The efficient functioning of any high-performance cutting tool relies heavily on its individual elements. Understanding how these components interact can significantly enhance both maintenance and operational efficiency. This knowledge empowers users to diagnose issues swiftly and ensures optimal performance during demanding tasks.

In this section, we delve into a comprehensive overview of the essential elements that comprise this particular cutting machine. By examining the layout and connection of each piece, users can appreciate the intricate design that contributes to its reliability and effectiveness in various environments.

Additionally, recognizing the unique characteristics of each component aids in proper upkeep and potential upgrades. This proactive approach to understanding the machinery can prolong its lifespan and maintain its cutting prowess, making it an invaluable tool for both professionals and enthusiasts alike.

This section provides a comprehensive examination of the essential elements that contribute to the functionality of a high-performance cutting tool. Understanding the various components involved is crucial for maintenance and repair, ensuring optimal performance and longevity.

| Component Name | Description |

|---|---|

| Engine | The heart of the device, providing the necessary power for operation. |

| Guide Bar | A metal bar that supports the chain and guides it during cutting. |

| Chain | Composed of interconnected links, it is responsible for cutting through wood. |

| Air Filter | Prevents dirt and debris from entering the engine, maintaining efficiency. |

| Fuel Tank | Holds the mixture of fuel and oil needed for operation. |

| Throttle Trigger | Controls the engine speed and cutting power, allowing for precise adjustments. |

| Starter Mechanism | Engages the engine to initiate operation, often involving a recoil system. |

| Clutch | Connects and disconnects the engine from the chain, allowing for safe operation. |

| Handle | Provides grip and control for the operator, essential for maneuverability. |

Each of these components plays a pivotal role in ensuring the efficient and safe operation of the equipment. Familiarity with these parts enables users to perform maintenance and troubleshooting more effectively.

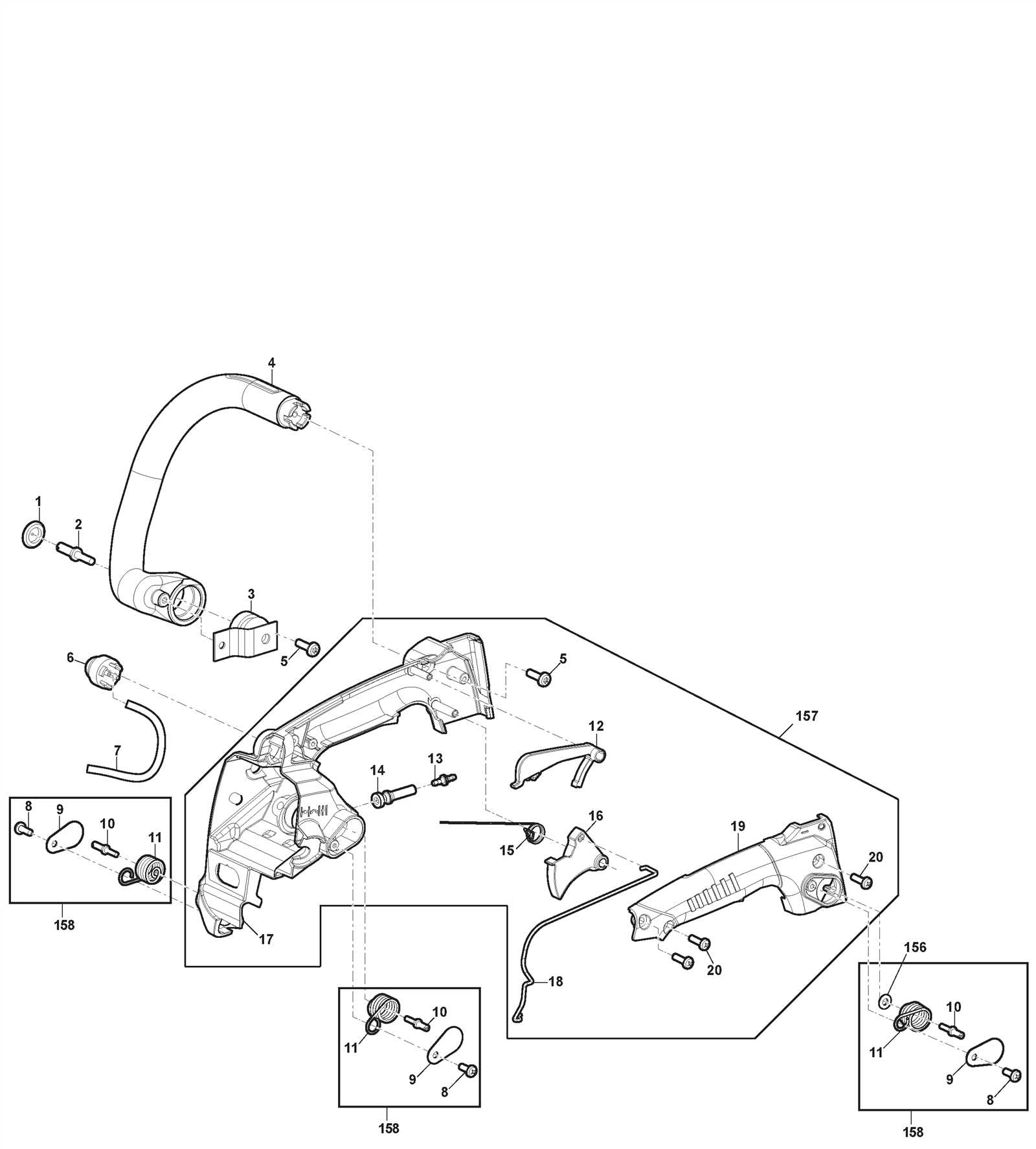

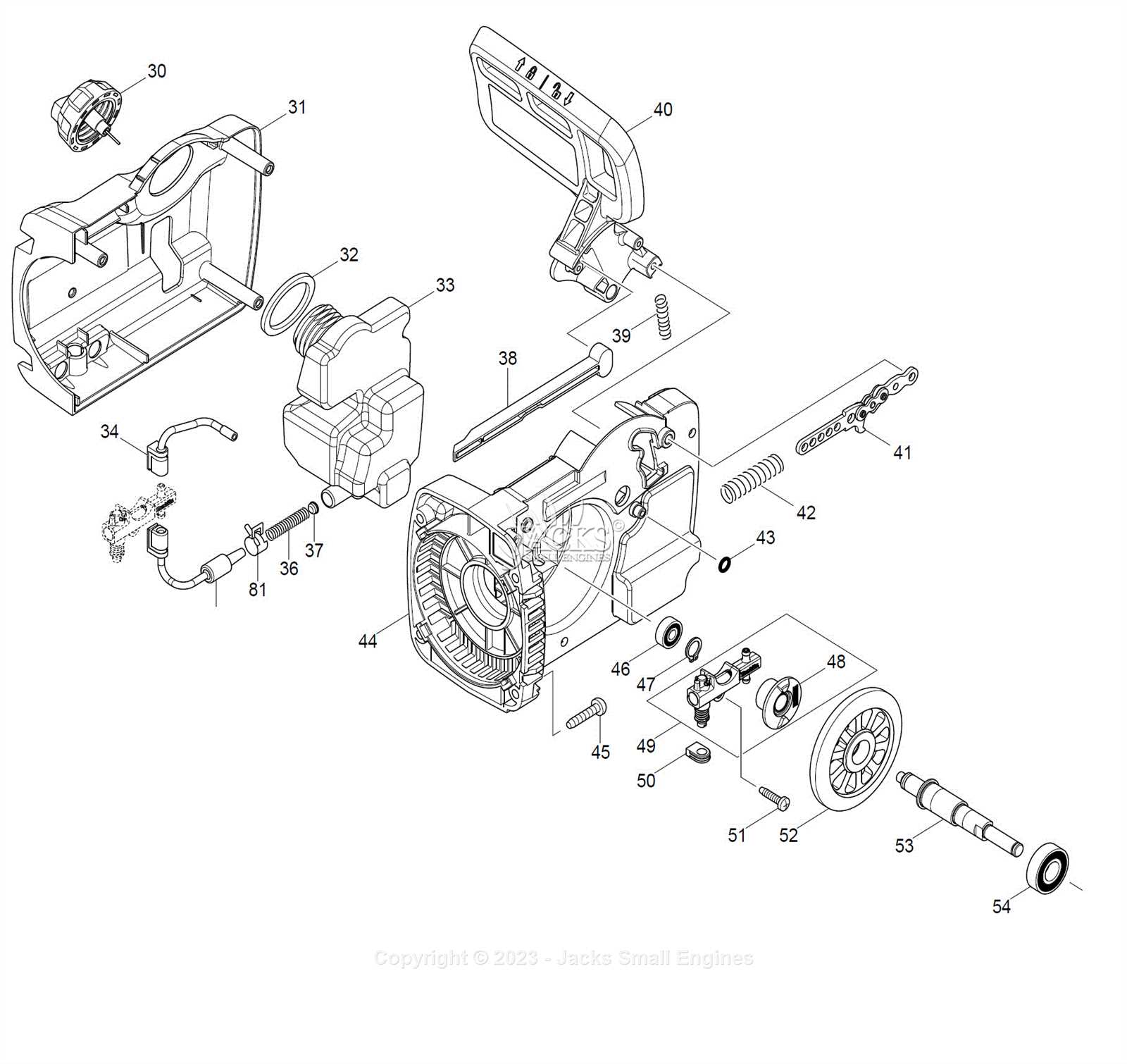

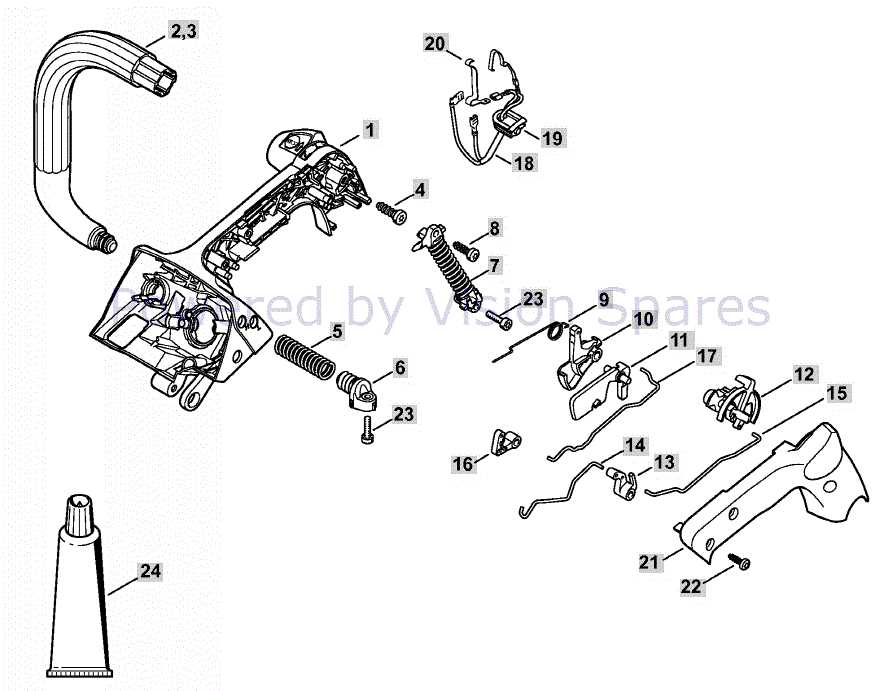

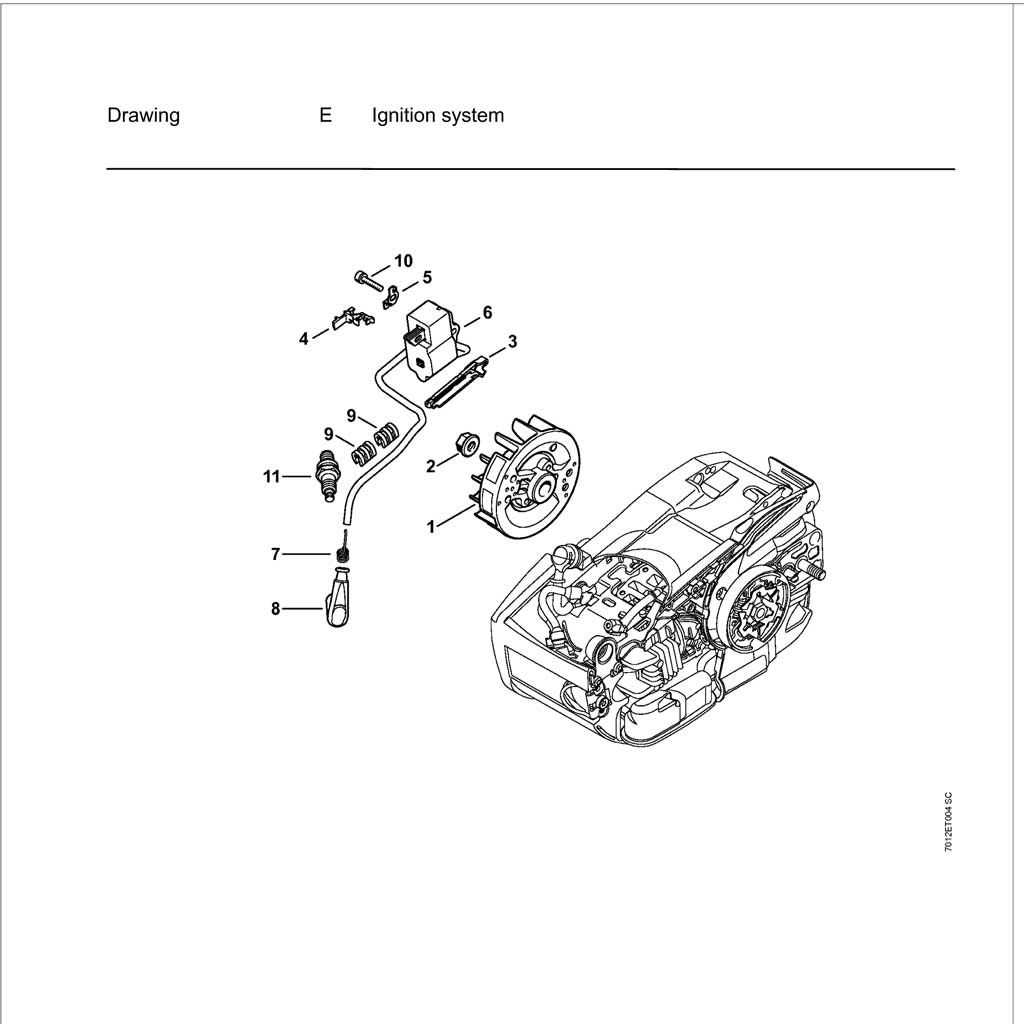

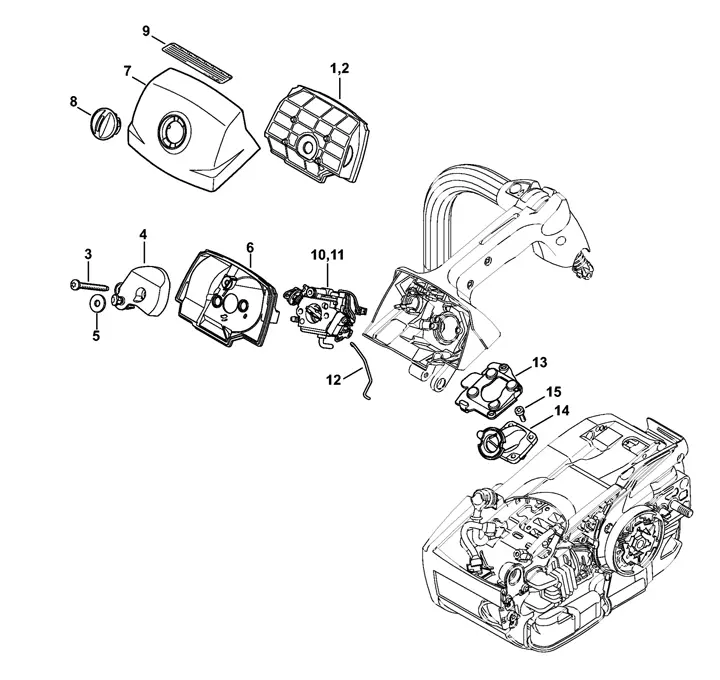

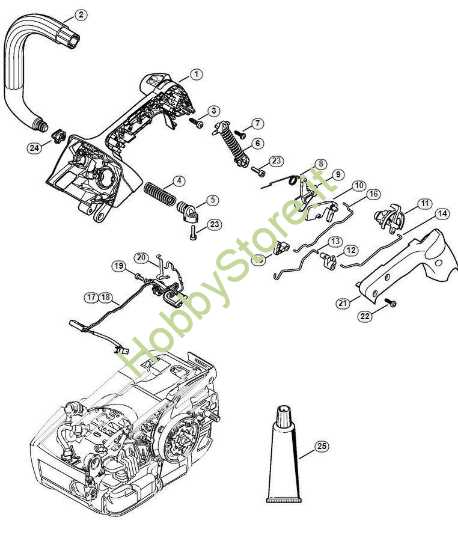

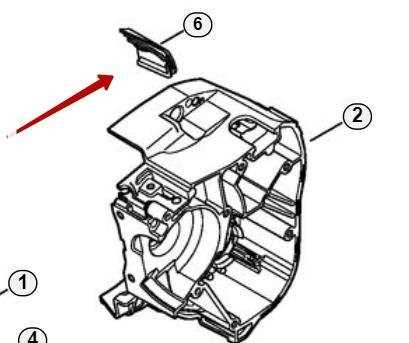

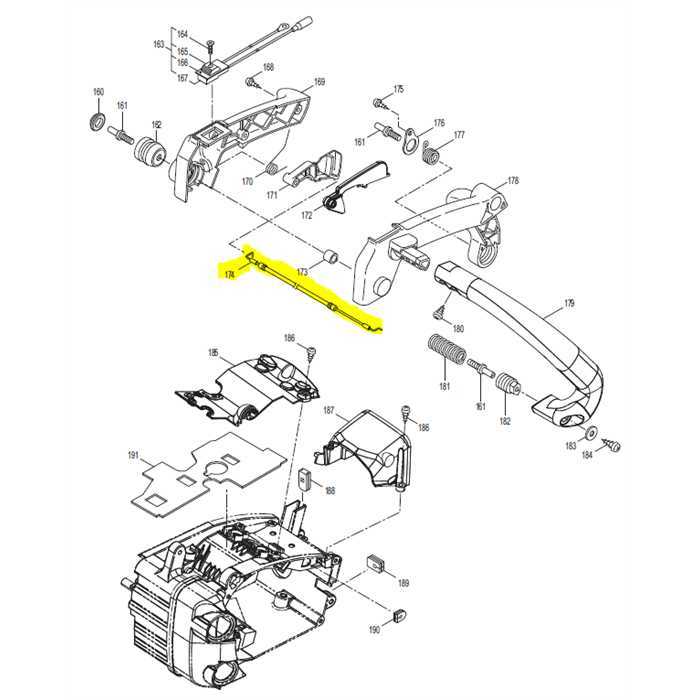

Understanding the Parts Diagram

Grasping the layout of components is essential for maintaining and servicing your equipment effectively. This overview aids in identifying each section and its function, enabling users to perform repairs or upgrades with confidence. A visual representation serves as a roadmap, illustrating how various elements interact and contribute to the overall performance.

Key Components Explained

Every piece plays a specific role in the machinery’s operation. Familiarizing yourself with these parts enhances your understanding of how the tool functions as a whole. Here are some critical elements often found:

- Engine: The heart of the machine, responsible for generating power.

- Fuel System: Includes components that store and deliver fuel to the engine.

- Bar and Chain Assembly: Essential for cutting; understanding its parts helps in maintenance.

- Handle and Housing: Provide grip and protect internal components.

Benefits of Familiarity

Becoming acquainted with the configuration of these components offers several advantages:

- Enhanced Maintenance: Knowing how parts fit together allows for easier troubleshooting.

- Improved Safety: Understanding the layout helps in recognizing hazards during operation.

- Informed Upgrades: Identifying compatible components aids in customizing or enhancing performance.

Common Replacement Parts for MS201TC

Maintaining your equipment is essential for optimal performance and longevity. Various components may need to be replaced over time due to wear and tear or damage. Understanding the common elements that often require replacement can help ensure that your device continues to operate efficiently and effectively.

Frequently Replaced Components

Several components are particularly prone to wear and require regular replacement. These include filters, spark plugs, and drive belts. Keeping track of these items can save you time and effort in the long run.

Component Specifications

| Component | Description | Replacement Interval |

|---|---|---|

| Air Filter | Prevents debris from entering the engine, ensuring clean air intake. | Every 25 hours of use |

| Spark Plug | Ignites the fuel-air mixture for combustion; essential for starting the engine. | Every 100 hours of use |

| Drive Belt | Transfers power from the engine to the cutting mechanism; crucial for operation. | Every 50 hours of use |

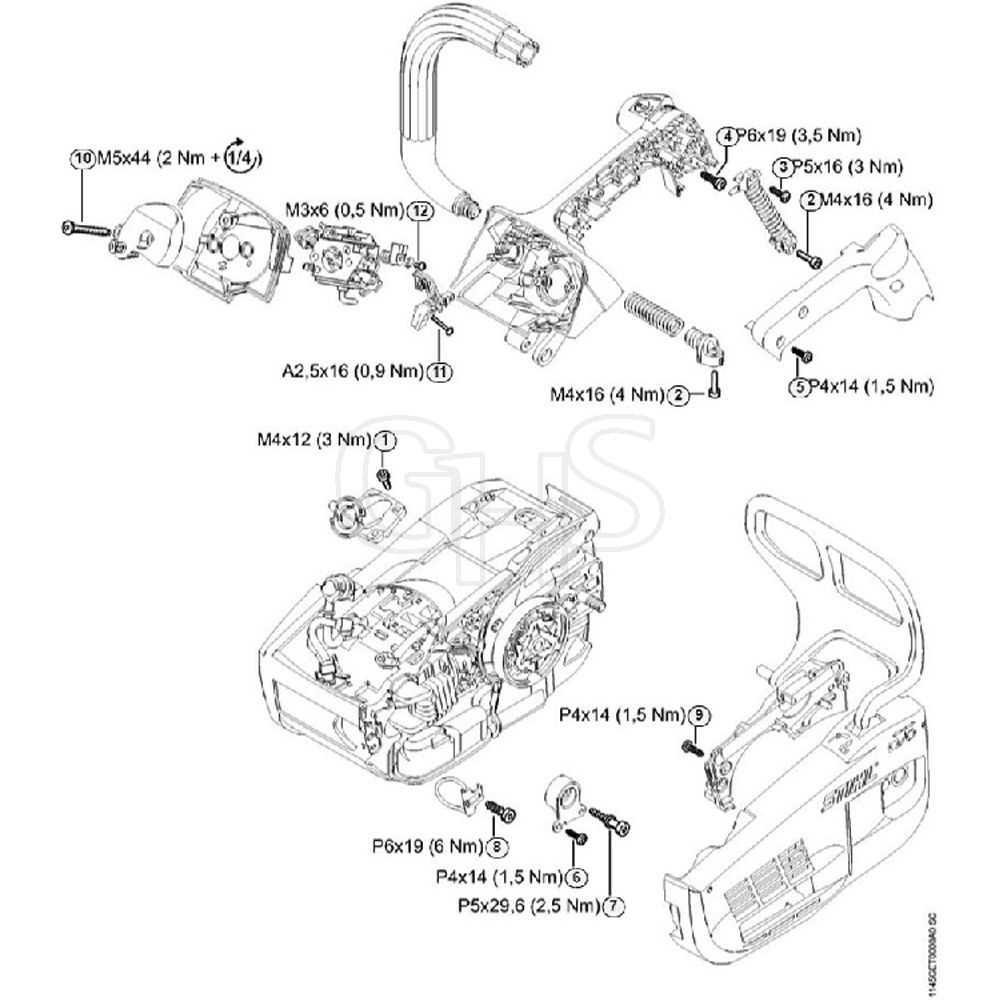

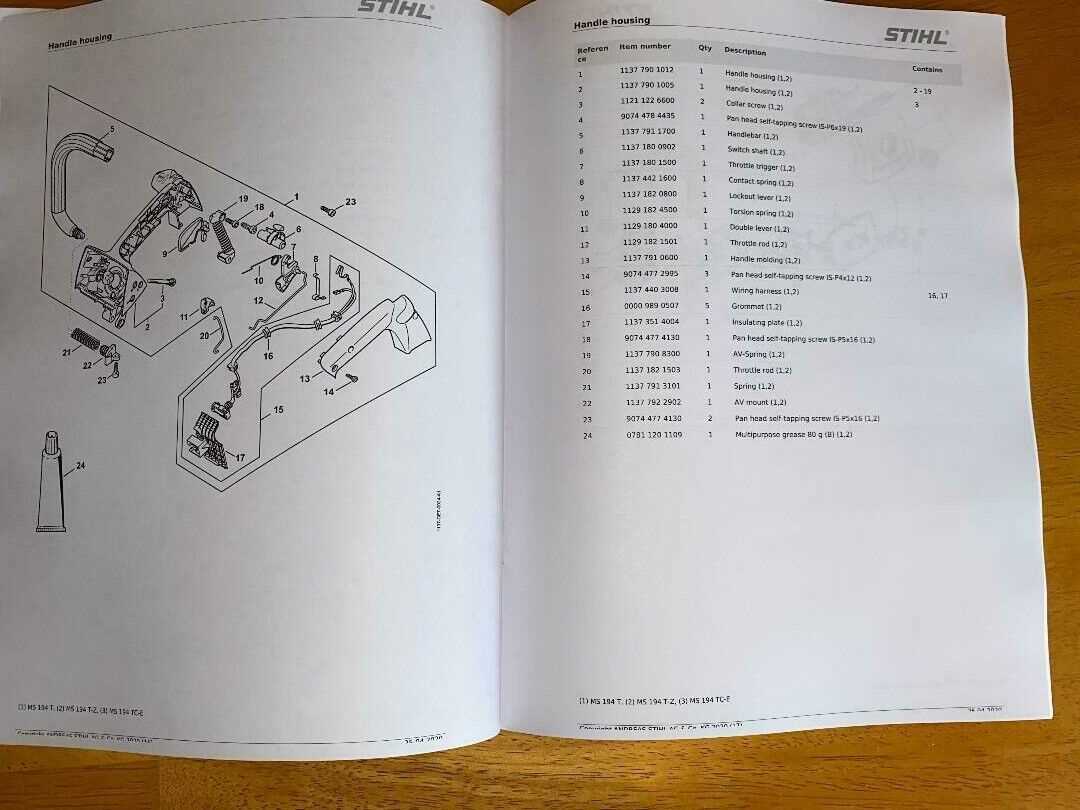

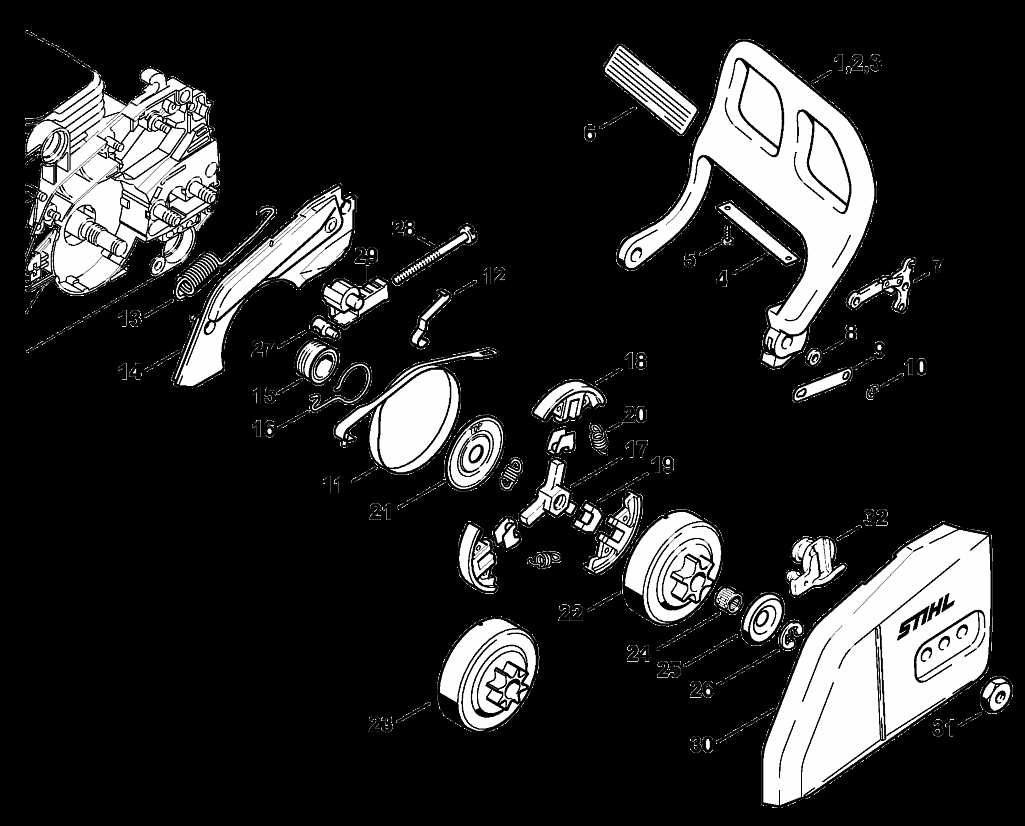

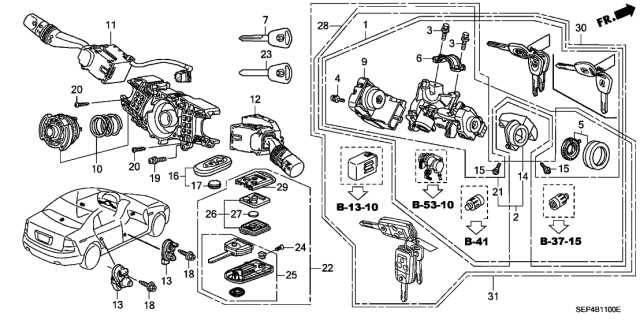

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual aids provide a clear overview of the various elements, their arrangement, and how they interact within the machine. Familiarity with these illustrations can significantly enhance troubleshooting and facilitate the ordering of replacement items.

Identifying Components

Each component in the illustration is typically labeled with a unique identifier, making it easier to locate specific items. Pay attention to the reference numbers, as they correspond to the parts list, which includes detailed descriptions and part numbers. This connection simplifies the process of finding and purchasing the correct elements when needed.

Understanding Connections and Assembly

Besides identifying individual components, these representations often illustrate how parts are assembled and connected. Arrows and lines may indicate relationships and flow between different elements, highlighting how they fit together within the overall structure. Analyzing these connections is crucial for proper reassembly after maintenance or repairs.

Maintenance Tips for Stihl MS201TC

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few simple practices, you can keep your machinery running smoothly and efficiently. Proper care not only enhances functionality but also prevents unexpected breakdowns.

Start by checking and cleaning the air filter periodically. A clogged filter restricts airflow, leading to reduced performance. Make it a habit to inspect the spark plug for wear and replace it if necessary to maintain a strong ignition. Additionally, lubricating moving parts will reduce friction and wear, extending the life of your tool.

Fuel quality is crucial; always use fresh, high-quality fuel mixed with the recommended oil to prevent engine issues. After prolonged use, inspect the cutting chain for sharpness and tension. A dull or loose chain can lead to inefficient cutting and potential accidents.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check air filter | Every 10 hours | Clean or replace as needed |

| Inspect spark plug | Every 25 hours | Replace if worn |

| Lubricate moving parts | Every use | Use appropriate lubricant |

| Check fuel quality | Before each use | Use fresh fuel |

| Inspect cutting chain | Every use | Sharpen and adjust tension as needed |

Adhering to these guidelines will not only improve performance but also enhance the safety and reliability of your equipment.

Identifying Essential Components

Understanding the fundamental elements of a tool is crucial for effective operation and maintenance. Recognizing each part’s function aids in troubleshooting and enhances overall performance. This section will delve into key components, emphasizing their roles and significance.

Key Elements to Consider

- Engine: The powerhouse of the device, responsible for providing the necessary energy for operation.

- Fuel System: Ensures the proper mixture of fuel and air for optimal combustion and efficiency.

- Cutting Mechanism: This includes the blade or chain that performs the actual cutting task.

- Starter System: Facilitates the initiation of the engine, allowing the user to begin operation smoothly.

- Guide Bar: Supports the cutting tool and helps maintain stability during use.

Importance of Each Component

Each essential element plays a vital role in the overall functionality of the device. Understanding their interrelationships can significantly improve maintenance practices. For example, regular inspection of the fuel system can prevent performance issues, while ensuring the cutting mechanism remains sharp and undamaged enhances efficiency.

By familiarizing oneself with these components, users can ensure a longer lifespan for the tool and more effective operation during tasks.

Where to Find Replacement Parts

Finding the right components for your equipment can be a daunting task, but several resources can simplify the process. Whether you’re looking for OEM options or aftermarket solutions, understanding where to search is essential for maintaining your device’s performance.

- Official Retailers: Start by visiting authorized dealers who specialize in your equipment. They often carry genuine components and can provide expert guidance.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized outdoor equipment sites feature a wide range of options. Always check seller ratings and reviews before making a purchase.

- Local Hardware Stores: Many local retailers stock common replacement items. Visit or call to inquire about availability.

- Manufacturer’s Website: The official website of your device’s manufacturer usually has a section dedicated to replacement items, allowing you to order directly.

- Forums and Community Groups: Engaging with online communities or forums can lead you to reliable sources where fellow users share their experiences and recommendations.

By utilizing these resources, you can ensure that you find the necessary components to keep your equipment running smoothly and efficiently.

Impact of Genuine Parts on Performance

Utilizing authentic components in machinery significantly influences their overall functionality and longevity. Genuine items are designed to meet specific engineering standards, ensuring optimal compatibility and efficiency. This adherence to quality contributes to the machine’s effectiveness, minimizing risks associated with substandard alternatives.

Enhanced Reliability

When employing original components, users can expect improved reliability. These items undergo rigorous testing, resulting in superior durability compared to aftermarket substitutes. Authentic parts provide peace of mind, reducing the likelihood of unexpected breakdowns during operation.

Optimal Performance

The integration of original components facilitates optimal performance. These elements are engineered to work harmoniously with the machinery, allowing for smoother operation and better fuel efficiency. Investing in genuine components ensures that the equipment operates at its peak, enhancing productivity and effectiveness.