When the cold season arrives, maintaining your machinery is crucial for efficient operation. Knowing the components of your equipment can make a significant difference in performance and longevity. This section aims to provide a comprehensive overview of the essential elements that keep your winter tools running smoothly.

Familiarity with the various components allows users to troubleshoot issues and perform necessary maintenance effectively. By exploring the intricate relationships between different parts, one can better understand how to achieve optimal functionality. This knowledge empowers users to tackle challenges head-on and enhance the overall experience.

In addition, having a clear visual representation can simplify the process of identifying specific items. This clarity is key for both seasoned operators and newcomers alike, ensuring everyone can navigate their equipment with confidence. By delving into this topic, you’ll discover the ultimate insights that will elevate your skills in winter machinery management.

Understanding Snapper Snowblower Components

Grasping the intricacies of a winter clearing machine involves familiarizing oneself with its essential elements. Each component plays a crucial role in ensuring efficiency and reliability during harsh weather conditions. By understanding these elements, operators can enhance performance and troubleshoot issues effectively.

Key Elements of the Machine

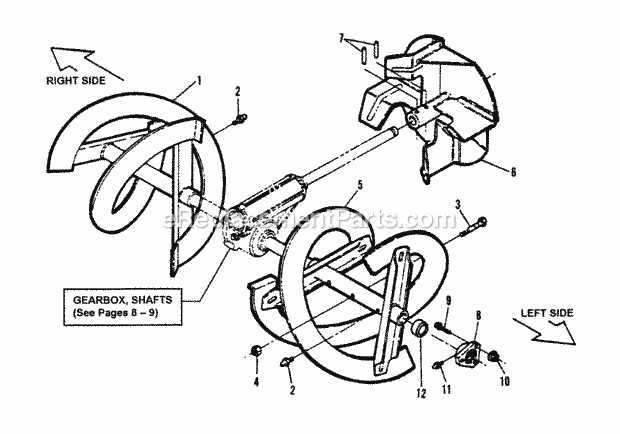

The core structure comprises several integral pieces that work in harmony. From the engine to the auger system, each part is designed for a specific function, contributing to the overall operation and durability.

Component Overview

| Component | Function |

|---|---|

| Engine | Powers the entire unit for movement and operation. |

| Auger | Collects and displaces snow efficiently. |

| Chassis | Provides structural support and stability. |

| Controls | Allows the operator to manage speed and direction. |

Common Issues with Snowblower Parts

In the realm of winter equipment, various components can encounter challenges that affect performance and efficiency. Understanding these common problems can help users identify potential issues early and ensure proper maintenance.

One frequent concern is wear and tear, which can lead to diminished functionality. Over time, components such as belts and blades may become frayed or dull, requiring timely replacement to maintain optimal operation.

Another issue often arises from improper lubrication, which can cause moving parts to seize or operate inefficiently. Regular checks and maintenance of lubricants can prevent these complications and extend the lifespan of the machinery.

Corrosion is also a significant problem, especially when equipment is exposed to harsh winter conditions. Rust can weaken structures and impair performance, making it crucial to inspect for signs of deterioration regularly.

Lastly, misalignment of key components can lead to uneven operation or increased strain on the engine. Regular adjustments and checks can help mitigate these risks, ensuring smooth functionality during the winter months.

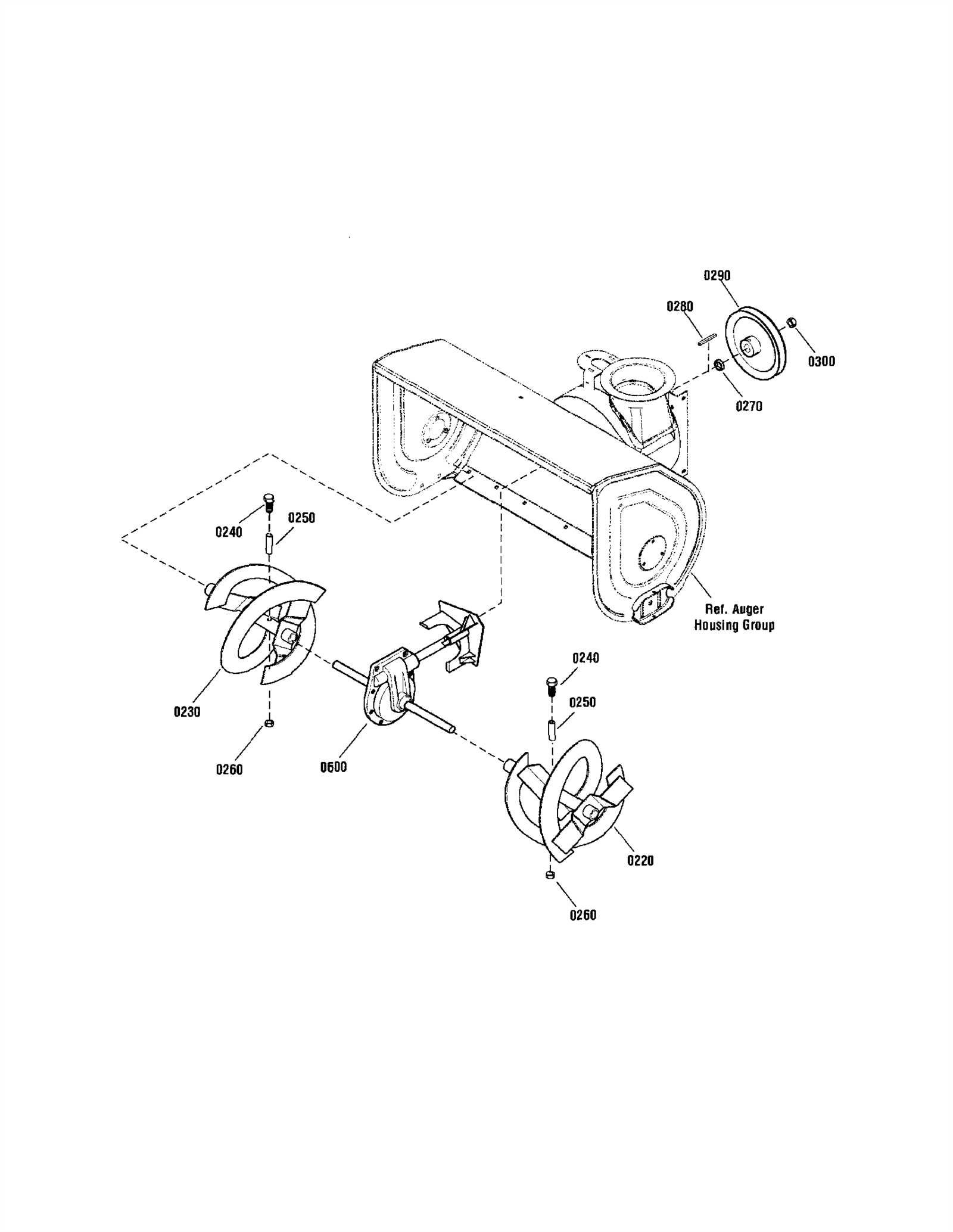

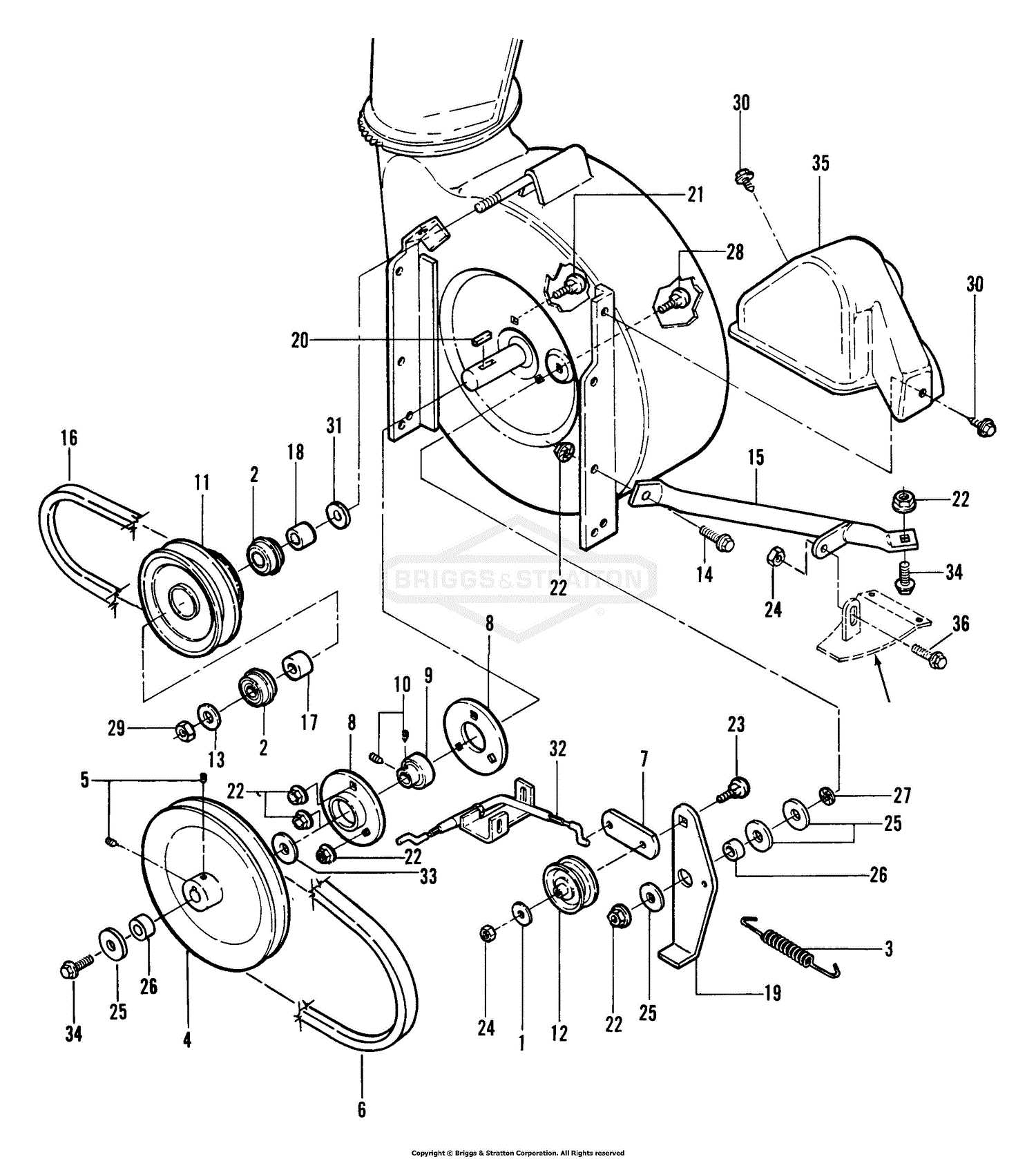

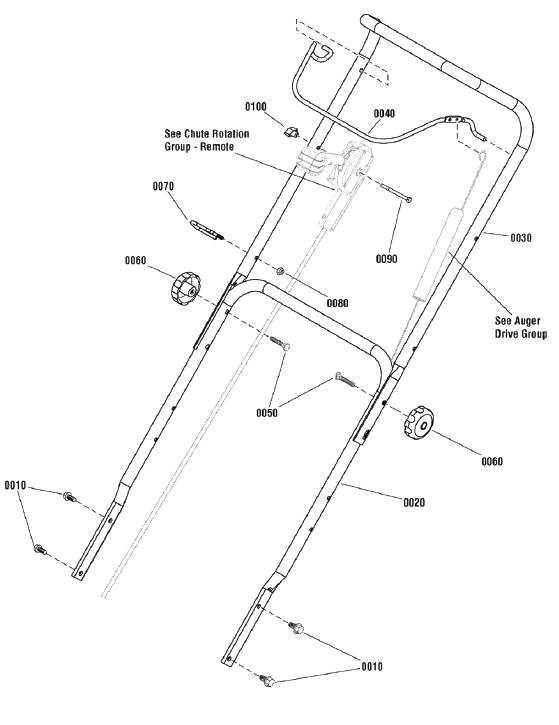

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide valuable insights into how individual elements fit together and function within a larger system. By learning to interpret these visuals, users can enhance their troubleshooting skills and streamline the replacement process.

Here are key elements to consider when examining these visuals:

| Element | Description |

|---|---|

| Labels | Identify specific components, often accompanied by reference numbers for easy lookup. |

| Connections | Illustrate how different elements link and interact with one another. |

| Symbols | Indicate functions or types of components, such as fasteners or electrical connections. |

| Scale | Provide a sense of size and proportion to help visualize placement and compatibility. |

By mastering these aspects, users can ultimately enhance their understanding and efficiency in managing mechanical systems.

Essential Tools for Repairs

Having the right tools is crucial for effective maintenance and repairs. Whether you’re tackling minor adjustments or major overhauls, a well-equipped toolkit can save you time and frustration. Below is a list of indispensable instruments that will facilitate your repair tasks.

- Wrenches: A set of adjustable and socket wrenches allows for versatility in handling various bolt sizes.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for securing and removing screws efficiently.

- Pliers: Needle-nose and standard pliers help grip, twist, and manipulate small components.

- Hammer: A reliable hammer is essential for tapping parts into place or removing stubborn components.

- Utility Knife: This tool is useful for cutting through various materials with precision.

In addition to these primary tools, having a selection of specialized equipment can enhance your repair capabilities:

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Multimeter: A valuable tool for diagnosing electrical issues and ensuring proper connections.

- Jack Stands: Safety is paramount; jack stands are crucial when working underneath machinery.

- Cleaning Supplies: Keep your workspace tidy and components free of debris to ensure optimal performance.

Equipping yourself with these essential tools will not only streamline your repair processes but also enhance your overall efficiency and effectiveness in maintenance tasks.

Ordering Replacement Parts Online

Acquiring new components for your outdoor equipment has never been easier thanks to the convenience of online shopping. This approach allows users to explore a wide range of options, ensuring that they can find exactly what they need without the hassle of visiting multiple stores. Whether you’re looking for a specific item or just browsing, the internet offers a vast marketplace for all your repair requirements.

Benefits of Online Shopping

Shopping online for replacements offers several advantages. First, it provides access to numerous suppliers, often with competitive pricing. Additionally, detailed descriptions and customer reviews can help guide your decisions, making the selection process smoother and more informed.

Ensuring the Right Fit

When purchasing components, it’s crucial to verify compatibility with your existing machinery. Always cross-reference model numbers and specifications to avoid any mismatches. Utilizing manufacturer resources or consultation can ultimately lead to a successful and efficient replacement experience.

Maintenance Tips for Longevity

Proper upkeep of outdoor machinery is essential for ensuring its efficiency and extending its lifespan. Regular attention to key components can prevent costly repairs and ensure optimal performance throughout the seasons. Here are some essential maintenance practices to keep your equipment running smoothly.

Regular Cleaning

Removing debris and buildup after each use can significantly enhance the machine’s performance. Pay special attention to areas that tend to accumulate dirt and ice, as these can impede functionality. Use a brush or compressed air to clear out any obstructions.

Routine Inspections

Conducting regular checks on various elements is crucial. Look for wear and tear, loose connections, or any signs of corrosion. Early detection of potential issues can lead to timely interventions and avoid major breakdowns.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and cables | Monthly |

| Change oil | Every season |

| Sharpen blades | Before heavy use |

| Check fuel system | Every month |

| Clean air filters | After every use |

Identifying Model-Specific Components

Understanding the unique elements of each model is crucial for effective maintenance and repairs. This knowledge ensures optimal performance and longevity of the equipment.

To accurately identify components, consider the following steps:

- Consult the Manual: Each model typically comes with a manual that outlines its specific features.

- Examine Serial Numbers: Locate and note the serial number, which often indicates the production details and compatibility.

- Utilize Online Resources: Various websites offer detailed information and comparisons of different models.

When searching for parts, focus on:

- Shape and size variations

- Connector types and placements

- Material differences that may affect durability

Being thorough in this identification process allows for informed decisions when seeking replacements or upgrades.

Exploring Aftermarket Part Options

When it comes to enhancing the performance and longevity of your outdoor equipment, considering alternatives to original components can be a game-changer. Aftermarket offerings often provide a variety of benefits, from cost savings to improved durability. This section delves into the advantages of opting for these alternatives and how they can elevate your machine’s efficiency.

Benefits of Choosing Alternatives

One of the primary advantages of selecting aftermarket items is the potential for significant savings. Many third-party manufacturers create high-quality replacements that often come at a lower price than their original counterparts. Additionally, these alternatives may offer enhanced features or upgraded materials, leading to superior performance. Quality assurance is crucial, so always opt for reputable brands that have a history of positive reviews.

Finding the Right Fit

Ensuring compatibility is essential when exploring aftermarket options. Take the time to compare specifications and dimensions to avoid issues during installation. Resources such as online forums, user reviews, and specialized retailers can provide valuable insights into which alternatives have proven successful for others. Investing time in research can lead to a smoother experience and improved functionality of your machinery.

Seasonal Preparations for Snowblowers

As winter approaches, ensuring your equipment is ready for the cold months ahead is essential. Proper maintenance and preparation not only enhance performance but also prolong the lifespan of your machinery. Taking the time to service and check various components can make a significant difference when the snow begins to accumulate.

Essential Maintenance Tasks

Start by conducting a thorough inspection of the machine. Check the fuel system for any old gasoline, which can lead to starting issues. Replacing the fuel with fresh gasoline can help avoid complications. Additionally, examine the oil levels; changing the oil if it appears dirty or has not been replaced for some time is crucial. Maintaining clean oil is vital for optimal engine performance.

Checking and Preparing Components

Another critical aspect is to assess the mechanical elements. Look for any signs of wear on the belts and chains, as these can affect efficiency. Ensure that the blades or augers are sharp and free from debris. Lubricating moving parts will also aid in smooth operation. Finally, inspect the tires or tracks for adequate tread and pressure to ensure stability and traction on snowy surfaces.