As the colder months approach, ensuring that your winter machinery is in optimal condition becomes paramount. Whether you rely on these machines for residential use or professional purposes, familiarity with their inner workings is essential. This knowledge can help in troubleshooting issues, performing maintenance, and identifying necessary replacements to enhance performance.

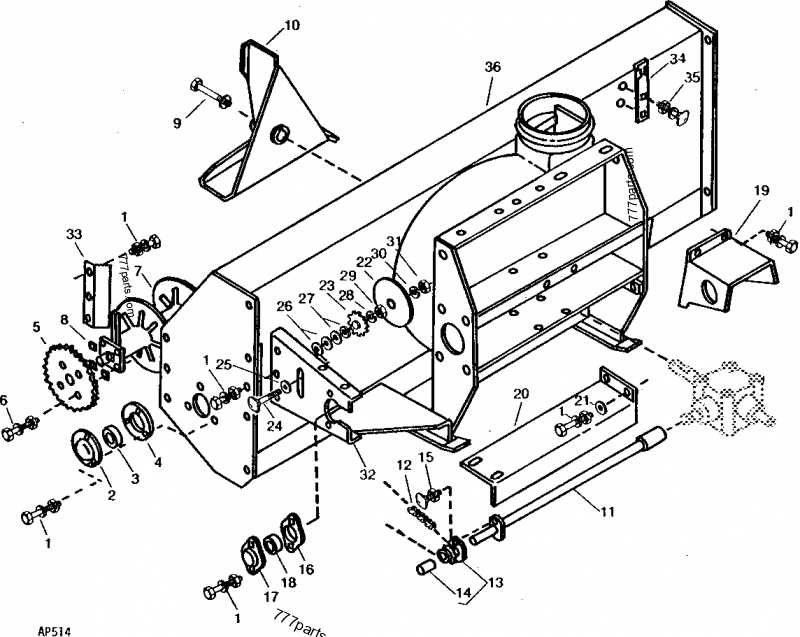

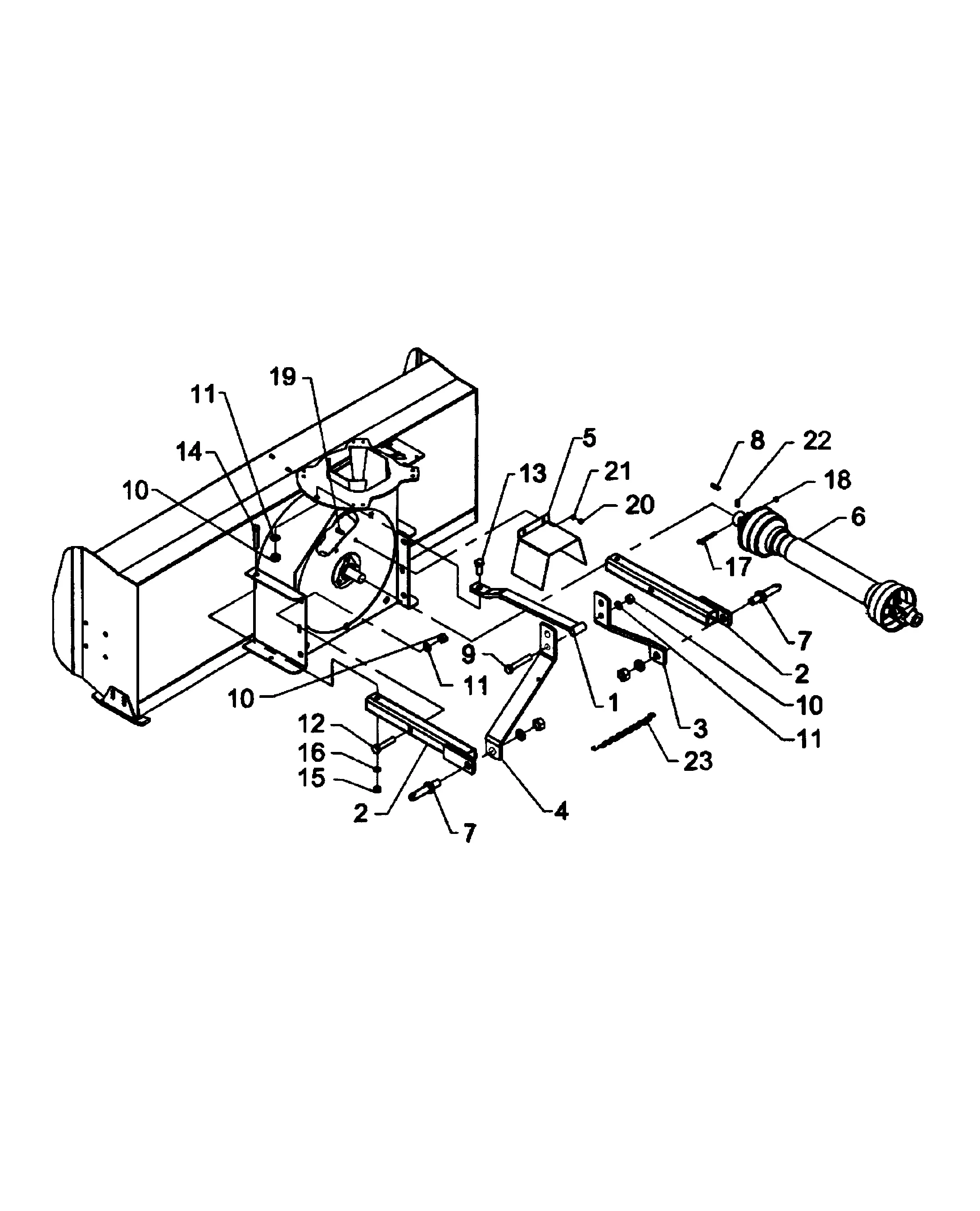

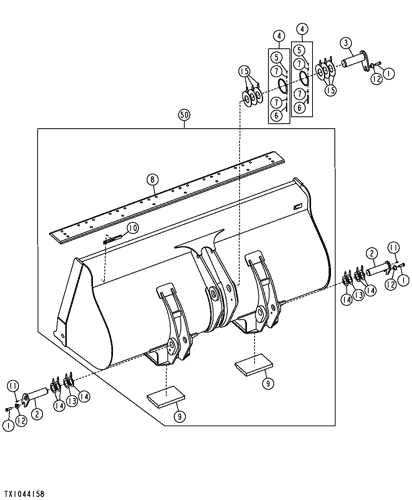

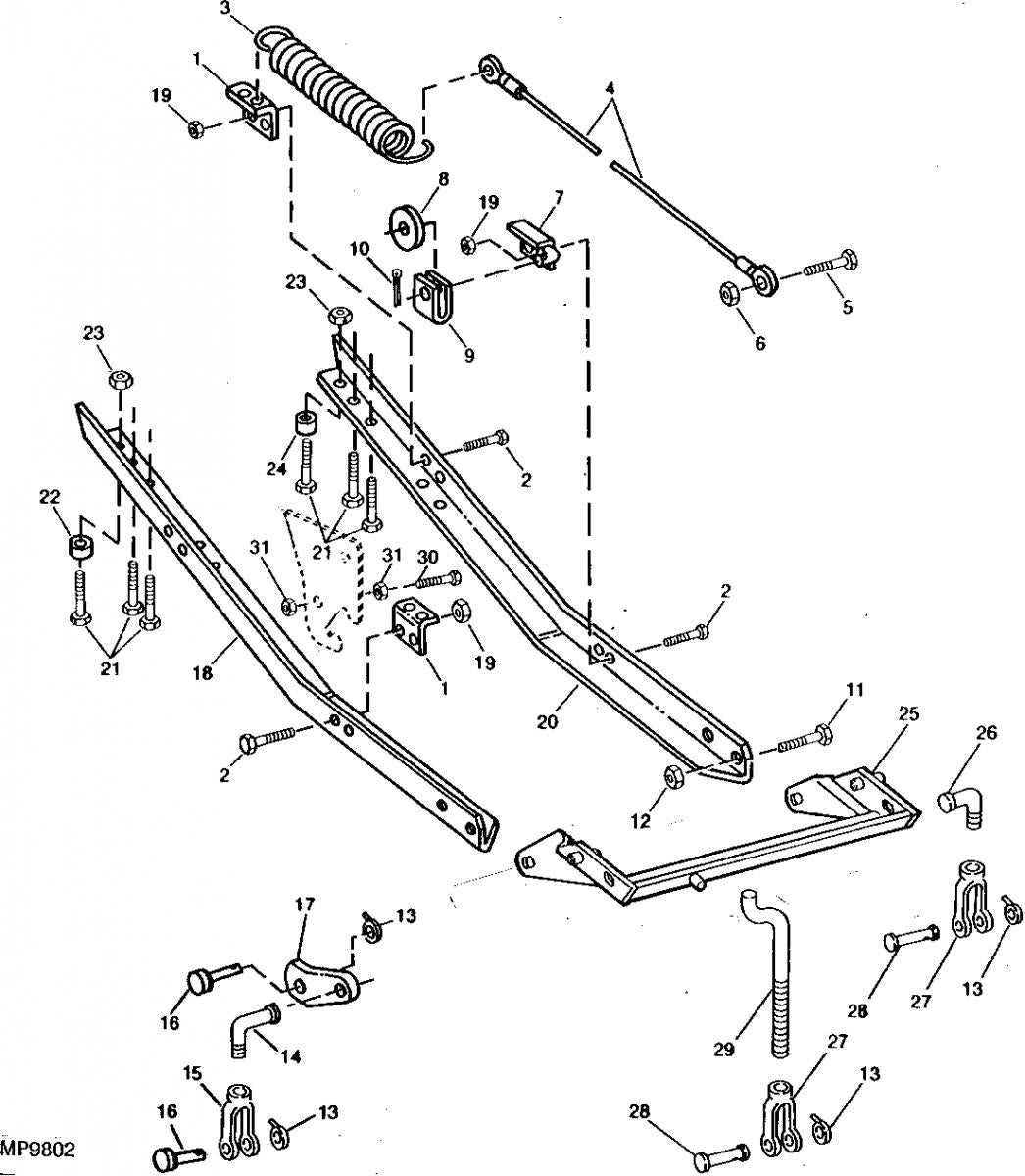

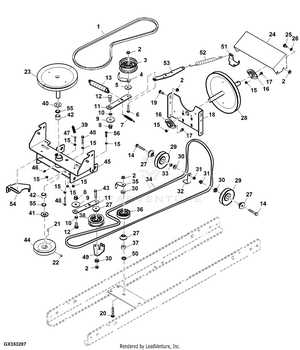

Familiarizing yourself with the specific components and their functions is crucial for any operator. Each element plays a significant role in the overall efficiency of your equipment. By studying a comprehensive layout of these components, you can gain valuable insights into how they interact and contribute to the effective operation of the machine during harsh weather conditions.

Moreover, understanding the arrangement of these components allows for a more informed approach to repairs and upgrades. Being equipped with this knowledge not only aids in immediate fixes but also fosters long-term care for your machinery, ensuring reliability and durability throughout the winter season.

Understanding John Deere Snowblower Components

When tackling winter conditions, familiarity with the essential elements of a snow clearing machine is crucial. Each component plays a significant role in the overall efficiency and effectiveness of the equipment, ensuring optimal performance and longevity. This section delves into the various mechanisms and features that contribute to the functionality of these machines.

Main Mechanisms

At the heart of any effective clearing tool are its primary mechanisms. These include the propulsion system, which drives the unit forward, and the discharge mechanism that expels the cleared material. Understanding how these parts interact can significantly enhance user experience and maintenance practices.

Maintenance and Care

Proper upkeep of individual components is vital for ensuring peak performance. Regular checks and timely replacements can prevent costly repairs and extend the lifespan of the machinery. Below is a summary of essential elements and their respective maintenance tips.

| Component | Maintenance Tips |

|---|---|

| Auger | Inspect for wear and ensure it spins freely. |

| Chassis | Keep clean and check for any rust or damage. |

| Belts | Regularly check tension and replace if frayed. |

| Engine | Change oil and check spark plugs routinely. |

Importance of Maintenance for Snowblowers

Proper upkeep of winter clearing equipment is essential for ensuring its longevity and efficiency. Regular maintenance not only enhances performance but also prevents unexpected breakdowns during critical times. Without consistent care, minor issues can escalate into major problems, potentially leading to costly repairs or replacements.

Timely inspections are crucial for identifying wear and tear on components that can affect functionality. By checking belts, blades, and other vital elements, users can address concerns before they compromise performance. Additionally, cleaning the machine after each use prevents the buildup of debris, which can hinder operation and contribute to rust and corrosion over time.

Another key aspect of maintenance is the proper storage of equipment during the off-season. Ensuring that the machine is stored in a dry, sheltered area protects it from environmental factors that can cause damage. Implementing these practices not only maximizes the equipment’s lifespan but also ensures reliable operation when needed most.

How to Identify Part Numbers

Understanding how to locate and interpret component identifiers is crucial for maintenance and repairs. These identifiers serve as a universal language that connects users with the appropriate items needed for their equipment, ensuring seamless functionality and longevity.

Step-by-Step Approach

Begin by checking the manufacturer’s manual, which typically includes a list of all identifiers associated with the machine. Additionally, inspecting the actual components may reveal stamped or labeled codes, making it easier to find replacements.

Utilizing Online Resources

Many manufacturers provide online databases where users can search for specific identifiers. Inputting the machine’s model or serial number can yield the ultimate results, allowing for a quick and efficient lookup.

Common Issues with Snowblower Parts

During winter operations, various components of a snow-clearing machine can encounter challenges that hinder performance. Understanding these issues is crucial for maintaining efficiency and prolonging the lifespan of the equipment.

Worn-Out Components

Worn-out components can significantly affect functionality. Over time, critical elements such as blades and belts may lose their effectiveness, leading to decreased clearing capability. Regular inspection and timely replacement are essential to avoid disruptions.

Clogging Problems

Clogging problems frequently occur, especially in heavy snowfall. Debris can accumulate in the chute or intake, causing the machine to operate inefficiently. Clearing out any obstructions promptly can help maintain optimal performance and prevent potential damage.

Where to Find Replacement Parts

When seeking components for your equipment, several reliable sources can facilitate your search. It’s essential to explore both online and local options to ensure you find what you need efficiently.

Online Retailers: Numerous websites specialize in machinery components, offering a vast selection and competitive prices. Search for trusted vendors that provide detailed descriptions and diagrams to assist in your selection.

Local Dealers: Visiting nearby distributors can yield quick results. They often stock essential items and can order specific components if not immediately available.

Community Forums: Engaging in online communities and forums dedicated to machinery can be beneficial. Experienced users frequently share valuable insights on sourcing hard-to-find items.

By exploring these avenues, you’ll increase your chances of obtaining the necessary components to keep your equipment running smoothly.

Step-by-Step Repair Guide

This section provides a comprehensive approach to maintaining and fixing your equipment efficiently. By following a structured method, you can ensure that every aspect of the repair process is covered, leading to optimal performance and longevity.

Preparation

- Gather necessary tools: screwdrivers, wrenches, pliers, and a socket set.

- Ensure you have the right replacement components on hand, as per your model’s specifications.

- Review the user manual for specific instructions related to your equipment.

Repair Steps

- Disconnect the power source to avoid accidents.

- Inspect the equipment for any visible damage or wear.

- Carefully disassemble the necessary parts, taking note of their arrangement.

- Replace any worn or damaged components with new ones.

- Reassemble the equipment, ensuring all parts are securely fastened.

- Reconnect the power source and test the functionality.

Following these steps will help you achieve a successful repair, enhancing the efficiency and reliability of your machinery.

Tips for Winter Preparation

As the colder months approach, it becomes essential to ensure that your outdoor equipment is ready to tackle the challenges of snow and ice. Proper preparation not only enhances performance but also extends the lifespan of your tools. Here are some crucial tips to help you gear up for winter.

1. Conduct a Thorough Inspection: Before the first snowfall, examine your equipment closely. Check for any signs of wear or damage, and ensure all components are in good working order. A well-maintained machine can make all the difference in harsh conditions.

2. Change Fluids: It’s vital to replace old oil and other fluids, as they can thicken and lose effectiveness in low temperatures. Use winter-grade fluids for optimal performance, ensuring that your equipment runs smoothly when needed.

3. Clear Debris: Remove any dirt, leaves, or other debris from your tools and storage areas. This helps prevent rust and maintains optimal functionality. Keeping your equipment clean ensures it is ready for immediate use.

4. Stock Up on Essentials: Ensure you have all necessary supplies, such as fuel, oil, and replacement components. Having these on hand will prevent delays when the snow starts to fall.

5. Test Before Use: Once everything is checked and ready, test your equipment in a controlled environment. This allows you to identify any potential issues before facing winter’s challenges head-on.

By following these simple guidelines, you can ensure that your outdoor tools are well-prepared to handle whatever winter has in store, keeping your surroundings safe and accessible.

Comparing Different John Deere Models

When it comes to winter maintenance equipment, various models offer distinct features and capabilities. Understanding the differences between these machines is essential for selecting the right one to meet your specific needs. Each design serves a unique purpose, tailored for different snow removal tasks, ensuring optimal performance in various conditions.

Performance and Power

Different models come with varying engine sizes and power outputs, which directly affect their efficiency in clearing snow. Some machines are designed for heavy-duty tasks, equipped with robust engines that can handle deeper drifts and larger areas. Conversely, lighter models are more suited for residential use, providing adequate performance for small driveways and sidewalks.

Features and Usability

Another important aspect is the array of features offered across different machines. Higher-end models may include advanced steering capabilities, adjustable augers, and heated grips for enhanced comfort. On the other hand, basic variants might focus on simplicity and ease of use, making them ideal for those who prioritize straightforward operation without unnecessary complexities.

Ultimately, comparing these various options allows potential buyers to make informed decisions based on their specific requirements and preferences.

Upgrading Your Snowblower Efficiency

Enhancing the performance of your winter clearing equipment can significantly reduce the time and effort needed to tackle snow-covered surfaces. By focusing on specific areas of improvement, you can ensure that your machine operates at its best, making your tasks easier and more efficient.

Key Areas to Focus On

- Regular Maintenance

- Upgrading Components

- Optimizing Settings

Effective Upgrades

- Improved Blades: Consider replacing old or dull blades with high-performance alternatives designed for better cutting and throwing.

- Power Enhancements: Upgrading the engine or motor can provide the necessary power boost for more challenging conditions.

- Adjustable Chute: Installing a more versatile chute can improve snow directing capabilities, allowing for better control during operation.

By investing time and resources into these enhancements, you can transform your winter equipment into a highly efficient tool, making snowy days less daunting and more manageable.