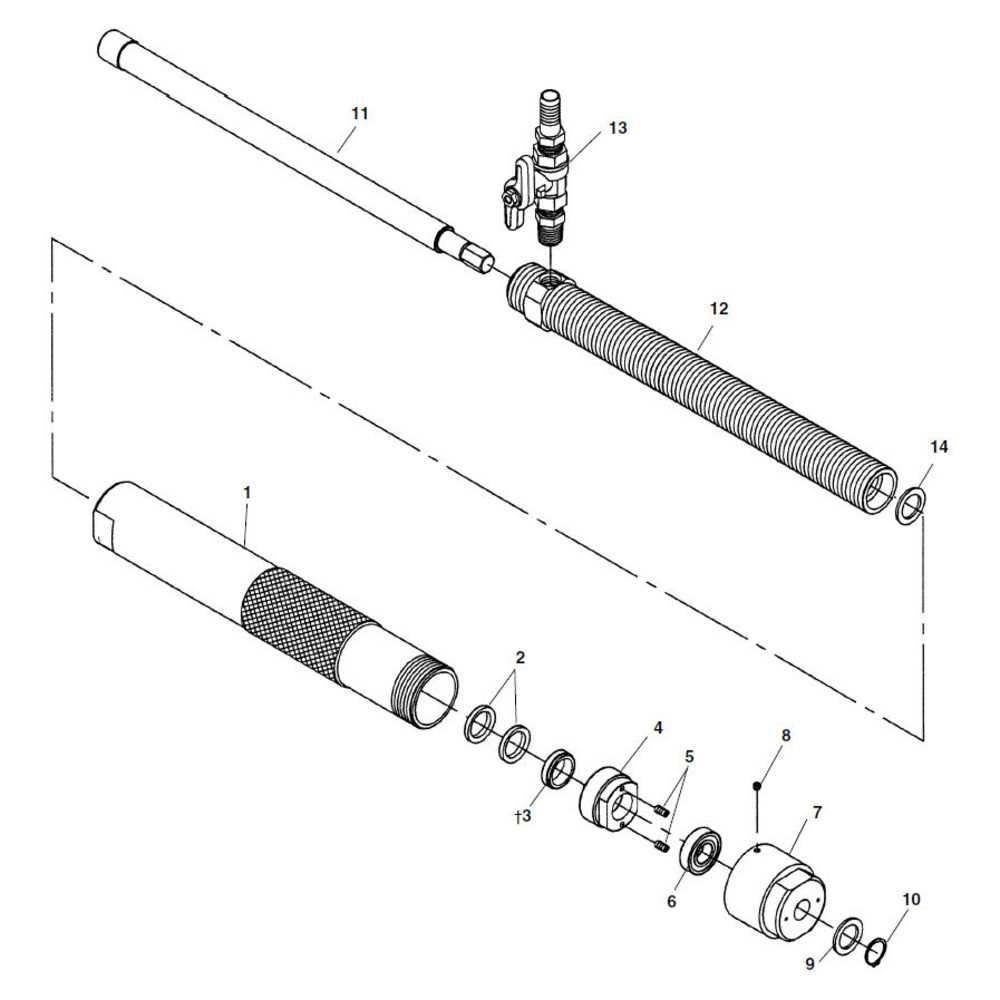

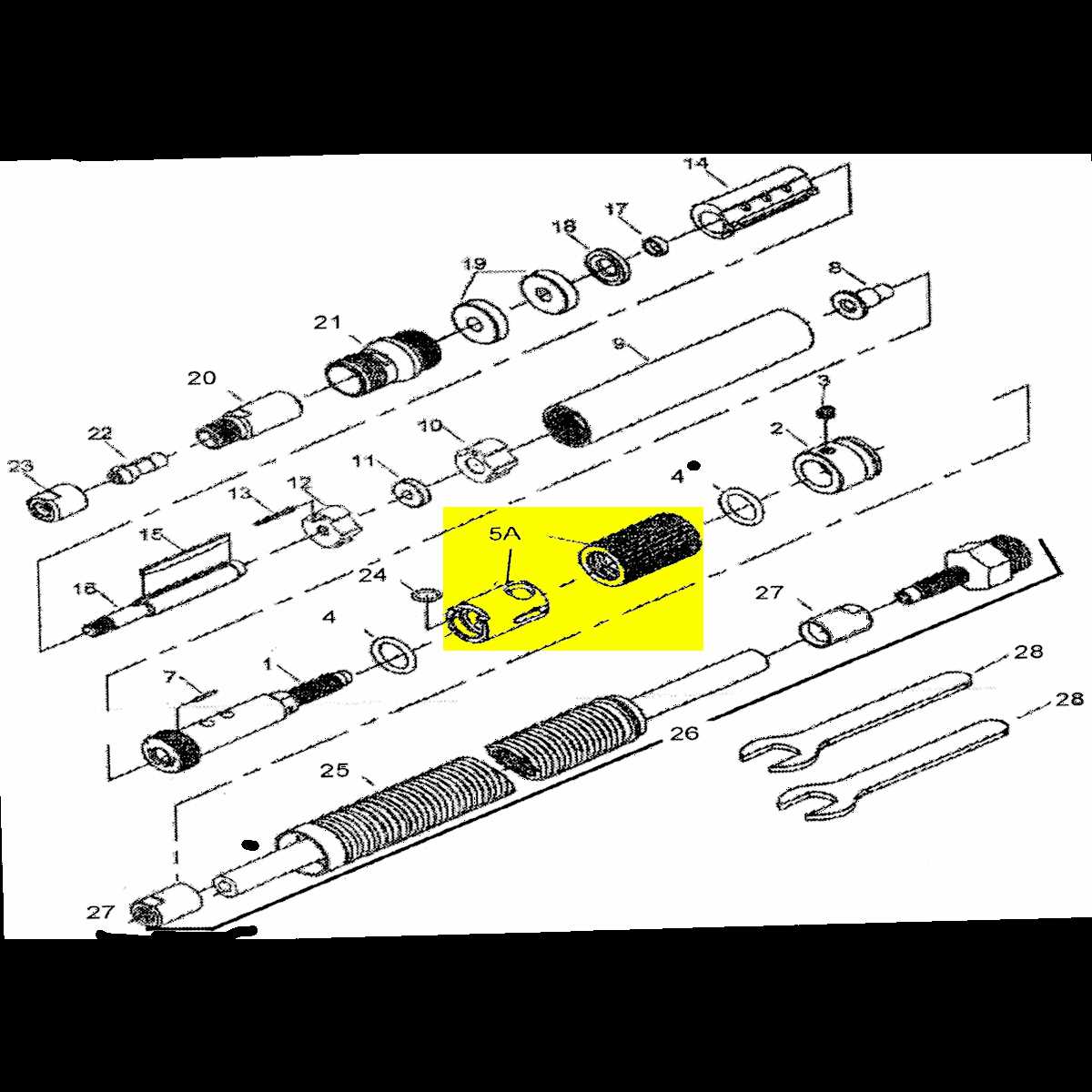

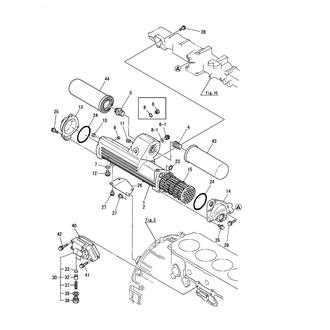

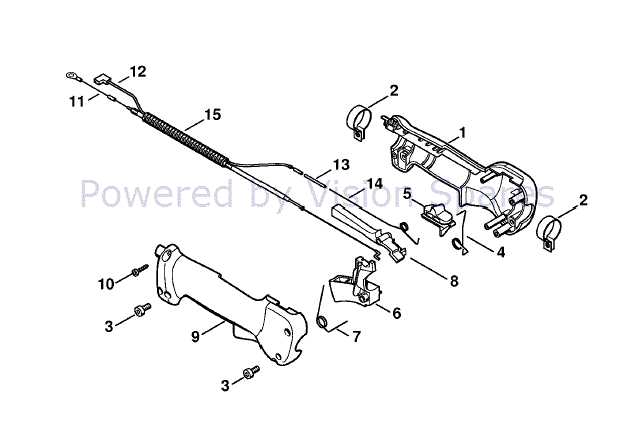

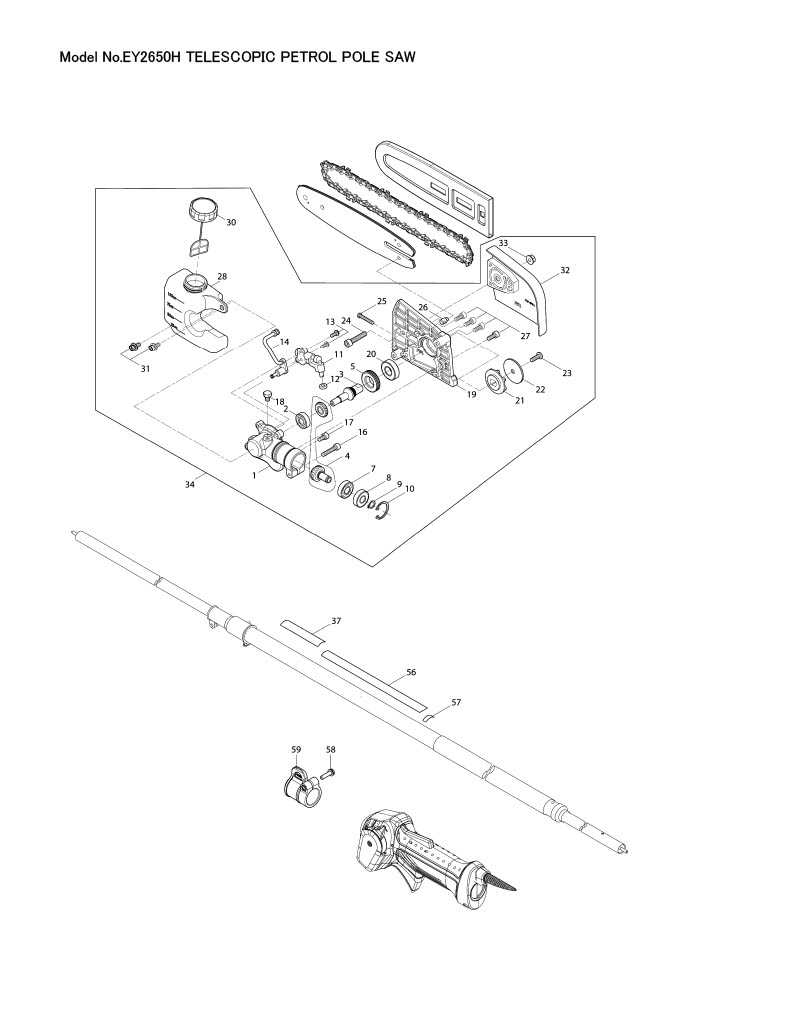

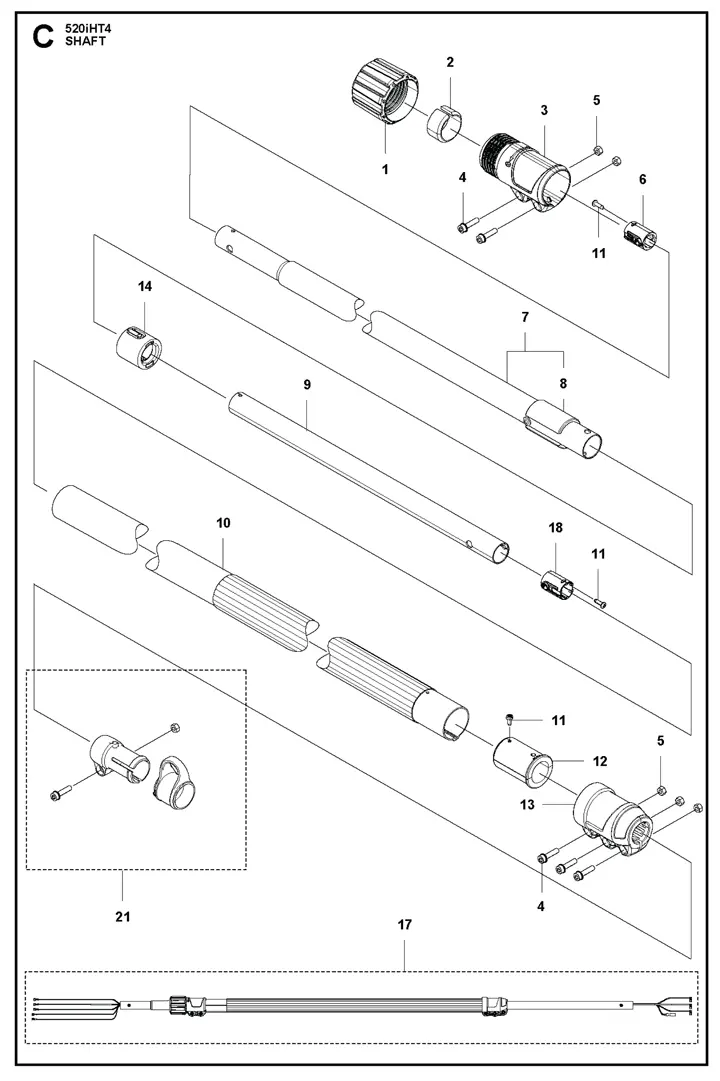

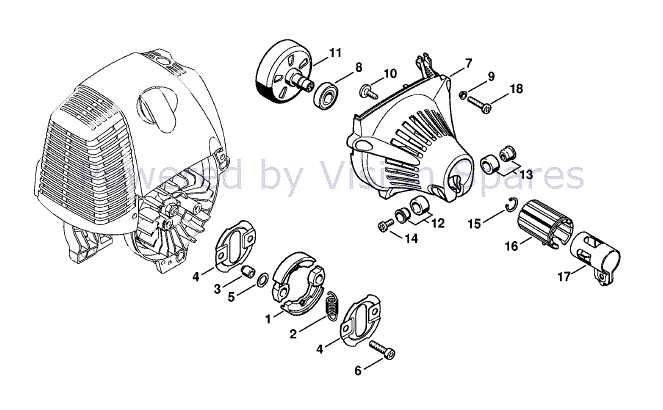

Common Parts and Components

This section provides an overview of the typical elements and constituents found in a specific type of cutting tool designed for tree maintenance. Understanding these components is essential for proper usage, maintenance, and potential replacement to ensure the equipment operates effectively and efficiently.

Key Components

The functionality of this tool relies on several key components that work together harmoniously. Below are some of the fundamental parts you might encounter:

| Component | Description |

|---|---|

| Motor | Drives the entire mechanism, providing the necessary power for operation. |

| Blade Assembly | Engages with branches and foliage, designed for precise cutting action. |

| Extension Shaft | Allows for reach adjustments, enabling access to higher branches. |

| Handle | Provides grip and control, essential for safe operation. |

| Chain | Facilitates movement of the cutting edge, essential for effective slicing. |

Additional Features

In addition to the core elements, various enhancements can improve the overall performance and usability of the device. These might include vibration dampening systems, automatic lubrication mechanisms, and safety guards to protect the operator during use.

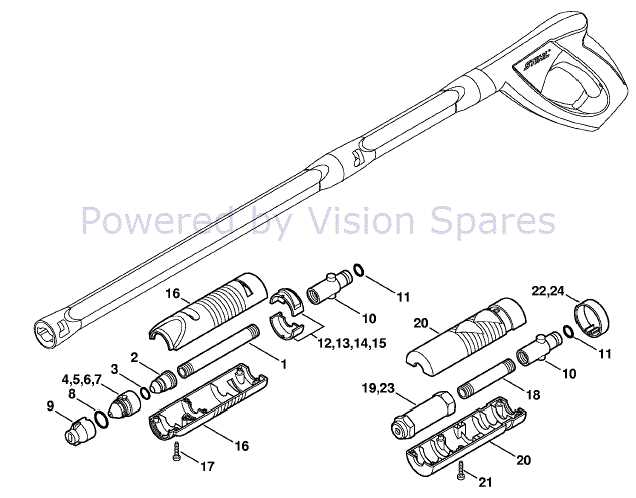

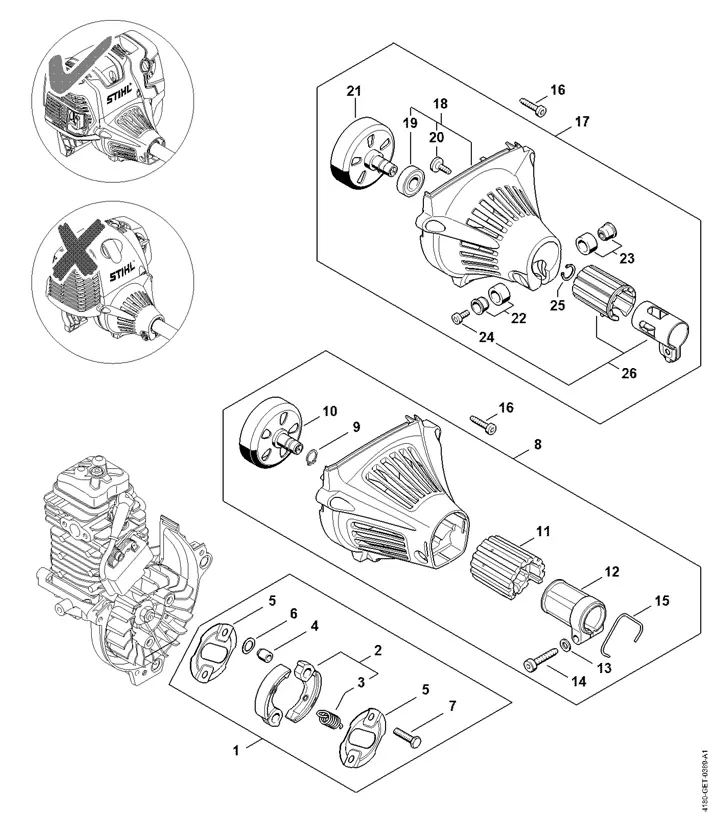

Parts Diagram Overview

This section provides a comprehensive view of the components involved in the equipment. Understanding the arrangement and function of these elements is crucial for effective maintenance and operation. By familiarizing oneself with the layout, users can ensure proper handling and troubleshooting when necessary.

The following table illustrates the various components typically found in such equipment, along with their corresponding functions:

| Component | Function |

|---|---|

| Handle | Provides grip and control for operation. |

| Motor | Powers the entire system for efficient cutting. |

| Blade Assembly | Responsible for the cutting action and precision. |

| Guard | Enhances safety by covering the cutting area. |

| Fuel Tank | Holds the fuel needed for engine operation. |

| Trigger | Controls the activation of the motor. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. Implementing effective maintenance practices can significantly extend the lifespan of your tools and enhance their performance. Below are several strategies to keep in mind for optimal care.

Routine Cleaning

After each use, it is crucial to remove debris and residues from the equipment. Clean all surfaces thoroughly to prevent buildup that can hinder functionality. Use a soft brush or cloth to wipe down components, ensuring they remain free of dirt and grime.

Periodic Inspections

Conducting regular assessments of your equipment is vital. Check for any signs of wear or damage, such as frayed cables or loose connections. Addressing these issues promptly can prevent more significant problems and ensure the tool operates safely and effectively.

Identifying Replacement Parts

When maintaining your outdoor equipment, recognizing the correct components for replacement is crucial for optimal performance. Understanding the various elements that make up your device ensures that you can efficiently restore its functionality without unnecessary complications.

To aid in identifying the necessary components, consider the following steps:

- Consult the User Manual: The manual often contains detailed information regarding the specific elements and their functions.

- Utilize Online Resources: Many websites provide exploded views and lists of components, making it easier to pinpoint what you need.

- Examine the Current Parts: Take a close look at the existing components for any numbers or identifiers that may indicate the model or type.

- Contact Support: If you’re uncertain, reaching out to customer service or support forums can provide valuable insights.

By following these steps, you can accurately identify the components required for your maintenance tasks, ensuring that your equipment remains in peak condition.

Assembly Instructions for Users

This section provides a comprehensive guide for users on how to effectively assemble the equipment. Proper assembly ensures optimal performance and longevity, allowing for safe and efficient operation. Follow these guidelines carefully to achieve a successful setup.

Step-by-Step Assembly Process

Begin by gathering all necessary components and tools required for assembly. Refer to the included documentation to identify each item. Start with the main body, connecting it securely to the handle section. Ensure that all connections are tight and properly aligned to prevent any operational issues.

Final Checks and Adjustments

Once the assembly is complete, conduct thorough checks to verify that all parts are securely attached. Adjust any components as needed to ensure smooth operation. It’s crucial to test the functionality in a controlled environment before regular use. Proper maintenance and regular inspections will enhance the equipment’s performance and durability.

Safety Precautions During Use

Ensuring safety while operating outdoor equipment is essential to prevent accidents and injuries. Proper preparation and awareness of the surrounding environment can significantly reduce risks associated with maintenance tasks. Always prioritize personal safety and adhere to guidelines to ensure a secure working experience.

- Wear appropriate protective gear, including gloves, goggles, and helmets, to shield against debris and accidents.

- Inspect the equipment thoroughly before use to identify any potential issues or wear that may affect performance.

- Maintain a clear working area by removing obstacles, ensuring a safe path for movement.

- Stay alert and aware of your surroundings, particularly when operating near others or in crowded spaces.

- Follow the manufacturer’s instructions and guidelines to ensure proper handling and operation of the equipment.

By adhering to these safety precautions, users can enhance their protection and promote a safe working environment, minimizing the likelihood of mishaps during maintenance tasks.

Frequently Asked Questions

This section addresses common inquiries related to the operation and maintenance of specific equipment. Here, users can find valuable information that aids in enhancing their understanding and experience with the tools at hand.

Common Inquiries

- What is the recommended maintenance schedule for my equipment?

- How can I identify if a component needs replacement?

- Where can I find high-quality replacement items?

Usage Tips

- Always refer to the user manual for proper handling techniques.

- Keep tools clean and free of debris to ensure optimal performance.

- Regularly check for wear and tear to prolong the lifespan of the equipment.