The efficient functioning of an internal combustion engine relies on various mechanisms that control the flow of air into the combustion chamber. One crucial aspect of this system involves several interconnected elements that ensure the proper mixture of air and fuel. These components work in harmony to optimize performance and enhance fuel efficiency, playing a vital role in overall vehicle operation.

Recognizing the significance of these elements can provide valuable insights into engine performance. A well-designed arrangement allows for precise adjustments in airflow, which is essential for maintaining the desired power output and responsiveness. Moreover, understanding how these components interact can aid in troubleshooting potential issues that may arise over time.

In this section, we will explore the various elements involved in air regulation systems, highlighting their functions and relationships. This knowledge can empower vehicle owners and technicians alike, enabling them to make informed decisions regarding maintenance and repairs.

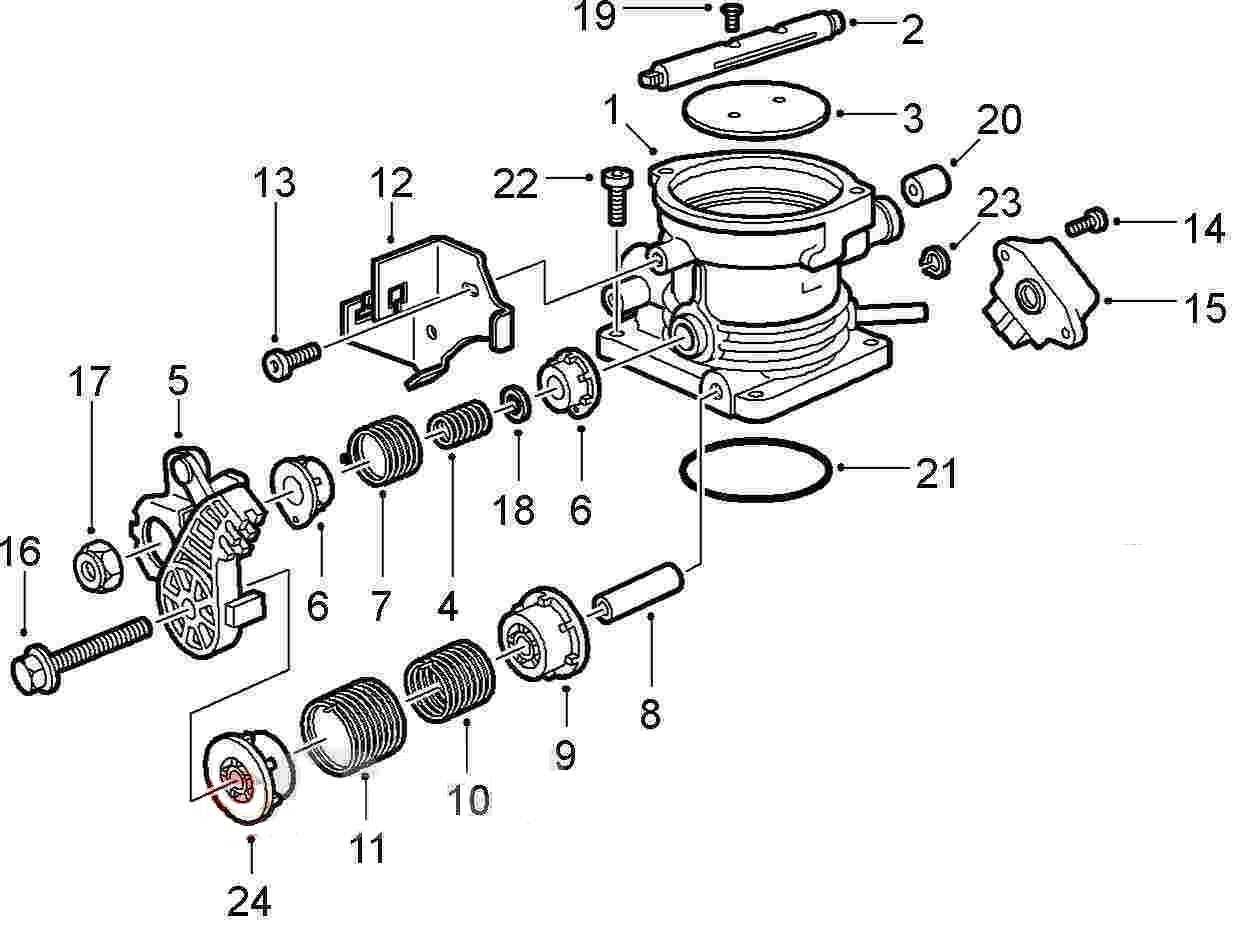

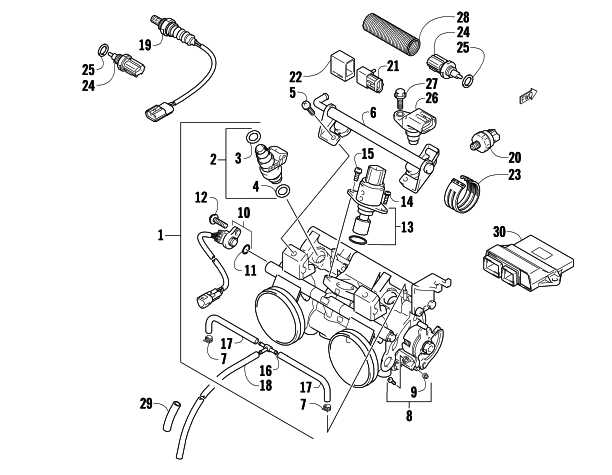

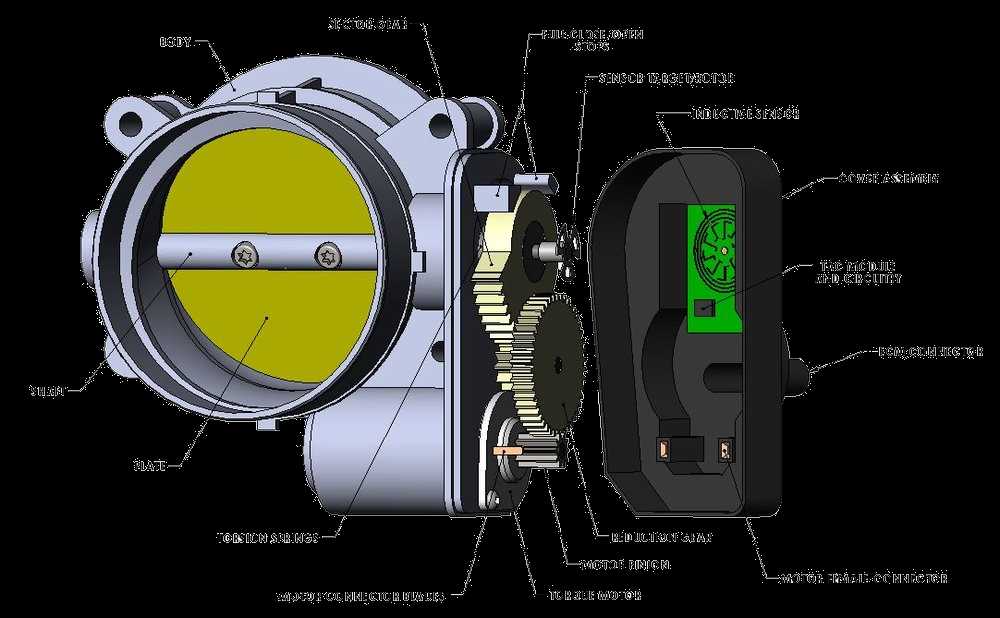

This section aims to provide a comprehensive overview of the various elements that comprise the mechanism responsible for regulating air intake in an internal combustion engine. Understanding these components is crucial for both maintenance and troubleshooting.

Key Elements of the Mechanism

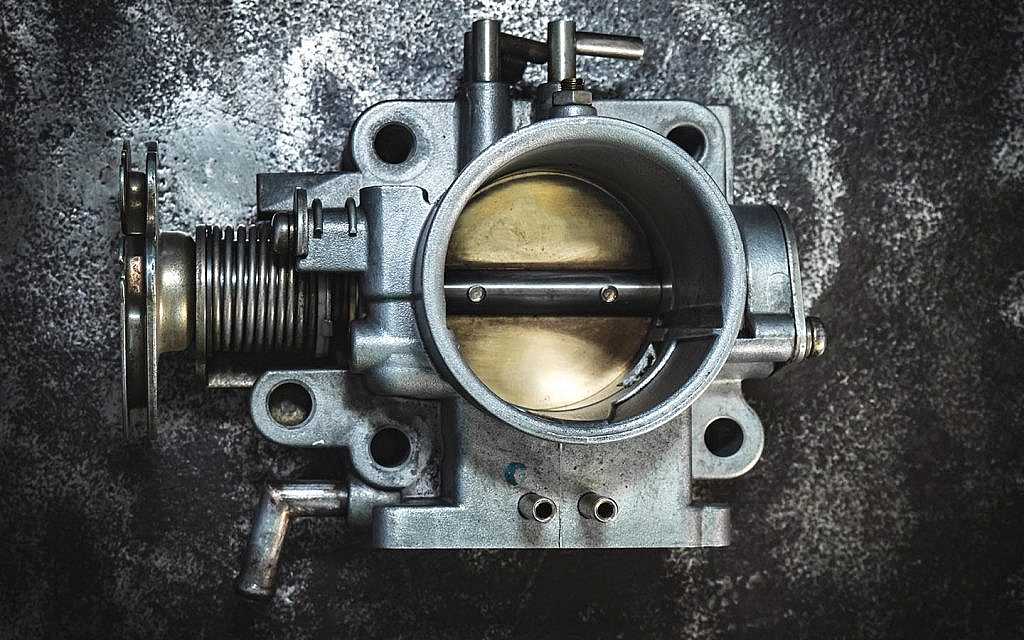

- Air Intake Valve

- Throttle Position Sensor

- Butterfly Valve

- Spring Mechanism

- Housing Assembly

Functionality and Importance

Each of these components plays a significant role in ensuring optimal performance and efficiency. The air intake valve controls the amount of air entering the engine, while the throttle position sensor provides feedback for accurate adjustments. The butterfly valve, aided by the spring mechanism, manages the flow of air based on driver input.

- Ensure proper functioning for engine responsiveness.

- Regular maintenance can prevent issues related to air intake.

- Understanding these components aids in effective troubleshooting.

Functionality of Throttle Body Parts

The components within an air control mechanism play a crucial role in regulating the flow of air into an engine, significantly influencing its performance and efficiency. Understanding the functions of these elements is essential for both automotive enthusiasts and professionals. Each component works together to ensure optimal air intake, enabling precise fuel-air mixture control for better combustion.

Key Components and Their Roles

Various elements within the assembly are responsible for managing airflow and enhancing engine responsiveness. For instance, a pivotal component is responsible for modulating the air intake volume based on the driver’s input. This modulation is essential for maintaining the engine’s performance under different operating conditions.

Importance of Proper Functioning

Effective operation of these components directly impacts engine efficiency, throttle response, and overall vehicle performance. Any malfunction can lead to issues such as poor acceleration, reduced fuel efficiency, or increased emissions. Regular maintenance and timely inspection of these elements are vital for ensuring that the engine operates smoothly and effectively.

Common Issues with Throttle Assemblies

Components responsible for controlling air intake in engines often encounter a variety of operational challenges. These issues can affect the overall performance, causing inconsistent responses or even complete system failure. Regular maintenance and timely detection of such malfunctions are key to ensuring smooth engine operation.

| Issue | Possible Cause | Solution | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inconsistent acceleration | Accumulation of dirt or carbon deposits | Clean the mechanism or replace affected parts | ||||||||||||||||||||

| Engine stalling | Faulty sensor or damaged wiring | Inspect and repair or replace sensors and electrical connections | ||||||||||||||||||||

| Poor fuel efficiency | Improper alignment or stuck valve | Adjust or replace the affected components

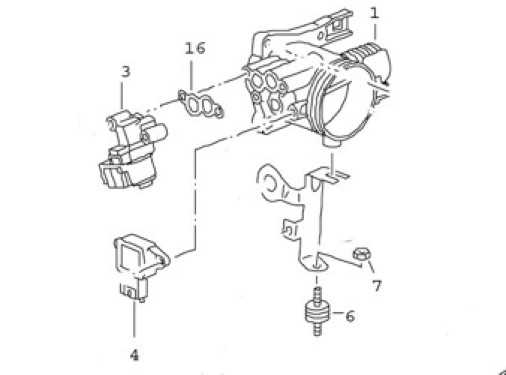

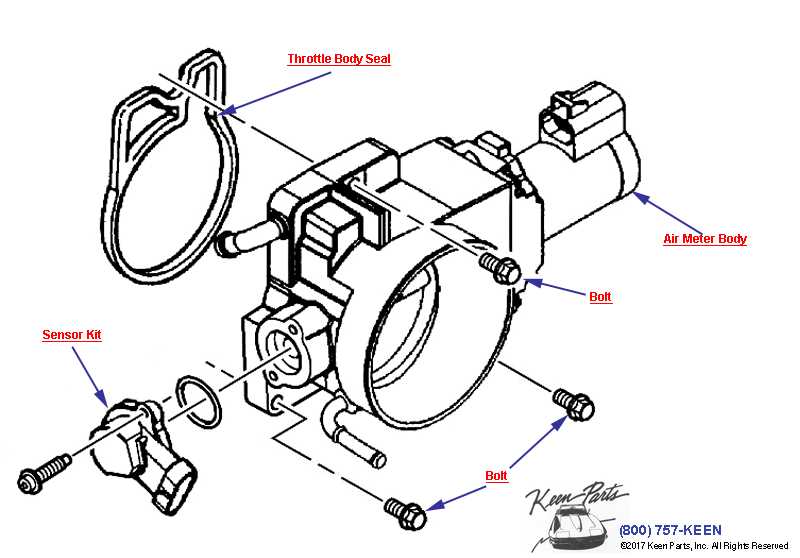

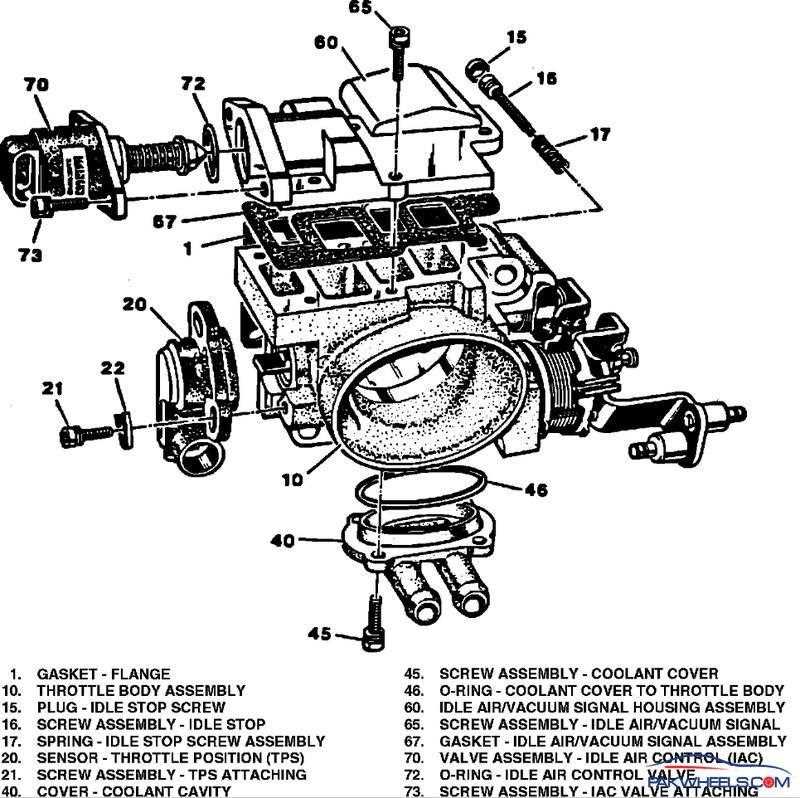

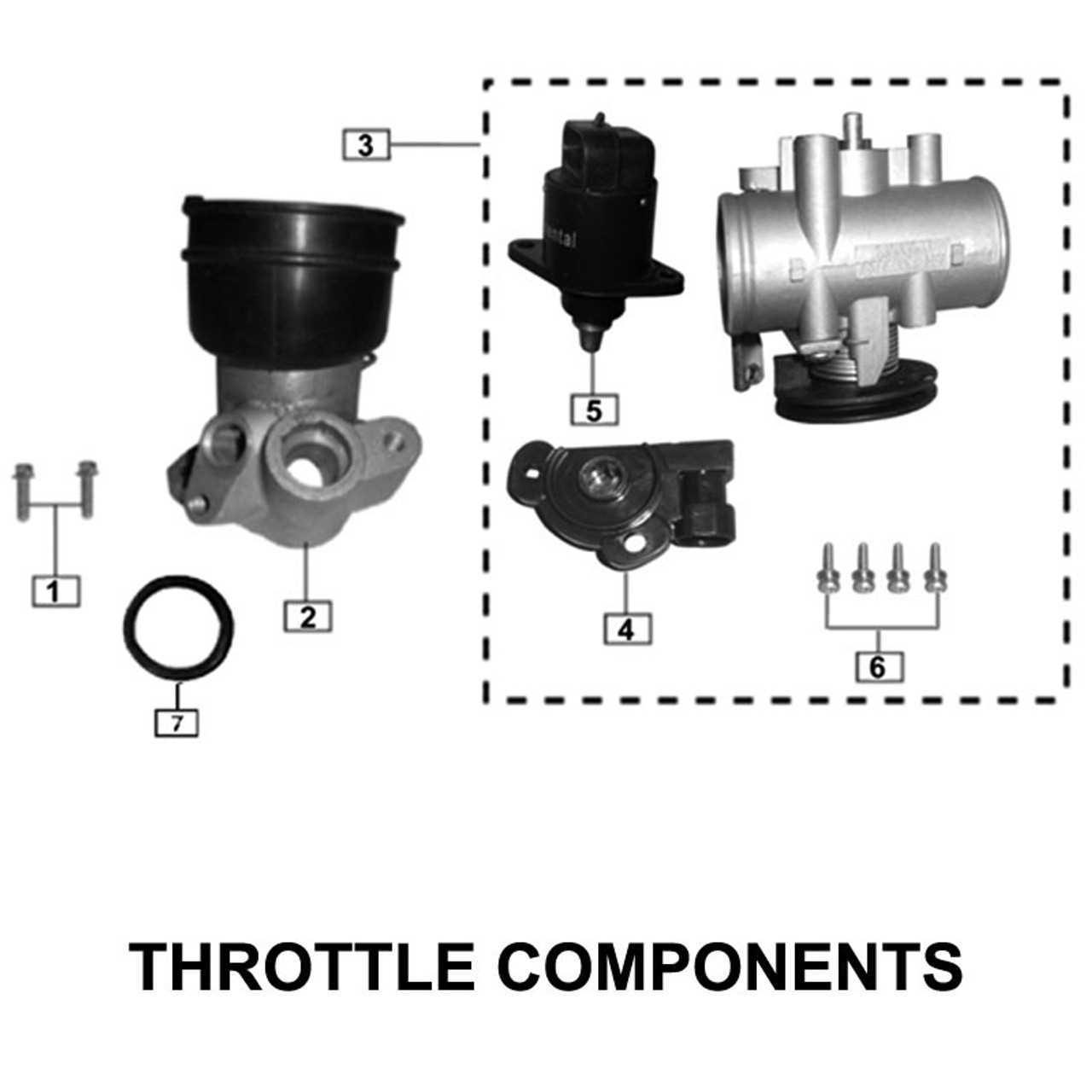

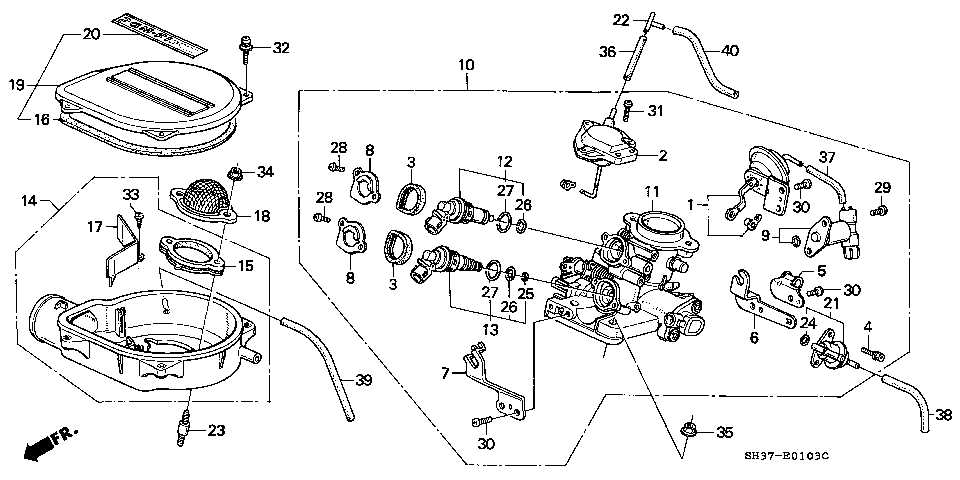

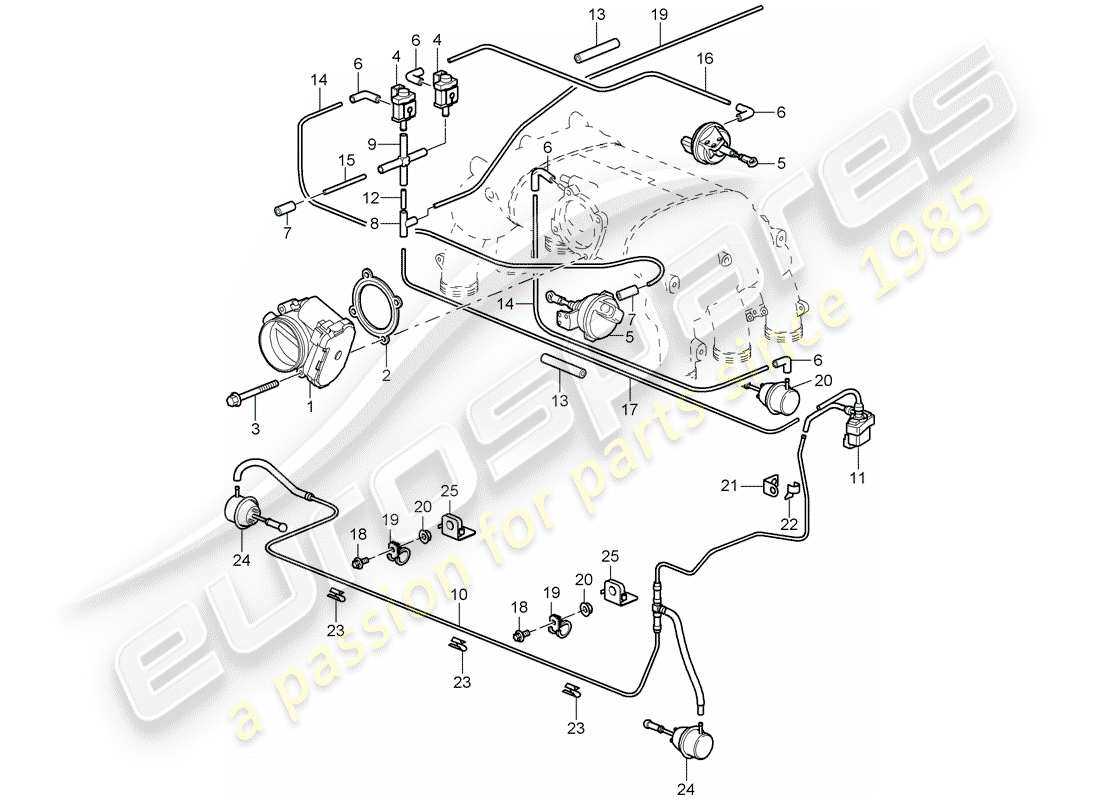

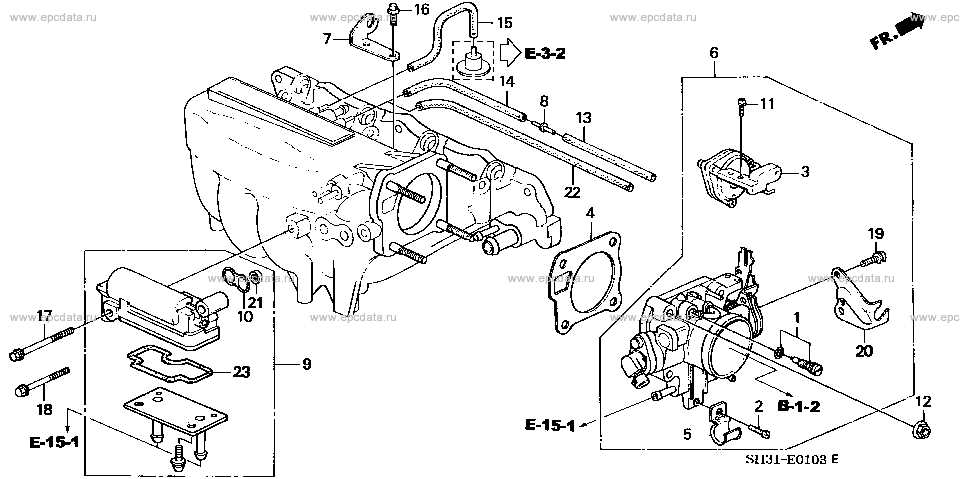

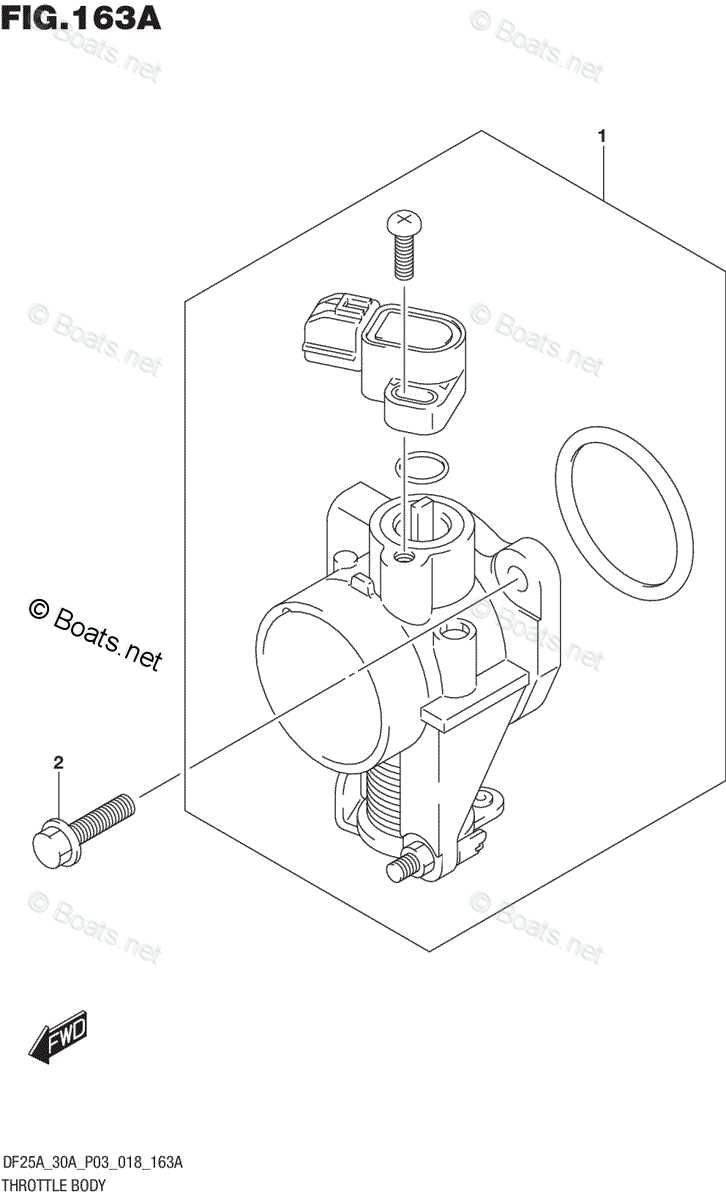

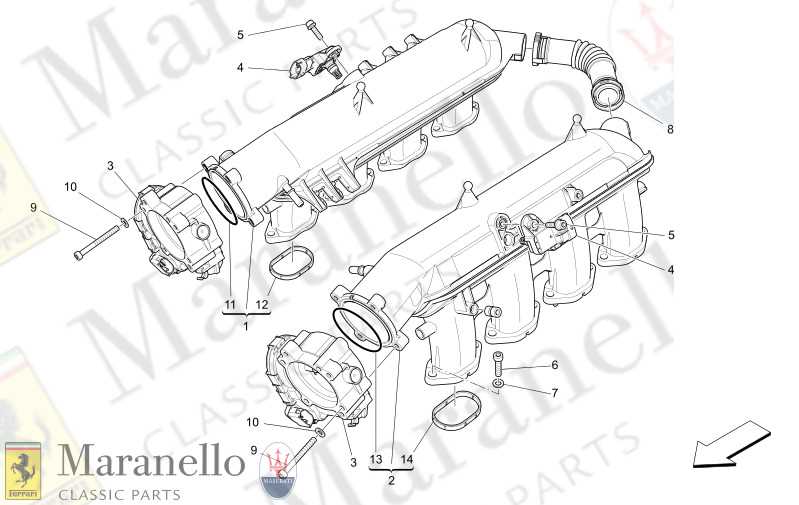

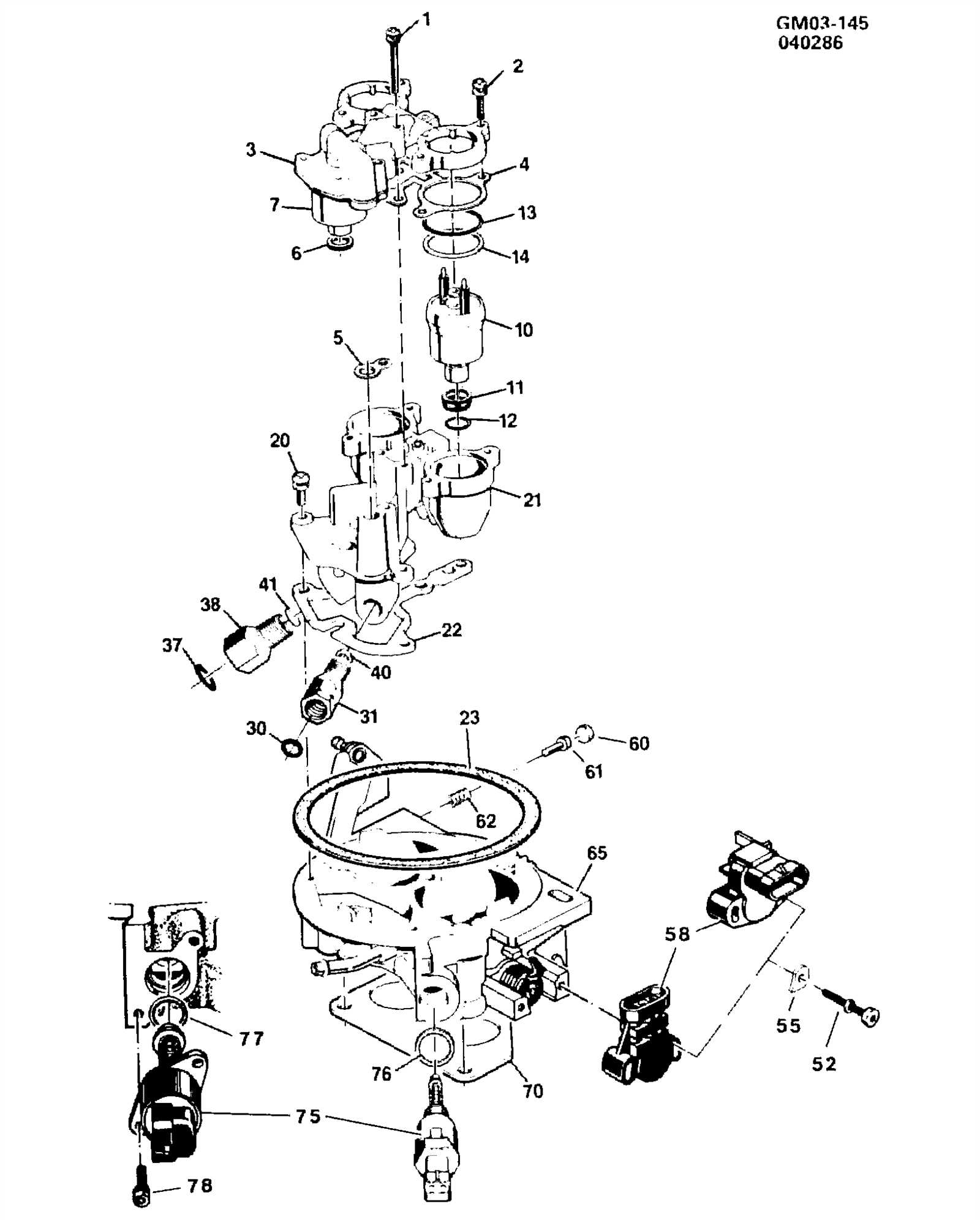

Identifying Throttle Body Parts in Diagrams

Understanding the components of an air intake assembly is crucial for effective maintenance and troubleshooting. By examining illustrations, one can recognize various elements that contribute to the overall functionality of the system. Familiarity with these components aids in diagnosing issues and facilitating repairs. Common Components and Their Functions

The following table outlines typical elements found within an air intake assembly, along with their respective roles:

Tips for Accurate Identification

When reviewing illustrations, it’s beneficial to cross-reference the components with a service manual for precise identification. Pay attention to the shape, size, and placement of each element, as these features can significantly aid in accurate recognition. Maintenance Tips for Throttle Bodies

Proper upkeep of the air intake system is essential for optimal engine performance. Regular care ensures smooth airflow, prevents carbon buildup, and enhances fuel efficiency. Implementing simple maintenance practices can significantly extend the lifespan of this crucial component. Regular InspectionFrequent checks help identify potential issues before they escalate. Look for signs of wear or damage and ensure that connections are secure. Consider the following:

Cleaning Procedures

Keeping the intake system clean is vital for performance. Accumulated deposits can hinder airflow and affect efficiency. Follow these steps:

Types of Throttle Body Designs

Various configurations of air control mechanisms play a crucial role in regulating engine performance. Each design offers unique advantages, adapting to different engine requirements and driving conditions. Understanding these configurations is essential for optimizing efficiency and power delivery. Single Plate Design

The single plate mechanism is among the most common configurations, characterized by a single flap that controls airflow. This design provides a straightforward solution for many vehicles, ensuring reliable performance and ease of maintenance. Its simplicity often translates to reduced manufacturing costs, making it a popular choice in budget-friendly models. Multi-Plate Design

In contrast, the multi-plate configuration incorporates multiple flaps to enhance airflow management. This design is particularly beneficial for high-performance engines, allowing for more precise control of air intake. By enabling faster response times and improved throttle response, it contributes significantly to the overall driving experience, especially in sports and racing vehicles. Impact of Throttle Body on Performance

The component responsible for regulating airflow into the engine plays a crucial role in enhancing overall vehicle efficiency. Its design and functionality significantly influence the engine’s responsiveness and power output, thereby affecting the driving experience. A well-functioning unit ensures optimal air intake, leading to better combustion and improved performance metrics. Influence on AccelerationEfficient airflow management directly impacts the acceleration capabilities of the vehicle. When the airflow is unrestricted and properly calibrated, the engine can produce more power, resulting in quicker acceleration times. Conversely, a malfunctioning unit can cause delays in response, hindering the vehicle’s ability to reach desired speeds swiftly. Fuel Efficiency ConsiderationsThe efficiency of air intake also relates to fuel consumption. A properly functioning component allows for precise mixing of air and fuel, ensuring the engine operates at its peak efficiency. This balance minimizes fuel wastage and contributes to better mileage, making it essential for both performance enthusiasts and those focused on economy. Upgrading Your Throttle Body System

Enhancing the air intake system can significantly improve engine performance and responsiveness. Upgrading the components involved in this process allows for better airflow and more efficient combustion, ultimately leading to enhanced power and efficiency. By focusing on key modifications, enthusiasts can experience noticeable gains in vehicle dynamics. When considering enhancements, it’s essential to explore various options that can be integrated into the existing setup. This may include high-performance airflow devices, advanced sensor technologies, and optimized control mechanisms. Each of these modifications contributes to a more efficient air supply, which is crucial for maximizing engine potential.

|