For those who tackle winter’s challenges, maintaining an efficient machine is essential for ensuring optimal performance. A well-organized overview of the various elements involved in this type of equipment can significantly enhance your understanding and facilitate effective repairs or upgrades. By exploring the intricate layout of its components, operators can achieve greater proficiency in handling snow removal tasks.

Recognizing how each segment interacts within the overall system is vital for troubleshooting and maintenance. Each part plays a crucial role, from the mechanisms that facilitate movement to those that manage power and efficiency. A clear visual representation can demystify the complexities, allowing users to quickly identify areas that may require attention or replacement.

Furthermore, familiarity with the assembly can empower users to perform their own repairs, ultimately saving time and resources. Understanding the intricacies of the machine not only ensures smoother operation but also extends its lifespan, making it a worthy investment for any winter warrior.

Understanding John Deere 1032D Snowblower

This section aims to provide insights into a specific winter maintenance machine designed for efficient snow removal. Users will find it essential to familiarize themselves with the various components that contribute to its functionality.

Key features include:

- Powerful engine performance

- Ergonomic controls for ease of use

- Adjustable chute for directing snow

For optimal operation and maintenance, consider the following:

- Regularly check the oil levels.

- Inspect the auger for wear and tear.

- Ensure all belts are in good condition.

Understanding these elements can enhance the overall experience and longevity of the equipment, making winter tasks more manageable.

Key Components of the Snowblower

Understanding the essential elements of a snow-clearing machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance during winter months, allowing for efficient removal of snow and ice.

1. Auger System

The auger system is responsible for breaking up and gathering snow. Its design typically includes sharp blades that effectively chop through heavy accumulation, making it easier to process and expel the snow through the chute.

2. Discharge Chute

This component directs the ejected snow away from the machine. A well-designed discharge chute allows for adjustable angles, enabling users to control where the snow lands, thereby enhancing maneuverability and efficiency.

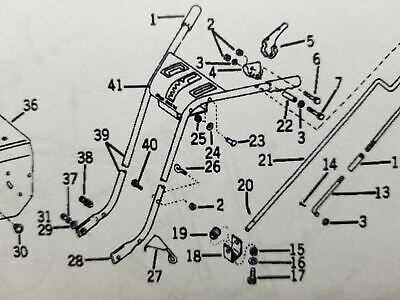

Importance of Parts Diagrams

Understanding the intricacies of machinery requires visual aids that can clarify complex structures and components. These illustrations serve as invaluable resources for users and technicians alike, enabling effective maintenance and repair procedures.

Enhanced Clarity

Visual representations break down the components into easily digestible segments. They highlight the relationship between different elements, allowing for a more intuitive grasp of assembly and disassembly processes.

Facilitating Efficient Repairs

When facing mechanical issues, these visual tools become essential. They guide users in identifying specific components, ensuring that replacements and adjustments can be made swiftly and accurately, ultimately minimizing downtime.

Common Issues with Snow Removal Equipment

When operating machinery designed for winter maintenance, various challenges may arise that can hinder performance. Understanding these common complications can help users maintain efficiency and extend the lifespan of their equipment.

Frequent Problems

- Clogging: Ice and debris can block the chute, reducing effectiveness.

- Worn Blades: Dull cutting edges can lead to ineffective snow clearing.

- Fuel Issues: Poor-quality fuel can cause engine performance problems.

Maintenance Tips

- Regularly inspect and clean the chute to prevent blockages.

- Sharpen or replace blades as needed to ensure optimal cutting.

- Use high-quality fuel to maintain engine health.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often seem daunting. However, with the right strategies, the process can be streamlined significantly. Utilizing various resources and approaches not only saves time but also ensures you find what you need without unnecessary hassle.

Start by exploring online marketplaces that specialize in outdoor machinery. These platforms often have extensive catalogs, complete with detailed descriptions and images, making it easier to identify the correct components. Additionally, user reviews can provide insights into the quality and compatibility of the items.

Another effective method is to consult the manufacturer’s official website. Many companies offer online catalogs and part locators, which can help you pinpoint the specific items tailored for your model. Don’t overlook the value of community forums and groups where fellow users share their experiences and recommendations regarding replacements.

Finally, visiting local retailers or repair shops can yield immediate results. Staff members are often knowledgeable and can assist you in finding the exact components you need. This hands-on approach also allows for a quick assessment of the parts before purchase, ensuring you make informed decisions.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By following simple yet effective maintenance practices, you can enhance performance and extend the lifespan of your machinery.

Regular Inspections

Conduct routine checks to identify wear and tear early. Look for signs of damage, and ensure all components are securely fastened. This proactive approach can prevent more significant issues down the line.

Proper Storage

Store your machine in a dry, sheltered location to protect it from harsh weather conditions. Using a cover can shield it from dust and moisture, further contributing to its longevity. Remember that a well-protected machine is less prone to corrosion and other environmental damage.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear view of how individual elements interact within a larger system, making it easier to identify what you need. Familiarizing yourself with the layout and symbols used in these visuals can save time and enhance your repair experience.

Start by identifying the sections within the illustration. Components are typically grouped based on their function, which helps in locating specific items quickly. Take note of the labels and numbers that correspond to each part, as these references are crucial when searching for replacements.

Next, pay attention to the symbols and color coding often used in these visuals. Different shapes and colors can indicate various types of components, such as electrical parts or mechanical elements. Understanding these indicators will enhance your ability to navigate the illustration efficiently.

Finally, cross-reference the visual guide with a written list of components or a catalog. This will ensure that you are selecting the correct items for your repair needs. By mastering these techniques, you can approach any maintenance task with confidence and clarity.

Upgrades for Enhanced Performance

Boosting the efficiency of your outdoor equipment can significantly improve its functionality and longevity. By integrating advanced components and innovative enhancements, users can achieve a superior performance level that meets their specific needs.

Engine Optimization: Upgrading the engine can lead to better fuel efficiency and increased power output. Consider replacing filters and adding performance-enhancing additives to maximize your machine’s capabilities.

Augmented Blades: Investing in high-quality, durable blades can improve cutting efficiency. Enhanced designs can reduce wear and ensure that the machine operates at peak performance even in challenging conditions.

Improved Drive System: A more robust drive mechanism can lead to smoother operation and greater reliability. Look for kits that enhance traction and minimize slippage, ensuring your equipment can handle various terrains.

Control Features: Upgrading control systems with modern technology can provide greater precision and ease of use. Features such as joystick controls or remote operation can significantly enhance the user experience.

By carefully selecting these upgrades, enthusiasts can truly delve into maximizing their machinery’s performance for ultimate satisfaction in their outdoor tasks.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. Genuine parts ensure compatibility and reliability, ultimately saving time and money in repairs and replacements. This section will guide you through various avenues to acquire these high-quality items.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These locations offer a wide selection of original items and provide expert advice to help you choose the right ones for your machinery. Additionally, purchasing from authorized dealers often comes with warranties that further safeguard your investment.

Online Retailers

In today’s digital age, many online retailers specialize in genuine components. These platforms often feature detailed descriptions and specifications, making it easier to find exactly what you need. Always ensure that the seller is reputable and offers return policies, ensuring a smooth purchasing experience.