The structure and arrangement of various mechanical elements play a crucial role in ensuring the efficient operation of a device. Understanding how different components are organized helps in maintaining the overall performance and addressing potential issues that may arise during use. By exploring these configurations, one can gain insights into the key features and interactions within the machinery.

Whether you’re a seasoned professional or a first-time user, familiarizing yourself with the layout of these mechanical parts is essential for troubleshooting and maintenance. It allows you to pinpoint areas that may need adjustment, replacement, or repair, thereby extending the life of the equipment and ensuring its smooth operation.

In this guide, we will delve into the organization and functionality of the various critical elements, providing you with a clear understanding of how everything fits together. This knowledge will empower you to handle the machinery more effectively and perform necessary upkeep

Stihl 025 Chainsaw Components Overview

The mechanical structure of this cutting tool is composed of several interconnected elements that ensure efficient operation. Each element has a specific role, contributing to the overall performance and durability of the equipment. Understanding these components can help in maintenance and troubleshooting.

Engine and Ignition System

The core of this tool is its motor, which provides the necessary power for cutting tasks. The ignition system is responsible for starting the motor, ensuring a smooth and reliable operation. Regular inspection of these parts is essential for long-term functionality.

Cutting Mechanism

The cutting process is driven by a rotating chain, which moves over a bar, allowing precise cuts. The tension of the chain, as well as the condition of the bar, directly influences the efficiency and safety of the tool. Proper adjustment and sharpening of the chain are critical for optimal performance.

Essential Internal Mechanisms of Stihl 025

Understanding the vital internal components of a powerful cutting tool provides insight into its efficient operation and durability. These key elements work together to ensure smooth performance and long-lasting functionality, even under demanding conditions.

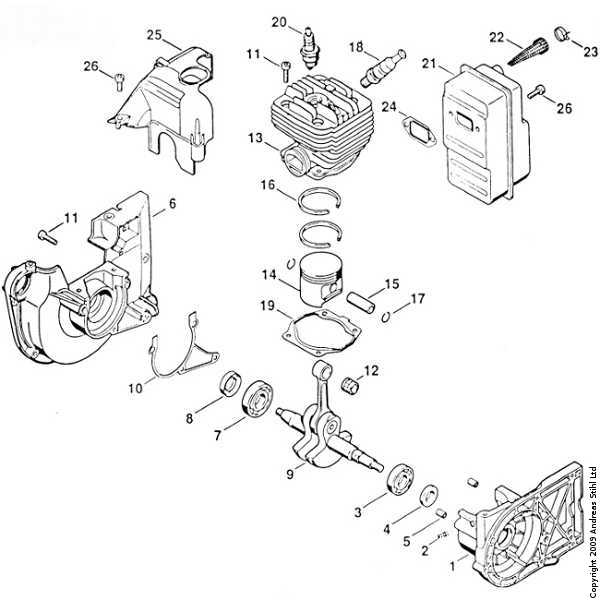

- Engine Assembly: The core of any cutting equipment, this mechanism converts fuel into the energy required to power the tool. Its design impacts efficiency, noise levels, and vibration control.

- Ignition System: Responsible for generating the spark that ignites the fuel, the ignition setup plays a critical role in starting the tool and keeping it running consistently.

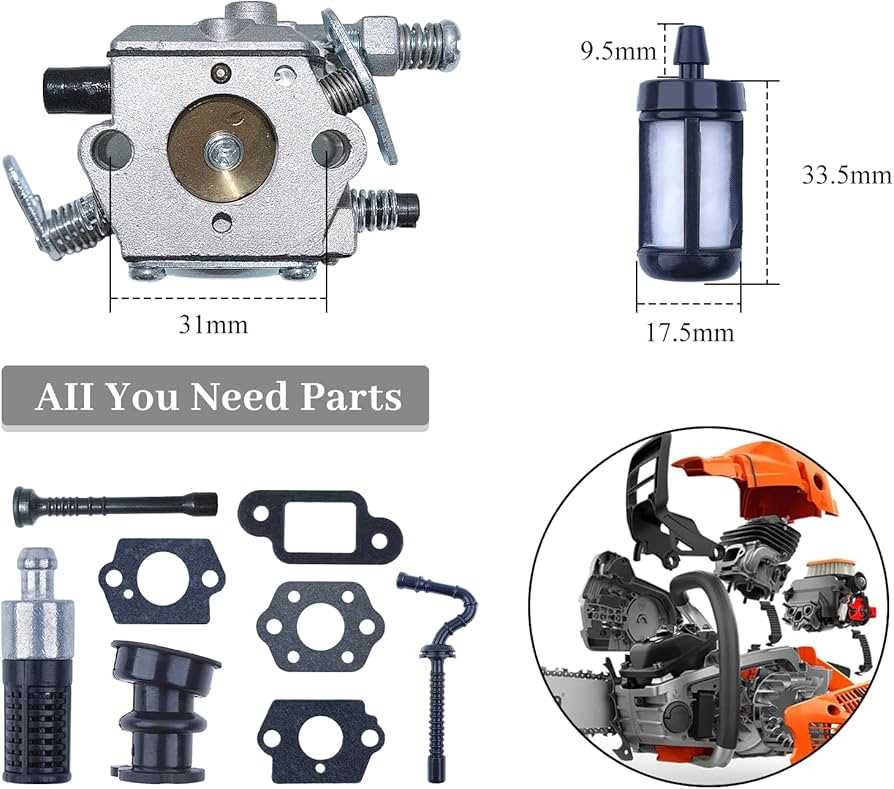

- Fuel Delivery Mechanism: This system ensures the appropriate mix of air and fuel reaches the engine. Proper adjustment of this part affects the tool’s overall power output and fuel efficiency.

- Cooling System: Essential for preventing overheating, the cooling system manages the

Guide to Stihl 025 Chainsaw Engine Parts

Understanding the internal components of this machine’s motor is essential for efficient maintenance and repair. Each element plays a crucial role in the overall performance, and knowing how these components work together ensures smooth operation and longevity of the equipment.

Cylinder and piston are the heart of the motor, responsible for converting fuel into mechanical energy. The piston moves inside the cylinder, compressing the fuel-air mixture before ignition, driving the crankshaft and providing power.

The crankshaft transfers the energy produced by the piston to the machine’s mechanisms. Attached to the crankshaft, the connecting rod links the movement between the piston and crankshaft, ensuring seamless energy transfer.

Another important element is the carburetor, which mixes fuel and air in the correct proportions. A well-maintained carburetor ensures efficient fuel combustion and prevents stalling.

The

Understanding the Ignition System of Stihl 025

The ignition system plays a critical role in ensuring the engine operates smoothly and efficiently. It generates the necessary spark at precisely the right moment, enabling combustion to power the motor. By understanding the key components involved, one can diagnose potential issues and maintain optimal performance. This section delves into the structure and function of the system that controls the timing of sparks and the overall operation of the engine.

Component Function Spark Plug Produces the spark that ignites the fuel-air mixture in the combustion chamber. Flywheel Generates magnetic energy that powers the ignition coil through its rotation. Ignition Coil Transforms low voltage from the flywheel into high voltage for the spark plug. Fuel and Oil Systems of the Stihl 025

The fuel and lubrication systems play a crucial role in the performance of any cutting tool. These mechanisms ensure that the engine runs smoothly, and the cutting chain operates efficiently. Without proper management of these systems, the tool would struggle with consistent operation and could face premature wear.

Let’s dive into the key components involved in these essential systems:

- Fuel Tank: This reservoir stores the mixture required for powering the engine. Ensuring that it remains sealed and free of debris is essential for optimal performance.

- Fuel Filter: Located within the tank, this component prevents contaminants from entering the engine, prolonging its lifespan.

- Oil Tank: The container responsible for holding the lubrication needed to keep the chain moving smoothly.

- Oil Pump:

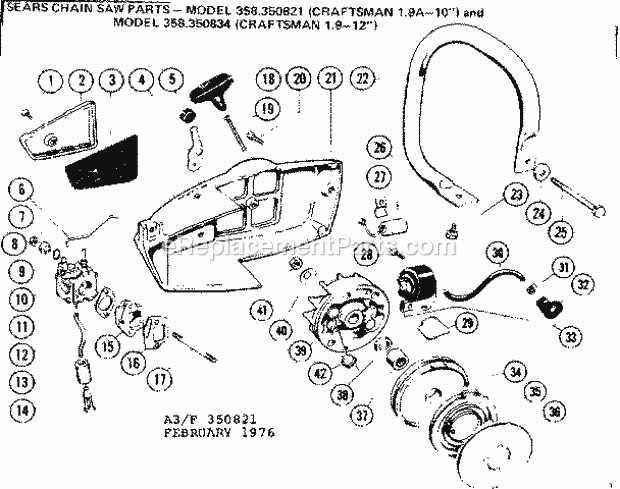

Chain and Bar Assembly in Stihl 025

The chain and bar assembly is a crucial component of any cutting tool designed for woodwork. This assembly plays a significant role in ensuring efficient cutting performance and overall functionality. Understanding its structure and operation can greatly enhance the user experience and maintenance of the equipment.

The assembly typically consists of a guide bar, which provides a path for the chain to follow, and the chain itself, which is equipped with sharp teeth for slicing through various materials. Proper alignment and tensioning of the chain are essential for optimal performance and safety. Users should regularly check these components for wear and tear to ensure longevity and reliability.

Moreover, lubricating the chain and bar assembly is vital. Adequate lubrication minimizes friction and heat buildup during operation, thus extending the lifespan of the components. Regular maintenance, including cleaning and adjusting the chain tension, contributes to the efficient functioning of the tool.

In conclusion, familiarity with the assembly of the chain and bar enhances not only the efficiency of the cutting process but also the safety of the operator. Keeping these components in good condition is essential for achieving the best results while minimizing risks.

Maintenance Tips for Stihl 025 Chainsaw Parts

Proper upkeep of your power tool ensures its longevity and optimal performance. Regular maintenance not only prevents breakdowns but also enhances safety while operating. Here are some essential practices to keep your equipment in excellent condition.

Regular Cleaning

After each use, it’s crucial to clean the exterior thoroughly. Remove any debris, such as sawdust or dirt, that may have accumulated during operation. A clean exterior prevents potential overheating and allows for better airflow, improving efficiency. Use a soft brush or cloth to gently wipe down surfaces, paying attention to vents and openings.

Routine Inspections

Conduct periodic inspections to identify wear and tear on various components. Check for any signs of damage, such as cracks or loose fittings. Regularly examine the cutting element for sharpness and integrity. Keeping an eye on these elements will help you address minor issues before they escalate into major repairs. Remember to consult the manufacturer’s guidelines for specific recommendations regarding maintenance intervals.

Troubleshooting Common Issues with Stihl 025 Parts

When operating a power tool, encountering problems is not uncommon. Understanding the various components and their functions can significantly aid in diagnosing and resolving typical malfunctions. This section provides insights into common issues and solutions related to the key components of the equipment.

Common Problems and Solutions

Issue Possible Causes Suggested Solutions Engine won’t start Empty fuel tank, clogged air filter, spark plug failure Refill fuel, clean or replace the air filter, check and replace the spark plug Inconsistent power output Fuel mixture issues, dirty carburetor Ensure correct fuel mixture, clean the carburetor thoroughly Excessive vibration Loose or damaged components Tighten screws and bolts, inspect for any damaged parts and replace if necessary Overheating Blocked cooling fins, low oil level Clear debris from cooling fins, check and refill oil as needed Maintenance Tips

Regular maintenance is key to preventing issues. Ensure to check fuel levels, replace filters periodically, and inspect components for wear and tear. Keeping the equipment clean and well-lubricated will enhance its longevity and performance.

Buying Genuine Replacement Parts for Stihl 025

When it comes to maintaining your outdoor power equipment, selecting authentic replacement components is essential for ensuring optimal performance and longevity. Using genuine components not only enhances the reliability of your tool but also helps in preserving its value over time. This section will explore the benefits of sourcing original replacements and guide you through the process of acquiring them.

Benefits of Genuine Components

Choosing authentic components offers several advantages. Firstly, these components are specifically designed to fit seamlessly with your equipment, reducing the risk of malfunction. Secondly, they often come with manufacturer warranties, providing you with added assurance. Lastly, utilizing genuine parts can improve the efficiency and safety of your tool, minimizing the likelihood of repairs in the future.

Where to Purchase Authentic Components

To ensure you are buying authentic components, it’s recommended to shop through authorized dealers or the manufacturer’s official website. These sources guarantee that you are receiving quality replacements that meet the required standards. Additionally, avoid purchasing from unverified vendors, as they may offer counterfeit or subpar components that could jeopardize your equipment’s performance.