In the realm of modern farming, the efficiency and reliability of machinery play a crucial role in successful operations. Knowledge of individual elements and their interactions can significantly enhance performance and maintenance. A thorough comprehension of these components not only aids in repairs but also ensures the longevity of the equipment.

To maximize productivity, it is essential to have a clear visual representation of how various elements work together. This insight allows operators to quickly identify potential issues and streamline their workflows. By examining the configuration and functionality of these crucial mechanisms, users can foster a more effective approach to agricultural practices.

In this article, we delve into the intricate layout of essential equipment components. By breaking down their specific roles, we aim to empower farmers with the knowledge needed to maintain and optimize their machinery, ultimately contributing to a more prosperous farming experience.

Understanding Vermeer Hay Rake Components

The operation of agricultural machinery relies heavily on its various elements working in harmony. Each component plays a crucial role, contributing to overall efficiency and functionality. Familiarity with these elements is essential for proper maintenance and effective usage.

Frame: The foundational structure supports all other components, ensuring stability and durability during operation. It must be robust enough to withstand various field conditions.

Tines: These essential implements are designed to gather and lift materials. Their configuration can significantly affect performance, making selection based on specific needs vital.

Drive System: This mechanism powers movement, transferring energy from the engine to the operational elements. Understanding its components helps in troubleshooting and optimizing efficiency.

Wheel Assembly: Providing mobility, the wheels must be appropriately sized and positioned to ensure smooth navigation across diverse terrains. Proper alignment is crucial for effective operation.

Hydraulic Components: These elements facilitate the adjustment and control of various functions, allowing for precision in operation. Regular checks are necessary to maintain optimal performance.

Each component’s role is interconnected, highlighting the importance of a comprehensive understanding for effective agricultural practices. Maintenance and proper care can enhance longevity and performance, leading to better outcomes in the field.

Essential Parts of a Hay Rake

Understanding the fundamental components of this agricultural tool is crucial for efficient operation and maintenance. Each element plays a vital role in ensuring optimal functionality and effectiveness in the field.

Frame: The robust structure provides stability and support, allowing the implement to withstand various conditions while in use.

Teeth: These protruding elements are designed to gather and lift material, making them essential for effective collection and distribution.

Wheel Assembly: The set of wheels facilitates movement, enabling smooth navigation across different terrains and enhancing maneuverability.

Drive Mechanism: This system converts power into motion, ensuring that the implement operates efficiently and consistently during tasks.

Adjustable Settings: The ability to modify certain features allows operators to tailor performance according to specific requirements, improving overall productivity.

In summary, familiarizing oneself with these critical components can lead to better care and improved performance in agricultural endeavors.

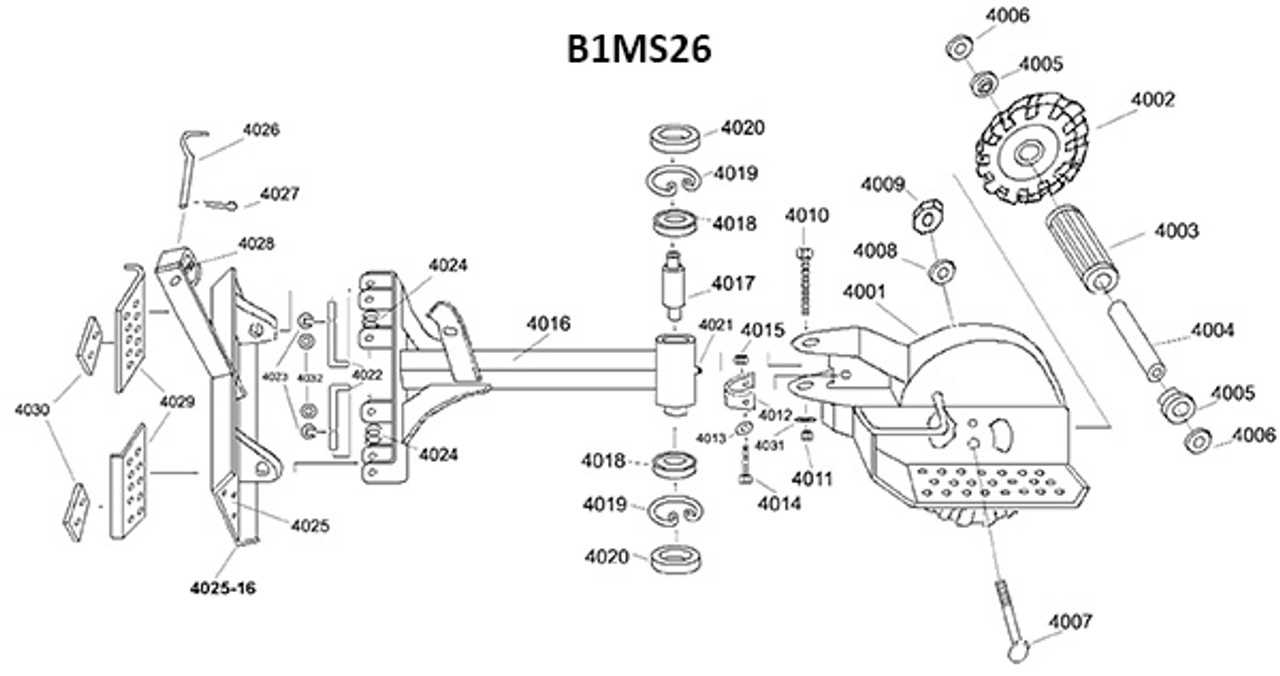

How to Read the Parts Diagram

Understanding a technical illustration is crucial for efficient maintenance and repair of machinery. This guide will help you navigate the essential elements, ensuring you can identify and locate various components effectively.

Key Elements to Consider

- Labels: Look for clear identifiers that indicate specific parts.

- Symbols: Familiarize yourself with common symbols used to represent different elements.

- Connections: Pay attention to lines that show how components are linked or interact.

Steps for Effective Interpretation

- Start by reviewing the overall layout to grasp the general arrangement.

- Identify major sections and break them down into smaller units.

- Cross-reference with a list of components to ensure comprehensive understanding.

Common Issues with Hay Rake Parts

Operating agricultural equipment often presents various challenges that can hinder efficiency and productivity. Understanding the frequent complications that arise with essential components is crucial for maintaining optimal functionality. Regular inspections and timely interventions can prevent minor problems from escalating into major setbacks.

Wear and Tear: Over time, components can experience significant wear, leading to diminished performance. Regular checks are necessary to identify signs of fatigue and address them promptly.

Misalignment: Components can become misaligned due to regular use or improper installation. This misalignment can cause uneven functioning and increase the risk of damage to adjacent parts.

Corrosion: Exposure to the elements can lead to rust and deterioration of metallic components. Ensuring proper storage and applying protective coatings can mitigate this issue.

Breakage: Stress and strain during operation can result in breakage of critical components. It’s essential to use quality materials and adhere to operational guidelines to reduce the risk of such failures.

Lack of Lubrication: Insufficient lubrication can cause friction and overheating, leading to premature failure. Regular maintenance and lubrication schedules are vital for longevity.

By being proactive and addressing these common challenges, operators can ensure smoother operations and extend the lifespan of their equipment.

Maintenance Tips for Longevity

Ensuring the extended life of your agricultural equipment requires regular attention and care. By implementing effective maintenance practices, you can significantly reduce wear and tear, enhance performance, and prevent costly repairs. This section highlights essential strategies to keep your machinery in optimal condition.

Regular Inspections

Conduct routine checks to identify any signs of damage or wear. Pay close attention to critical components, ensuring that all parts function as intended. Timely detection of potential issues can save you from more extensive problems down the line.

Lubrication and Cleaning

Maintaining proper lubrication is vital for reducing friction and preventing corrosion. Clean your equipment regularly to remove debris and dirt that can impede functionality. Utilize appropriate oils and greases to ensure all moving parts operate smoothly, contributing to a longer lifespan.

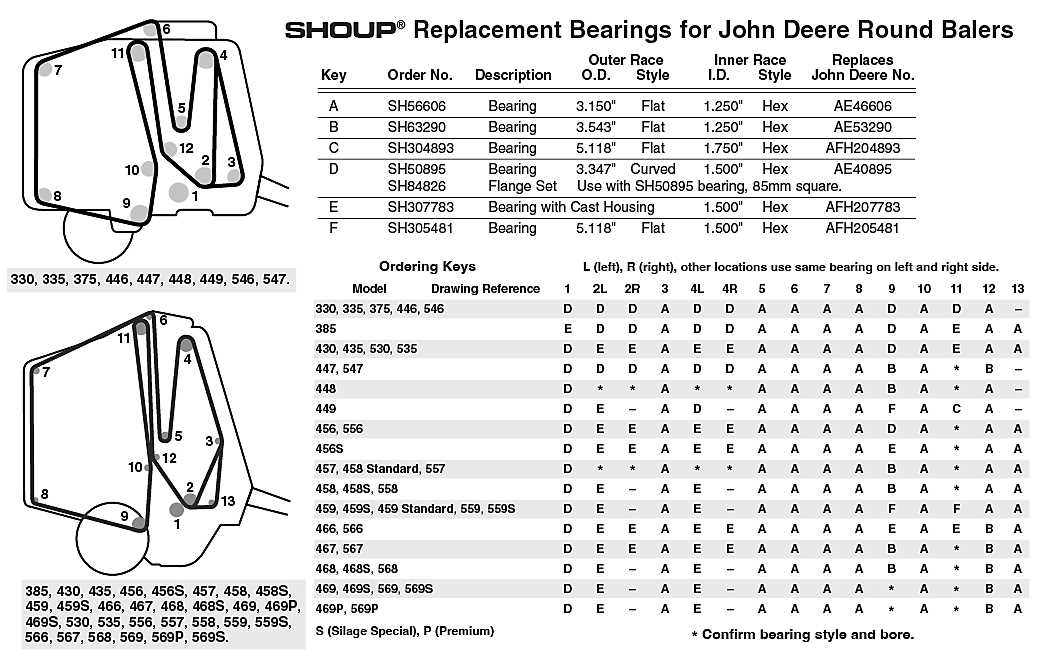

Replacement Options for Worn Parts

When components of your agricultural equipment show signs of wear, timely action is essential to maintain optimal performance. Identifying suitable alternatives can help restore functionality and extend the lifespan of your machinery.

Original Equipment Manufacturer (OEM) Solutions: Choosing OEM replacements ensures compatibility and reliability. These components are designed specifically for your machine, providing the same quality as the originals.

Aftermarket Choices: Many aftermarket suppliers offer a variety of options that can be more cost-effective. While these alternatives may vary in quality, they often provide comparable performance at a lower price.

Reconditioned Components: Rebuilt or refurbished parts can serve as a viable option. These items have been restored to a functional state and often come with a warranty, providing a balance between cost and quality.

Custom Fabrication: For unique requirements or hard-to-find pieces, custom fabrication can be an excellent solution. Skilled professionals can create specific components tailored to your machine’s needs, ensuring a perfect fit and function.

Assessing the options available for replacing worn components can lead to significant improvements in efficiency and reliability, ultimately contributing to the success of your operations.

Upgrading Your Hay Rake System

Enhancing your forage collection apparatus can significantly boost efficiency and productivity. By investing in modern components and technologies, you can ensure a smoother operation and better results during harvesting seasons.

Benefits of Modernization

Upgrading your machinery leads to improved performance, reduced maintenance costs, and greater reliability. Newer elements often feature advanced engineering that optimizes functionality, enabling you to manage larger fields more effectively.

Key Considerations

When considering an upgrade, assess the compatibility of new components with your existing setup. Research the latest innovations and seek advice from experts to make informed choices. Additionally, evaluate the long-term benefits versus initial investment to ensure the ultimate return on your enhancement efforts.

Safety Considerations During Repairs

When undertaking maintenance on agricultural machinery, prioritizing safety is crucial to prevent accidents and injuries. Understanding the inherent risks associated with mechanical repairs can help ensure a secure working environment. Implementing proper safety measures and using appropriate personal protective equipment (PPE) is essential for every technician and operator involved in the process.

Firstly, always disconnect the power source before starting any repair work. This simple step can prevent unintended machinery movement, reducing the risk of serious injuries. Additionally, it is vital to inspect tools and equipment for any damage or wear before use. Faulty tools can lead to unexpected failures during maintenance.

Furthermore, maintaining a clean and organized workspace is critical. Clutter can pose tripping hazards and make it difficult to access tools quickly in case of an emergency. Ensure that all safety devices, such as guards and shields, are in place and functioning properly to protect against potential hazards.

In conclusion, adhering to safety guidelines not only protects individuals during maintenance activities but also enhances the overall efficiency of repair work. A commitment to safety is a responsibility that should never be overlooked in any technical setting.

Resources for Parts and Support

Accessing reliable resources for components and assistance is crucial for maintaining machinery efficiency and performance. Whether you require replacement elements or technical guidance, various options are available to ensure your equipment operates smoothly.

Numerous online platforms provide comprehensive catalogs of components, allowing users to browse and identify necessary items. These websites often feature detailed specifications and compatibility information, making it easier to find what you need. Additionally, many offer customer service support through chat or phone, ensuring quick answers to any queries.

Local dealerships and service centers can also be valuable resources. They often maintain stock of essential components and have trained professionals ready to assist with installation and maintenance issues. Engaging with these experts can provide insights that enhance the longevity and reliability of your equipment.

Furthermore, online forums and communities dedicated to equipment enthusiasts can serve as excellent sources of knowledge and advice. Members often share their experiences, troubleshooting tips, and recommendations for where to find specific items. Tapping into this collective wisdom can greatly aid in resolving issues effectively.