When it comes to maintaining your outdoor machinery, a clear understanding of its individual elements is crucial for optimal performance. Each component plays a significant role in ensuring efficiency and longevity. Grasping the intricate details of these mechanisms empowers users to troubleshoot effectively and carry out necessary repairs.

Within this section, we aim to provide a comprehensive overview of the essential elements that contribute to the functionality of your machine. By exploring various components, users can identify potential issues and make informed decisions regarding maintenance and replacement.

Utilizing a visual reference can enhance your comprehension and ultimately lead to a smoother operational experience. A thorough examination of each piece not only facilitates better care but also fosters a deeper appreciation for the technology at play.

Understanding John Deere 49 Snowblower

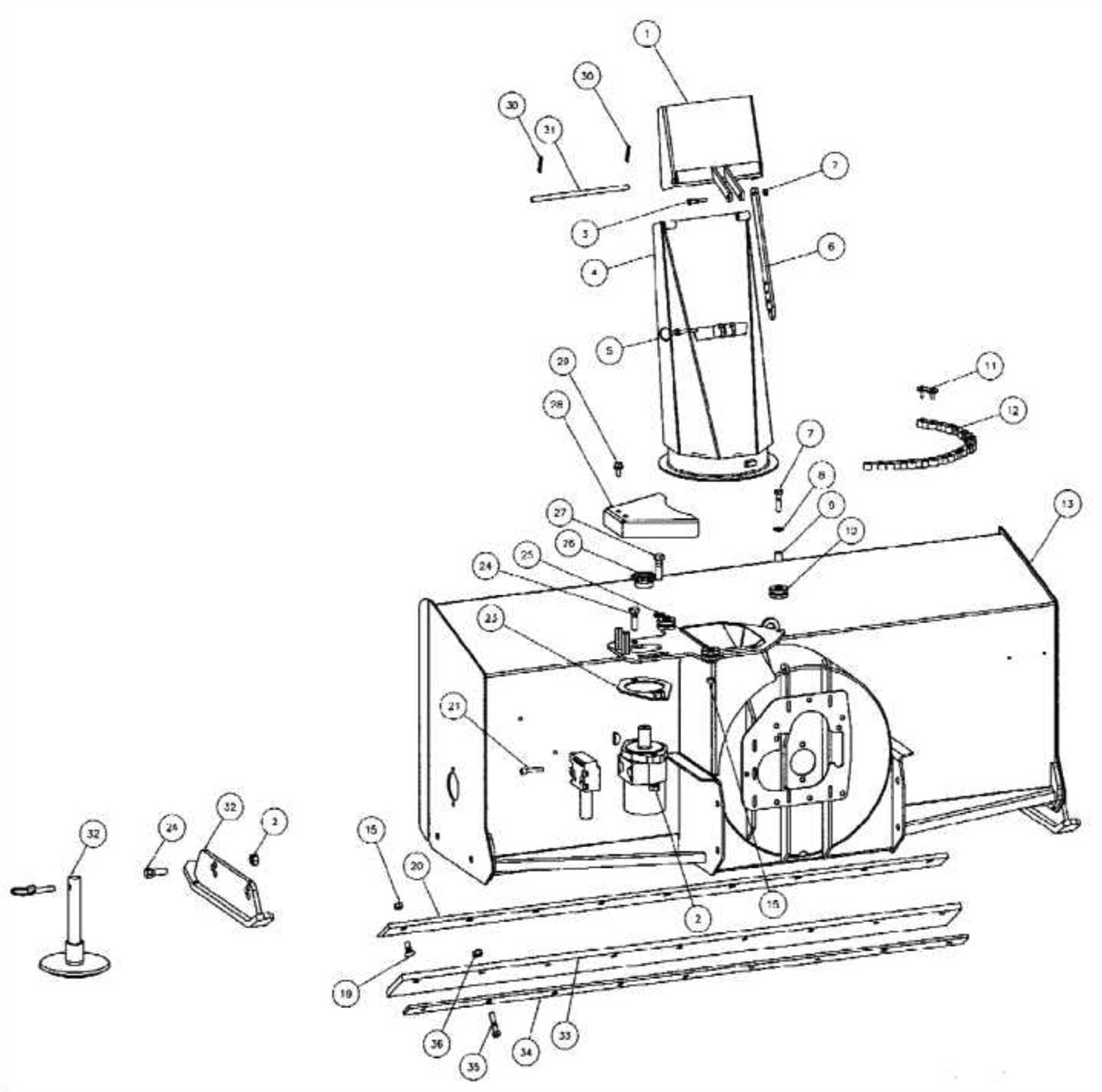

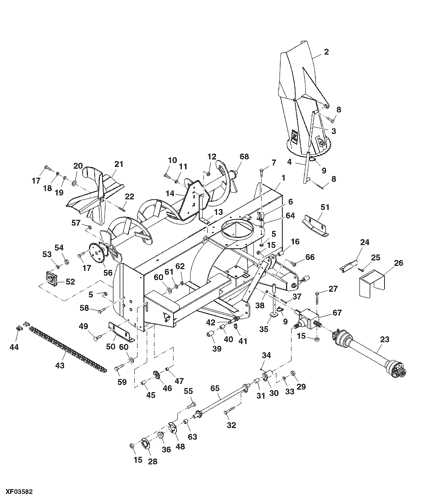

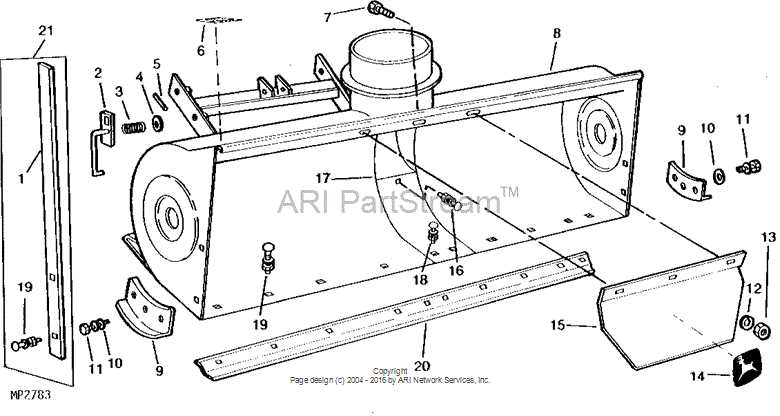

This section aims to explore the intricacies of a popular winter clearing machine, focusing on its components and functionality. Knowledge of these elements can significantly enhance user experience and maintenance practices.

Equipped with a powerful mechanism, this equipment is designed to tackle heavy snowfall efficiently. Users benefit from its robust build and performance, making it a reliable choice during winter months.

Delving into the machine’s structure reveals key aspects that contribute to its effectiveness. Each element plays a vital role, ensuring optimal operation and durability under challenging conditions.

For those seeking the ultimate understanding, familiarizing oneself with the inner workings will prove invaluable. Comprehensive insights can empower users to make informed decisions regarding care and usage.

Key Components of Snowblower System

A well-functioning machine relies on several critical elements that work together to ensure efficient operation during winter tasks. Understanding these key components helps users maintain and optimize their equipment for the ultimate performance.

- Auger: This rotating blade is responsible for gathering and moving the snow towards the chute.

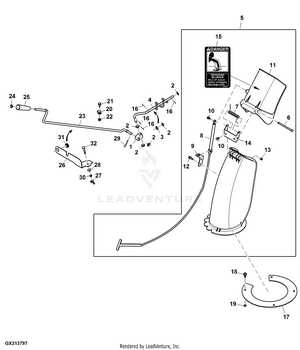

- Chute: The structure that directs the expelled snow away from the pathway, allowing for effective clearing.

- Engine: The power source that drives the entire mechanism, influencing speed and performance.

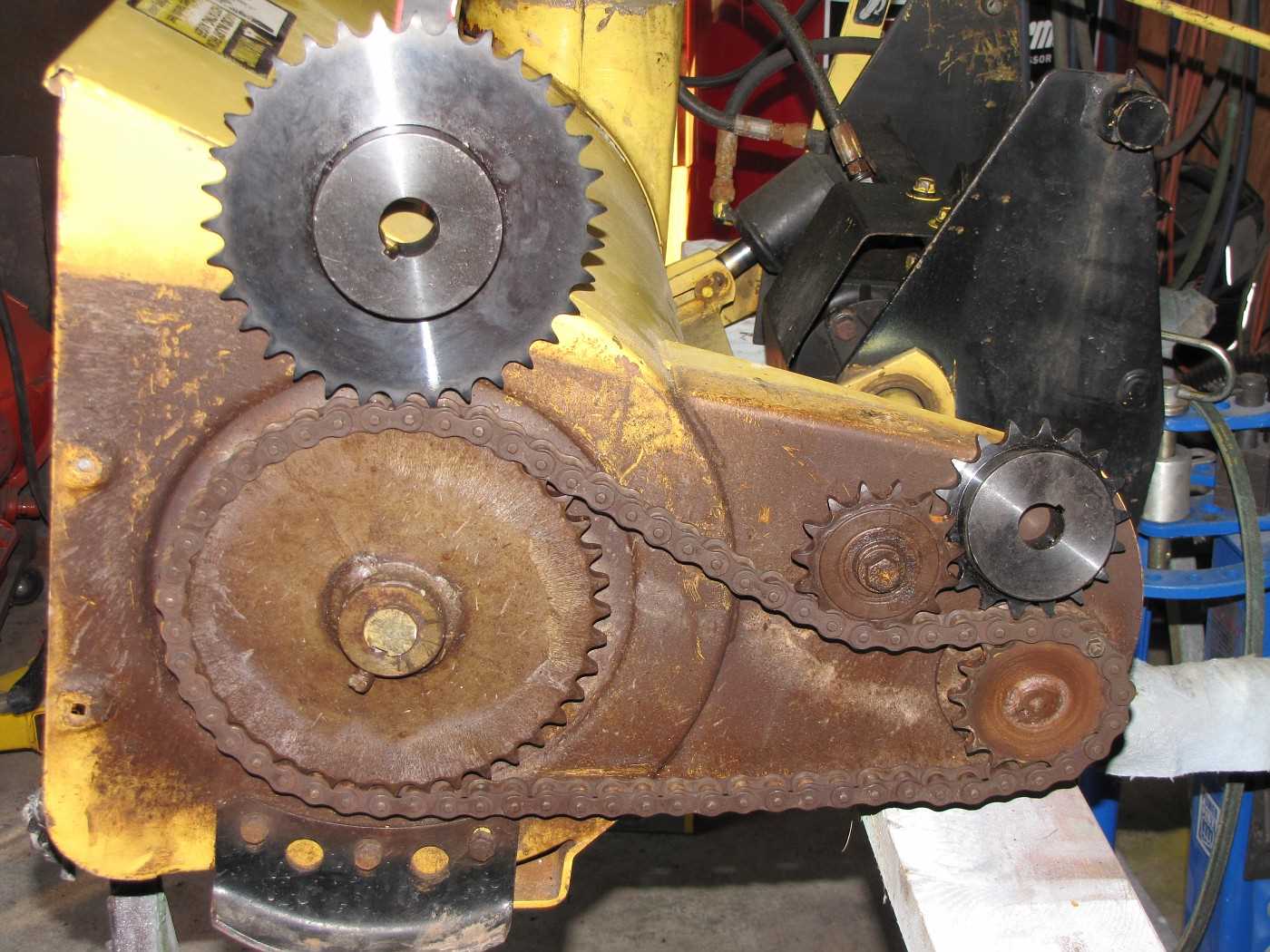

- Transmission: This system transfers power from the engine to the wheels and auger, enabling movement and operation.

- Skid Shoes: Adjustable components that help control the height of the machine, ensuring it operates effectively on various surfaces.

Familiarity with these elements enables users to address issues promptly and maintain optimal functionality throughout the snowy season.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure your equipment functions efficiently throughout the winter season. Proper maintenance not only enhances performance but also extends the lifespan of the machinery.

- Inspect Components: Regularly check all moving parts for wear and tear.

- Lubricate Mechanisms: Apply appropriate lubricants to prevent rust and ensure smooth operation.

- Check Belts: Examine belts for cracks or fraying, and replace them as needed.

- Clean the Equipment: Remove any accumulated snow, ice, or debris after each use.

- Fuel Quality: Use fresh fuel and consider adding stabilizers to enhance performance.

By adhering to these maintenance strategies, you can delve into the ultimate care for your equipment, ensuring reliable performance when you need it most.

Common Issues and Troubleshooting Steps

Understanding frequent problems that arise with outdoor equipment can enhance performance and longevity. Identifying these challenges and applying effective solutions is crucial for maintenance and efficiency.

Typical Problems

- Inconsistent operation

- Reduced power output

- Obstruction in the chute

- Starting difficulties

Troubleshooting Techniques

- Check fuel levels and quality.

- Inspect for clogs or debris in the discharge area.

- Examine belts and cables for wear and tear.

- Ensure spark plug is clean and properly connected.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process with the right approach. By utilizing various resources and strategies, you can ensure that you find what you need without unnecessary hassle. Here are some effective methods to help streamline your search.

Online Resources

- Manufacturer Websites: Many manufacturers offer comprehensive catalogs that list all available components, along with descriptions and compatibility information.

- Online Retailers: E-commerce platforms often provide a wide range of options, allowing for price comparisons and customer reviews to aid in decision-making.

- Forums and Communities: Joining online groups can connect you with other users who may share their experiences and recommendations for sourcing parts.

Local Suppliers

- Authorized Dealers: These establishments typically stock original items and can assist with identifying the right ones for your machinery.

- Hardware Stores: Local shops may carry commonly needed components or can help order them for you.

- Salvage Yards: Sometimes, second-hand options can be found at a fraction of the cost, providing a viable alternative.

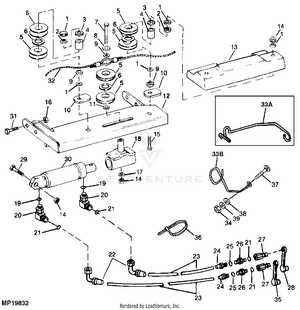

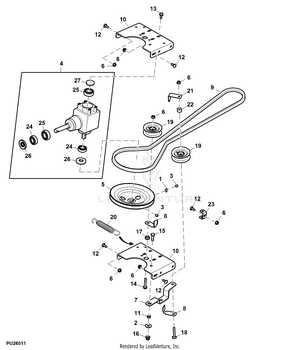

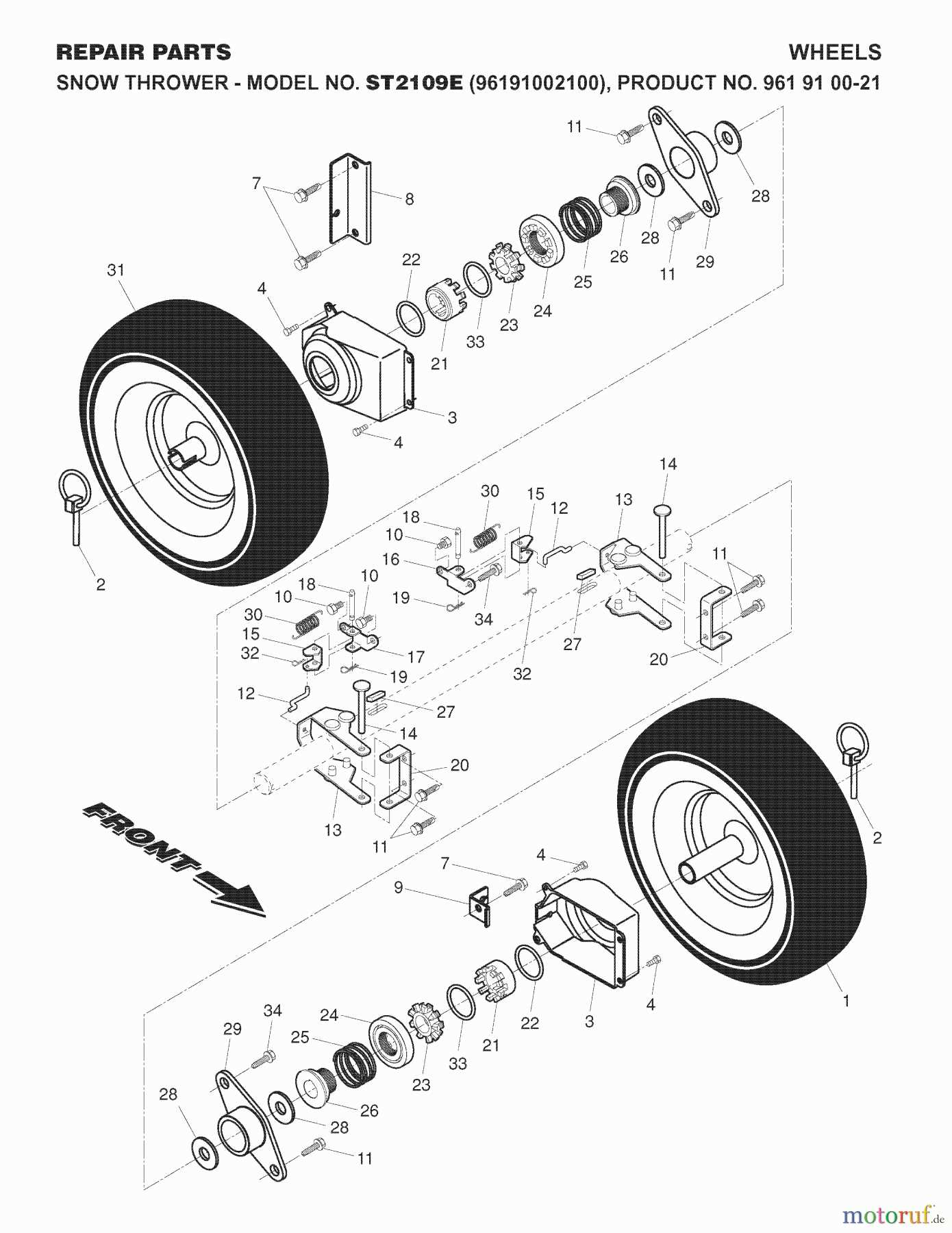

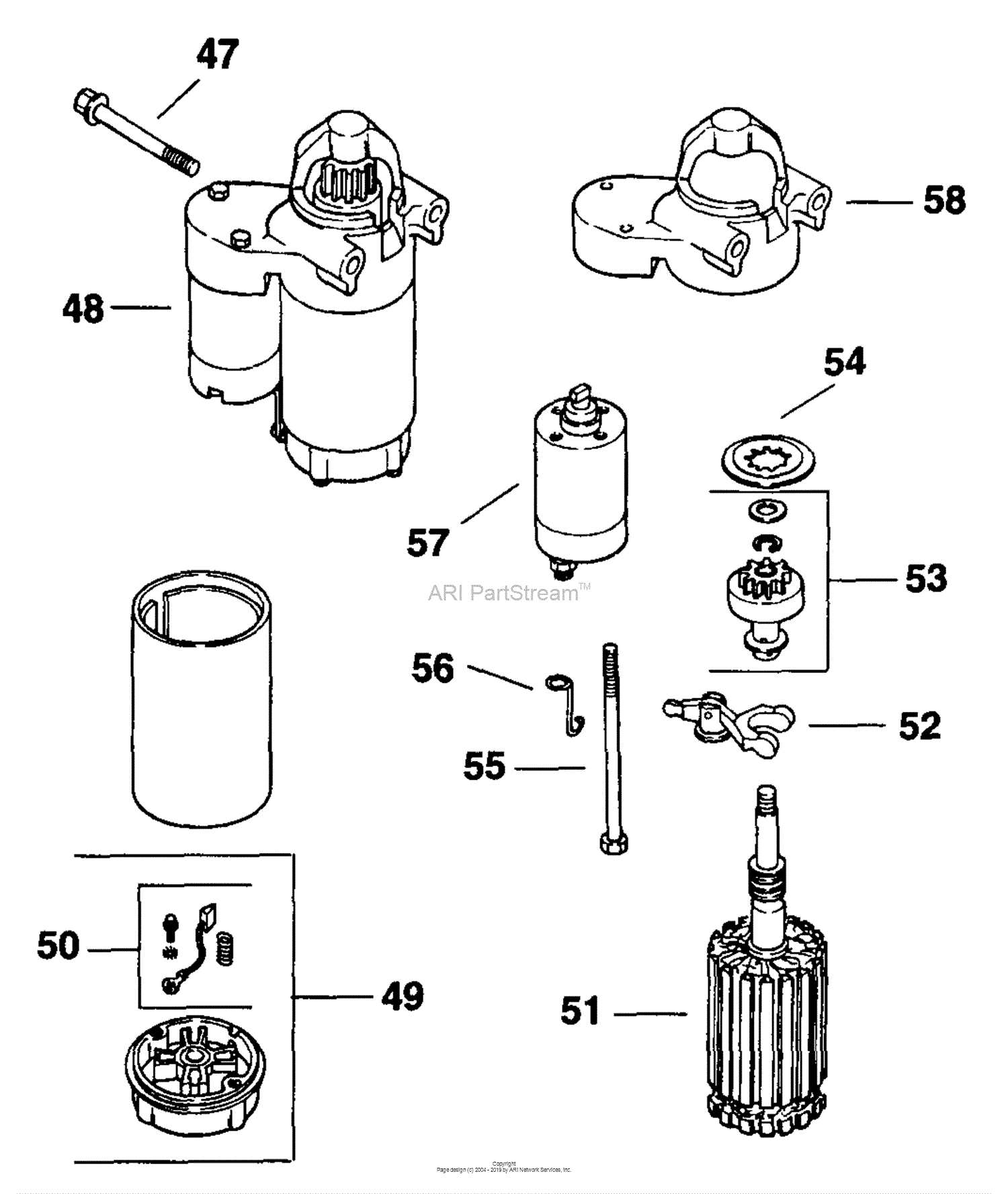

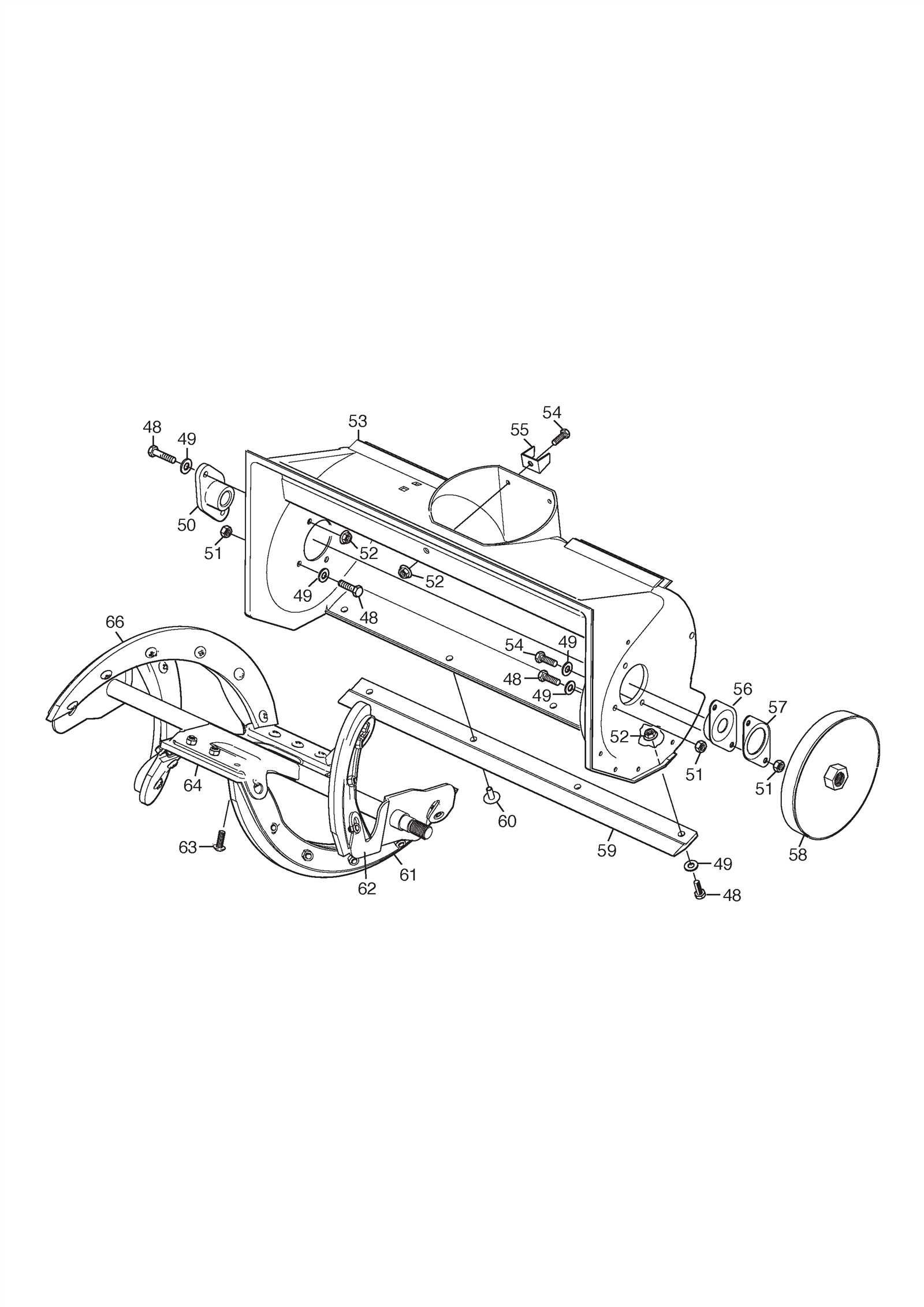

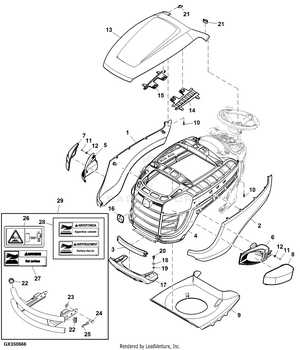

Diagram Interpretation for Assembly

Understanding assembly visuals is crucial for the effective construction and maintenance of machinery. These illustrations serve as a guide, outlining the components and their relationships. Proper interpretation can streamline the assembly process, ensuring that each element is placed correctly and functions as intended.

When approaching these visuals, consider the following key aspects:

- Component Identification: Recognize each part depicted, paying attention to labels and numbers that correspond to specific elements.

- Assembly Sequence: Note the order in which parts should be connected, as this can impact functionality and safety.

- Connection Types: Observe the types of joints and fasteners required, such as screws, bolts, or clips.

To ensure a smooth assembly experience, follow these steps:

- Gather all necessary components and tools prior to starting.

- Refer to the visuals frequently to confirm correct placement.

- Double-check alignment and fitting of parts before securing them.

- Consult the manual for any specific notes or warnings related to assembly.

By mastering the interpretation of these visuals, you can enhance your assembly skills and ensure your machinery operates effectively and efficiently.

Comparing Models: What to Look For

When evaluating different models of outdoor equipment designed for snow removal, several key factors should guide your decision-making process. Understanding the features and specifications can significantly enhance performance and ease of use.

First, consider the engine power and efficiency. Models with higher horsepower typically provide better performance, especially in heavy conditions. Look for specifications that highlight fuel efficiency, as this can impact long-term operational costs.

Next, examine the clearing width and height capabilities. A wider and taller chute can help tackle larger amounts of snow more effectively. Additionally, assess the throw distance, which determines how far the snow can be projected, influencing how quickly you can clear an area.

Another essential aspect is maneuverability. Evaluate the design of the controls and the ease with which you can navigate through different terrains. Features like adjustable speed settings and power steering can make a significant difference in user experience.

Lastly, check for available accessories and maintenance requirements. Some models offer attachments that can enhance functionality, while others might require more frequent upkeep. Understanding these elements will help you select a unit that meets your needs efficiently and reliably.

Seasonal Preparation and Storage Advice

As the colder months approach, ensuring optimal performance of your outdoor equipment becomes essential. Proper maintenance and careful storage can prolong the life of your machinery and enhance its efficiency when needed. This section outlines key practices for preparing and storing your tools effectively.

Maintenance Steps

Before the onset of winter, perform a thorough inspection and servicing of your equipment. Focus on cleaning, lubricating moving parts, and replacing any worn components to ensure readiness for heavy usage.

Storage Guidelines

When it’s time to store your machinery, select a dry and sheltered location to protect it from the elements. Consider using a cover to shield against dust and moisture, which can lead to deterioration.

| Task | Frequency |

|---|---|

| Check oil levels | Before storage |

| Clean exterior | After each use |

| Inspect belts and cables | Monthly |

| Sharpen blades | Seasonally |

User Reviews: Performance Insights

Feedback from users provides valuable perspectives on the functionality and efficiency of outdoor clearing equipment. These insights can help potential buyers understand how well a product performs in real-world conditions.

Reliability is a common theme among reviews, with many users praising the equipment for its consistent performance during heavy snowfall. The ease of use and minimal maintenance requirements are frequently highlighted, making it a popular choice for both casual and frequent users.

Many customers note the power of the machine, which enables it to tackle dense and heavy snow with ease. The performance in different types of weather conditions is also mentioned, emphasizing how well it operates even in challenging scenarios.

On the other hand, some users point out specific challenges, such as occasional clogging or difficulty in maneuverability in tight spaces. These insights can guide potential buyers in setting realistic expectations and preparing for possible limitations.

Overall, user reviews present a comprehensive view of how the equipment functions, helping others make informed decisions based on real experiences.