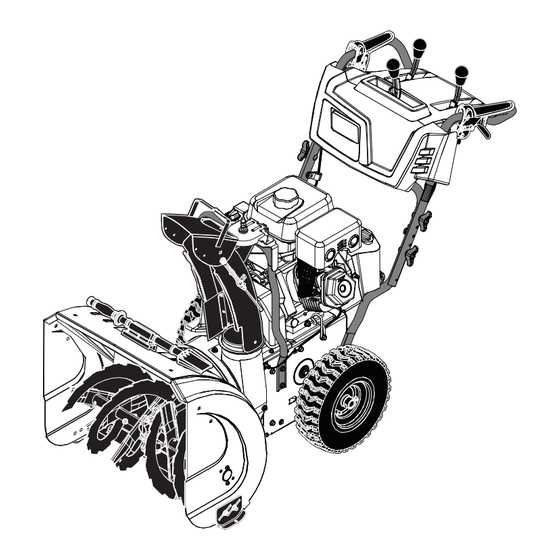

Winter machinery plays a vital role in helping us navigate through the toughest weather conditions. For many, having a reliable system that can handle heavy snowfall is essential. However, over time, different elements of this equipment may need attention to ensure continued performance and efficiency.

Knowing the layout and structure of these systems can make it easier to identify specific elements that might require maintenance. By familiarizing yourself with the main mechanical elements and their function, you can keep your winter tools operating smoothly throughout the season.

In this guide, we’ll explore various components and how they work together to provide seamless functionality. This understanding can help you troubleshoot issues more effectively and ensure that each element is properly cared for when needed.

Understanding Your Husqvarna Snowblower’s Components

To maintain smooth operation during winter months, it’s essential to have a basic understanding of the various mechanical elements that make up your machine. These components work together to ensure effective performance, enabling you to handle even the toughest winter conditions with ease.

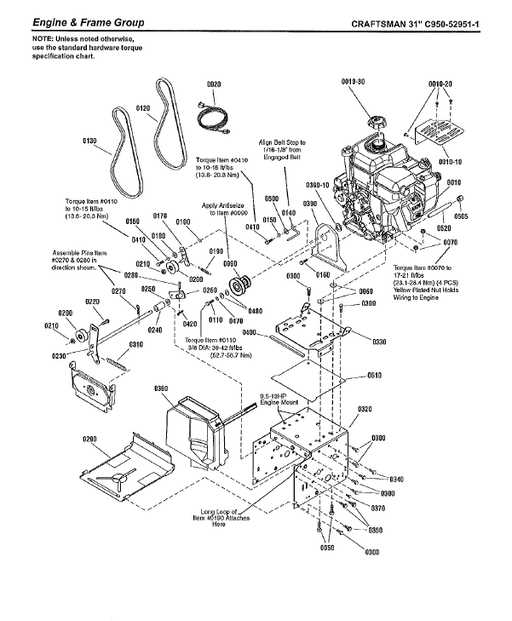

Engine and Power Mechanism

The motor is the heart of the device, providing the necessary energy to power all other systems. A well-maintained engine ensures consistent performance, while its surrounding mechanisms, like belts and pulleys, help transfer energy to the moving parts.

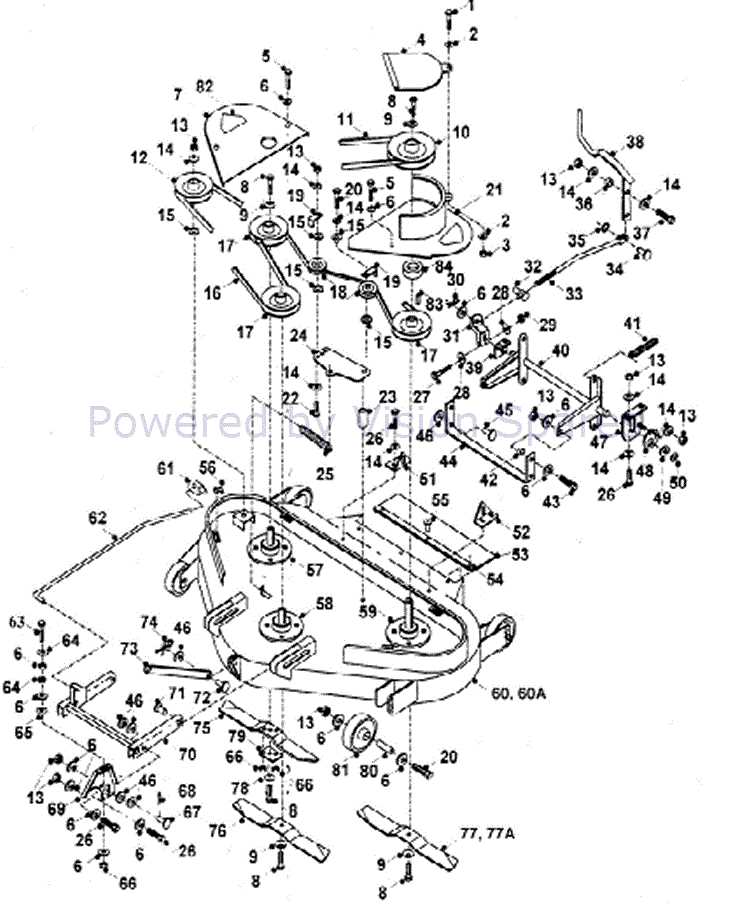

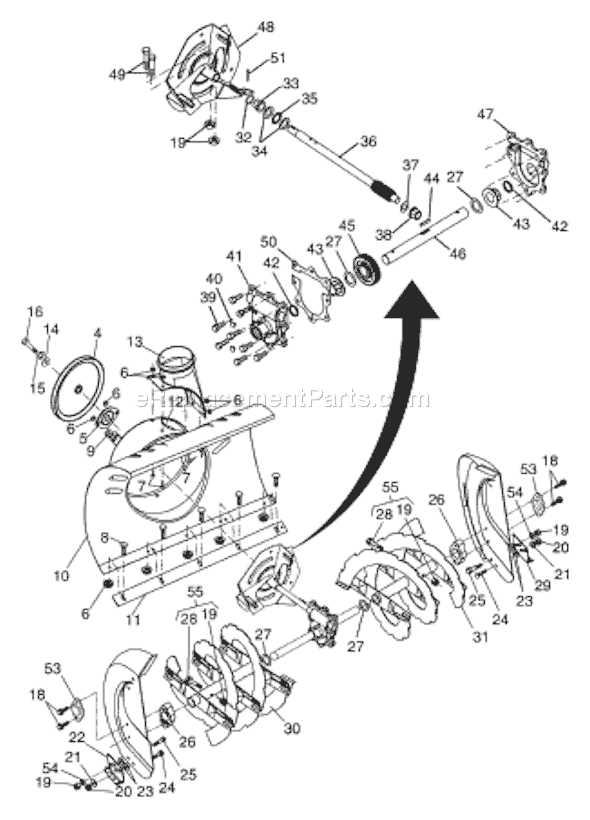

Auger and Impeller System

The auger is responsible for gathering the snow, while the impeller throws it out through the chute. Together, these two systems efficiently clear paths by breaking up compacted material and ejecting it far from your working area.

Key Features of Husqvarna Snowblower Models

These machines are designed to handle tough winter conditions, making snow removal easier and more efficient. Built with durability and user convenience in mind, they provide reliable performance in even the harshest weather. Whether dealing with light snowfall or heavy accumulation, these units are equipped to deliver powerful results while maintaining ease of operation.

Power and Performance

The engines powering these models are specifically crafted to generate high torque, ensuring effective operation in dense snow. The robust construction allows them to handle large amounts of snow effortlessly, while the efficient transmission system ensures smooth transitions between speeds, making it easy to maneuver through different terrains.

User-Friendly Controls

Designed for maximum comfort and convenience, these machines feature ergonomic handles, adjustable height settings, and intuitive controls that allow for precise operation. The systems are engineered to minimize physical strain, ensuring the operator can work for extended periods without fatigue.

Commonly Used Parts in Husqvarna Snowblowers

The reliable operation of outdoor clearing machines depends on the frequent maintenance and replacement of essential components. These machines are composed of various key elements that ensure efficient functionality during demanding tasks. Regular upkeep of these components is necessary to maintain optimal performance and extend the lifespan of the equipment.

One of the most vital sections of the machine includes rotating blades responsible for cutting through dense material. These blades work together with a set of gears and belts, transmitting power from the engine to the moving parts. Without proper care, these components can wear down, leading to reduced effectiveness.

Other important elements include the tires, which provide traction on slippery surfaces, and the handles that allow easy maneuverability. Additionally, the control levers and throttle systems enable precise adjustments during operation, ensuring smooth and efficient clearing processes in various conditions.

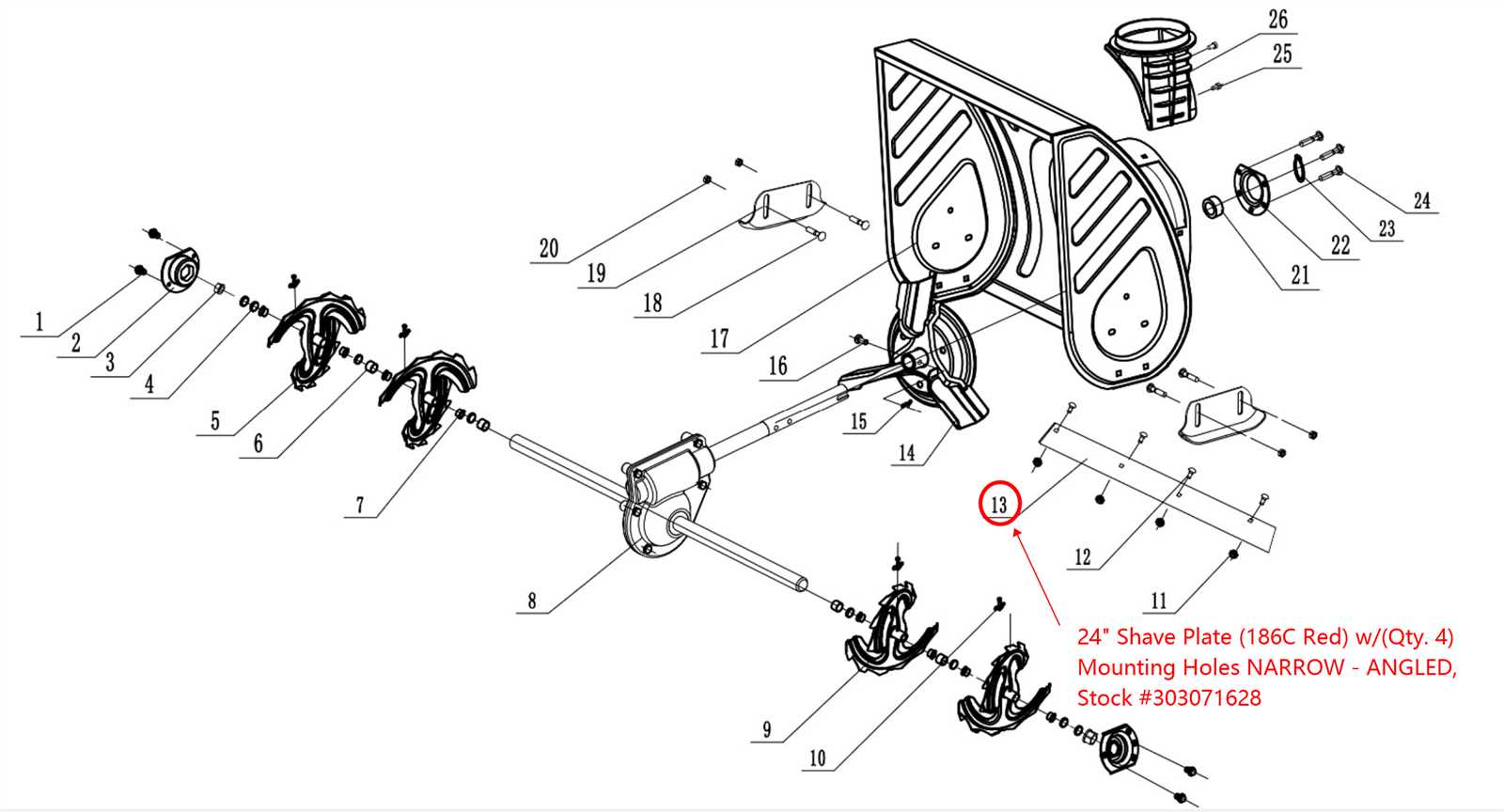

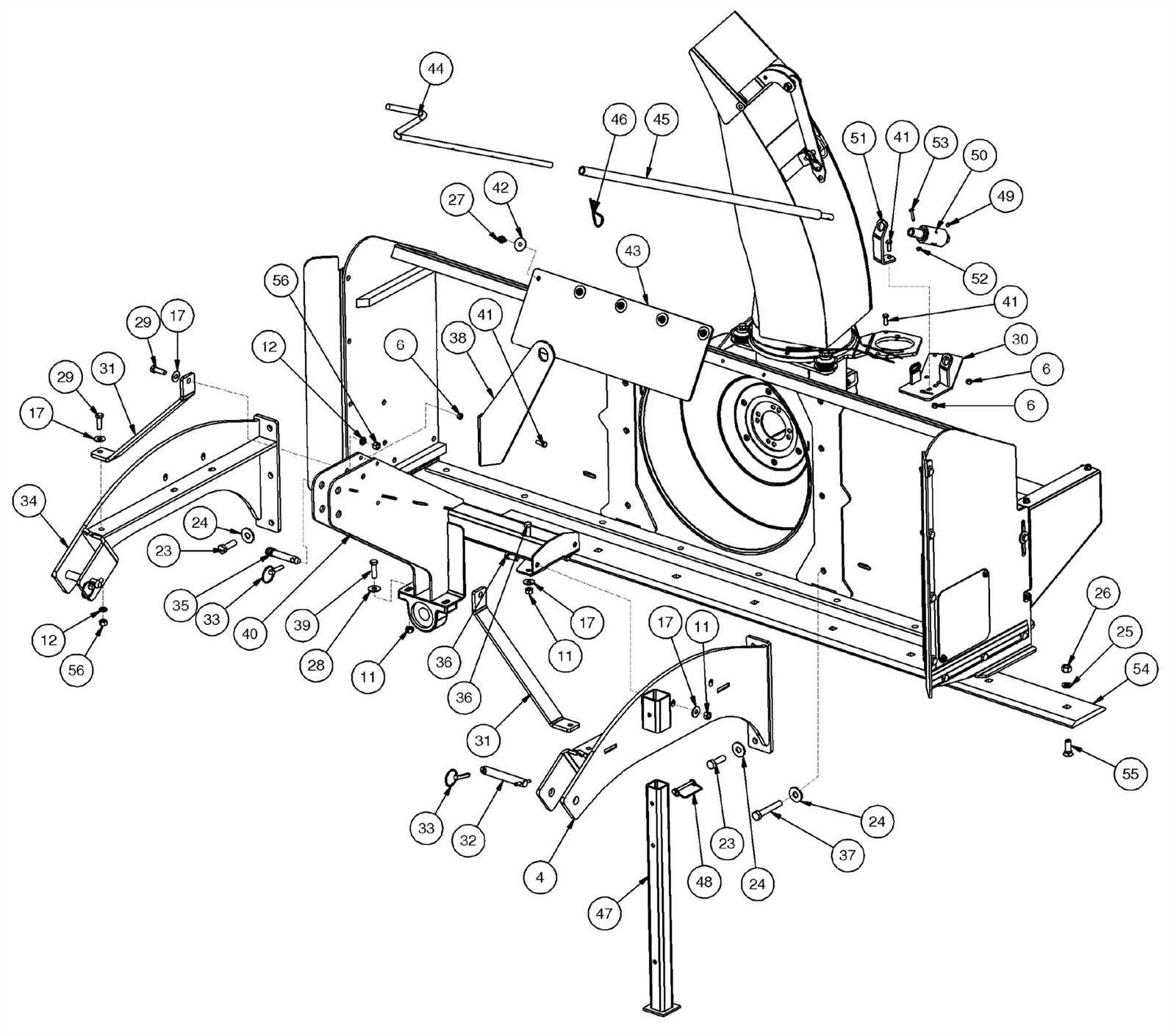

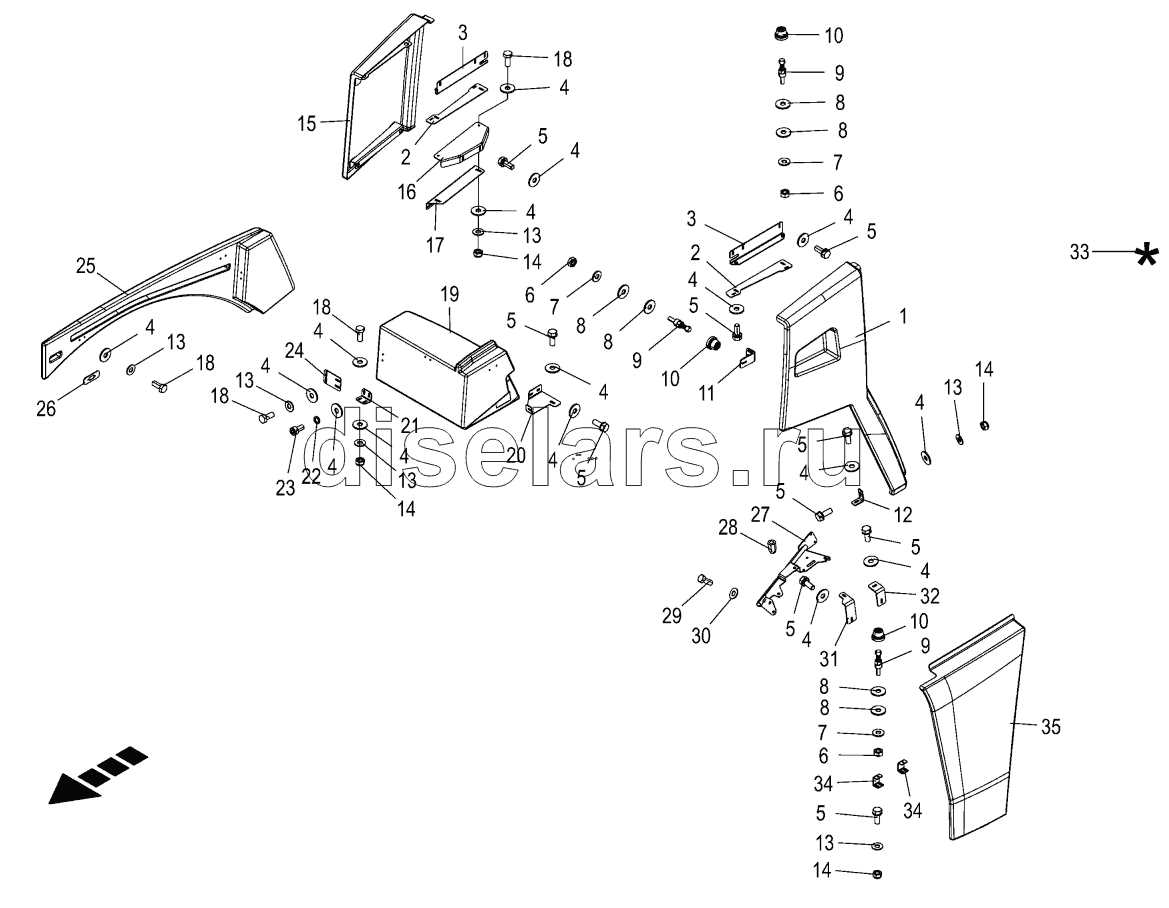

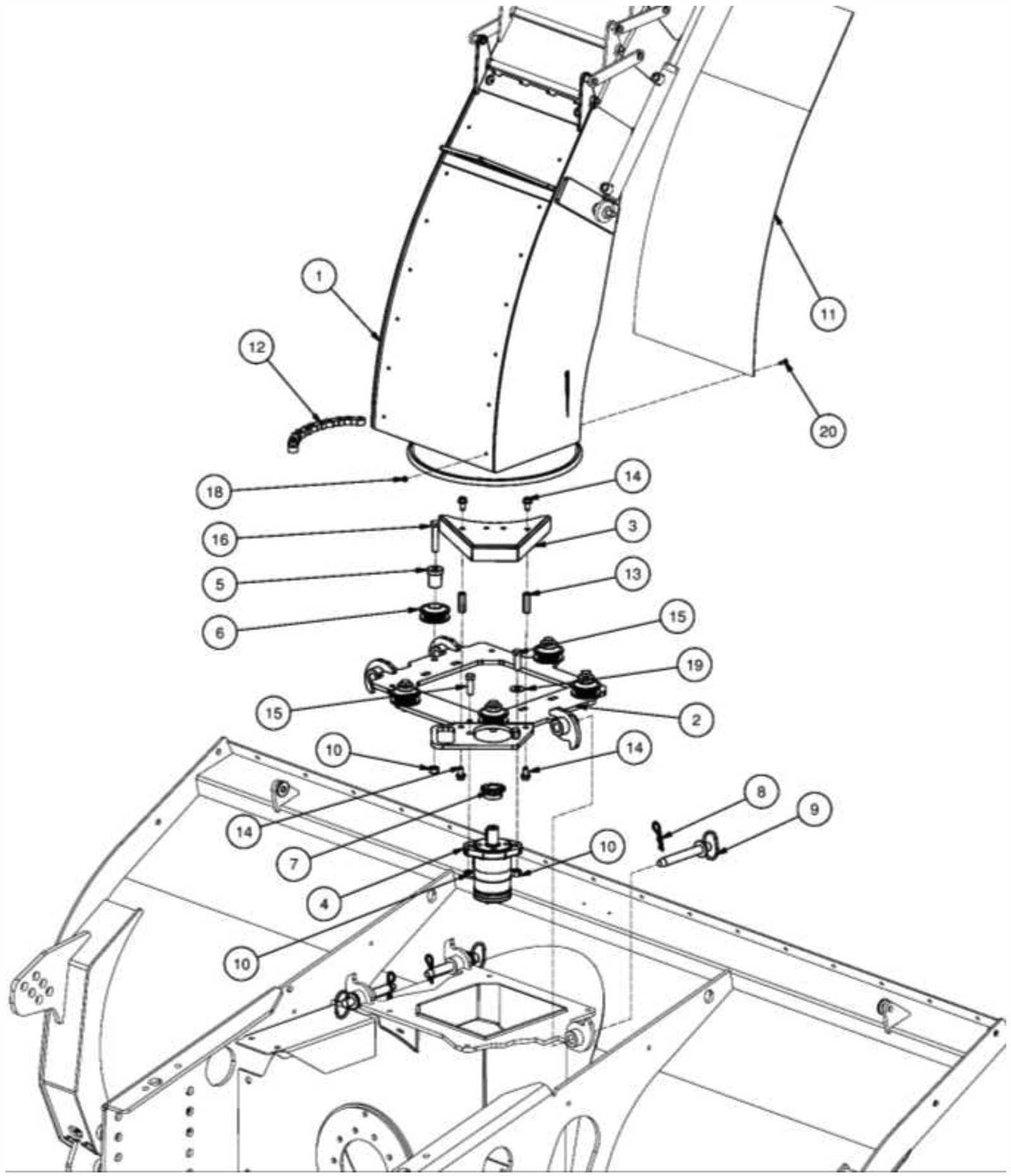

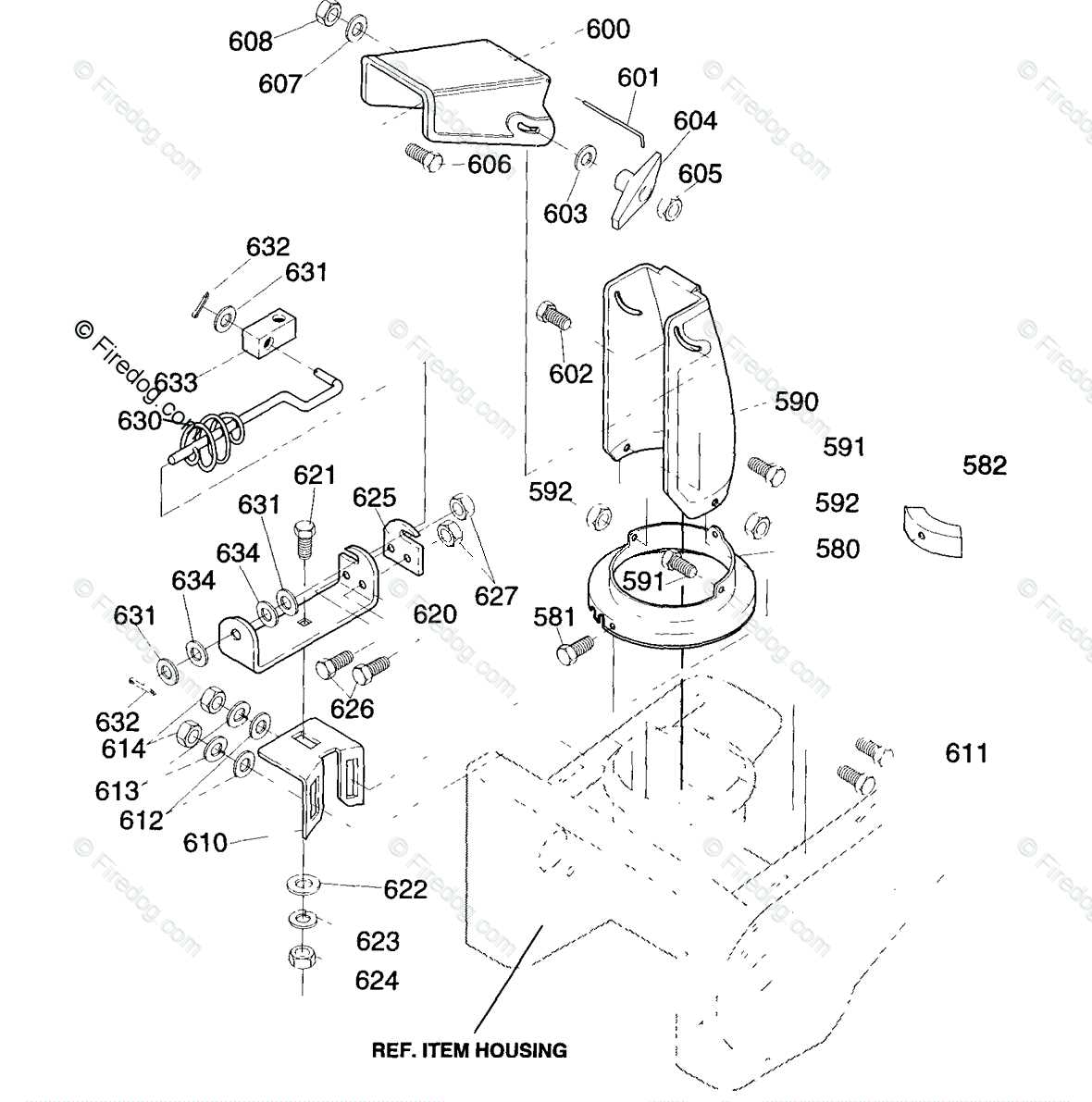

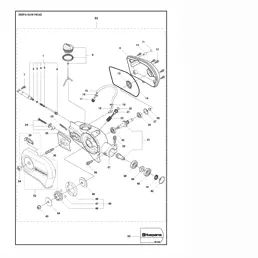

How to Read a Husqvarna Snowblower Diagram

Understanding the layout of your machine’s components is essential for proper maintenance and repairs. A visual guide provides an organized view of each element, making it easier to identify individual components and their connections. With this knowledge, you can ensure that every part is correctly placed and functioning as intended.

Key sections of the guide will typically show mechanical and operational elements in detail. By following the illustrations, you’ll find it easier to locate various parts and understand how they fit together within the overall system.

When reviewing the guide, focus on the relationship between components. Often, each section is clearly labeled, helping you trace how one element interacts with others, enabling smoother troubleshooting and repair processes.

Where to Find Husqvarna Snowblower Parts

Maintaining efficient performance in winter conditions often requires regular upkeep and timely replacement of components. Whether it’s for improving functionality or ensuring long-term durability, sourcing the right elements is crucial to avoid unnecessary interruptions during the cold months. Finding the appropriate replacements can sometimes be a challenge, but there are several reliable options available for locating the essentials you need.

Authorized Retailers and Service Centers

The most dependable way to ensure you’re getting authentic components is to visit official dealers and authorized service providers. These sources usually have access to a wide range of items that are compatible with your equipment, ensuring both quality and compatibility. Additionally, they often provide expert guidance on installation and maintenance.

Online Stores and Marketplaces

Another convenient option for sourcing essential replacements is through various online platforms. Many reputable websites offer detailed listings and user reviews, helping you make informed decisions. It’s important to verify the authenticity of sellers to avoid counterfeit products, and reading customer feedback can provide insight into the

Replacing Worn-Out Components in Your Snowblower

Over time, certain elements of your snow-clearing machine may begin to show signs of wear, impacting its efficiency and performance. Recognizing when to replace these components is crucial for maintaining optimal functionality. This section provides guidance on identifying and replacing deteriorated parts, ensuring your equipment remains in top condition for effective snow management.

Identifying Worn-Out Components

It is essential to regularly inspect your machinery to detect any signs of deterioration. Common indicators of wear include:

- Unusual noises during operation

- Reduced clearing efficiency

- Visible cracks or damage on critical parts

- Excessive vibration while in use

Steps for Replacement

Once you have identified components that require replacement, follow these steps to ensure a smooth process:

- Gather the necessary tools and replacement components.

- Consult your user manual for specific instructions on disassembly and reassembly.

- Carefully remove the worn-out parts, taking note of their placement.

- Install the new components, ensuring a secure fit.

- Test the machine to verify proper operation before returning it to regular use.

Maintaining Your Husqvarna Snowblower Efficiently

Regular upkeep of your winter equipment is essential for optimal performance and longevity. Understanding how to care for your machine ensures it operates smoothly during the harshest weather conditions. Implementing a systematic approach to maintenance can prevent unnecessary breakdowns and enhance efficiency.

To keep your apparatus in top condition, consider the following key practices:

- Routine Inspections: Regularly check for any signs of wear and tear. Look for loose bolts, frayed belts, and damaged components that may require immediate attention.

- Cleaning: After each use, clean off any snow, ice, and debris. This helps to prevent corrosion and keeps the equipment functioning properly.

- Lubrication: Apply the appropriate lubricants to moving parts to reduce friction and ensure smooth operation. Follow the manufacturer’s recommendations for specific lubrication points.

- Fuel Management: Use fresh fuel and add stabilizers if the machine will be stored for an extended period. This prevents fuel degradation and starting issues.

- Storage Practices: When not in use, store the equipment in a dry, protected area. Covering it with a breathable tarp can shield it from dust and moisture.

By adhering to these maintenance strategies, you can significantly extend the life of your winter machinery, ensuring it remains reliable throughout the cold season. Consistent care not only optimizes performance but also contributes to a safer operating environment.

Troubleshooting Snowblower Issues with Diagrams

When operating a snow removal machine, encountering various problems is common. Understanding the mechanics involved can aid in effectively diagnosing and resolving these challenges. Visual representations of components can significantly enhance comprehension, allowing users to identify issues with ease and precision.

Common Problems and Their Solutions

One frequent concern is the inability of the equipment to start. This issue may arise from various factors, such as fuel supply problems or battery deficiencies. Checking the fuel level and ensuring the battery is charged can often resolve this.

Utilizing Visual Aids for Quick Identification

Utilizing illustrations can simplify the troubleshooting process. By referencing specific components, users can quickly pinpoint areas that require attention. For instance, understanding the function of the drive mechanism can clarify whether a blockage or mechanical failure is the root of the issue. Consulting these diagrams can lead to a more efficient resolution. Moreover, familiarity with the layout enhances overall maintenance practices, preventing future complications.