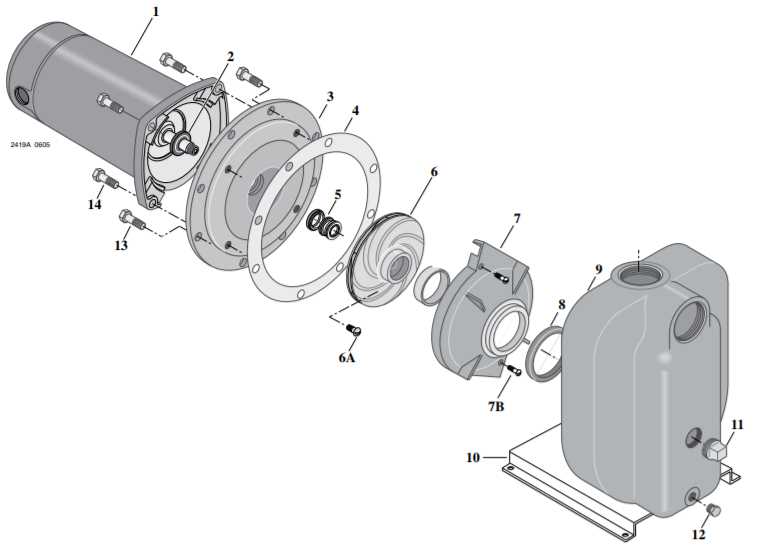

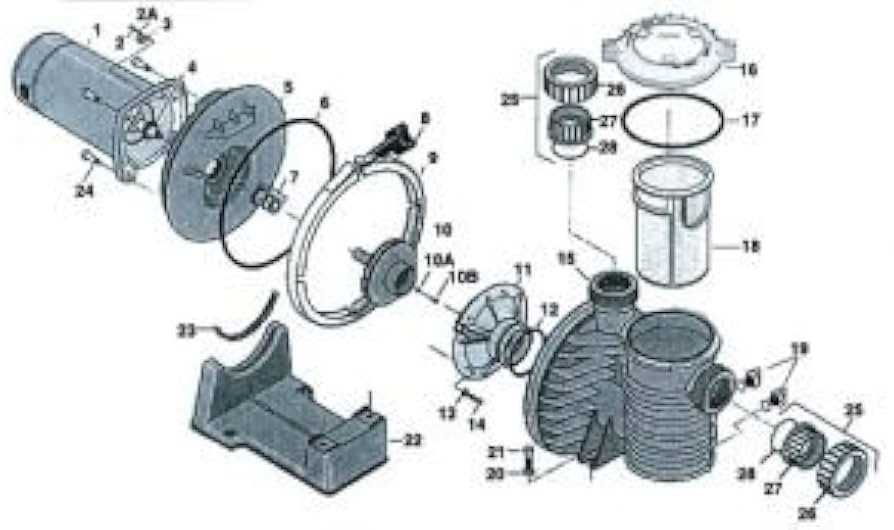

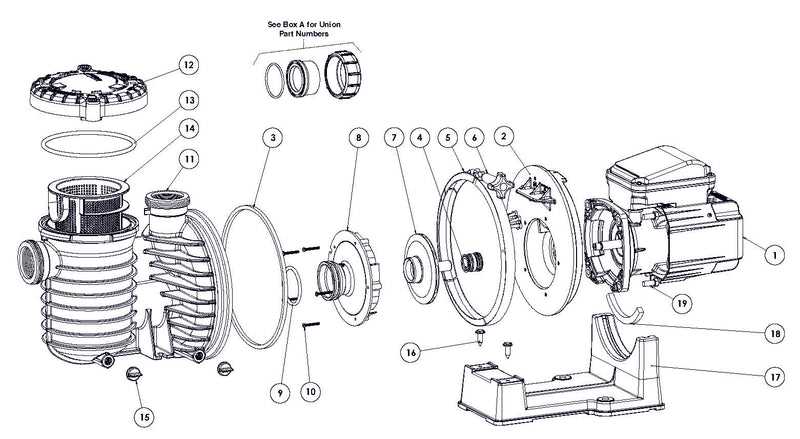

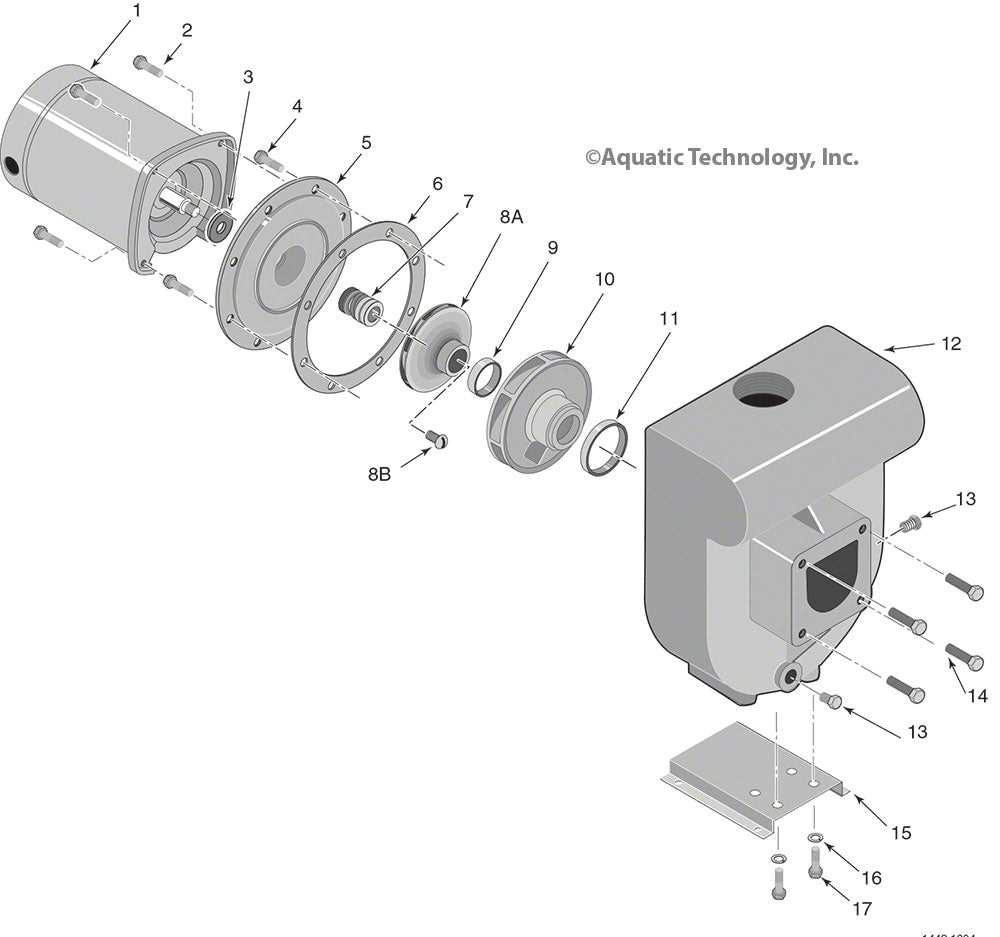

In the realm of fluid transfer technology, a comprehensive understanding of the various components is essential for effective maintenance and operation. This section delves into the intricate configurations and interrelations of different elements within these systems. By visualizing how each piece fits into the overall structure, users can enhance their comprehension and troubleshooting skills.

Having a clear representation of these configurations not only simplifies the identification of individual elements but also assists in recognizing potential issues. Whether for installation, repair, or upgrade, grasping the nuances of these assemblies empowers users to make informed decisions. This knowledge serves as a valuable resource for both professionals and enthusiasts alike.

Moreover, understanding these structures can lead to improved efficiency and longevity of the entire system. By familiarizing oneself with the layout and function of each component, operators can ensure optimal performance and minimize downtime. Thus, a detailed examination of these arrangements becomes indispensable for anyone involved in fluid management technology.

Understanding Sta-Rite Pump Components

The functionality of any water management system relies heavily on its individual elements. A comprehensive grasp of these components is essential for efficient operation, maintenance, and troubleshooting. Each piece plays a crucial role in the overall performance, ensuring fluid is circulated effectively throughout the system.

Key Elements and Their Functions

Among the critical components, the motor acts as the driving force, converting electrical energy into mechanical energy. This transformation enables other elements to function optimally. Additionally, the volute casing is designed to direct the flow, maximizing efficiency and minimizing energy loss. Understanding how these components interact can significantly enhance your ability to maintain and optimize performance.

Maintenance and Troubleshooting

Regular inspection of these essential elements is vital to ensure longevity and efficiency. Signs of wear or malfunction can often be traced back to specific components. By familiarizing yourself with their roles, you can quickly identify issues and implement corrective actions, thereby extending the lifespan of the entire system.

Importance of Accurate Pump Diagrams

Precise representations of mechanical components are crucial for ensuring optimal functionality and efficiency. Accurate schematics facilitate effective communication among engineers and technicians, ultimately enhancing maintenance and troubleshooting processes.

Benefits of Detailed Representations

Having comprehensive layouts allows for quick identification of issues and streamlines repair tasks. Furthermore, it aids in training new staff and ensures consistency in maintenance practices.

Consequences of Inaccuracies

Inaccurate representations can lead to costly mistakes, inefficient operations, and potential safety hazards. Ensuring the reliability of these visuals is essential for the longevity of the machinery and the safety of the personnel involved.

| Aspect | Impact of Accuracy |

|---|---|

| Maintenance | Faster and more efficient repairs |

| Training | Improved understanding for new employees |

| Safety | Reduced risk of accidents |

| Cost | Minimized operational expenses |

Common Issues with Sta-Rite Pumps

Maintaining optimal performance in water circulation systems can be challenging. Various complications may arise, affecting efficiency and longevity. Understanding these common problems can aid in timely identification and resolution, ensuring smooth operation.

Insufficient Water Flow

One prevalent issue involves inadequate water movement. This can result from clogs in the system, worn-out seals, or improper installation. Regular maintenance, including cleaning and checking for obstructions, is essential to restore flow and prevent further damage.

Noisy Operation

Another frequent concern is excessive noise during operation. This may indicate air leaks or vibrations caused by misalignment. Addressing these issues promptly can enhance performance and reduce wear on components, leading to a quieter and more efficient system.

How to Read Pump Parts Diagrams

Understanding technical illustrations can enhance your ability to maintain and repair machinery. Familiarizing yourself with the symbols, labels, and layouts used in these visuals is essential for effective troubleshooting and assembly. By decoding these images, you can gain insights into component relationships and functionalities.

| Symbol | Description |

|---|---|

| Circle | Represents a valve or a connector. |

| Arrow | Indicates direction of flow or movement. |

| Square | Denotes a housing or enclosure. |

| Line | Shows the pathway for connections or tubes. |

Focusing on these elements will enable you to delve deeper into machinery operation and lead to more efficient repairs and enhancements.

Identifying Replacement Parts Easily

Recognizing components for your equipment can often be a challenging task. Having a clear understanding of the various elements involved allows for efficient maintenance and quicker replacements. With the right approach, one can streamline the process of sourcing the necessary items without unnecessary complications.

Steps to Identify Components

Start by gathering all relevant information about your equipment, including model numbers and specifications. This data will aid in narrowing down your search for replacements.

Common Component Types

| Type | Description |

|---|---|

| Seals | Prevent leaks and ensure tight connections. |

| Valves | Control the flow and direction of liquids. |

| Filters | Remove impurities and maintain fluid clarity. |

| Housings | Encase and protect internal components. |

Maintenance Tips for Sta-Rite Pumps

Proper upkeep of your equipment is essential to ensure its longevity and optimal performance. Regular maintenance not only enhances efficiency but also helps in identifying potential issues before they escalate into major problems.

1. Regular Inspections: Frequently examine your unit for any signs of wear or damage. Look for leaks, unusual noises, or vibrations that may indicate a problem.

2. Clean Filters: Ensure that filters are kept clean and free from debris. Clogged filters can restrict flow and cause overheating, leading to premature failure.

3. Monitor Water Levels: Check water levels regularly to prevent running the device dry, which can cause severe damage. Maintaining appropriate levels helps in smooth operation.

4. Lubrication: Apply lubricant to moving parts as specified in the user manual. Proper lubrication reduces friction and wear, extending the lifespan of components.

5. Seasonal Maintenance: Before and after seasonal changes, perform a thorough inspection and service. This includes checking electrical connections, seals, and the overall integrity of the system.

6. Professional Servicing: Schedule routine check-ups with a qualified technician. Their expertise can provide valuable insights and help address issues that may go unnoticed.

By following these guidelines, you can ensure that your equipment remains reliable and efficient, ultimately saving you time and money in the long run.

Where to Find Original Parts

Locating authentic components for your equipment is essential for maintaining optimal performance and longevity. Many users seek reliable sources that offer genuine items, ensuring compatibility and durability. With the right approach, you can find high-quality replacements that meet the specifications of your device.

Authorized dealers are often the best starting point for obtaining original components. These suppliers are certified by manufacturers and typically provide a wide range of options along with expert advice. Additionally, official websites often have sections dedicated to parts, allowing you to browse and purchase directly from the source.

Another useful resource is online marketplaces that specialize in equipment components. These platforms frequently feature a variety of suppliers, giving you access to a broad selection of authentic products. Be sure to verify the seller’s reputation and check for authenticity guarantees to avoid counterfeit items.

Lastly, local repair shops and service centers can be invaluable. They usually have access to genuine items and can offer installation assistance. Building a relationship with these professionals may also lead to insider tips on where to find hard-to-locate components.

Upgrading Your Pump System

Enhancing your fluid transfer system can significantly improve efficiency, reliability, and overall performance. Whether you’re looking to replace outdated components or integrate advanced technology, thoughtful upgrades can lead to noticeable benefits in operation and maintenance.

Benefits of System Enhancement

- Increased Efficiency: Modern components often offer better energy consumption, leading to lower operating costs.

- Improved Durability: Upgraded materials and designs can withstand wear and tear, extending the lifespan of your system.

- Enhanced Performance: New technologies can provide better flow rates and pressure management, ensuring optimal functionality.

Key Considerations for Upgrading

- Assessment of Current System: Analyze the existing setup to identify areas for improvement.

- Research Options: Investigate various alternatives that suit your specific needs and requirements.

- Compatibility: Ensure that new components will integrate seamlessly with existing infrastructure.

- Budgeting: Consider the overall investment versus the potential savings and benefits.

Implementing thoughtful enhancements can transform your operation, leading to a more efficient and reliable system. Prioritize planning and research to maximize the benefits of your upgrade.

Frequently Asked Questions About Pumps

This section aims to address common inquiries related to fluid-moving devices, providing clarity on their functionalities, maintenance, and selection criteria. Understanding these aspects can greatly enhance efficiency and performance in various applications.

What are the key factors to consider when choosing a fluid-moving device?

When selecting a device, it’s essential to evaluate the required flow rate, pressure, and the type of fluid being handled. Additionally, consider the operational environment, such as temperature and potential exposure to chemicals, as these factors influence compatibility and longevity.

How can I ensure the longevity of my fluid-moving device?

Regular maintenance is crucial for extending the lifespan of these machines. This includes routine inspections, timely replacement of worn components, and ensuring proper lubrication. Moreover, keeping the device clean and operating within its specified limits can prevent premature wear and potential failures.