In the realm of outdoor machinery, maintaining peak performance is essential for longevity and efficiency. Knowing the intricate components and their interrelations empowers users to handle repairs and upgrades confidently. This section aims to illuminate the various elements that contribute to the optimal functioning of your device.

By familiarizing yourself with the layout and specifications of each component, you can better appreciate how they work in harmony. This knowledge not only enhances troubleshooting skills but also fosters a deeper connection with your tools. As we explore these intricacies, you’ll discover valuable insights that could significantly impact your maintenance approach.

Whether you are a novice or an experienced user, having access to a detailed visual reference can ultimately streamline your repair process. Dive into the specifics and elevate your understanding, ensuring your equipment remains in top shape for all your outdoor endeavors.

Understanding Stihl FS 85 Components

Exploring the essential elements of the FS 85 model provides insight into its functionality and performance. Each component plays a critical role, contributing to the overall efficiency and reliability of the equipment. Recognizing these individual parts helps users maintain their devices effectively and ensures optimal operation during use.

Main Functional Elements

The primary operational components include the engine, cutting mechanism, and control systems. The engine powers the machine, delivering the necessary torque and speed for various tasks. The cutting mechanism, whether it be a blade or line, is crucial for achieving desired results in landscaping or gardening. Control systems, such as the throttle and safety features, enhance user experience and promote safety while operating the equipment.

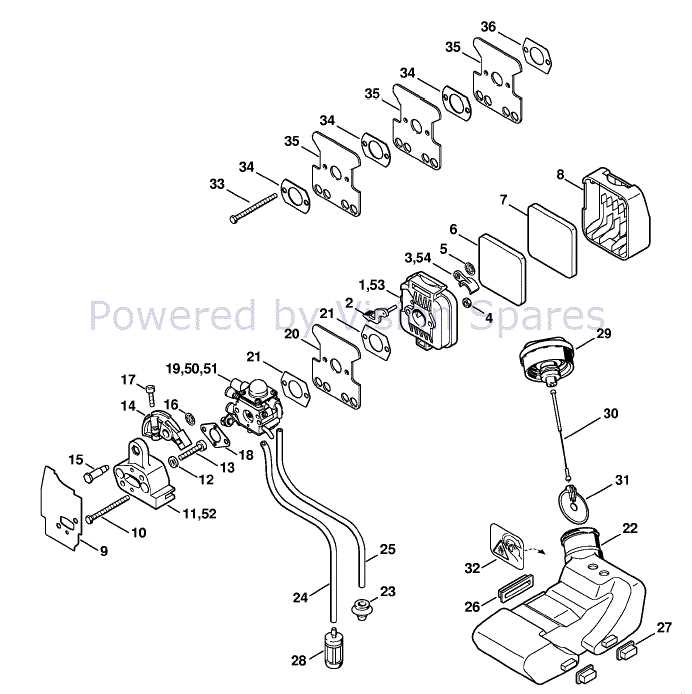

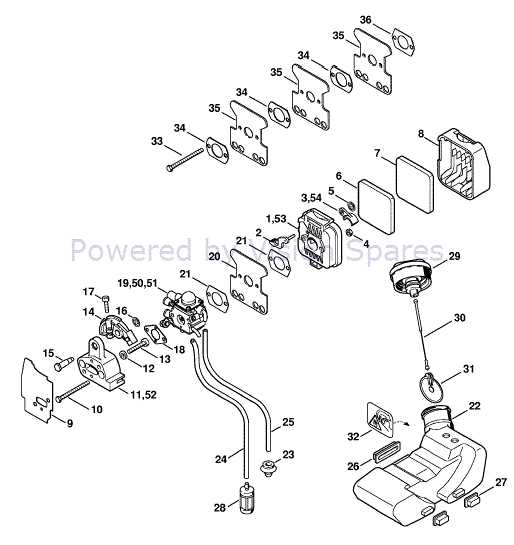

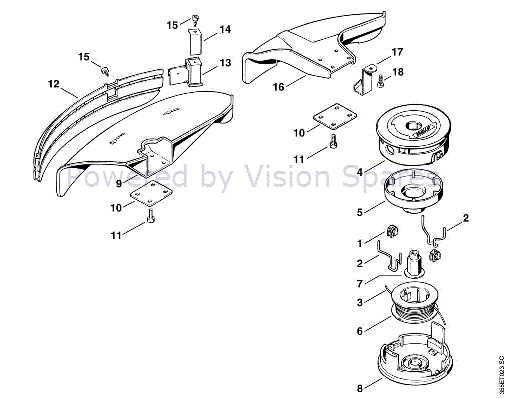

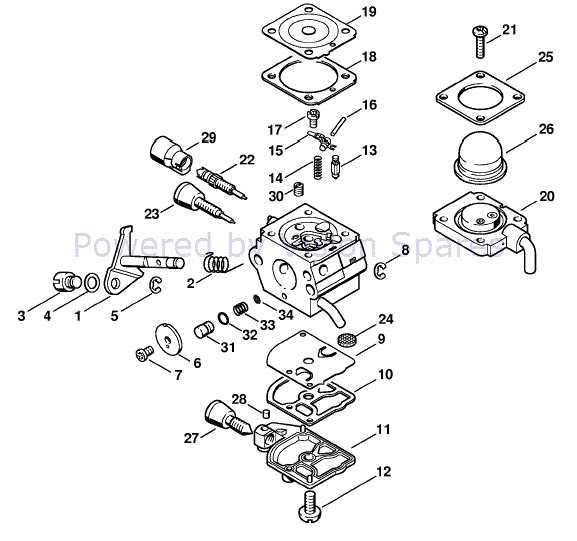

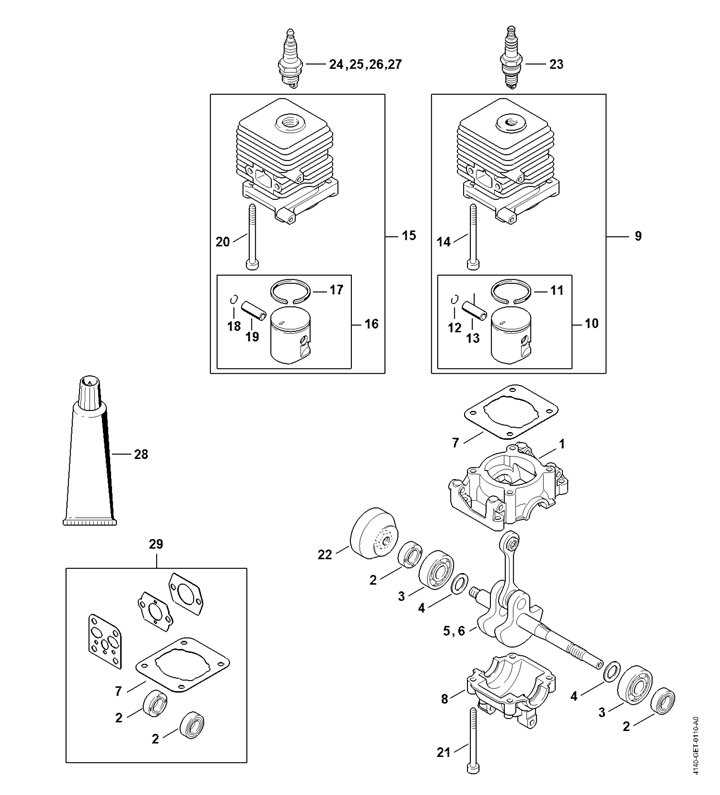

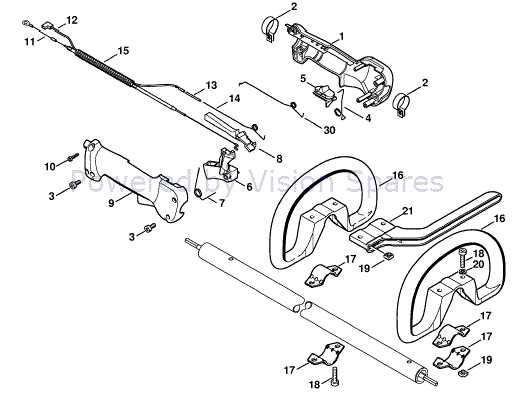

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations play a crucial role in helping users identify individual elements, ensuring that each part is correctly understood and managed. These illustrations facilitate the comprehension of complex systems, making it easier for technicians and enthusiasts alike to perform tasks accurately.

Moreover, such visual guides streamline the ordering process for replacements, preventing confusion and errors. When users can clearly see how each piece fits within the larger assembly, they are better equipped to troubleshoot issues and execute repairs efficiently. This ultimately leads to improved equipment longevity and performance.

In addition, having access to these resources can empower users to take on repairs themselves, fostering a greater sense of confidence and independence. Knowledge of how components interact encourages proper usage and care, which can significantly enhance operational effectiveness.

How to Access PDF Resources

Accessing digital documents can be essential for obtaining crucial information quickly and efficiently. Whether you are looking for technical guides, user manuals, or instructional materials, knowing how to find and retrieve these resources is vital. This section will explore effective methods for locating and accessing digital files relevant to your needs.

Search Techniques

Utilizing search engines effectively can significantly enhance your ability to find digital resources. Here are some strategies to consider:

| Method | Description |

|---|---|

| Keyword Optimization | Use specific keywords related to the content you are seeking, incorporating terms like “manual,” “guide,” or “resource.” |

| File Type Filters | Incorporate file type filters in your search query, such as adding “filetype:pdf” to focus on particular document formats. |

| Official Websites | Visit manufacturer or organization websites directly to find a repository of documents available for download. |

Accessing Resources from Libraries

Public and university libraries often provide access to a wealth of digital documents. Many libraries offer online databases and archives that members can access remotely. Ensure you have your library card or membership details ready to take advantage of these valuable resources.

Key Features of FS 85 Model

The FS 85 model is recognized for its exceptional performance and reliability in various outdoor tasks. It combines power with user-friendly design, making it a preferred choice for both professionals and hobbyists.

- Powerful Engine: Equipped with a robust engine that ensures high efficiency and quick cutting capabilities.

- Lightweight Design: Constructed with lightweight materials, allowing for easy maneuverability and reduced fatigue during prolonged use.

- Ergonomic Handle: Features an ergonomic handle that provides comfort and better control, enhancing user experience.

- Versatile Cutting Options: Compatible with various cutting attachments, making it suitable for different applications such as trimming and edging.

- Durable Construction: Built with high-quality materials that ensure longevity and withstand tough working conditions.

These attributes collectively contribute to the model’s effectiveness, making it a reliable tool for a range of landscaping and maintenance tasks.

Common Replacement Parts Explained

Understanding the essential components of your outdoor equipment can significantly enhance its performance and longevity. Many elements may require regular upkeep or occasional replacement due to wear and tear. This section provides insights into the most frequently needed components and their functions, ensuring you can maintain your machinery effectively.

Key Components

Below are some of the primary elements that are often replaced, along with their roles in ensuring optimal functionality.

| Component | Description |

|---|---|

| Fuel Filter | Ensures clean fuel reaches the engine, preventing clogging and maintaining performance. |

| Air Filter | Prevents dust and debris from entering the engine, which can cause damage and reduce efficiency. |

| Spark Plug | Ignites the fuel-air mixture in the combustion chamber, crucial for engine start-up and operation. |

| Line Trimmer Head | Houses the cutting line and facilitates trimming grass and weeds with precision. |

Maintenance Tips

Regular inspection and timely replacement of these components can lead to smoother operation and prolonged equipment life. Keep track of usage and be proactive about any signs of wear to ensure your machine remains reliable and efficient.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular attention to maintenance not only enhances performance but also prevents costly repairs in the long run. By following a few straightforward practices, you can keep your machine running smoothly and efficiently.

Start with routine inspections to identify any signs of wear or damage. Pay special attention to moving parts and connections, as these areas are prone to issues over time. Cleaning the machine after each use is equally important; removing debris and dirt helps prevent buildup that could lead to malfunctions.

Additionally, ensure that you are using the correct fuel and lubricants specified for your equipment. Using improper materials can cause significant harm and reduce overall efficiency. Changing filters and spark plugs at regular intervals also contributes to optimal operation and reduces the risk of breakdowns.

Finally, store your equipment properly when not in use. Keeping it in a dry, protected environment prevents rust and corrosion, extending its lifespan. By incorporating these maintenance tips into your routine, you can enjoy reliable performance for many years to come.

Identifying Wear and Tear Signs

Recognizing indicators of deterioration is crucial for maintaining equipment efficiency and prolonging its lifespan. Regular inspections help ensure optimal performance and prevent unexpected failures.

| Sign | Description |

|---|---|

| Cracks | Visible fissures on components may lead to structural weakness. |

| Rust | Corrosion can compromise functionality and durability. |

| Excessive Vibration | Unusual movement may indicate misalignment or damage. |

| Worn Edges | Blades or surfaces that are blunt can affect performance. |

| Leaks | Fluid loss can signal seal failure or component issues. |

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for maintaining its performance and longevity. Purchasing from reliable sources ensures that you receive high-quality items that fit perfectly and function as intended. Below are some recommended avenues to explore when looking for these essential supplies.

Authorized Dealers

- Visit local authorized dealerships, which often stock a wide range of genuine components.

- Consult the manufacturer’s website to locate nearby certified sellers.

- Authorized dealers typically offer expert advice and support, ensuring you make informed purchases.

Online Retailers

- Look for reputable e-commerce platforms that specialize in outdoor equipment supplies.

- Check user reviews and ratings to gauge the reliability of the seller.

- Be cautious of counterfeit products by verifying the authenticity of the items through detailed descriptions and images.

By choosing the right sources, you can ensure that your equipment operates efficiently and effectively, ultimately extending its lifespan and enhancing your experience.

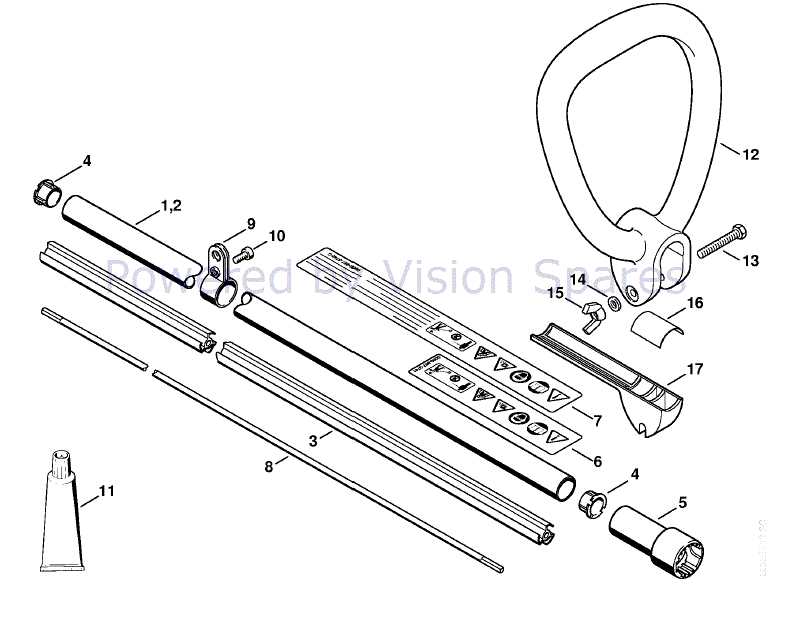

Assembly Instructions for FS 85

This section provides a comprehensive guide to effectively assembling the FS 85 model. Following these instructions will ensure proper functionality and longevity of the equipment. It is essential to adhere to the steps carefully to achieve optimal results.

Preparation Steps

- Gather all necessary components and tools before starting the assembly process.

- Ensure the workspace is clean and free of any debris to avoid distractions.

- Familiarize yourself with each component and its intended function.

Assembly Procedure

- Begin by attaching the handle to the main shaft. Secure it tightly to avoid any wobbling during use.

- Next, connect the engine unit to the shaft. Make sure all bolts are tightened according to the manufacturer’s specifications.

- Install the cutting head, ensuring it aligns properly with the shaft and is securely fastened.

- Finally, check all connections and perform a visual inspection to confirm everything is in place.

Once the assembly is complete, conduct a brief test to ensure everything operates smoothly. Regular maintenance will help keep the equipment in optimal condition for future use.