The effective operation of a chainsaw relies on a well-organized arrangement of its essential components. Understanding how these parts interact with each other is crucial for maintenance and troubleshooting. This section delves into the intricate layout of a widely recognized chainsaw, providing insights into its various elements and their functions.

By examining the configuration of the unit, users can gain a better understanding of how each component contributes to the overall performance. Familiarity with the layout not only aids in identifying potential issues but also enhances the ability to make informed decisions regarding repairs and replacements. This knowledge empowers users to maintain their equipment efficiently and effectively.

In this discussion, we will highlight key features of the assembly, ensuring that both novice and experienced operators can benefit from the information provided. With a clear overview of the configuration, users can approach their tasks with greater confidence and competence.

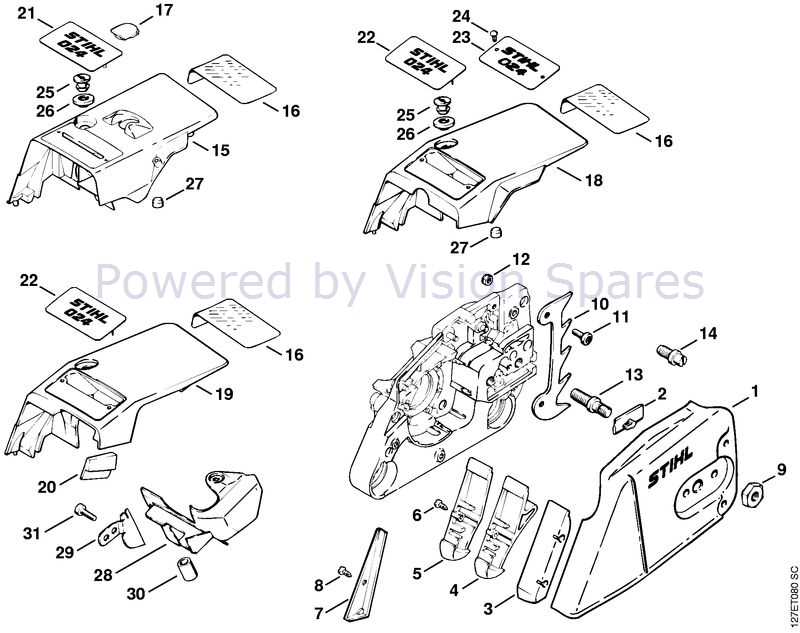

Understanding the Parts Diagram

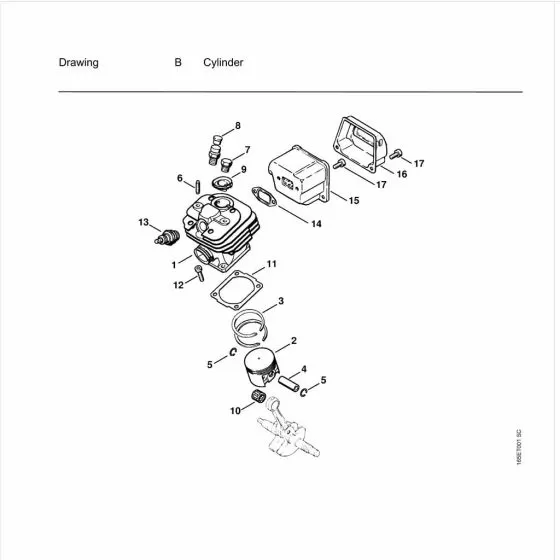

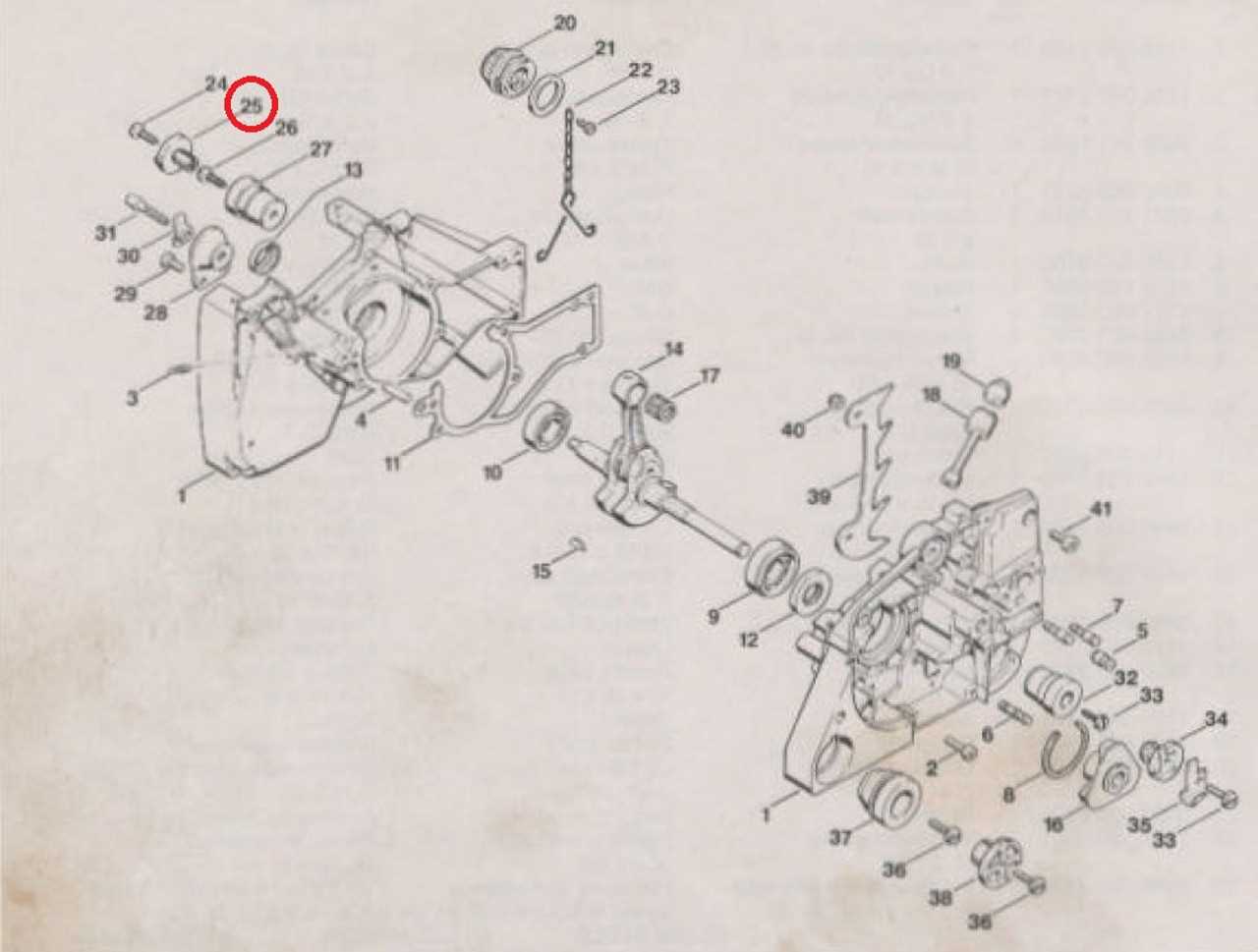

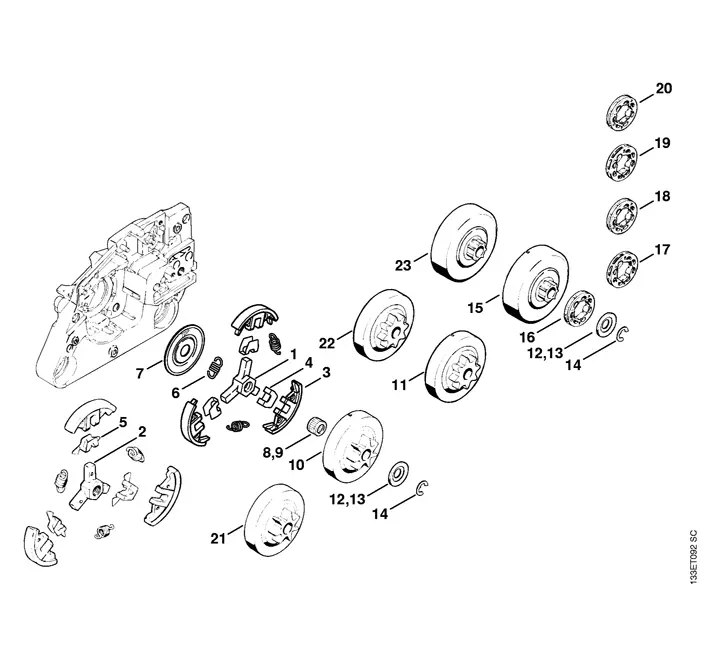

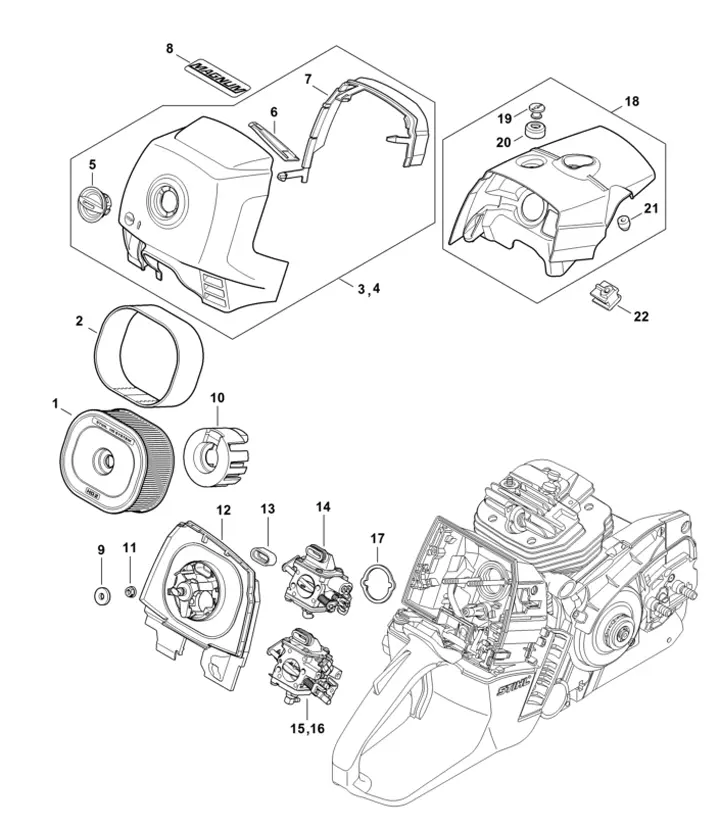

Analyzing the visual representation of components is essential for effective maintenance and repair of machinery. A well-structured illustration not only aids in identifying various elements but also enhances the comprehension of their interrelations. Grasping this information facilitates smoother troubleshooting and supports the assembly or disassembly process, ensuring optimal functionality.

Importance of Component Identification

Recognizing each element within the illustration is crucial for performing repairs and replacements accurately. A clear understanding of each part’s role contributes to effective problem-solving, leading to improved efficiency and longevity of the equipment.

How to Use the Visual Guide

When engaging with the visual guide, it is vital to follow a systematic approach. Start by familiarizing yourself with the layout and categorization of the components. Then, refer to the accompanying legend or labels to understand the specific functions and compatibility of each element.

| Component Name | Description |

|---|---|

| Engine | The primary source of power that drives the machinery. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

| Chain Brake | A safety feature that stops the chain in case of kickback. |

| Guide Bar | Supports the chain and provides a surface for cutting. |

Key Components of the Chainsaw

The chainsaw consists of several essential elements that work together to facilitate efficient cutting and performance. Understanding these components is crucial for proper maintenance and effective use of the equipment. Each part plays a significant role in the overall operation, ensuring the tool functions optimally in various applications.

Engine and Power System

The heart of the chainsaw is its engine, which generates the necessary power to drive the cutting chain. This system can be either electric or fueled by gasoline, providing flexibility based on the user’s needs. A reliable power source is vital for consistent performance, enabling the saw to tackle different types of wood efficiently.

Cutting Mechanism

The cutting mechanism includes the chain and the bar, which work in tandem to achieve precise cuts. The chain is designed with sharp teeth that rotate around the bar, allowing for smooth and effective slicing through various materials. Maintaining the sharpness of the chain is essential for optimal performance and safety during operation.

Assembly Instructions for a Chainsaw Model

When putting together your cutting tool, it’s essential to ensure that all components fit seamlessly. Proper alignment of parts will lead to smoother operation and extend the lifespan of the machine. These instructions provide an overview of the process and key points to consider during assembly. Always refer to detailed documentation for specific steps.

Key Steps for Assembling

Begin by securing the main housing and ensuring the internal mechanisms are correctly positioned. Align the engine compartment carefully before attaching any external pieces. Pay close attention to the connection points between the motor unit and the blade section, ensuring they lock into place firmly.

Checklist for Completion

Use the following checklist to confirm that every section is properly assembled:

| Component | Action |

|---|---|

| Engine Housing | Securely fasten all screws and check for tightness |

| Blade Alignment | Ensure correct placement and lock securely |

| Fuel and Oil Compartments | Confirm proper sealing to avoid leaks |

| Handle and Trigger | Test the movement and stability |

Following these assembly steps and checking each component will guarantee that your machine is ready for optimal performance.

Maintenance Tips for Longevity

To ensure your equipment serves you for an extended period, proper care and regular upkeep are essential. With a few simple practices, you can enhance its durability and performance, preventing premature wear and tear. This section provides useful insights on how to maintain your tools for reliable long-term use.

Regular Cleaning

One of the most effective ways to keep your device in top condition is by cleaning it after every use. Dirt and debris can accumulate in various components, potentially leading to malfunctions. Regularly inspect and clean moving parts to ensure smooth operation.

- Wipe down the exterior after use.

- Remove debris from ventilation areas.

- Use appropriate tools for detailed cleaning.

Lubrication and Tightening

Maintaining proper lubrication of moving components is crucial for smooth functionality. Additionally, over time, bolts and screws may loosen, so regular checks and adjustments are necessary to avoid any issues during operation.

- Apply lubricant to essential moving parts.

- Inspect for any loose screws and tighten them as needed.

- Replace any damaged components to prevent further wear.

Troubleshooting Common Issues

When working with outdoor equipment, it’s not uncommon to encounter various operational problems. These can often arise due to regular wear and tear or incorrect usage. Addressing these challenges early on helps ensure the longevity of your tool and prevents larger mechanical failures.

Engine Won’t Start

- Check the fuel supply to ensure it’s not depleted or stale.

- Inspect the spark plug for signs of wear or fouling, and replace if necessary.

- Ensure the air filter is clean and not clogged, as this can affect airflow.

Power Loss or Stalling

- Verify that the fuel mixture is correctly balanced; improper ratios can lead to poor performance.

- Examine the exhaust for any blockages, which may restrict airflow.

- Clean or replace the carburetor if it’s dirty or malfunctioning.

- Regular maintenance is key to avoiding most operational issues.

- Follow manufacturer guidelines for proper tool care and part replacement schedules.

Replacement Parts and Upgrades

Over time, various components of any tool may experience wear and tear, making it essential to replace or upgrade certain elements. Proper maintenance ensures that the device continues to function efficiently, enhancing its longevity and performance. Regularly inspecting and identifying which elements need attention can help avoid potential issues during use.

When choosing new components, it’s important to focus on compatibility and durability. Opting for high-quality upgrades can offer better functionality, while also providing smoother operation and improved results. Whether it’s minor adjustments or complete replacements, careful selection can make a noticeable difference in the tool’s overall efficiency.

Safety Guidelines for Operation

Operating outdoor equipment requires careful attention to ensure both efficiency and safety. By following essential precautions, users can prevent accidents and maintain optimal performance. Prioritizing safety measures can help avoid potential risks during use.

Proper Handling

Always make sure to handle the equipment with both hands and maintain a stable posture while in operation. Wearing protective gear, including gloves and eye protection, reduces the chance of injury. Familiarize yourself with the controls to ensure you can quickly respond to any unexpected situation.

Regular Maintenance

Maintaining your tool in good condition is vital for safe operation. Regularly check for wear or damage, and clean all parts to ensure they are functioning correctly. Keeping the equipment in top shape not only enhances safety but also prolongs its lifespan. If any irregularities are noticed, address them immediately before further use.

Resources for Further Assistance

When you are working with mechanical systems, it’s essential to know where to find additional support for troubleshooting and maintenance. Whether you’re looking for instructional guides, detailed illustrations, or advice from experts, numerous options are available to help you understand and service your equipment effectively.

Online Support Platforms

Various digital platforms provide access to manuals, user forums, and expert advice. These resources often include community-based discussions, which can offer insights into common issues and solutions. It’s a good idea to explore these forums to find recommendations or tips from experienced users.

Technical Documentation

If you’re seeking detailed technical documents, many websites host comprehensive materials such as schematics and service guides. These resources can be invaluable for those needing precise instructions on assembly, repair, or replacing specific components. Always ensure the materials are from reputable sources to guarantee accurate information.