Maintaining clean and safe water in various systems requires the use of specialized equipment. Each piece within this setup plays a crucial role in ensuring the proper flow and purification of water. Knowing the structure and elements involved allows for better maintenance and troubleshooting when issues arise.

At the heart of any water system is a combination of key mechanisms designed to work together seamlessly. These mechanisms ensure that unwanted particles are removed, and the water remains clear. The way these mechanisms are arranged and how they interact are essential to the system’s overall effectiveness.

Exploring the individual elements of this setup reveals how each piece contributes to the broader operation. From the core mechanisms that capture impurities to the auxiliary components that support efficient functioning, every part has a purpose. Understanding these components will aid in achieving optimal performance and longevity of your water purification system.

Overview of Pentair DE Filter Systems

These systems are designed to provide clear and clean water through a process that captures fine particles. Using a specialized medium, they ensure optimal purification by trapping even the smallest contaminants. Their construction allows for efficient operation in various conditions, offering reliability and consistent performance over time.

The technology behind these systems focuses on enhancing water quality by maximizing surface area and optimizing flow rates. Their advanced mechanisms ensure that the cleaning process is thorough, reducing the need for frequent maintenance while maintaining high standards of purity.

These systems are known for their longevity, with robust components that withstand the demands of continuous use. By ensuring effective operation, they play a crucial role in maintaining the overall efficiency of water management solutions. Their adaptability to different environments and ease of use make them a popular choice for both residential and commercial applications.

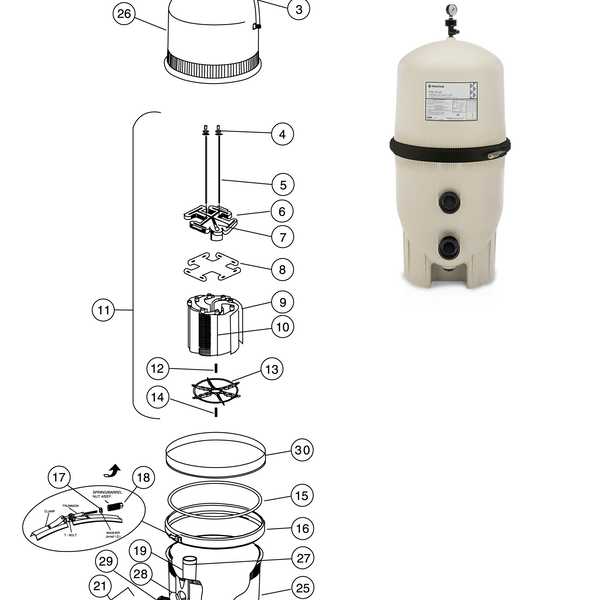

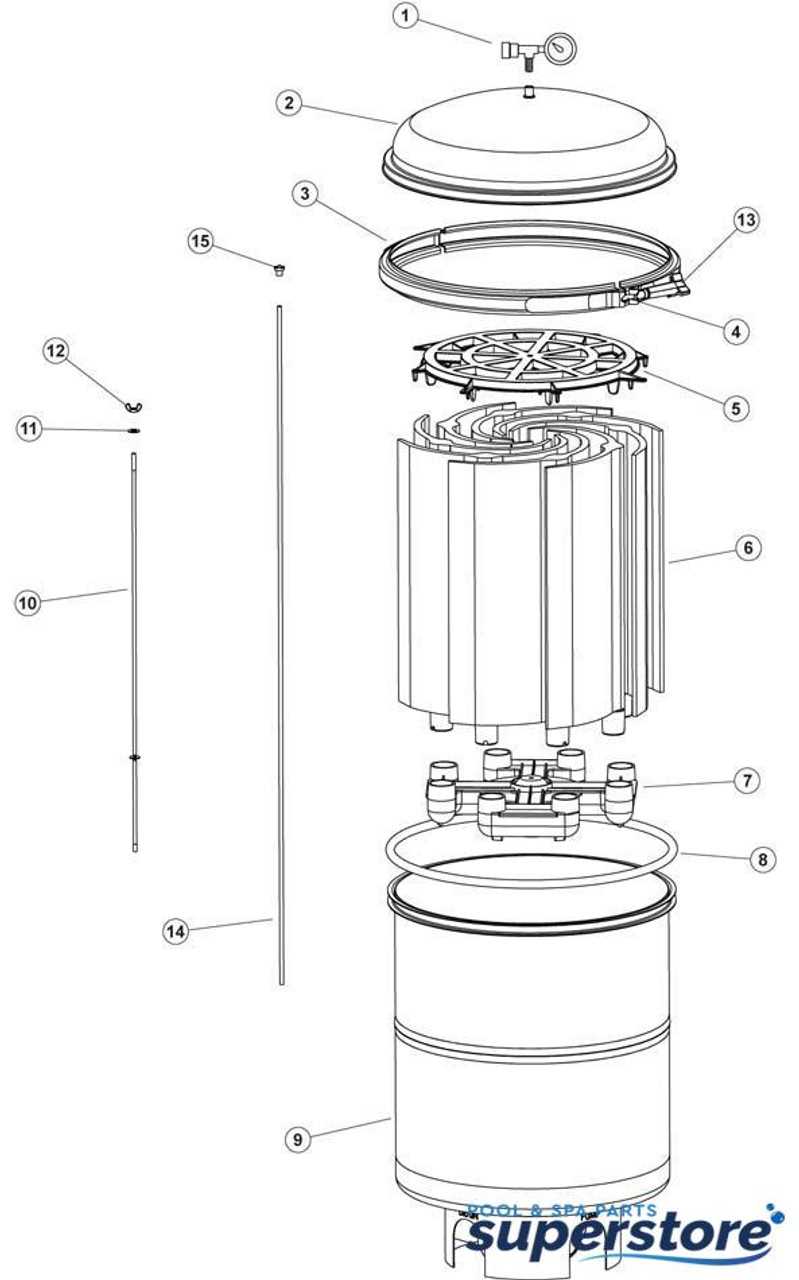

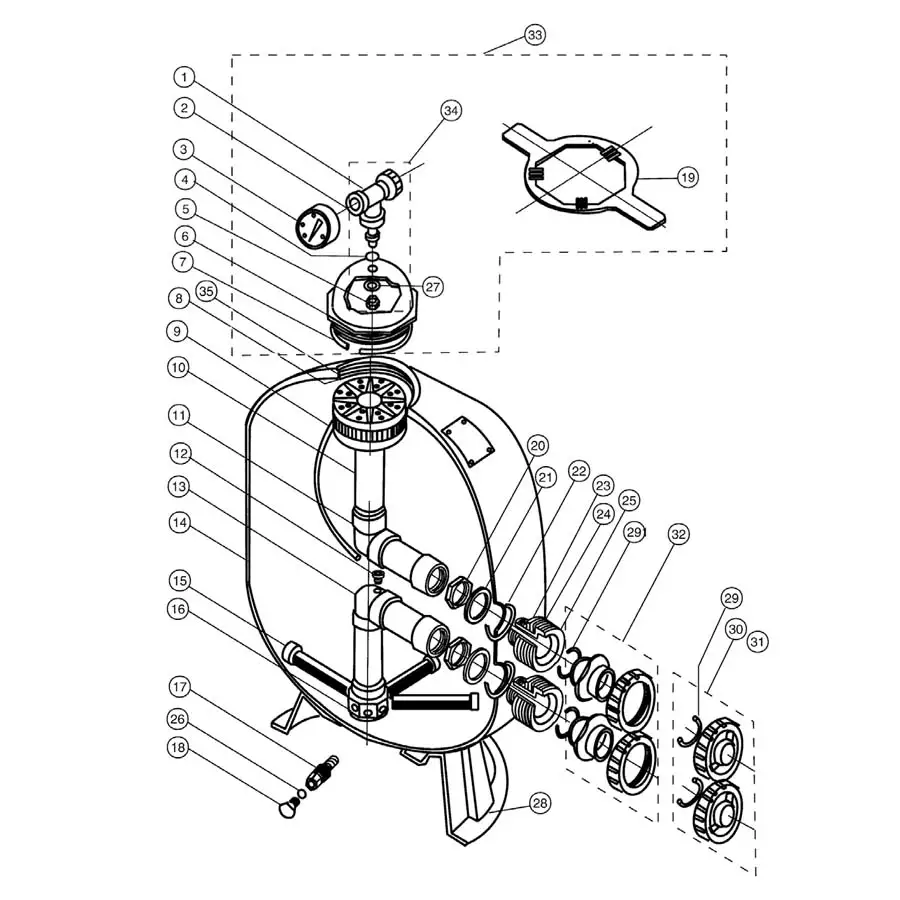

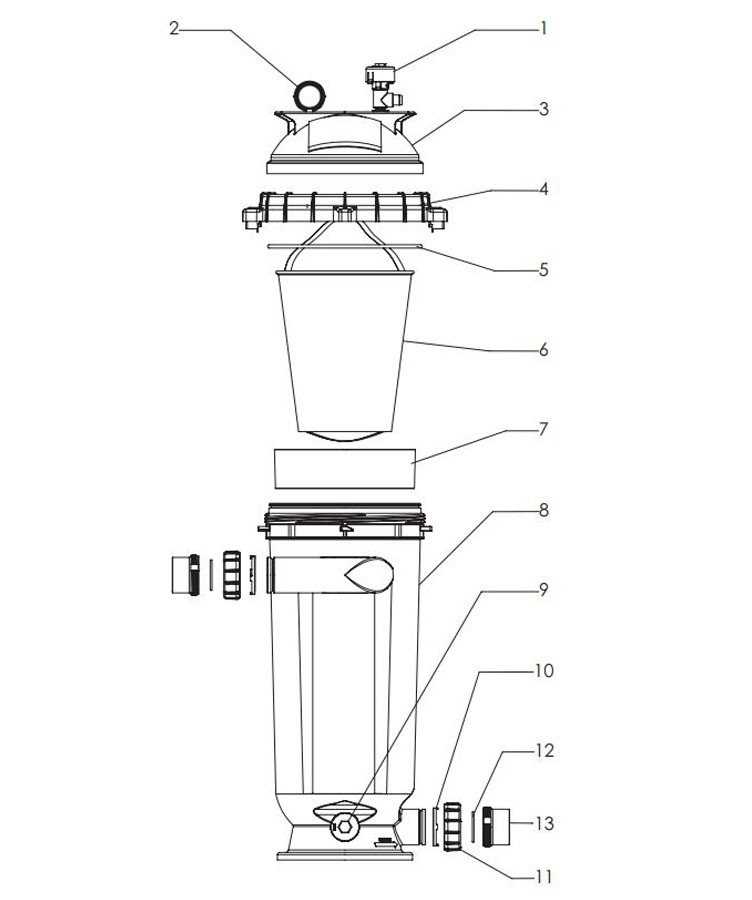

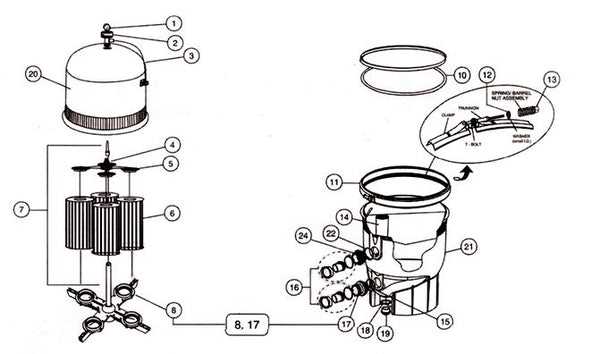

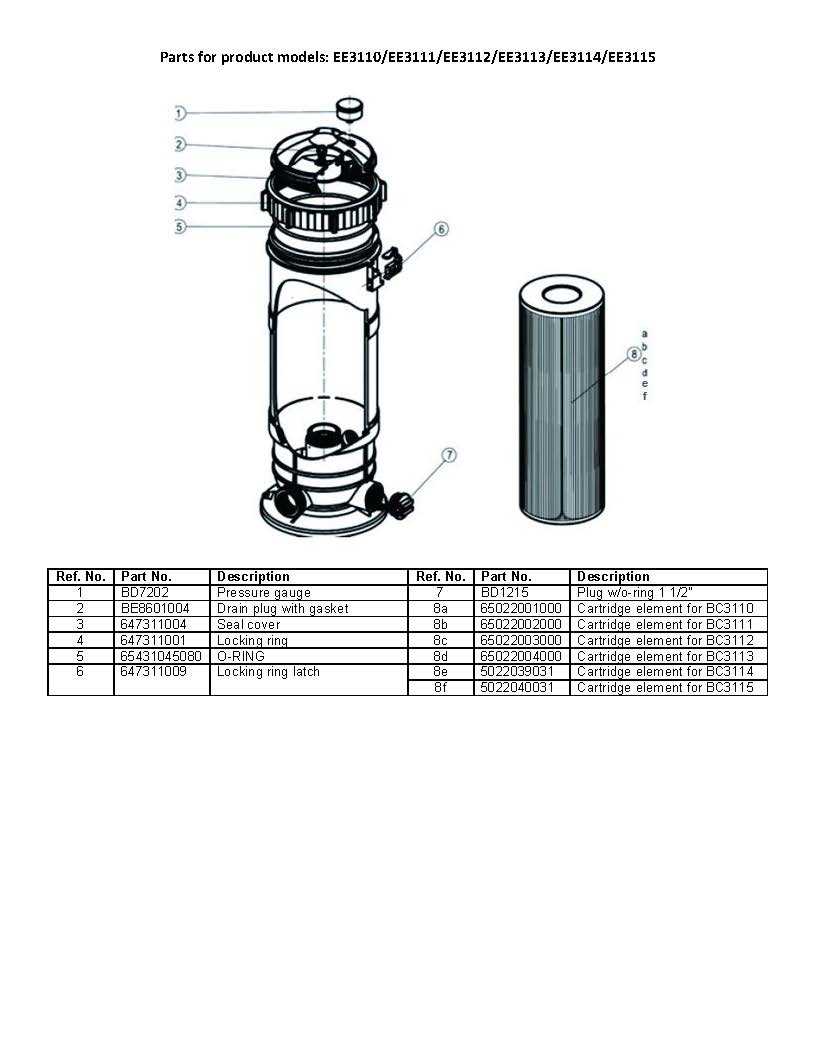

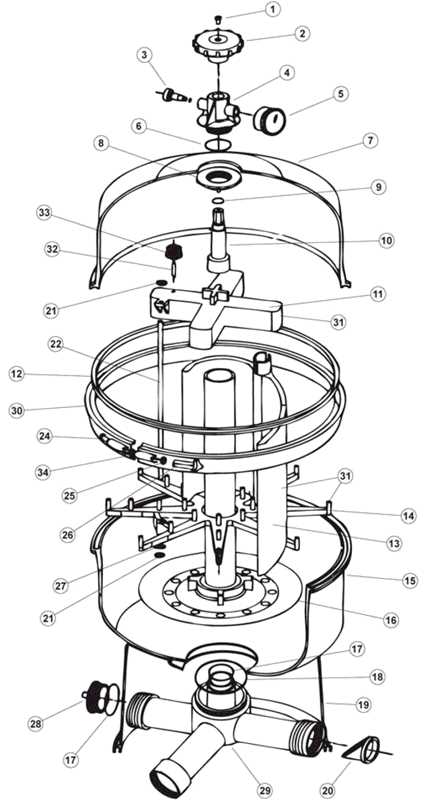

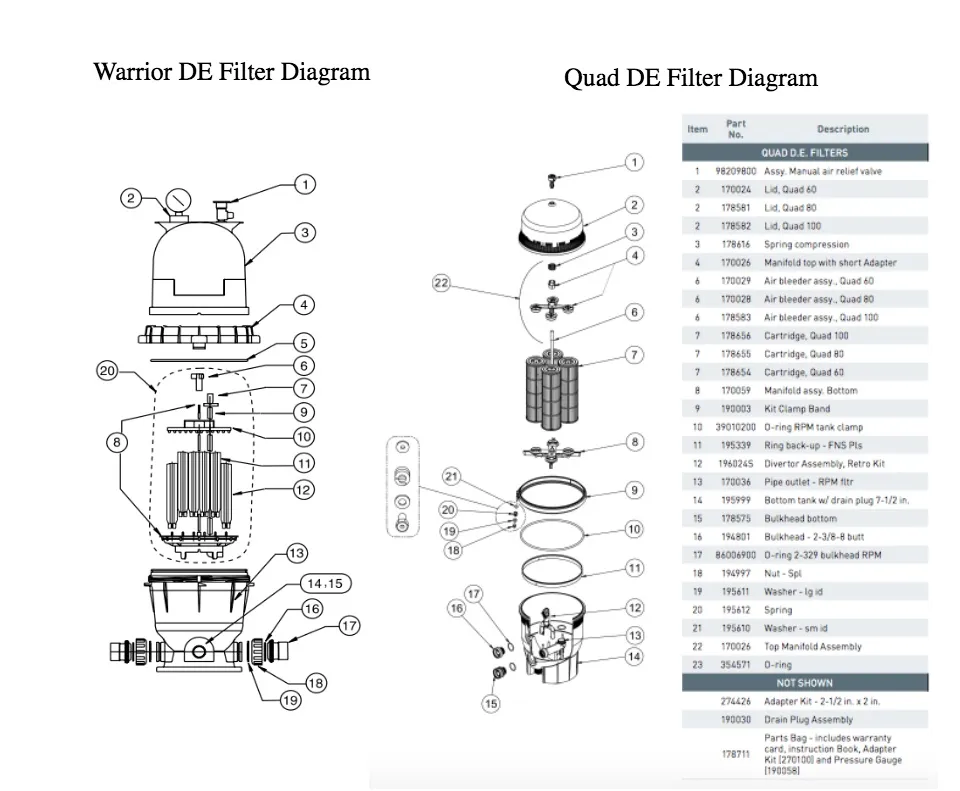

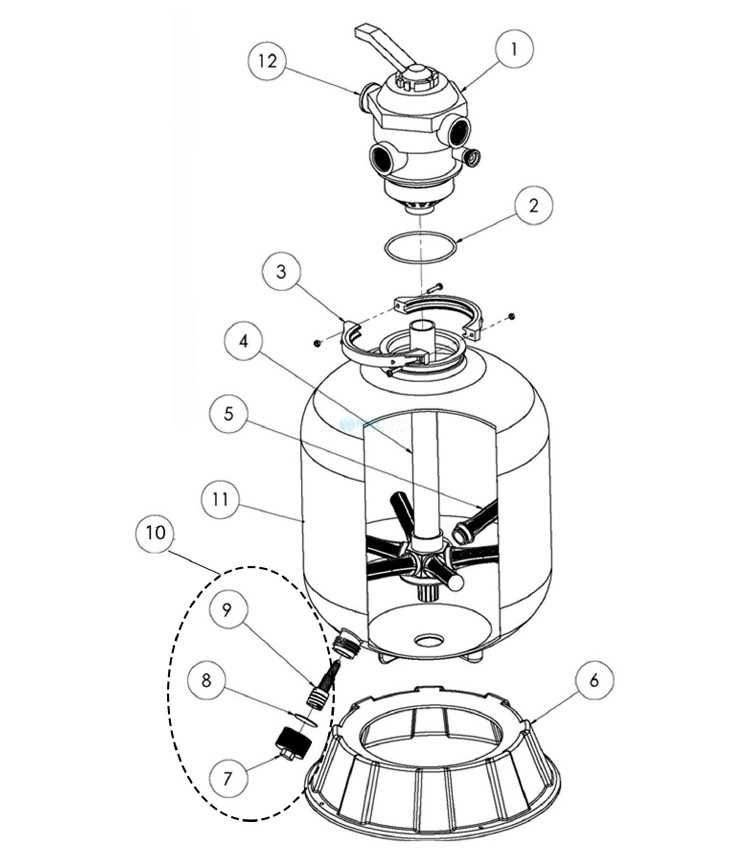

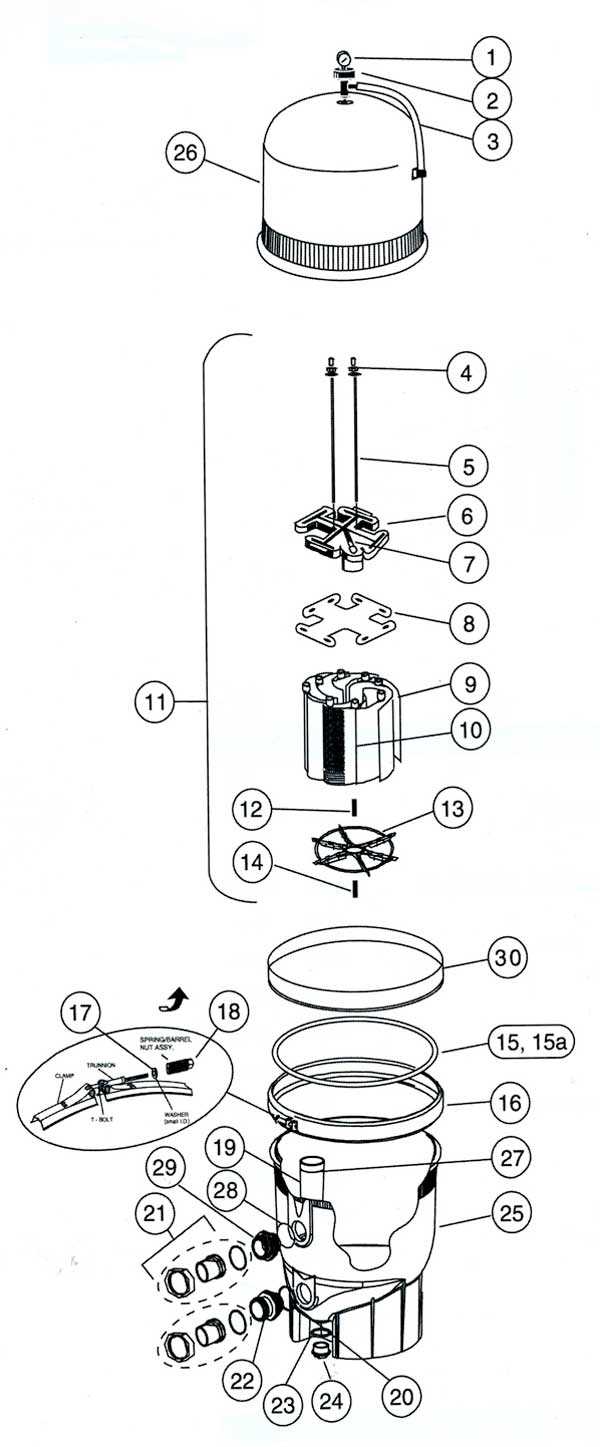

Main Components of Pentair DE Filters

The essential components of a DE system are designed to ensure effective operation and maintenance of water quality. Each element plays a crucial role in the overall functioning, contributing to both the filtration process and system longevity.

- Grid Assembly: This is the heart of the system, where the main cleaning process takes place. The grids capture fine particles, allowing only clean water to pass through.

- Manifold: Positioned at the top or bottom, this part distributes the flow of water across the grids evenly, ensuring efficient filtration.

- Tank Body: The outer shell that houses the internal components. It must withstand high pressure and is typically constructed from durable materials.

- Multiport Valve: A versatile control point that directs water flow. It allows you to switch between various modes such as cleaning, filtering, or backwashing.

- Air Relief Valve: Releases trapped air from the system, preventing pressure buildup and ensuring smooth operation.

- Pressure Gauge: This tool monitors the pressure

How to Identify Filter Parts

Understanding the components of your cleaning system is essential for efficient maintenance. Each element plays a specific role in the overall function, and recognizing them helps ensure everything works smoothly. By learning to differentiate these elements, you can troubleshoot issues and maintain performance with ease.

Examining Key Components

Begin by familiarizing yourself with the primary sections of your system. Look for the central unit, where most of the work happens, and note any adjoining elements that assist in keeping the flow uninterrupted.

- Main housing: This is the core of the setup, containing the most critical features.

- Circulation elements: These ensure that the movement is consistent throughout the system.

- Seals and connections: Small but vital, these ensure no leaks occur during operation.

Step-by-Step Identification

- Turn off the system and allow it to settle.

- Carefully disassemble, noting where each piece fits within the structure.

Replacing Worn-Out Filter Elements

Over time, essential components within your system will experience natural wear and tear. This degradation can reduce the overall efficiency and affect the quality of performance. Identifying when these parts need to be replaced is crucial for maintaining optimal operation and ensuring a clean, safe environment. Proper maintenance and timely renewal of these elements are key to extending the life of the system and avoiding costly repairs in the future.

Before beginning any replacement process, make sure you are familiar with the structure of the equipment and have all necessary tools ready. Always turn off the system and release any pressure before disassembling. Carefully remove the old, worn components and inspect them for any signs of damage that may have occurred during usage. Once inspected, replace them with new, compatible parts that meet the system’s specifications.

After installation, it’s important to reassemble the equipment correctly and ensure all connections are secure. Once re

Understanding Filter Grids and Their Function

The core of any effective water cleaning system lies in the ability to separate debris from the flow, ensuring clean and clear results. One of the most essential elements in achieving this is a specialized structure designed to trap unwanted particles while allowing the purified liquid to pass through. Understanding how these structures operate is key to maintaining optimal performance.

The Role of Grids in the System

Grids act as the primary medium responsible for capturing small and large impurities. They are arranged in a way that maximizes surface area, making them highly efficient in managing the overall clarity of the liquid. These grids need to be properly maintained, as their efficiency directly impacts the overall performance of the system.

- Enhances the separation process by trapping particles of various sizes.

- Increases the surface area for a more thorough cleaning cycle.

- Ensures longevity and efficiency when kept in good condition.

- Use high-quality media to ensure proper filtration.

- Monitor water quality regularly to adjust chemical balances as needed.

- Keep the surrounding area clean to prevent debris from entering the system.

- Train users on the correct operating procedures to minimize errors.

- Compatibility: Ensure that the new component matches the specifications of your existing setup to avoid issues with installation and functionality.

- Quality: Look for products made from durable materials that can withstand harsh conditions, which will prolong the lifespan of your equipment.

- Efficiency: Choose options that promote better filtration performance to enhance water clarity and reduce the need for frequent maintenance.

- Cost: While price is a factor, consider the long-term benefits of investing in higher-quality components that may save you money on repairs and replacements in the future.

- Manufacturer Reputation: Research different brands and read customer reviews to find reliable sources known for quality and customer service.

Best Practices for Maintaining DE Filters

Regular upkeep of diatomaceous earth systems is essential for optimal performance and longevity. Implementing effective maintenance strategies not only enhances efficiency but also helps prevent costly repairs and replacements. Understanding the key components and their care is crucial for achieving a clean and safe environment.

Routine Maintenance Checklist

Establishing a consistent maintenance schedule is vital for ensuring the reliability of your diatomaceous earth setup. The following table outlines a recommended checklist for routine care:

Task Frequency Inspect the tank for leaks Monthly Replace diatomaceous earth media Every 4-6 weeks Clean the internal components Every 3 months Check pressure gauges Weekly Examine hoses and connections Monthly Tips for Optimal Performance

In addition to routine tasks, consider the following recommendations to maximize the effectiveness of your diatomaceous earth systems:

Common Issues with Pentair Filters

Maintaining a clean and efficient water system is crucial for optimal performance. However, users often encounter various challenges that can affect functionality and longevity. Identifying these common complications can help in troubleshooting and ensuring smooth operation.

One frequent problem is the accumulation of debris and contaminants, which can lead to reduced flow and pressure. Over time, this buildup can cause blockages, affecting the overall efficiency of the system. Regular inspection and cleaning are essential to prevent such issues.

Another concern is the wear and tear of components due to prolonged usage. Parts may become brittle or damaged, leading to leaks or malfunctions. It’s important to monitor the condition of individual elements and replace them as needed to maintain system integrity.

Additionally, improper installation can result in operational difficulties. Misalignment or inadequate sealing may cause inefficiencies, requiring careful attention during setup. Ensuring that all connections are secure and properly positioned can mitigate these issues.

Lastly, fluctuations in water chemistry can also pose challenges. Changes in pH levels or chemical concentrations may impact performance, necessitating regular water testing and adjustments to maintain optimal conditions. Understanding these factors is key to achieving reliable operation.

Choosing the Right DE Filter Replacement

Selecting the appropriate replacement for a diatomaceous earth system is crucial for maintaining optimal performance and ensuring water quality. Various factors influence this decision, including compatibility, efficiency, and longevity of the components involved.

Here are some key considerations to help you make an informed choice:

By taking these elements into account, you can confidently select a replacement that will enhance the efficiency and effectiveness of your water treatment system.