In the realm of heavy machinery, comprehending the layout of various components is crucial for effective maintenance and repair. A clear visualization of the intricate arrangement allows operators and technicians to identify specific elements quickly, ensuring optimal performance.

Having access to a comprehensive representation of these components fosters a deeper understanding of how each part interacts with the others. This knowledge is not only beneficial for troubleshooting but also enhances the overall efficiency of the machinery.

By exploring these layouts, users can delve into the complexities of machine assembly. Ultimately, a well-organized schematic serves as a valuable tool for both novice and experienced individuals, facilitating smoother operations and minimizing downtime.

Understanding Cat 247b Parts Diagram

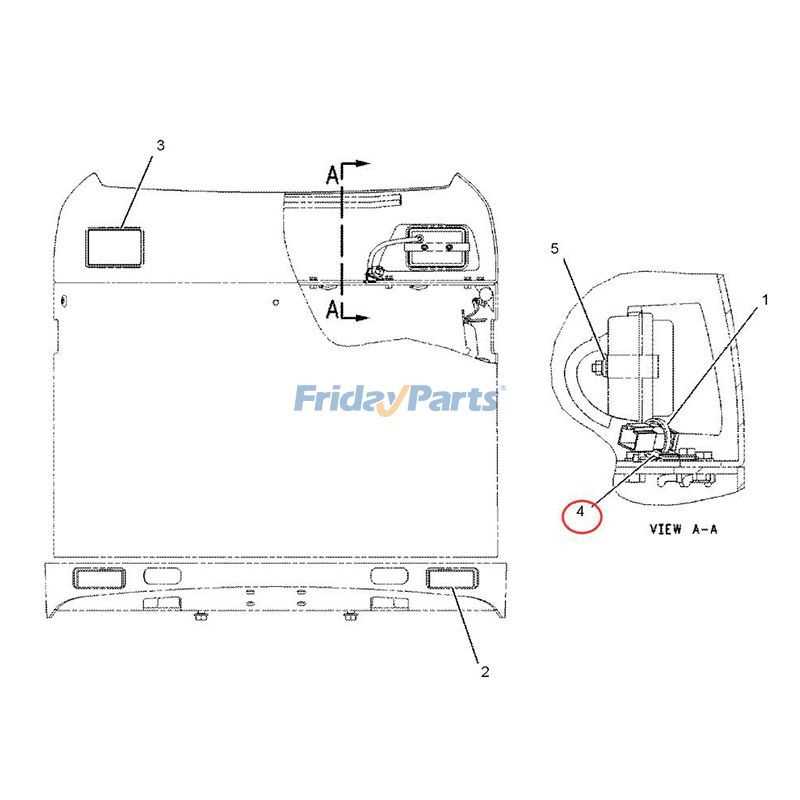

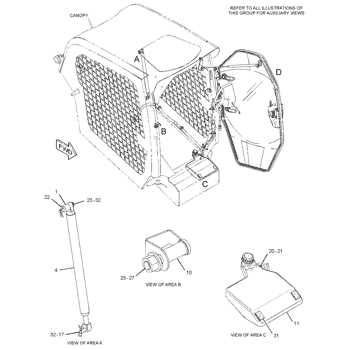

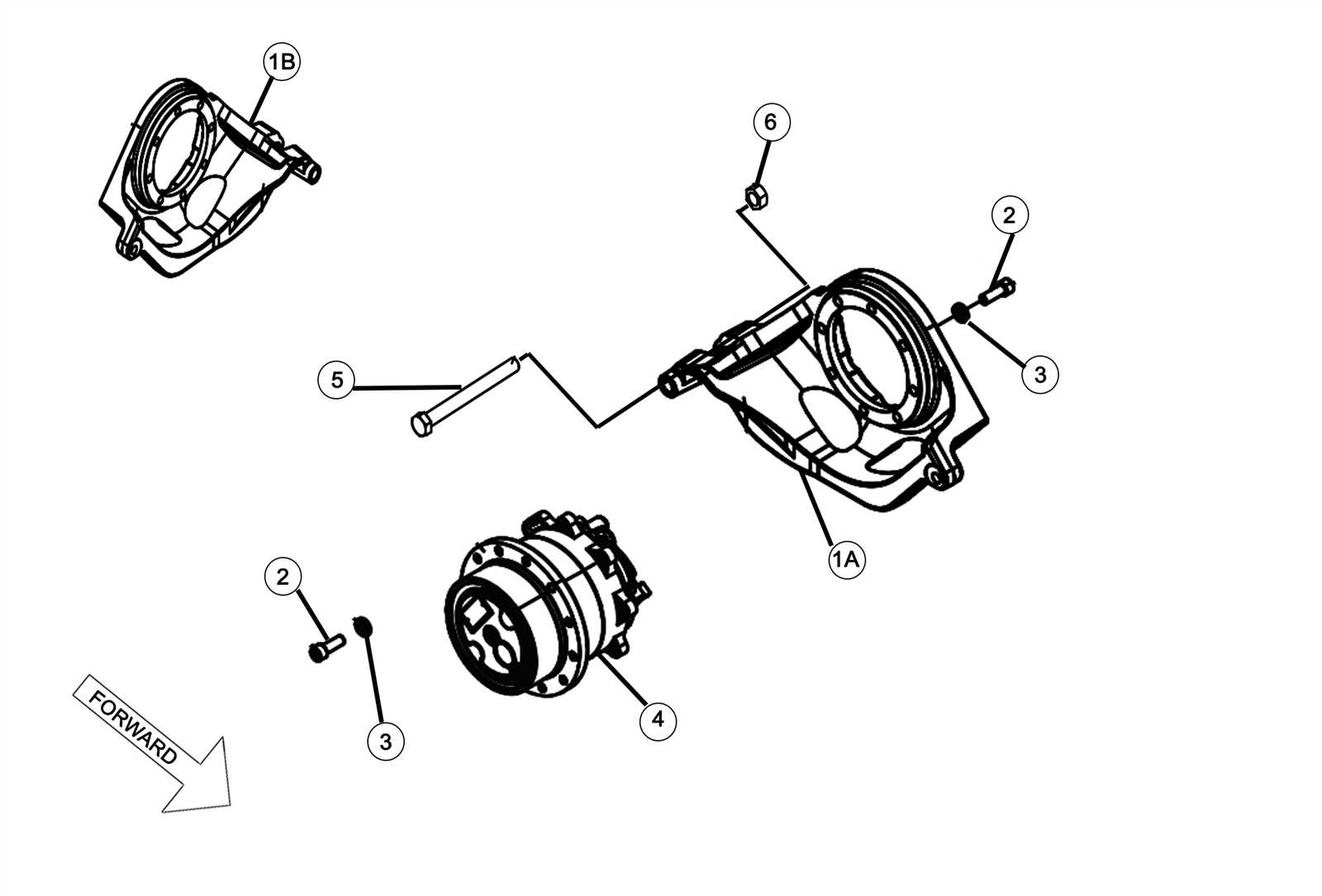

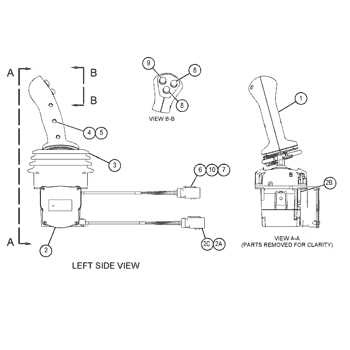

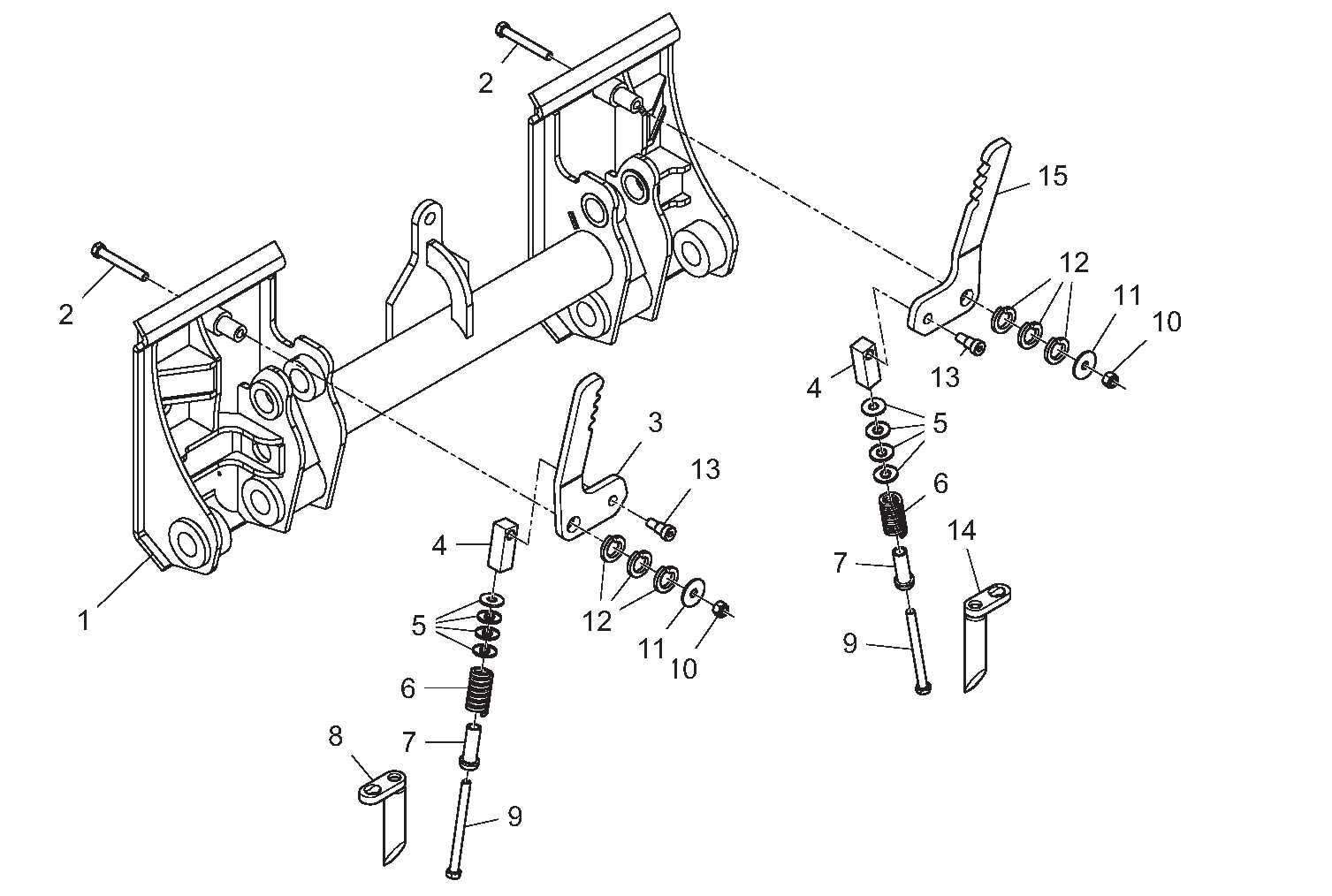

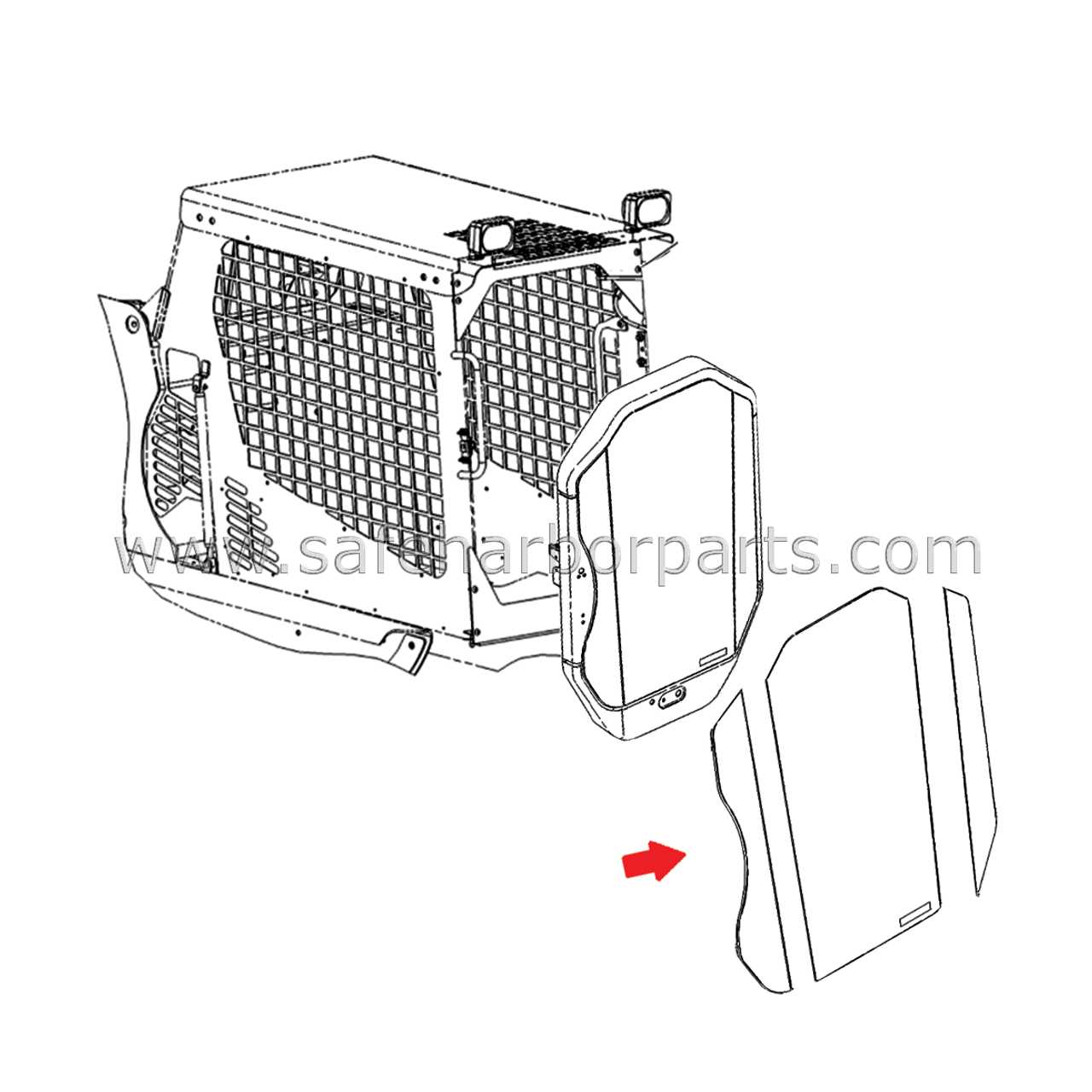

Interpreting the visual representation of machinery components is essential for effective maintenance and repair. A well-structured illustration serves as a valuable guide, helping operators and technicians identify and understand various elements and their functions within the equipment. By familiarizing oneself with this schematic, users can enhance their troubleshooting skills and ensure optimal performance.

Importance of Familiarity with Components

Knowledge of individual elements within the machinery enables efficient diagnosis of issues. Recognizing how each part interacts with others is crucial for maintaining operational integrity. Additionally, understanding the layout aids in pinpointing potential wear and tear, allowing for timely interventions and reducing downtime.

Utilizing the Illustration for Effective Repairs

When approaching repairs, consulting the schematic can significantly streamline the process. It provides a clear visual reference, making it easier to locate specific components and understand their arrangement. This clarity not only boosts confidence but also minimizes the risk of errors during reassembly. Ultimately, mastering the visual guide contributes to prolonged machinery life and enhanced productivity.

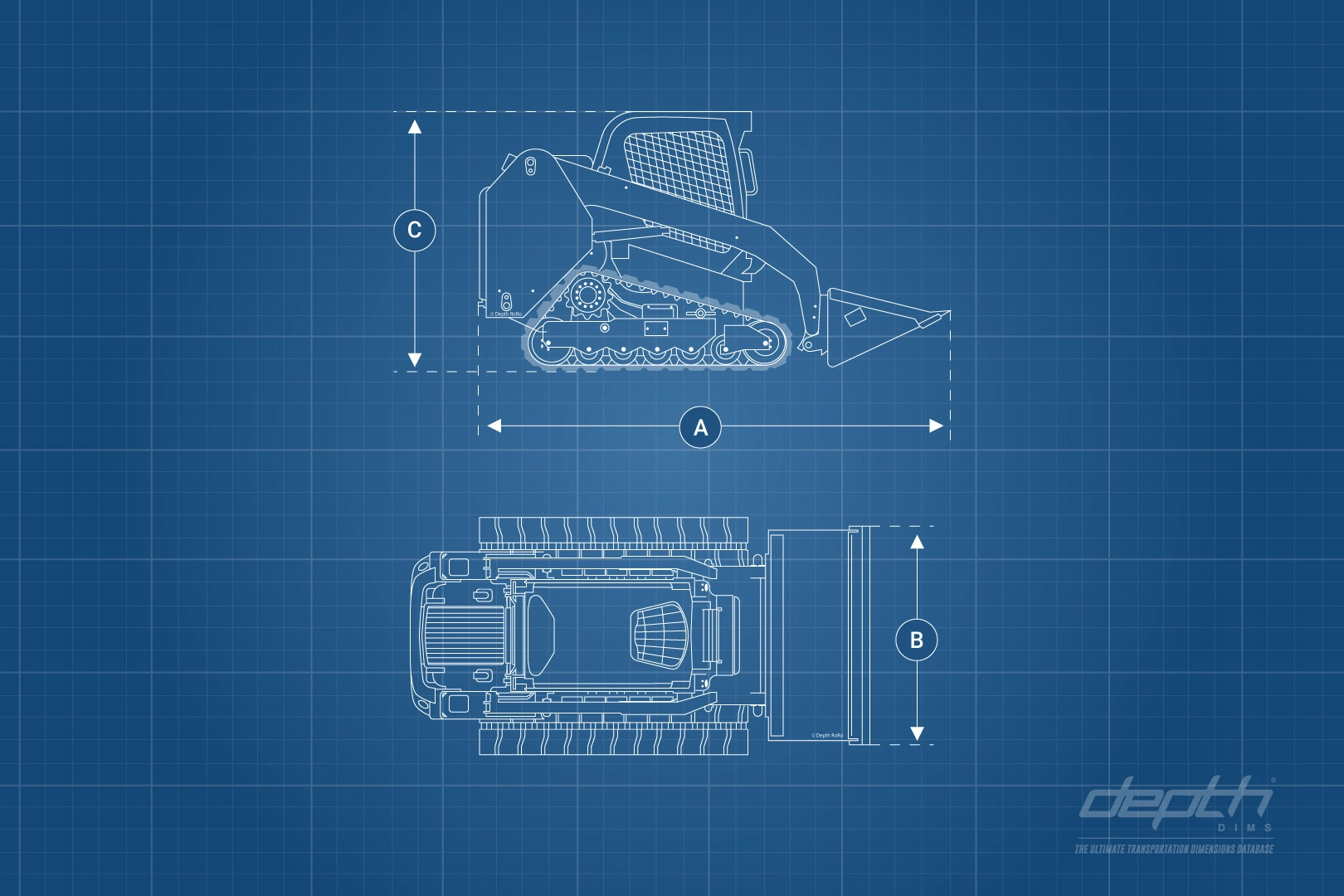

Key Components of Cat 247b

This section explores the essential elements that contribute to the functionality and efficiency of a specific compact loader model. Understanding these components allows operators to maintain and enhance performance, ensuring optimal operation in various tasks.

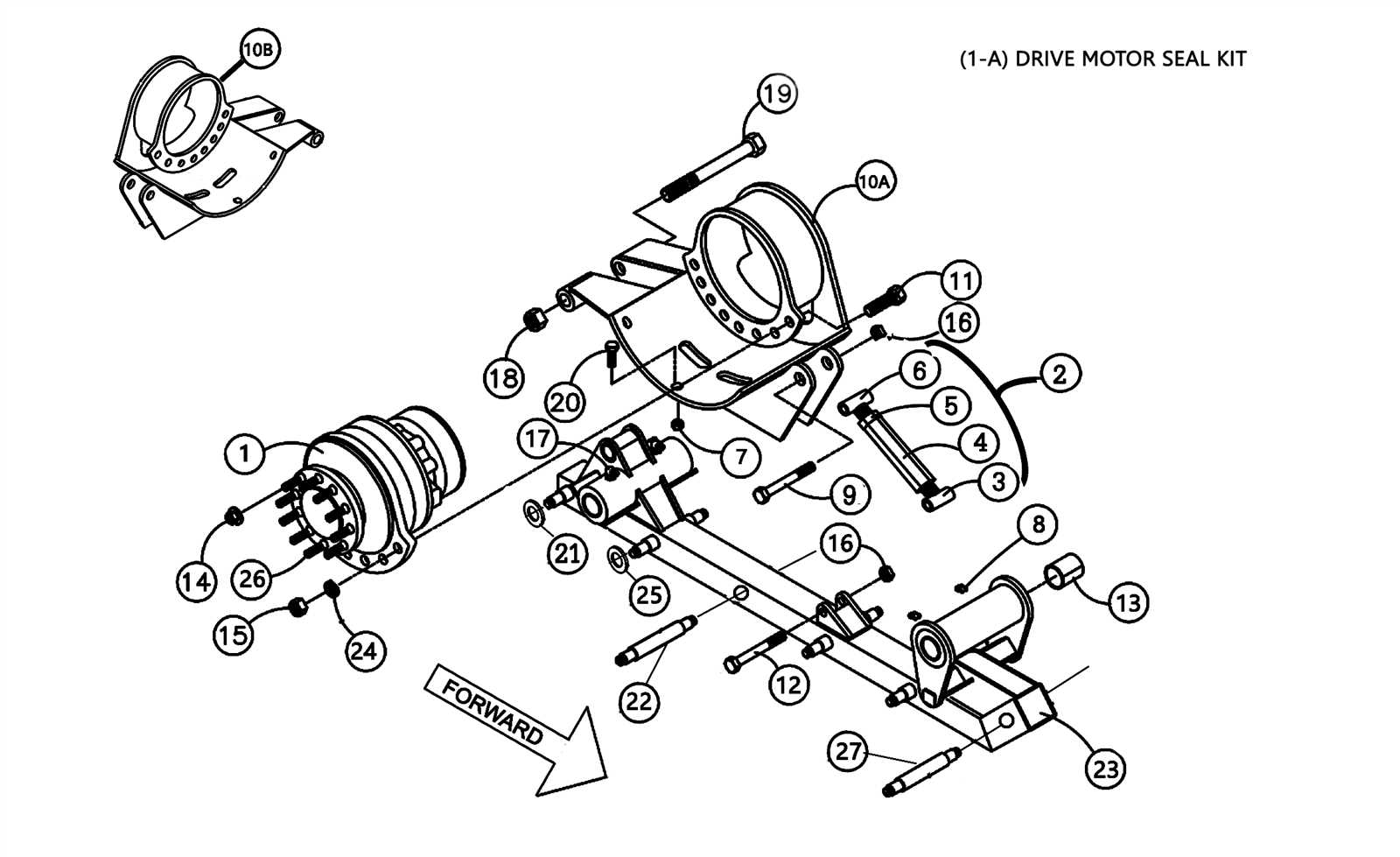

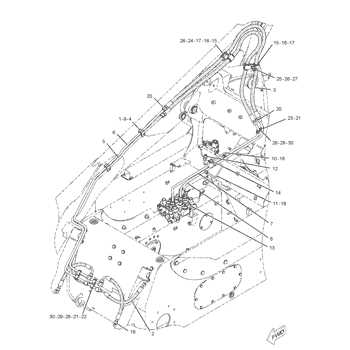

Hydraulic System

The hydraulic system is crucial for the machine’s lifting and digging capabilities. It comprises pumps, cylinders, and valves that work in tandem to provide the necessary force. Regular maintenance of this system is vital for sustaining high performance and preventing breakdowns.

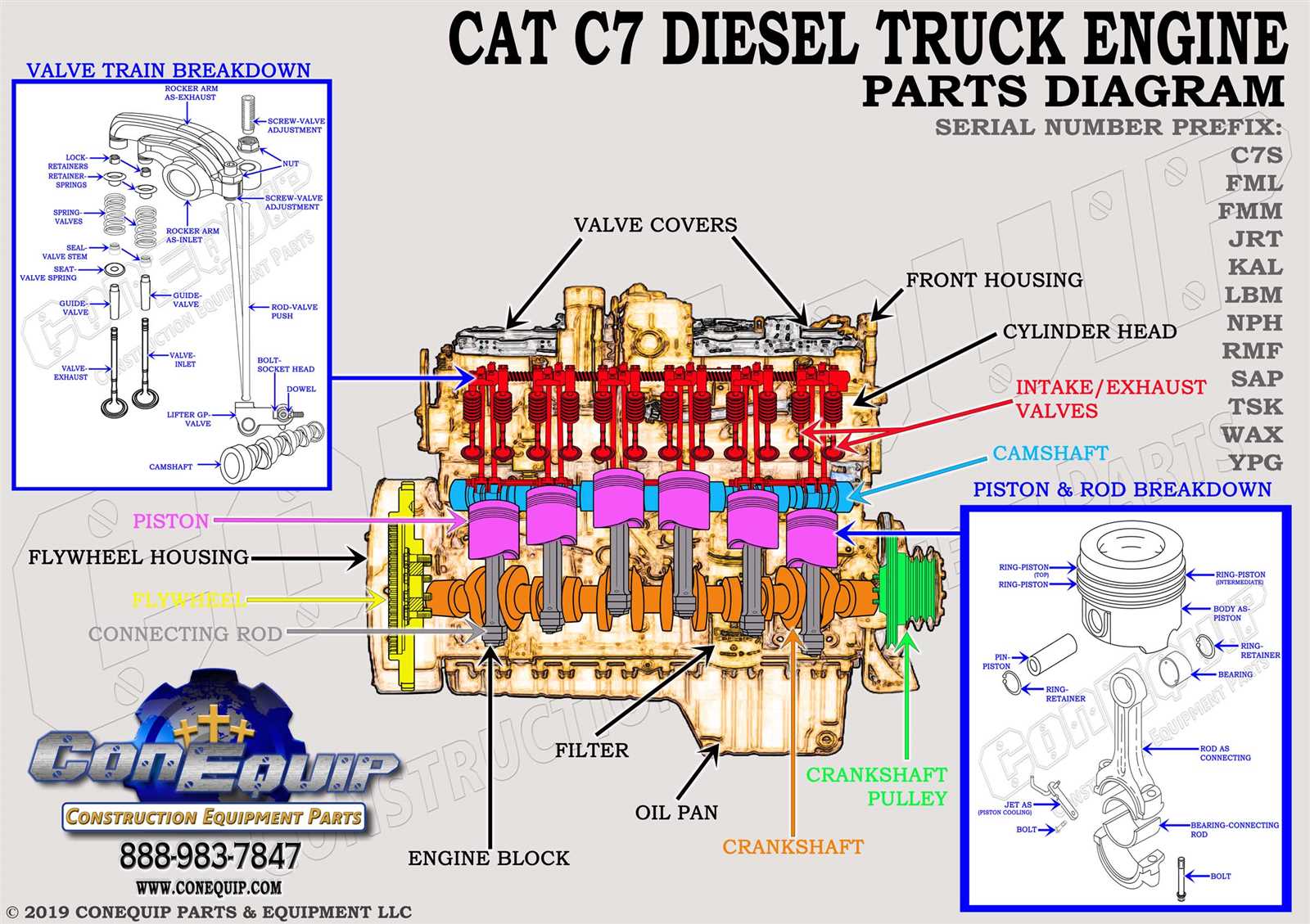

Engine and Powertrain

The heart of the loader lies in its engine and powertrain, which deliver power to various components. A robust engine ensures reliability, while the powertrain efficiently transfers this energy to the wheels, enabling smooth movement and maneuverability.

Importance of Parts Identification

Understanding the components of machinery is crucial for effective maintenance and repair. Accurate identification not only enhances operational efficiency but also minimizes downtime. When operators and technicians can precisely recognize each element, they are better equipped to address issues swiftly and effectively.

Moreover, having a clear grasp of individual components aids in ordering replacements and ensuring compatibility. This knowledge also supports proactive measures, allowing for timely replacements before failure occurs. Ultimately, thorough component recognition fosters a safer working environment and prolongs the lifespan of equipment.

Common Issues and Solutions

In any machinery, understanding potential problems and their remedies is crucial for maintaining optimal performance and longevity. This section highlights frequent challenges encountered and offers practical solutions to ensure efficient operation.

| Issue | Description | Solution |

|---|---|---|

| Hydraulic Leaks | Fluid loss can occur due to worn seals or damaged hoses. | Inspect seals and hoses regularly, replacing any that show signs of wear or damage. |

| Engine Overheating | Excessive temperature may result from coolant issues or blockages. | Check coolant levels and ensure that radiators are free of debris. |

| Electrical Failures | Malfunctions can stem from corroded connections or faulty wiring. | Regularly inspect electrical components and clean connections to prevent corrosion. |

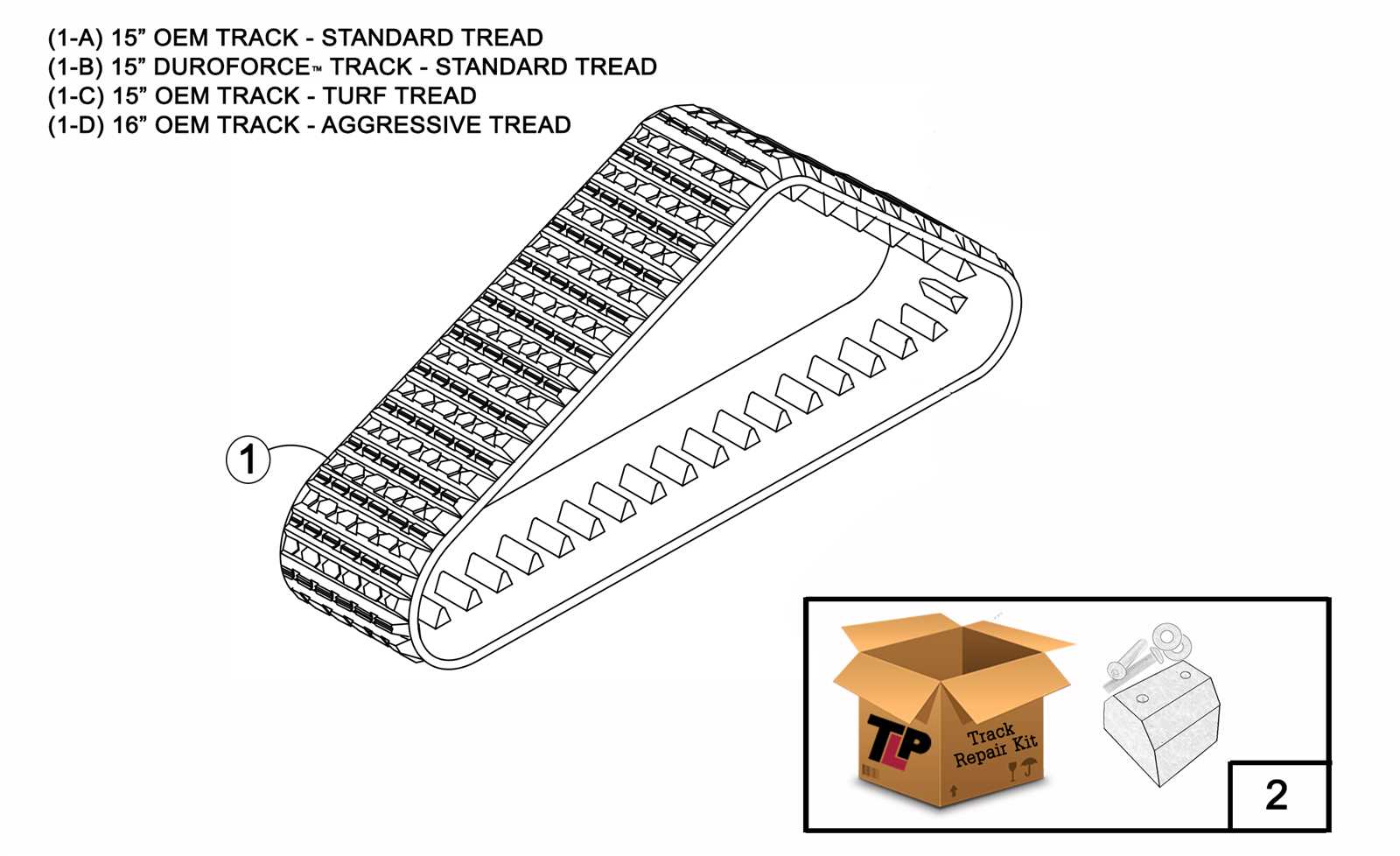

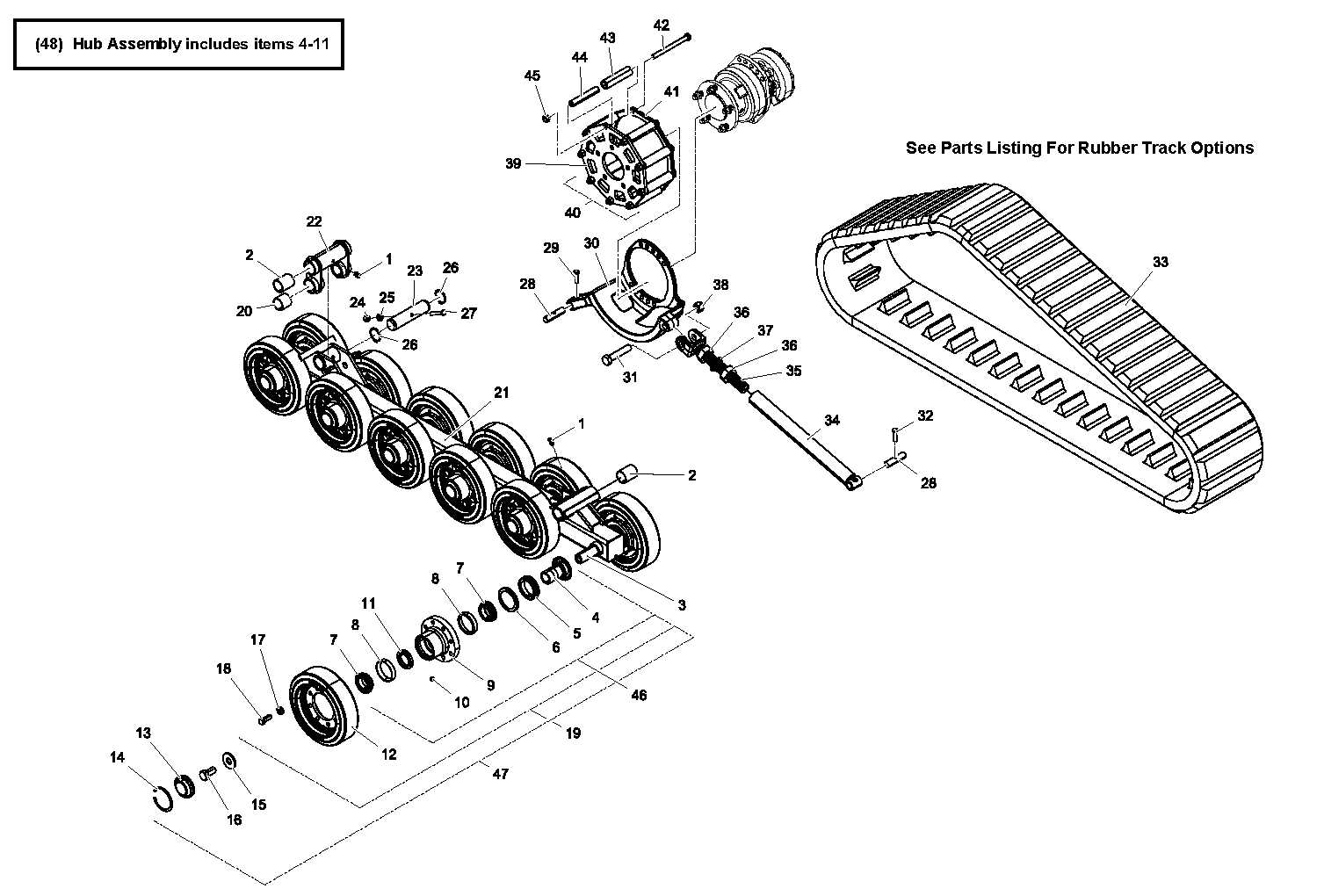

| Track Wear | Continuous use may lead to uneven wear and potential failure. | Monitor track conditions and adjust tension as needed to promote even wear. |

How to Use the Diagram Effectively

Utilizing a schematic representation can greatly enhance your understanding of mechanical systems and facilitate repairs or maintenance tasks. By following specific strategies, you can maximize the benefits of this visual tool and ensure a more efficient workflow. Here are some practical tips to get the most out of your schematic.

Familiarize Yourself with Symbols and Notations

Before diving into the illustration, take some time to learn the various symbols and notations used within it. Each icon represents a different component or function, and understanding these can prevent confusion during analysis. Pay close attention to legends or keys included in the representation, as they provide essential information that can aid in your comprehension.

Cross-Reference with Manufacturer Resources

Always cross-reference the visual guide with the manufacturer’s documentation. This can include manuals, technical bulletins, or service guides that may provide additional context or details about the components depicted. Using these resources together ensures that you have a comprehensive understanding and helps you identify any discrepancies that may arise during repairs or inspections.

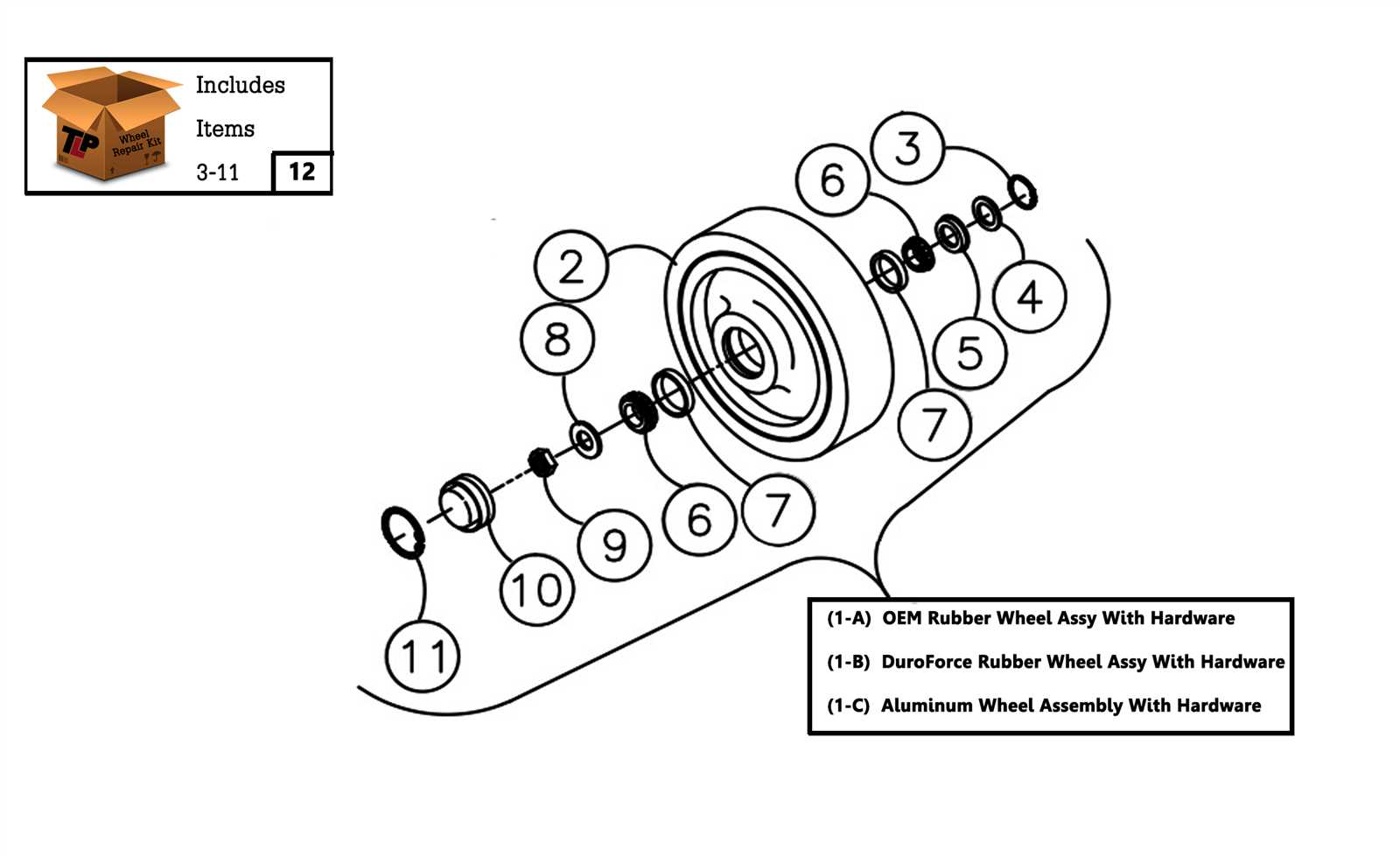

Replacement Parts Overview

When maintaining machinery, understanding the components that may need to be swapped out is essential for ensuring optimal performance. This section highlights the importance of knowing the various elements that can wear down over time and may require replacement to keep your equipment running smoothly.

Identifying Essential Components is the first step in effective maintenance. Regular inspections can help identify which items are prone to deterioration, allowing for proactive replacements before any major issues arise. This approach not only extends the lifespan of the machine but also enhances operational efficiency.

Quality and Compatibility are paramount when selecting new components. It is crucial to ensure that replacements meet the original specifications for seamless integration. Utilizing high-quality materials can significantly reduce the frequency of replacements and downtime, leading to cost savings in the long run.

Additionally, availability of components plays a vital role in maintenance strategies. Having a reliable source for obtaining these essential items ensures that repairs can be carried out promptly, minimizing disruptions to operations. Familiarity with the inventory of necessary components can aid in quicker decision-making when repairs are needed.

In conclusion, being knowledgeable about the various elements that may require replacement is vital for maintaining efficiency and reliability in machinery. Prioritizing quality, compatibility, and availability can lead to effective maintenance practices that support long-term operational success.

Maintenance Tips for Longevity

Ensuring the extended lifespan of heavy machinery requires consistent care and attention. By following a few essential practices, operators can maintain optimal performance and prevent costly breakdowns.

- Regular Inspections: Conduct routine checks to identify wear and tear early.

- Fluid Levels: Maintain appropriate levels of hydraulic and engine fluids to ensure smooth operation.

- Clean Components: Regularly clean filters and cooling systems to prevent overheating.

Implementing these strategies can significantly enhance the reliability and efficiency of your equipment.

- Document maintenance schedules to keep track of services.

- Use genuine replacement parts to ensure compatibility and performance.

- Train operators on best practices to avoid misuse.

By investing time in these maintenance activities, operators can ultimately enjoy longer-lasting machinery and fewer interruptions in productivity.

Where to Source Genuine Parts

Finding authentic components for heavy machinery is crucial for maintaining optimal performance and longevity. Using genuine replacements ensures reliability and minimizes the risk of malfunctions, which can lead to costly downtime. This section explores the best avenues to procure high-quality replacements.

Authorized Dealers

Working with certified dealers is one of the most reliable options. These vendors typically have direct access to the manufacturer’s inventory and can guarantee the authenticity of the items.

Online Platforms

Numerous online marketplaces offer a wide range of components. When purchasing online, it’s essential to verify the seller’s reputation and check for warranties.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert support | Higher prices |

| Online Marketplaces | Convenience, broader selection | Risk of counterfeit products |

| Manufacturer Websites | Direct sourcing, trustworthiness | Limited inventory |

FAQs About Cat 247b Maintenance

Maintaining heavy machinery is essential for optimal performance and longevity. Understanding common queries related to upkeep can help operators ensure their equipment runs smoothly and efficiently. This section addresses frequently asked questions, providing valuable insights into the best practices for maintenance.

What are the key maintenance tasks for this equipment?

Regular inspections, fluid changes, and filter replacements are critical tasks. Operators should also check the tracks, hydraulic systems, and electrical components periodically to prevent breakdowns.

How often should I perform maintenance?

It’s recommended to follow the manufacturer’s guidelines for maintenance intervals, usually outlined in the owner’s manual. Additionally, factors such as usage frequency and operating conditions can influence the maintenance schedule.

What signs indicate that maintenance is needed?

Unusual noises, leaks, decreased performance, or warning lights on the dashboard can signal the need for immediate attention. Regular monitoring can help identify these issues early.

Can I perform maintenance myself?

Many operators can handle basic maintenance tasks, but more complex repairs should be carried out by trained professionals. Always refer to the user manual for guidance on what can be safely managed in-house.

What are the benefits of proper maintenance?

Regular upkeep enhances the efficiency and lifespan of the machinery, reduces repair costs, and minimizes the risk of unexpected downtime. Properly maintained equipment also contributes to safety on the job site.