When it comes to maintaining your cutting tool, having a clear visual representation of its various elements is essential. Knowing how each piece interacts not only aids in troubleshooting but also enhances overall performance. This section will explore the intricate assembly of a popular model, shedding light on its essential parts.

Exploring the inner workings of a chainsaw allows users to grasp the significance of each component. From the engine to the chain, every section plays a pivotal role in ensuring efficiency and safety. This knowledge empowers operators to make informed decisions during maintenance and repairs.

By delving into the specifics of the assembly, enthusiasts can achieve the ultimate understanding of their tool. This exploration paves the way for better care, extending the life of the chainsaw and improving its cutting capabilities. Discover the essentials and elevate your maintenance routine.

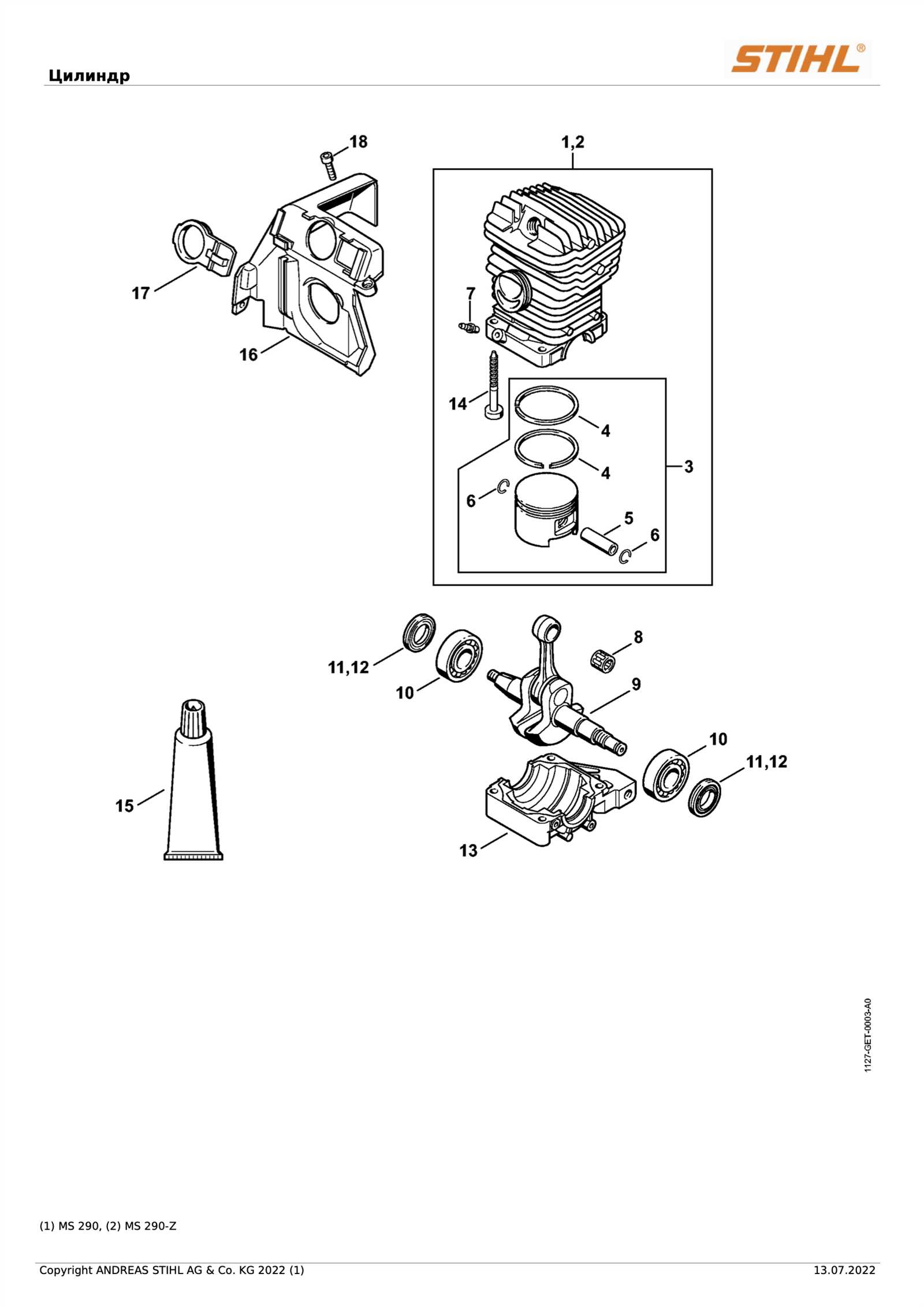

Understanding the Stihl MS290 Parts

When it comes to maintaining and repairing outdoor power equipment, a thorough comprehension of the various components is essential. Each element plays a crucial role in ensuring optimal performance and longevity of the machine.

Here are some key aspects to consider regarding the components:

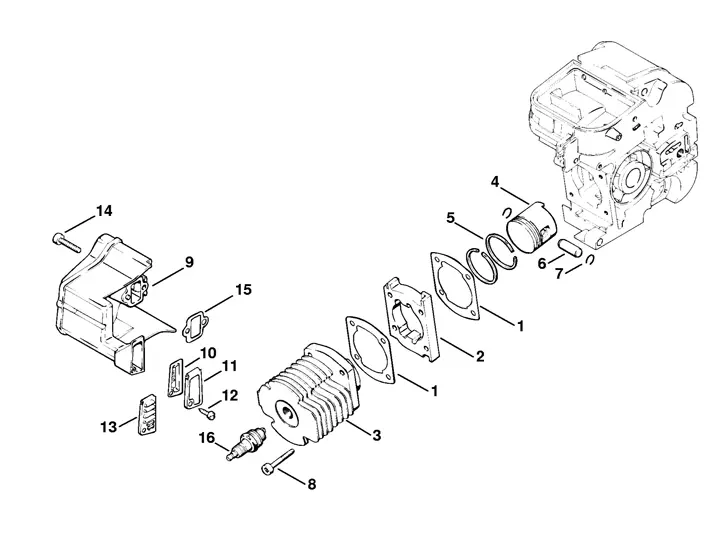

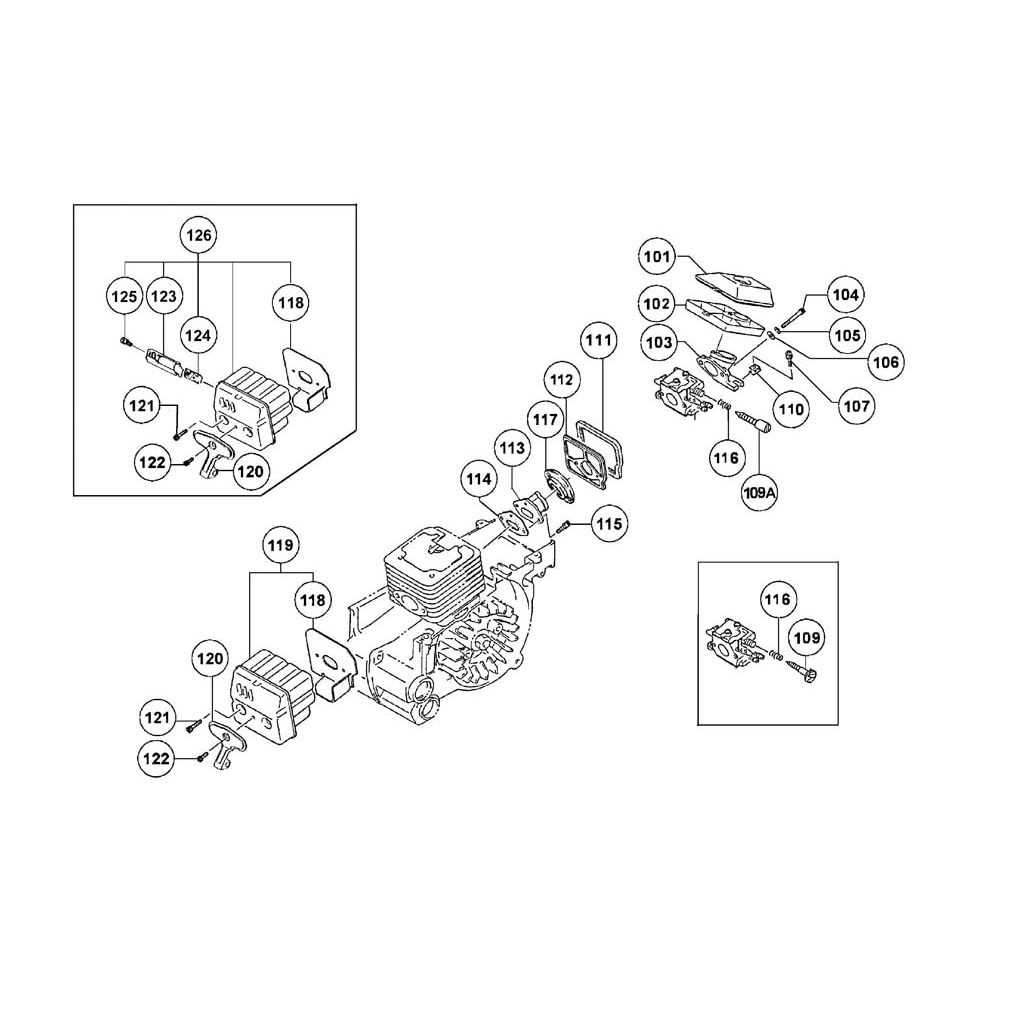

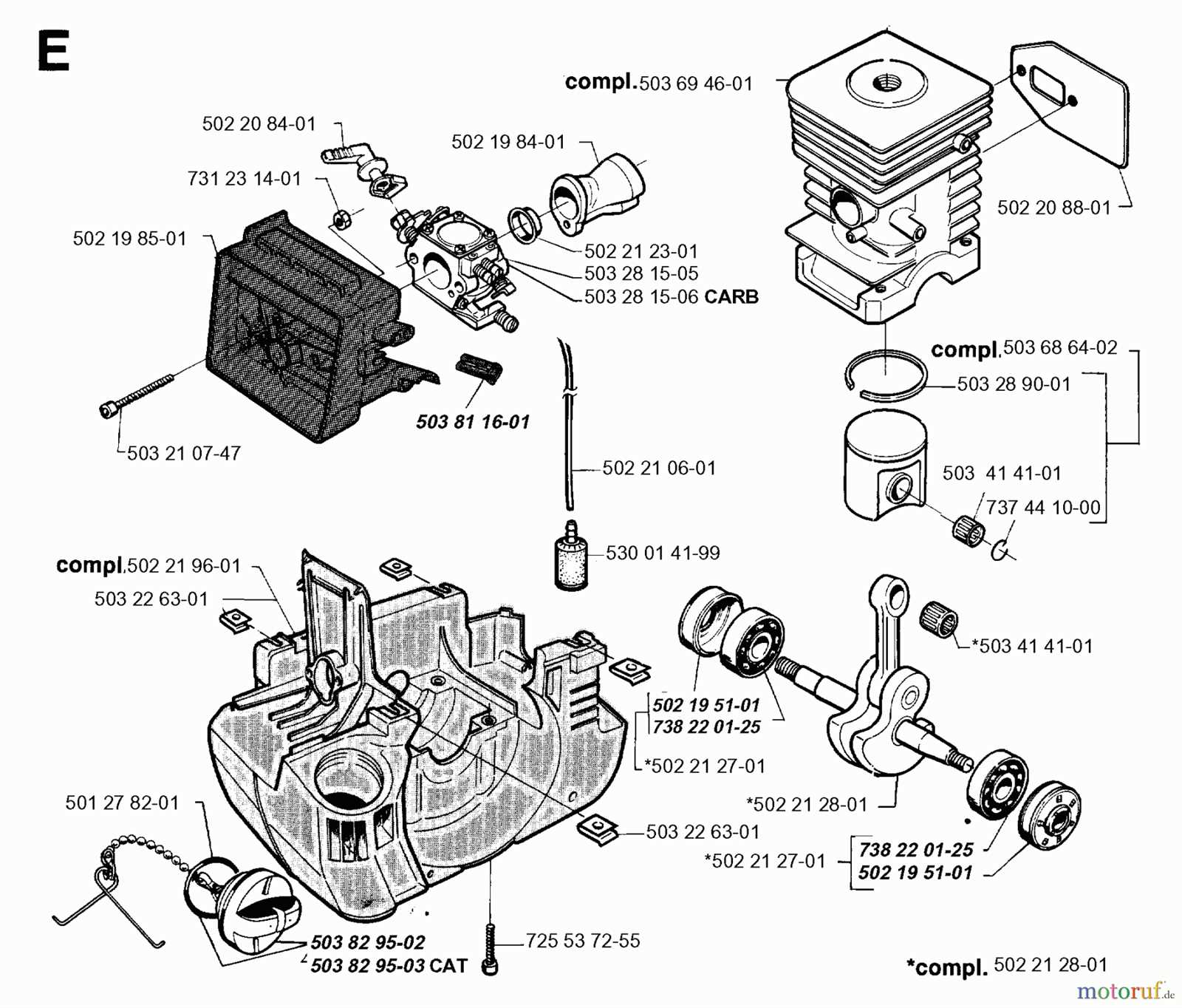

- Engine Assembly: The heart of the machine, responsible for generating power.

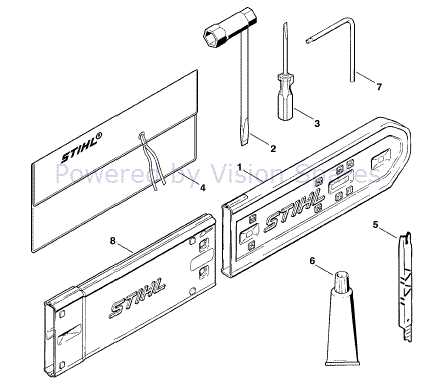

- Bar and Chain: Essential for cutting tasks, requiring proper tension and lubrication.

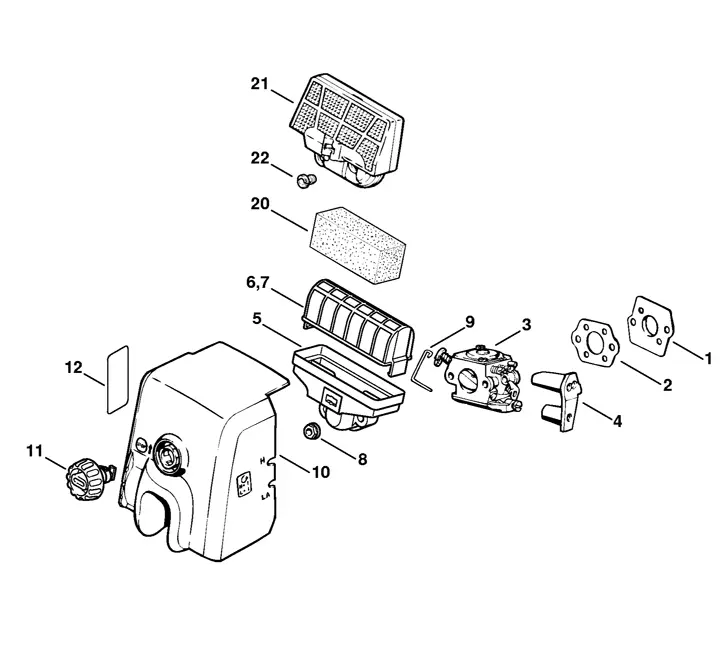

- Air Filter: Vital for maintaining engine efficiency by preventing debris from entering.

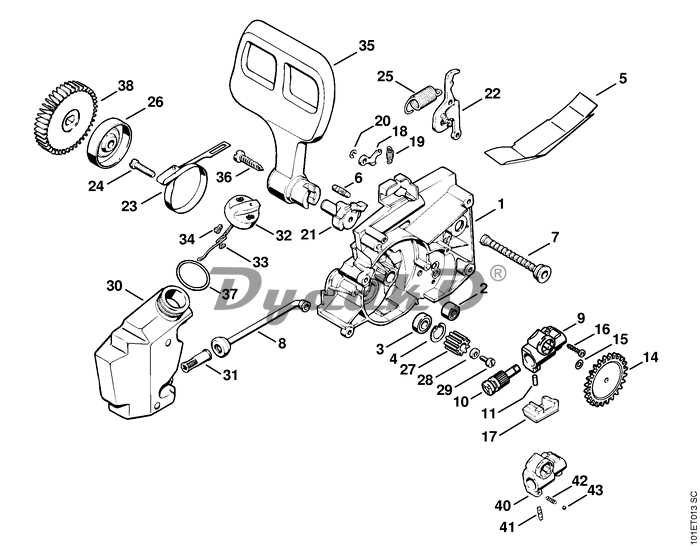

- Fuel System: Includes the tank, lines, and carburetor, all crucial for proper fuel delivery.

- Ignition System: Comprises the spark plug and ignition coil, vital for starting the engine.

Understanding these components can significantly enhance your ability to troubleshoot and perform maintenance effectively.

- Regularly check the condition of the air filter and replace it as needed.

- Ensure that the fuel system is free from clogs to prevent starting issues.

- Maintain the bar and chain by cleaning and lubricating them frequently.

- Inspect the ignition system to guarantee reliable starts.

By familiarizing yourself with these crucial elements, you can ensure the equipment operates smoothly and efficiently for years to come.

Overview of Chainsaw Components

Understanding the various elements of a chainsaw is essential for both maintenance and effective usage. Each component plays a vital role in the overall functionality and performance of the tool.

- Engine: The heart of the chainsaw, providing power.

- Guide Bar: The elongated metal piece that supports the cutting chain.

- Cutting Chain: Designed for slicing through wood, it features sharp teeth.

- Throttle Trigger: Controls the engine speed and cutting power.

- Chain Brake: A safety feature that stops the chain in emergencies.

- Fuel Tank: Holds the mixture of fuel and oil necessary for operation.

- Air Filter: Ensures clean air enters the engine, enhancing performance.

Each of these components contributes to the ultimate efficiency and safety of the chainsaw, making it crucial to understand their functions and interrelationships.

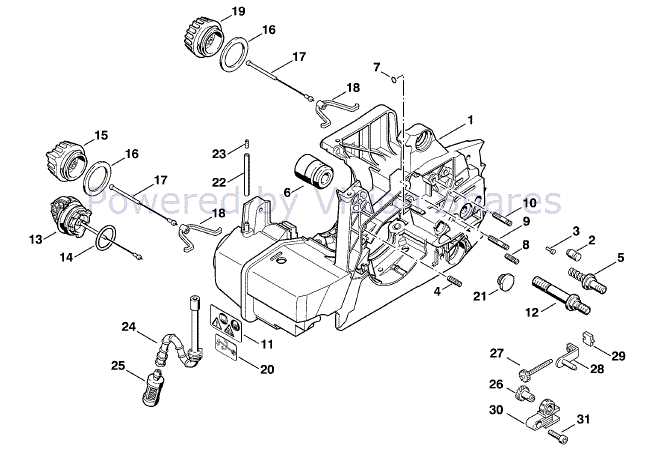

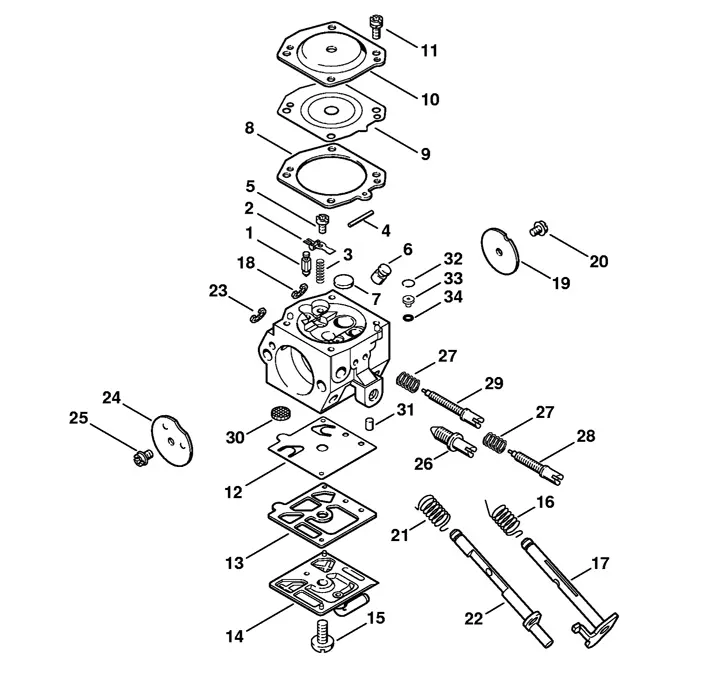

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both novice and experienced users, providing clarity and insight into complex assemblies. They simplify the process of identifying, locating, and replacing individual elements, ensuring that equipment operates at optimal efficiency.

There are several key reasons why these visual guides are invaluable:

- Enhanced Clarity: Visual aids break down intricate systems into easily digestible segments, allowing users to grasp the layout and functionality of each component.

- Streamlined Repairs: Quick identification of needed components minimizes downtime, facilitating faster and more efficient repairs.

- Accurate Reassembly: Following a visual guide ensures that all pieces are correctly reinstalled, reducing the risk of errors that can lead to malfunction.

- Informed Decision-Making: Understanding the relationships between parts enables better assessments when troubleshooting issues.

Incorporating these visual references into maintenance routines not only boosts proficiency but also fosters a deeper appreciation for the machinery itself. This knowledge empowers users to take charge of their equipment, ensuring longevity and peak performance.

How to Read a Parts Diagram

Understanding an illustration that outlines components is essential for effective maintenance and repairs. This visual representation serves as a guide, helping you identify each element and its relationship to others. Familiarity with the layout and notations can significantly enhance your ability to troubleshoot and replace items when necessary.

Key Elements of a Component Illustration

To effectively interpret a visual breakdown, consider the following aspects:

- Labels: Each item is typically labeled with a unique identifier, often a number or code. This aids in referencing specific components easily.

- Groupings: Items are often grouped by function or location, making it simpler to locate what you need within a particular section.

- Connections: Arrows or lines may indicate how different parts are connected, showing assembly order or relationship.

Steps to Utilize the Illustration

- Familiarize Yourself: Spend time reviewing the entire layout to understand the arrangement of components.

- Identify Components: Locate the part you need and note its identifier for future reference.

- Consult Reference Material: Use manuals or guides that correspond with the identifiers to gather more information about each component.

- Plan Repairs: Based on the visual representation, outline the necessary steps and tools required for your task.

By mastering these skills, you’ll be equipped to navigate any illustrative breakdown with confidence, ensuring a smoother repair process.

Common Replacement Parts for MS290

Regular maintenance is essential for ensuring the longevity and efficiency of your cutting equipment. Over time, certain components may wear out or require replacement to keep your machine functioning optimally. Understanding which elements are frequently replaced can help you maintain peak performance and avoid unexpected breakdowns.

1. Air Filter

The air filter plays a critical role in keeping the engine clean and efficient. A clogged or dirty filter can restrict airflow, leading to decreased performance. Regular replacement is recommended to ensure optimal operation.

2. Spark Plug

The spark plug ignites the fuel-air mixture in the engine. Worn or fouled plugs can cause starting issues and rough running. Changing the spark plug periodically can enhance engine performance and reliability.

3. Fuel Filter

A fuel filter ensures that impurities do not reach the engine. A blocked filter can reduce fuel flow and power output. Regular checks and replacements are essential for smooth operation.

4. Chain and Bar

The cutting chain and guide bar endure significant wear during operation. Dull chains or damaged bars can lead to inefficient cutting and increased strain on the engine. Keeping these components sharp and in good condition is vital for effective performance.

5. Fuel Lines

Fuel lines transport the mixture from the tank to the engine. Over time, these lines can become cracked or degraded, leading to leaks and performance issues. Regular inspection and replacement are important for safe operation.

By staying proactive with these essential components, you can ensure that your equipment remains reliable and efficient, ready to tackle any task you encounter.

Where to Find Stihl MS290 Parts

When it comes to sourcing components for your equipment, knowing the best places to look can save both time and money. Whether you need original replacements or aftermarket options, numerous avenues are available for acquiring the necessary items to keep your machine running smoothly.

Online Retailers

One of the most convenient options is to explore various online retailers. Websites specializing in outdoor equipment often have extensive inventories, allowing you to compare prices and find exactly what you need without leaving home.

Local Dealers

Your local dealership can also be a valuable resource. They typically stock genuine components and can provide expert advice on installation and maintenance, ensuring your device remains in peak condition.

Tips for Maintenance and Repair

Regular upkeep and prompt repairs are essential for prolonging the life of your equipment and ensuring optimal performance. By following a few simple guidelines, you can enhance efficiency and prevent potential issues that may arise during use.

Routine Checks

Conduct frequent inspections to identify wear and tear. Look for signs of damage or looseness in components. Keeping your equipment clean is crucial; dirt and debris can lead to serious malfunctions over time.

Utilize Quality Replacement Parts

When replacing worn components, always opt for high-quality substitutes. Using inferior parts can compromise functionality and safety. Ensure that you consult reliable sources for the ultimate fit and performance.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their functionalities. Understanding these elements can greatly enhance your experience and efficiency in maintenance and repairs.

What should I consider when selecting replacement components?

When choosing new elements, focus on compatibility, quality, and manufacturer recommendations. Ensuring the right fit can prevent issues down the line.

How can I identify the specific component I need?

Refer to the user manual or check the original item’s markings. Additionally, many online resources provide guides to help with identification.

Are aftermarket items a good choice?

Aftermarket options can offer cost savings, but quality varies. Research the supplier and read reviews to ensure you select reliable alternatives.

How often should components be replaced?

Replacement frequency depends on usage and wear. Regular inspections will help you determine when items need attention.

What are the benefits of using original components?

Original items are specifically designed for optimal performance and longevity. They may also come with warranties that provide additional peace of mind.

Resources for Chainsaw Owners

For enthusiasts and professionals alike, having access to reliable resources is crucial for maintaining and optimizing your equipment. This section offers a variety of tools, guides, and communities designed to support owners in their journey, ensuring they can effectively manage their tools and address any issues that may arise.

Online Communities and Forums

Joining online forums can be an excellent way to connect with other owners. These platforms often feature discussions about troubleshooting, modifications, and performance tips. Engaging with fellow users allows for the sharing of experiences and insights, fostering a sense of camaraderie.

Maintenance Guides and Tutorials

Numerous websites offer detailed guides and video tutorials focused on upkeep and repairs. These resources provide step-by-step instructions for tasks ranging from basic maintenance to complex repairs. Utilizing these materials can help extend the life of your equipment while enhancing your skill set.