The intricacies of a vehicle’s steering mechanism play a crucial role in its overall performance and handling. Each element contributes to the seamless operation of the system, ensuring stability and control during movement. Gaining insight into these essential components can enhance one’s appreciation for automotive engineering.

Visual representation of these elements allows enthusiasts and professionals alike to better comprehend their functions and interrelations. By examining how these segments work together, one can delve into the ultimate mechanics of vehicle dynamics. Such knowledge not only aids in maintenance but also empowers informed decisions regarding upgrades and repairs.

In this exploration, we will highlight the significance of each component, illustrating their respective roles within the assembly. Through a detailed examination, we aim to provide a clearer understanding of the underlying principles that govern the performance of these critical systems.

Understanding Front Axle Components

Grasping the intricacies of key elements in the vehicle’s steering mechanism is essential for anyone interested in automotive mechanics. These components work in harmony to provide stability, control, and safety during movement. Familiarity with their functions and relationships is crucial for effective maintenance and repair.

Key Components and Their Functions

The main elements involved in this system include bearings, hubs, and shafts, each playing a vital role. Bearings facilitate smooth rotation, while hubs connect wheels to the assembly, ensuring stability. Shafts transmit torque, allowing for efficient power transfer from the engine to the wheels.

Maintenance and Care

Regular inspection of these components is necessary to prevent wear and tear. Identifying signs of damage early can enhance vehicle performance and safety. Proper lubrication and timely replacements are essential practices that contribute to the longevity of the entire mechanism.

Key Functions of Front Axles

The components responsible for connecting the wheels to the vehicle play a crucial role in ensuring stability and handling. These elements not only facilitate movement but also contribute to the overall safety and performance of the automobile.

One primary function is weight distribution, which helps maintain balance during driving. This balance is essential for smooth maneuverability and responsiveness, particularly when navigating turns or uneven terrain. Additionally, these structures absorb shocks from the road, enhancing ride comfort and protecting other vehicle systems from damage.

Another vital aspect is steering control. These assemblies enable precise handling by allowing the wheels to pivot, ensuring accurate direction changes. This functionality is particularly important during sudden stops or quick maneuvers, where responsiveness can greatly affect safety.

Moreover, they contribute to braking efficiency. The connection between the wheels and braking systems ensures that the vehicle can come to a halt swiftly and securely, making them indispensable for effective stopping power.

In summary, these crucial components are integral to maintaining control, comfort, and safety, underscoring their importance in automotive engineering and design.

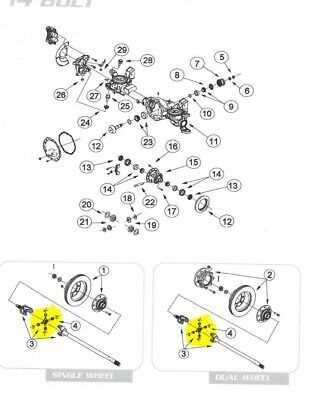

Common Types of Front Axles

In the realm of automotive design, various configurations play a crucial role in vehicle dynamics and handling. Understanding the diverse styles of these components can significantly enhance one’s knowledge of automotive engineering and maintenance.

Independent Suspension Systems

Independent designs allow each wheel to move independently, providing superior ride quality and handling. This configuration minimizes body roll during turns, enhancing stability. Advantages include improved traction and comfort, making them popular in modern vehicles.

Solid Beam Structures

Solid beam configurations feature a single, rigid unit that connects both wheels. This setup offers durability and strength, often found in heavier vehicles. Benefits include lower maintenance costs and a simpler design, but it may compromise ride quality compared to independent systems.

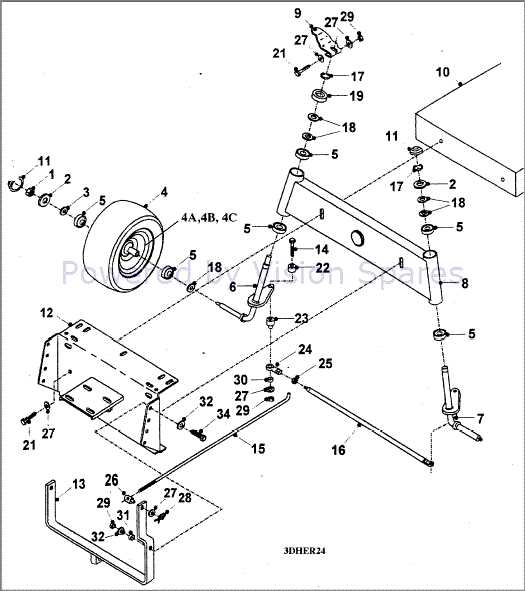

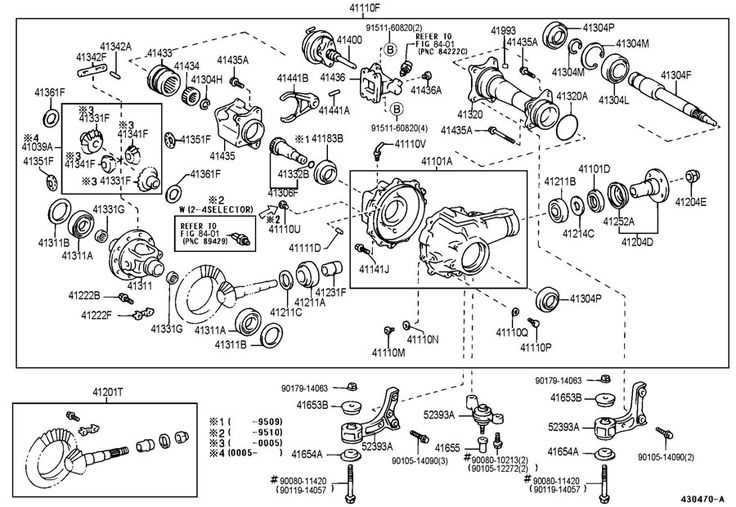

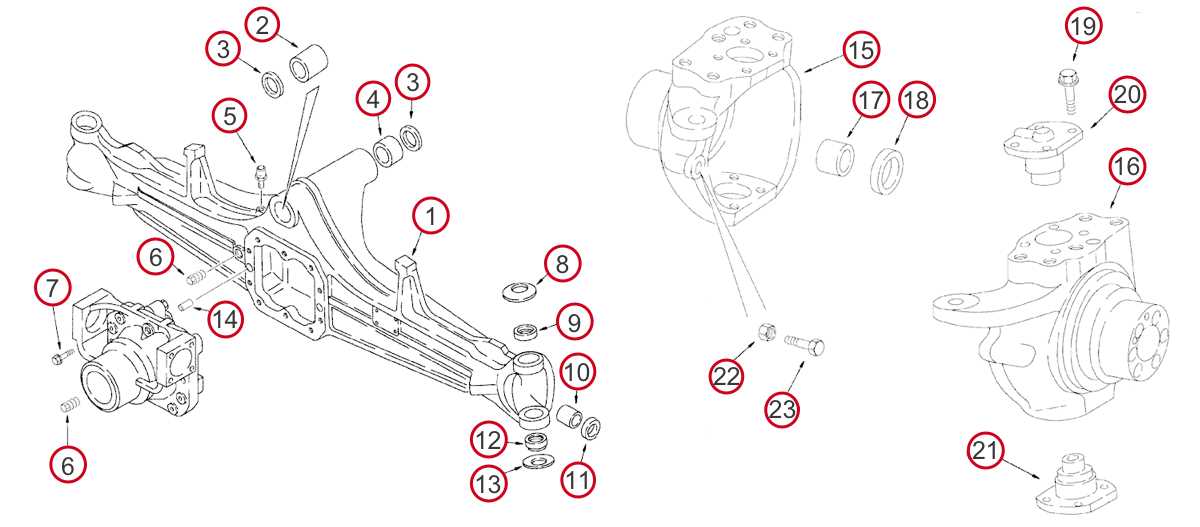

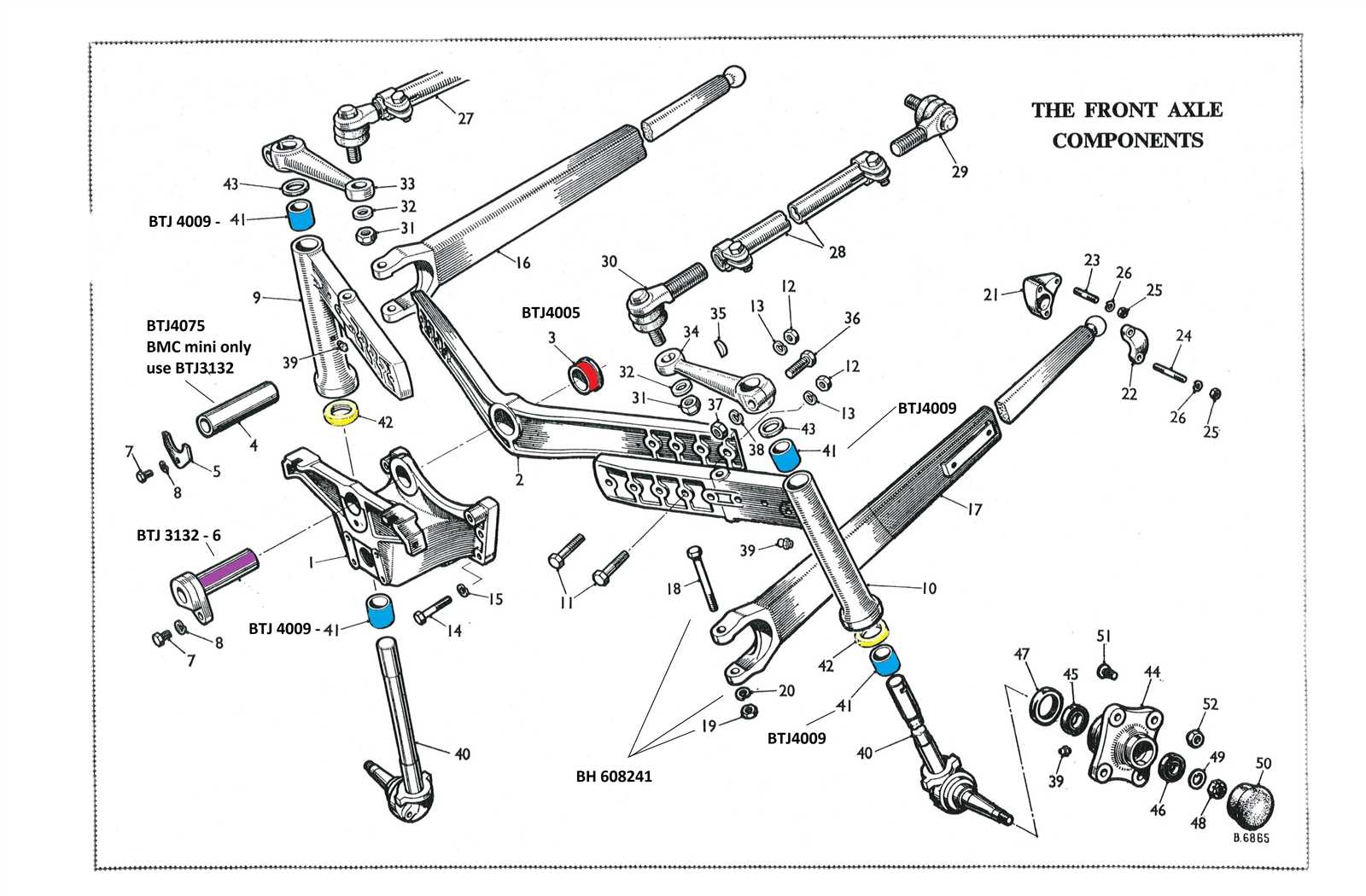

Components in Front Axle Diagrams

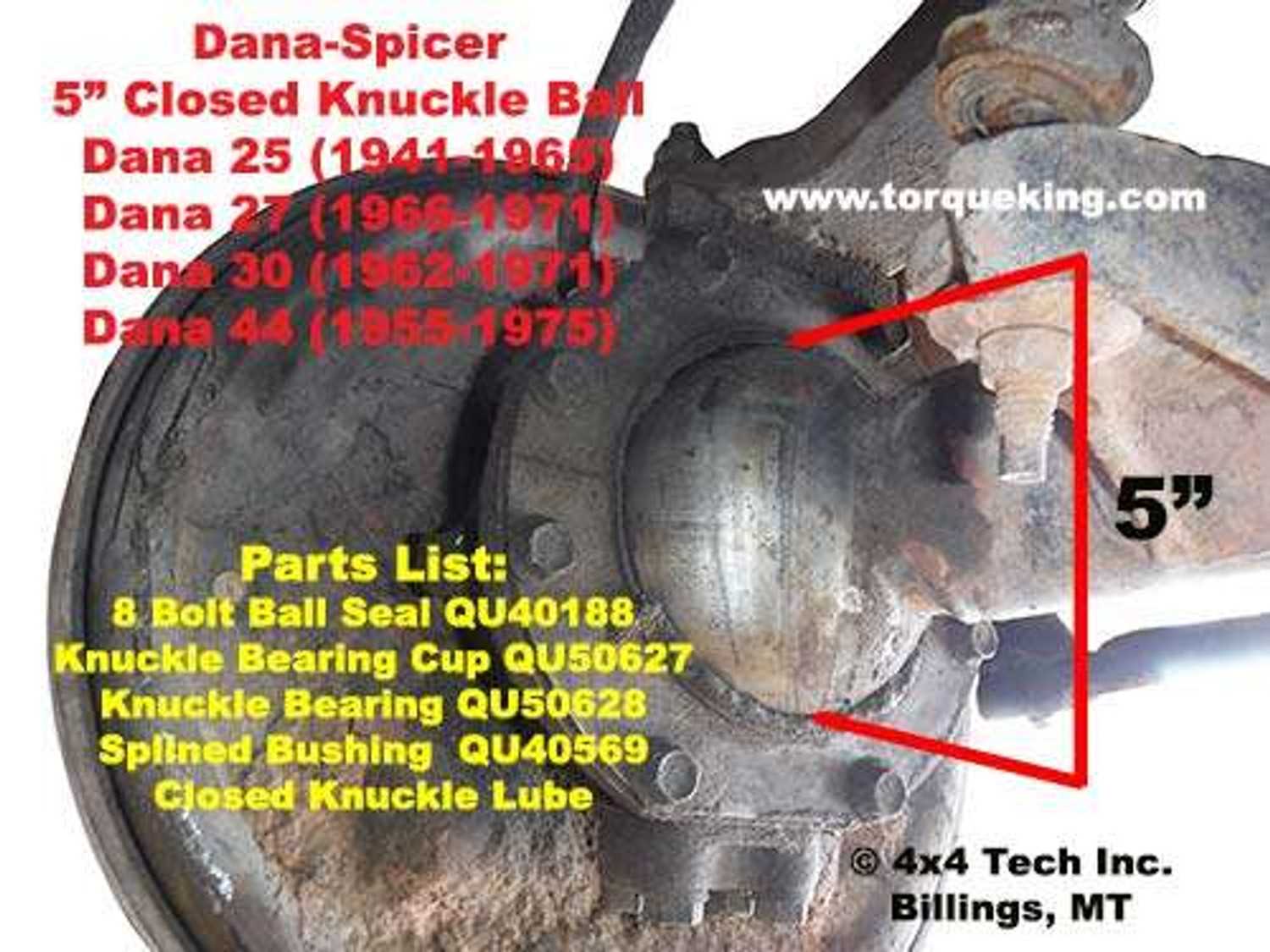

Understanding the essential elements that contribute to vehicle steering and suspension systems is crucial for both maintenance and repair. Each component plays a specific role in ensuring safety, stability, and overall performance. This section will explore the various items commonly depicted in visual representations of these systems.

- Hub Assembly: This is the central part where the wheel is mounted, allowing for rotation.

- Steering Knuckle: This connects the wheel to the suspension and provides pivot points for steering.

- Control Arms: These link the chassis to the wheel assembly, helping absorb road shocks.

- Spindle: This component connects the hub and the steering knuckle, playing a key role in wheel alignment.

- Ball Joints: These spherical bearings allow for flexible movement between different parts, essential for steering functionality.

- CV Joints: Constant velocity joints facilitate smooth power transfer to the wheels, accommodating varying angles of rotation.

Incorporating these elements into maintenance routines ensures optimal vehicle performance and longevity. Familiarity with each component aids in diagnosing issues and understanding repair needs.

Maintenance Tips for Front Axles

Regular upkeep of crucial components in your vehicle ensures optimal performance and safety. Addressing wear and tear promptly can prevent significant issues down the line. Here are essential tips to keep these vital elements in top shape.

1. Regular Inspections: Conduct routine checks to identify signs of damage or excessive wear. Look for any unusual noises or vibrations while driving.

2. Lubrication: Ensure that moving parts are adequately lubricated to reduce friction and prevent premature wear. Use manufacturer-recommended grease for best results.

3. Alignment Checks: Maintain proper alignment to ensure even tire wear and improve handling. Misalignment can lead to further complications and decreased fuel efficiency.

4. Component Replacement: Replace worn or damaged elements immediately to avoid cascading failures. Keep an eye on bushings and bearings, as these are often underappreciated.

5. Seasonal Maintenance: Adjust your maintenance routine according to seasonal conditions. Cold weather can affect performance, so inspect regularly during harsh conditions.

By following these guidelines, you can enhance the longevity and reliability of your vehicle’s essential systems.

Signs of Front Axle Problems

Identifying issues with the suspension components that connect the wheels to the vehicle is crucial for safe driving. Problems in this area can lead to various symptoms, which, if noticed early, can prevent more serious damage and costly repairs.

Unusual Noises: One of the first indicators of trouble is hearing strange sounds, such as clunks or grinding, especially when turning or going over bumps. These noises can suggest worn-out bearings or joints.

Vibration: If you experience excessive shaking or vibrations while driving, it may indicate misalignment or damage in the connection system. This can lead to poor handling and instability on the road.

Uneven Tire Wear: Inspecting your tires regularly can reveal uneven wear patterns. This often points to issues with the suspension elements, affecting the vehicle’s stability and grip.

Difficulty Steering: A lack of responsiveness or increased effort required to steer can signal a problem with the connection system. This not only compromises comfort but also poses significant safety risks.

Visible Damage: Regularly inspecting the components for signs of wear, such as cracks, leaks, or rust, can help you catch potential problems before they escalate. Ensuring these elements are in good condition is essential for overall vehicle performance.

Addressing these signs promptly can enhance safety and prolong the life of your vehicle, ensuring a smoother and more reliable driving experience.

Impact of Front Axles on Handling

The design and configuration of the leading suspension components play a crucial role in a vehicle’s overall performance and maneuverability. These elements directly influence steering responsiveness, stability during cornering, and the overall driving experience. A well-engineered assembly ensures optimal weight distribution and control, enhancing safety and comfort for the driver and passengers.

Precision in the alignment of these components can greatly affect the vehicle’s behavior on the road. When properly calibrated, they provide better traction and reduce the likelihood of skidding or loss of control. This precision not only improves handling but also extends the lifespan of the tires by ensuring even wear.

Additionally, flexibility in the system allows for improved absorption of shocks and vibrations, which contributes to a smoother ride. The interaction between the steering mechanism and these crucial elements ultimately determines how a vehicle reacts to various driving conditions, making it essential for manufacturers to focus on their design and function.

Choosing Quality Front Axle Parts

Selecting high-quality components for your vehicle’s steering mechanism is crucial for ensuring optimal performance and safety. The right elements contribute significantly to the overall driving experience, enhancing both stability and control.

Durability is a key factor to consider when evaluating options. Opting for robust materials can prevent premature wear and tear, ultimately saving you time and money on replacements.

Additionally, compatibility with your vehicle’s specific model is essential. Mismatched components can lead to serious mechanical issues, affecting not just performance but also safety. Always consult manufacturer specifications to ensure a perfect fit.

Finally, consider the reputation of the brand. Trusted manufacturers often provide warranties and customer support, giving you peace of mind with your purchase. Investing in quality will lead to long-term satisfaction and reliability on the road.