Car

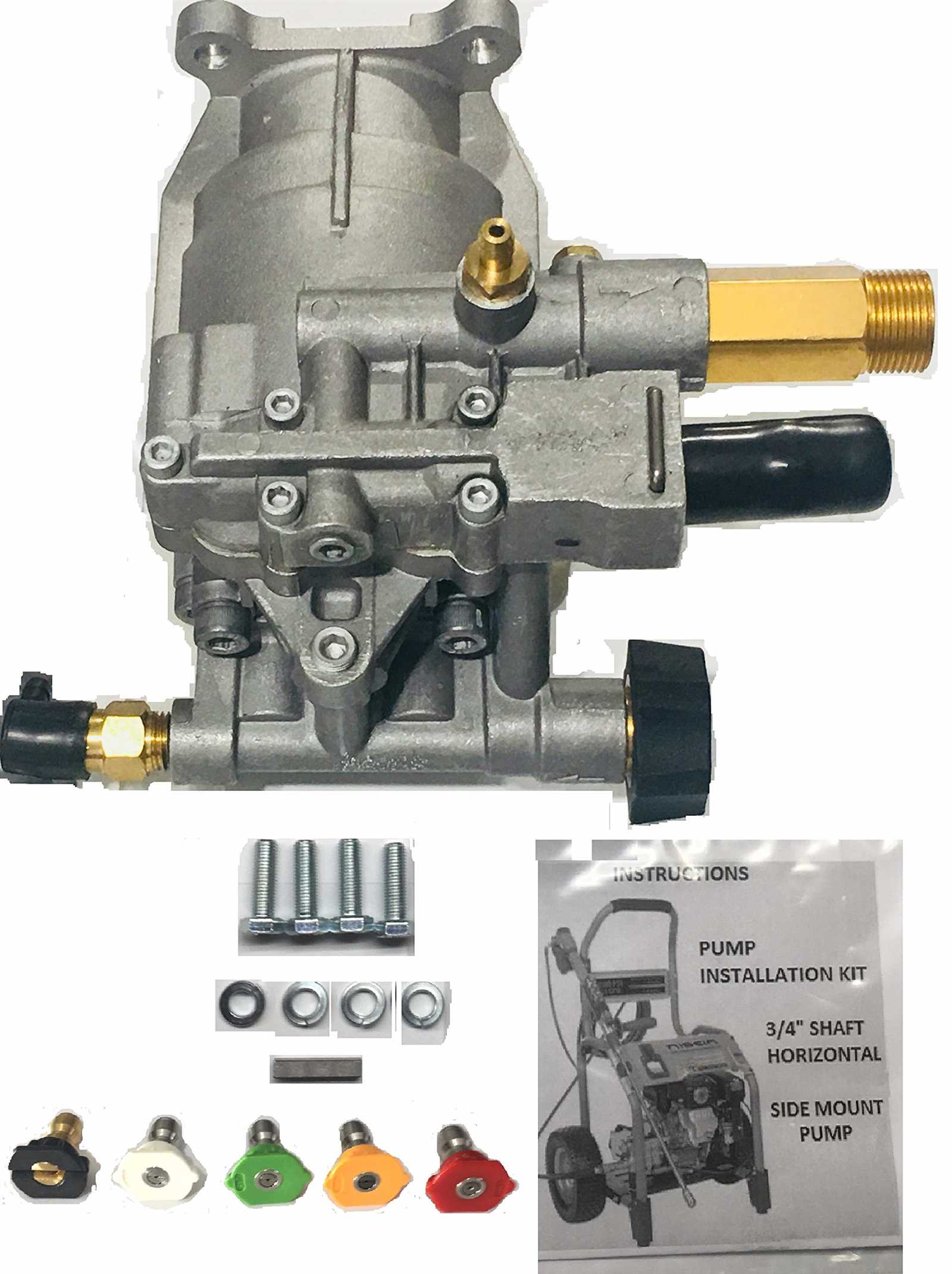

Pump Assembly Breakdown and Functions

The core of any cleaning system lies in the pump mechanism, responsible for generating the necessary fluid movement. Understanding the internal components of this crucial assembly helps to ensure smooth operation and maintenance. Each part plays a distinct role in driving the liquid, controlling flow, and maintaining balance within the system.

The pump is typically composed of several interconnected parts, each contributing to its overall functionality. These include pistons, seals, valves, and the crankcase, all of which work together to create consistent output. When any of these elements fail, the efficiency of the system can drop significantly, requiring precise troubleshooting and repair.

Pistons or plungers are tasked with moving the liquid through the system by creating pressure through a back-and-forth motion. Seals help to prevent leaks and maintain a stable internal environment, while valves manage the flow, ensuring that the fluid moves in the right direction. The crankcase houses the mechanical motion, converting rotational energy into linear force.

Routine inspection of these components ensures

Commonly Replaced Parts in the Washer

Over time, various components of a cleaning machine may wear out or become less effective, requiring replacement. These elements are crucial to the overall performance, ensuring the equipment operates smoothly and efficiently. Regular maintenance and timely replacement of worn-out items help extend the machine’s lifespan and maintain optimal functionality.

One of the most frequently replaced elements is the nozzle, which controls water flow and pressure. A damaged nozzle can lead to uneven water distribution, reducing the machine’s cleaning power. Another common issue arises with hoses, which can develop cracks or leaks over time, impacting water delivery.

Pumps are another critical component that may need replacement after extensive use. A malfunctioning pump can lead to decreased water pressure or complete failure of the machine. Valves, too, play a key role in regulating water flow and are prone to wear, especially when used in high-intensity cleaning tasks.

Lastly, connectors and seals are often overlooked but can cause major problems if damaged. These small yet essential parts ensure that water is properly contained and directed, preventing leaks and maintaining the machine’s efficiency

Understanding Hose and Spray Gun Structure

The components responsible for directing water flow in cleaning equipment are vital for ensuring effective operation. A hose and spray gun work together seamlessly to create a powerful stream, allowing users to tackle various surfaces efficiently. While the hose primarily carries water from the source to the cleaning unit, the spray gun controls and adjusts the flow to suit different tasks. Understanding the structure of these elements helps in maintaining and optimizing their performance.

The Hose: Functionality and Design

The hose serves as the conduit through which water is transported. Its design must withstand high-pressure conditions and be flexible enough for easy maneuverability. Typically, hoses are made from durable materials that prevent cracking, puncturing, or kinking. The internal diameter of the hose plays a crucial role in determining water flow rate, and thicker hoses are often used for higher demands.

The Spray Gun: Control Mechanism

The spray gun is designed to regulate the water flow, offering different spray patterns depending on the task. It often includes a trigger mechanism for easy control and adjustment. The nozzle on the spray gun can be interchangeable, offering various spray angles, from a narrow jet for deep cleaning to a wide fan for surface rinsing. The handle of the gun is ergonomically designed for user comfort during prolonged use.

| Component |

Function |

Material |

| Hose |

Transports water to the spray gun |

Rubber, PVC, or braided materials |

| Spray Gun |

Regulates water flow and directs the spray |

Plastic or metal, often with rubber grips |

| Nozzle |

Adjusts the spray pattern |

Plastic or stainless steel |

Maintenance Tips for Longevity

Proper care and regular maintenance are essential for ensuring the longevity of your equipment. By following a few simple steps, you can enhance its performance and extend its lifespan. Taking time to inspect and maintain your machine will help prevent unnecessary breakdowns and costly repairs.

- Regularly clean all surfaces to remove dirt, debris, and buildup that can impair functionality.

- Check the motor and other key components for signs of wear or damage. Address any issues promptly to avoid further complications.

- Ensure all connections, including hoses and nozzles, are secure and free from leaks to maintain optimal efficiency.

- Store the equipment in a dry, sheltered area when not in use to protect it from the elements and prevent rust or corrosion.

- Periodically inspect and replace consumable items like filters, seals, and gaskets to keep everything functioning smoothly.

Maintaining these steps will significantly increase the durability of your tool, ensuring that it remains a reliable asset for years to come.

Finding Correct Replacement Parts

When it comes to maintaining outdoor cleaning equipment, selecting the appropriate components is crucial for smooth operation and longevity. Identifying the right elements ensures that the machine functions effectively and avoids unnecessary damage or inefficiency. Whether you are dealing with a malfunction or looking to upgrade specific elements, understanding the specifications of each part is essential.

Step one in the process is determining the exact model and specifications of your machine. This information will guide you in choosing compatible items that are designed to fit and function as intended. Without this knowledge, there is a risk of purchasing items that do not meet the required standards or that may cause complications in performance.

Additionally, it is wise to consider the quality of the items you are acquiring. Opting for high-quality replacements may cost more initially, but they often offer better durability and longer-term performance. Make sure to review customer reviews and product ratings to gauge the reliability of the components before making a purchase.

Finally, keep in mind that some elements may require professional installation. If you are not familiar with assembly or maintenance procedures, seeking assistance from an expert can save time and prevent costly mistakes.

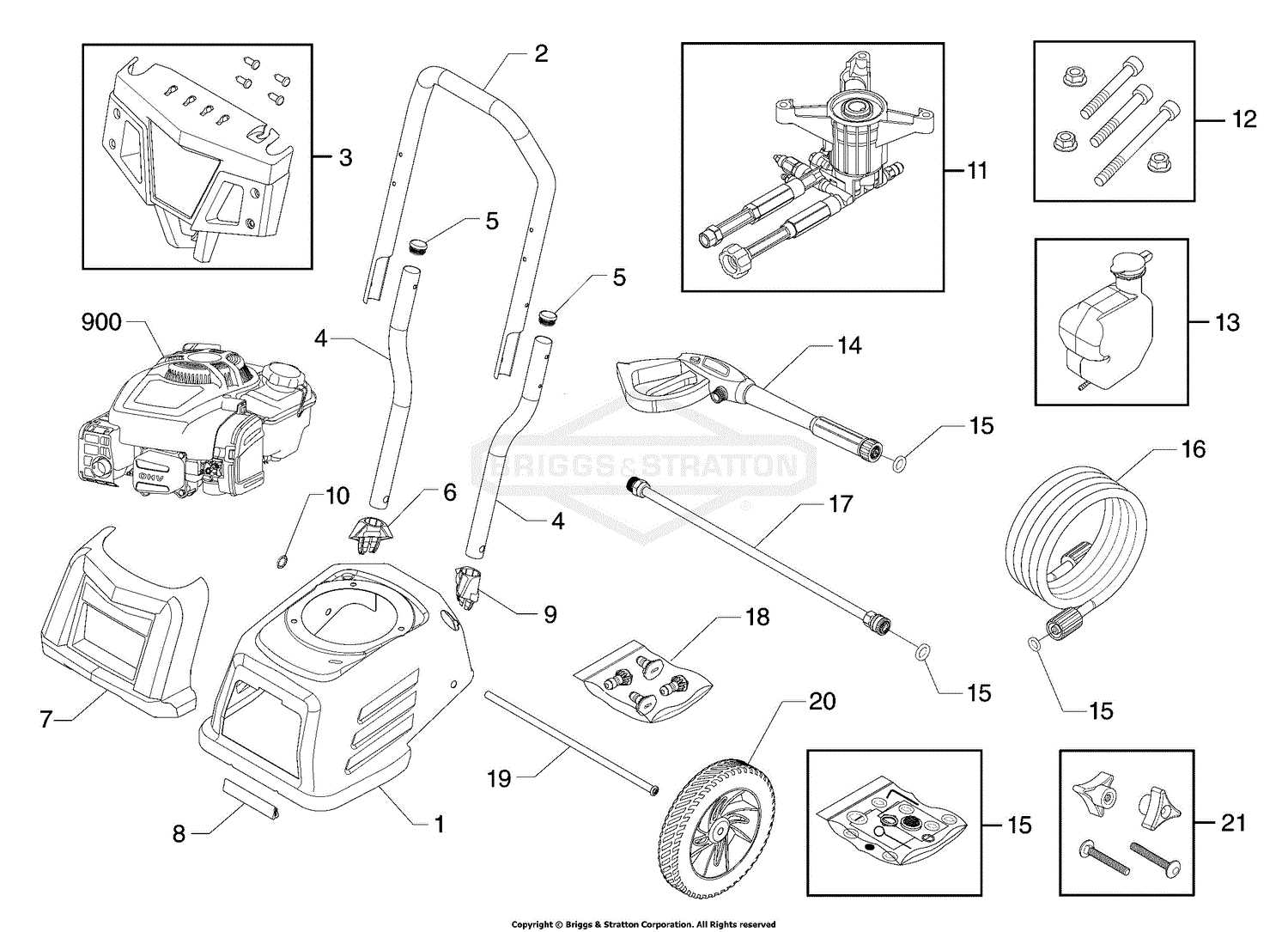

Exploded Diagram of Troy-Bilt Pressure Washer

The exploded view of a high-powered cleaning machine provides a clear and detailed representation of its internal and external components. It breaks down each individual piece, showing how they interconnect and function together. This type of illustration is essential for understanding the assembly, disassembly, and repair processes, ensuring that every part is in its correct position.

By viewing this detailed breakdown, users can identify specific elements such as hoses, pumps, nozzles, and other crucial pieces. This visual guide is useful when replacing worn-out components or performing regular maintenance.

- Engine assembly

- Water pump section

- Hose connections and fittings

- Trigger and spray gun mechanism

- Frame and wheel configuration

- Safety valve and pressure control system

Having access to this comprehensive illustration simplifies troubleshooting, enabling users to pinpoint exact issues with ease. Additionally, it serves as an instructional reference, assisting both novice and expert users in maintaining and enhancing the performance of the device.

|