When the colder months set in, ensuring that your outdoor equipment is in proper working order becomes crucial. With the right care, these machines can reliably handle the toughest winter conditions. However, understanding how to maintain and troubleshoot them can sometimes feel overwhelming. This section will help break down key components, allowing you to better manage and maintain your equipment effectively.

Each mechanical system relies on a variety of interconnected elements, and knowing their functions is essential for smooth operation. By focusing on these individual aspects, you can avoid common issues and ensure longevity. Proper upkeep can lead to increased efficiency and minimize downtime during critical use periods.

In this guide, we’ll explore how to identify and understand the different sections and mechanisms, giving you a clearer view of how everything works together. This knowledge will empower you to make informed decisions when it comes to repairs or replacements.

Understanding the Anatomy of a Snowblower

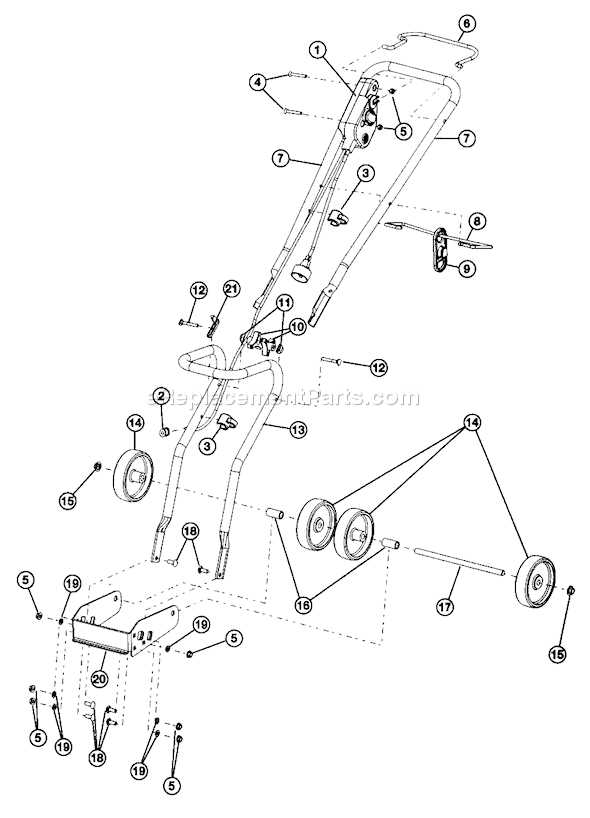

Machines designed to clear pathways during the winter months consist of several intricate components that work together to ensure smooth and efficient operation. Each element plays a critical role in making sure the equipment handles heavy snowfall with ease.

| Component | Function | ||||||

|---|---|---|---|---|---|---|---|

| Auger | Responsible for gathering and breaking up the snow, allowing it to be directed away from the pathway. | ||||||

| Impeller | Propels the snow through the chute at a high velocity, enabling the removal of snow from driveways and walkways. | ||||||

| Chute | Guides the snow, directing it to the desired location once it is processed by the impeller. | ||||||

| Skid Shoes | Ensure that the machine

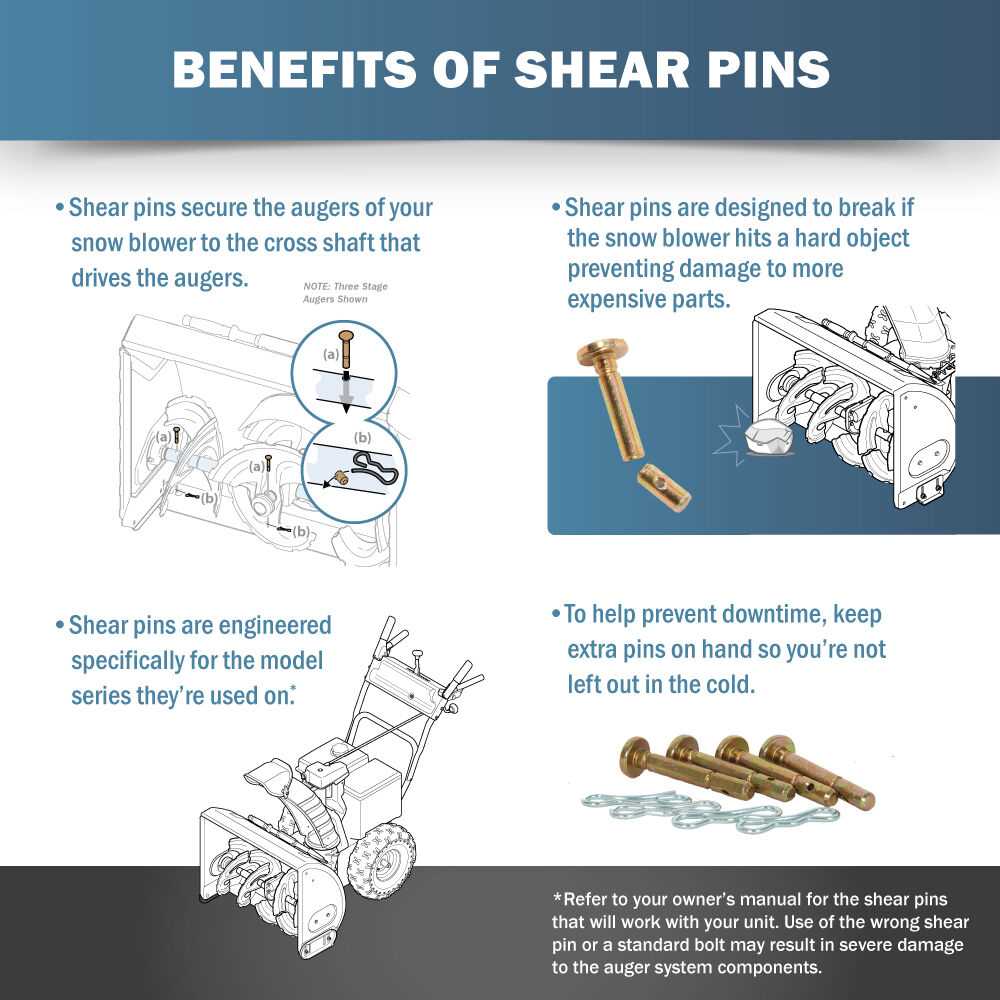

Key Components for Smooth OperationEnsuring seamless performance during challenging weather conditions requires understanding the critical elements that contribute to efficient functionality. Each part plays a specific role in maintaining balance and power, allowing the machine to operate smoothly and effectively. Focusing on these essential components can significantly enhance overall reliability and longevity. Engine and Power TransmissionThe core of the system relies on a well-functioning engine, which converts energy into motion. This energy is transferred through a series of gears and belts, ensuring that the power is evenly distributed. A well-maintained engine and transmission ensure that tasks are handled with ease, even in demanding conditions. Control and Adjustment MechanismsAnother crucial aspect is the set of controls that allows precise adjustments. These mechanisms provide flexibility in movement and control over direction and speed. Regular inspection and adjustment of these controls contribute to a smoother and more efficient performance, keeping the operation steady and manageable. Replacing Worn Parts for LongevityRegular upkeep is essential to ensure smooth operation and extend the lifespan of outdoor equipment. Over time, certain components naturally wear out due to continuous use, which can lead to reduced efficiency or even breakdowns. Addressing these issues promptly by replacing damaged elements can significantly enhance the performance and longevity of your machine. Identifying the Right ComponentsKnowing which components are prone to wear and tear helps in planning regular maintenance. Critical mechanical parts, such as belts, blades, or wheels, should be inspected regularly for signs of deterioration, such as cracks, fraying, or uneven wear. Replacing these early can prevent more severe damage and costly repairs down the line. Ensuring Compatibility and Proper FitWhen replacing worn-out parts, it is vital to select replacements that fit perfectly with the existing system. Incompatible components may not only perform poorly but could also cause additional strain on the machine, reducing its efficiency. Ensuring proper fit and function will keep your equipment running smoothly for years to come. How to Maintain Moving MechanismsEnsuring that machinery functions efficiently requires regular attention to its moving components. These systems are vital for operation, but they also present risks if not properly maintained. To prolong their lifespan and reduce potential hazards, it’s crucial to follow a systematic approach for inspection, lubrication, and parts replacement. Proper care can help prevent costly repairs and unexpected breakdowns.

|