When it comes to maintaining outdoor machinery, having a comprehensive understanding of its inner workings is essential. A detailed visual representation can significantly enhance your ability to identify and address issues that may arise over time. This guide aims to provide insights into the various elements that contribute to the efficient operation of your tool.

Knowing the layout of each component not only aids in troubleshooting but also facilitates smoother repairs and replacements. By familiarizing yourself with the assembly, you can ensure that your device runs optimally, extending its lifespan and improving performance.

In this article, we will explore the intricacies of the specific model, breaking down its structure and highlighting key sections. Whether you are a seasoned professional or a casual user, understanding these elements will empower you to make informed decisions about maintenance and upgrades.

Understanding the Stihl BR550 Overview

This section provides an insightful look into a powerful tool designed for outdoor maintenance and landscaping. With its robust engine and ergonomic design, it caters to both professional landscapers and avid gardeners. By examining the key components and functionality, users can appreciate how this equipment enhances efficiency and ease of use in various tasks.

Featuring a reliable motor, this device delivers impressive performance, ensuring that users can tackle challenging jobs with confidence. The design focuses on user comfort, minimizing fatigue during extended periods of operation. Additionally, the thoughtful arrangement of controls contributes to a seamless experience, allowing for precise handling and maneuverability.

Understanding the intricacies of this machine enables operators to maximize its potential. Regular maintenance and awareness of its features can significantly extend its lifespan and performance. By familiarizing oneself with the essential elements, users can ensure optimal operation and productivity in their outdoor endeavors.

Key Components of the BR550

This section delves into the essential elements that contribute to the effective operation of a popular outdoor power tool. Understanding these critical components can enhance maintenance efforts and ensure optimal performance during use. Each part plays a significant role in the overall functionality and reliability of the equipment.

Major Functional Elements

Among the various parts, several key elements are indispensable for the tool’s efficient operation. These components work in unison to deliver the desired power and precision, making them crucial for users who rely on their effectiveness.

| Component | Description |

|---|---|

| Engine | The powerhouse that provides the necessary force for operation. |

| Fuel System | Ensures the appropriate mix of fuel and air for optimal combustion. |

| Ignition System | Responsible for starting the engine and maintaining its operation. |

| Blower Housing | Directs airflow and enhances the efficiency of debris removal. |

| Handle Assembly | Provides user control and comfort during operation. |

Maintenance Considerations

Proper upkeep of these essential elements is vital for ensuring longevity and performance. Regular inspection and servicing can prevent potential issues, enabling users to achieve the best results with their equipment.

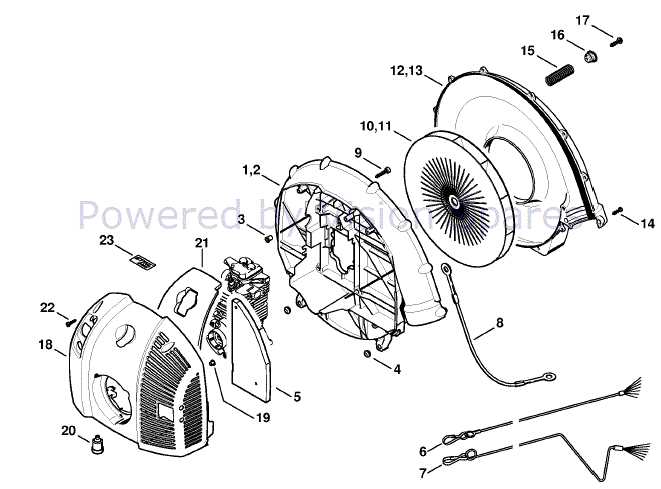

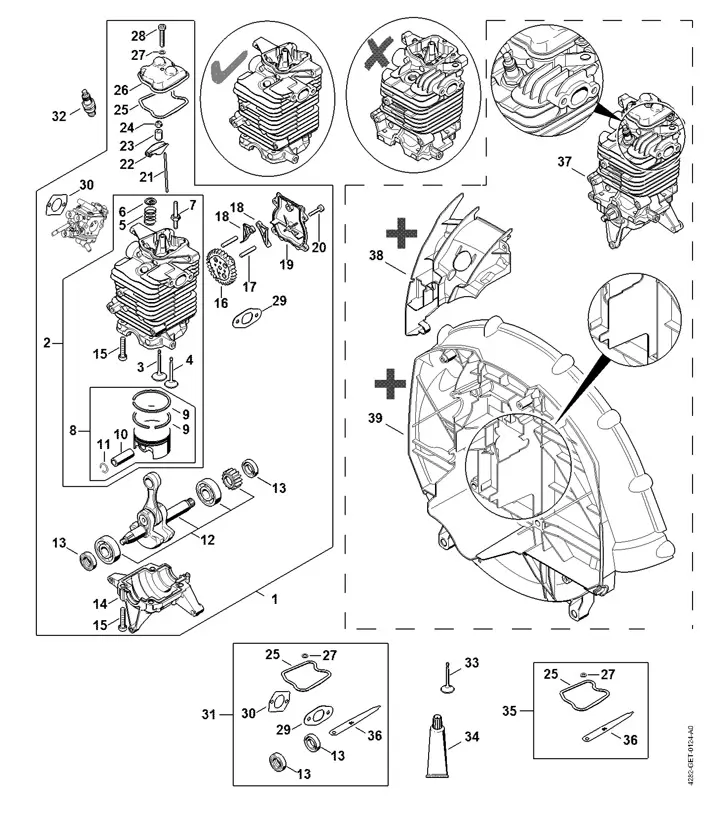

Importance of Parts Diagrams

Understanding the layout and function of components in machinery is essential for effective maintenance and repair. Visual representations of these elements play a crucial role in simplifying complex structures and enabling users to identify individual pieces easily.

Benefits of Visual Representation

- Facilitates quick identification of components

- Enhances understanding of assembly and disassembly processes

- Assists in troubleshooting by pinpointing potential issues

- Promotes accuracy in ordering replacements

Streamlining Maintenance Tasks

- Reduces the time needed for repairs

- Minimizes the risk of errors during assembly

- Improves overall efficiency of maintenance procedures

By utilizing these visual aids, users can ensure that their equipment remains in optimal condition, ultimately leading to improved performance and longevity.

How to Access the Diagram Online

Finding detailed schematics for machinery can greatly assist in maintenance and repairs. Accessing these resources online is essential for anyone looking to understand the components and their assembly. Here’s a guide on how to locate these valuable visual aids effectively.

Steps to Locate the Schematic

- Start by visiting the official website of the manufacturer.

- Navigate to the support or customer service section.

- Look for links to manuals or technical resources.

- Use the search function to enter the model name or number.

- Download the relevant documentation or view it online.

Alternative Resources

- Check third-party websites specializing in tool parts and maintenance guides.

- Explore online forums and community pages where users share resources.

- Utilize social media groups dedicated to machinery maintenance.

Common Issues and Solutions

In the world of outdoor power equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems and their remedies can significantly enhance the overall experience and longevity of the equipment.

Frequent Problems

| Issue | Description |

|---|---|

| Engine Won’t Start | Often caused by fuel issues, clogged air filters, or ignition system failures. |

| Uneven Performance | This can result from a dirty spark plug or an obstructed fuel line. |

| Overheating | Usually linked to insufficient lubrication or a blocked cooling system. |

Possible Solutions

Addressing these common issues typically involves straightforward troubleshooting steps. Regular maintenance, such as checking and replacing filters, ensuring proper fuel quality, and inspecting the ignition components, can prevent many problems. Additionally, keeping the equipment clean and well-lubricated plays a crucial role in optimal functionality.

Replacing Parts: Step-by-Step Guide

Maintenance is essential for ensuring the longevity and optimal performance of your equipment. When components wear out or become damaged, replacing them promptly can prevent further issues and enhance efficiency. This guide will walk you through the necessary steps to safely and effectively swap out the required elements in your machine.

Preparation

- Gather necessary tools: screwdrivers, wrenches, and any specific tools required for your model.

- Ensure you have the correct replacement components on hand.

- Consult the manual for detailed information about the model’s specifications and safety guidelines.

Step-by-Step Replacement

- Turn off the machine and disconnect it from any power source to ensure safety.

- Carefully remove any coverings or guards to access the components.

- Identify the part that needs replacing and take note of its position.

- Loosen and remove any screws, bolts, or fasteners holding the old component in place.

- Carefully detach the old piece, avoiding any damage to surrounding parts.

- Align the new component properly and secure it with the appropriate fasteners.

- Reassemble any coverings or guards removed during the process.

- Reconnect the machine to the power source and perform a test to ensure everything functions correctly.

Following these steps will help you maintain your equipment in peak condition, allowing for effective and reliable operation over time.

Where to Buy Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is essential for optimal performance and longevity. Reliable sources ensure that you receive high-quality replacements that fit perfectly and function as intended.

Here are some recommended places to find original components:

| Source | Description |

|---|---|

| Authorized Dealers | Visit local retailers that are officially recognized to sell the brand’s products, ensuring quality and warranty coverage. |

| Online Retailers | Reputable e-commerce platforms often carry a wide selection of genuine items, frequently with customer reviews for reference. |

| Manufacturer’s Website | Ordering directly from the official site guarantees authenticity and access to the latest components available. |

| Repair Shops | Local repair services may have direct access to genuine replacements and can assist with installation. |

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of your tools, ultimately saving you time and money in the long run.

Regular Inspection

Frequent checks of components help identify wear and tear before they escalate into serious issues. Look for signs of damage or corrosion that could hinder performance.

Cleaning and Lubrication

Keep your tools clean and well-lubricated to prevent debris buildup and ensure smooth operation. Use appropriate cleaning agents and lubricants for optimal results.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every Use | Check for damage or loose parts. |

| Cleaning | Weekly | Remove dirt and debris. |

| Lubrication | Monthly | Apply suitable lubricants to moving parts. |

| Filter Replacement | Every 3 Months | Ensure optimal airflow and performance. |

Ultimate Resources for Further Learning

Expanding your knowledge about equipment maintenance and repair can greatly enhance your skills and confidence. This section provides a collection of valuable resources that will guide you through various aspects of understanding machinery, tools, and their components. Whether you’re a beginner or an experienced enthusiast, these materials will help deepen your comprehension and practical abilities.

Online Learning Platforms

- Udemy: Offers courses on mechanical repair and equipment management.

- Coursera: Features programs from universities focusing on engineering principles related to machinery.

- YouTube: A wealth of video tutorials demonstrating hands-on repair techniques and maintenance tips.

Books and Manuals

- Repair Manuals: Look for specialized guides that cover the specific machinery you are interested in.

- Technical Books: Explore literature on mechanical engineering and equipment design for deeper insights.

- Industry Magazines: Subscribe to publications that provide updates and tips on machinery care and innovations.

Utilizing these resources will empower you to effectively troubleshoot and maintain various types of equipment, ensuring optimal performance and longevity.