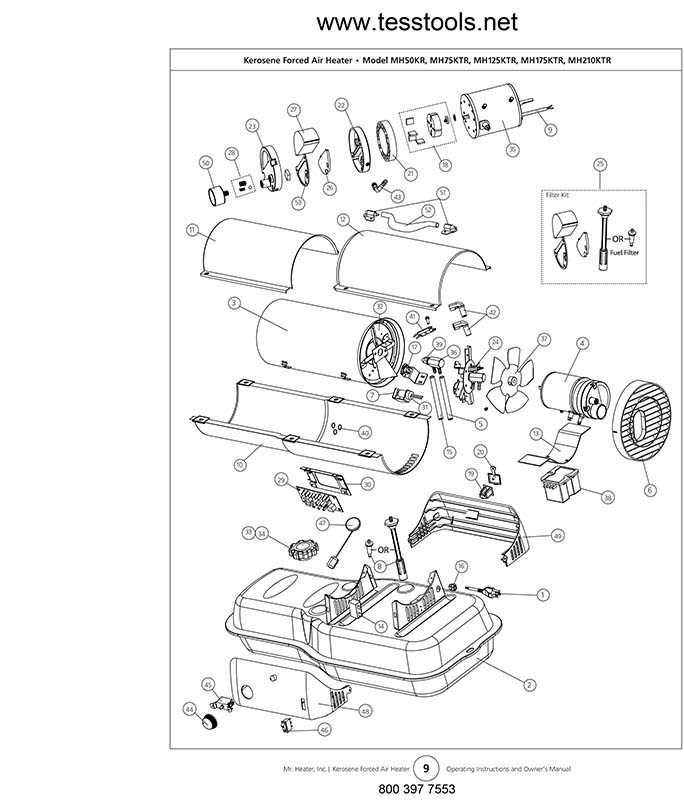

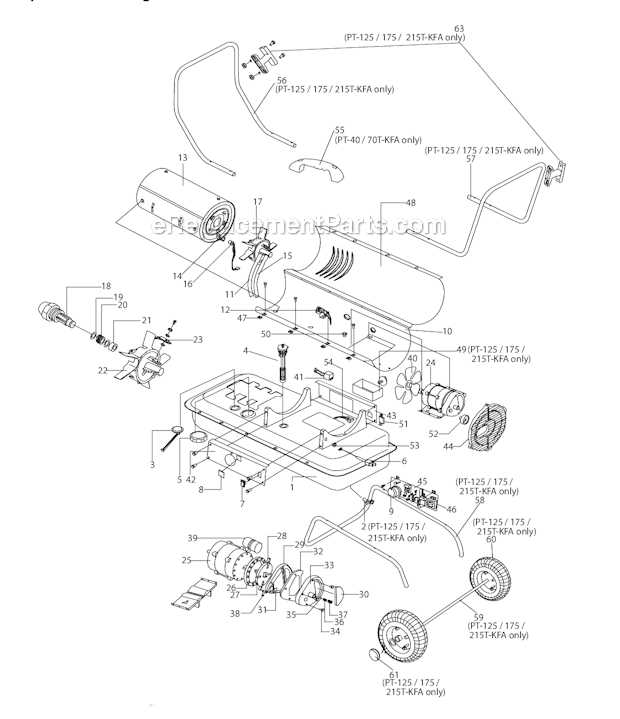

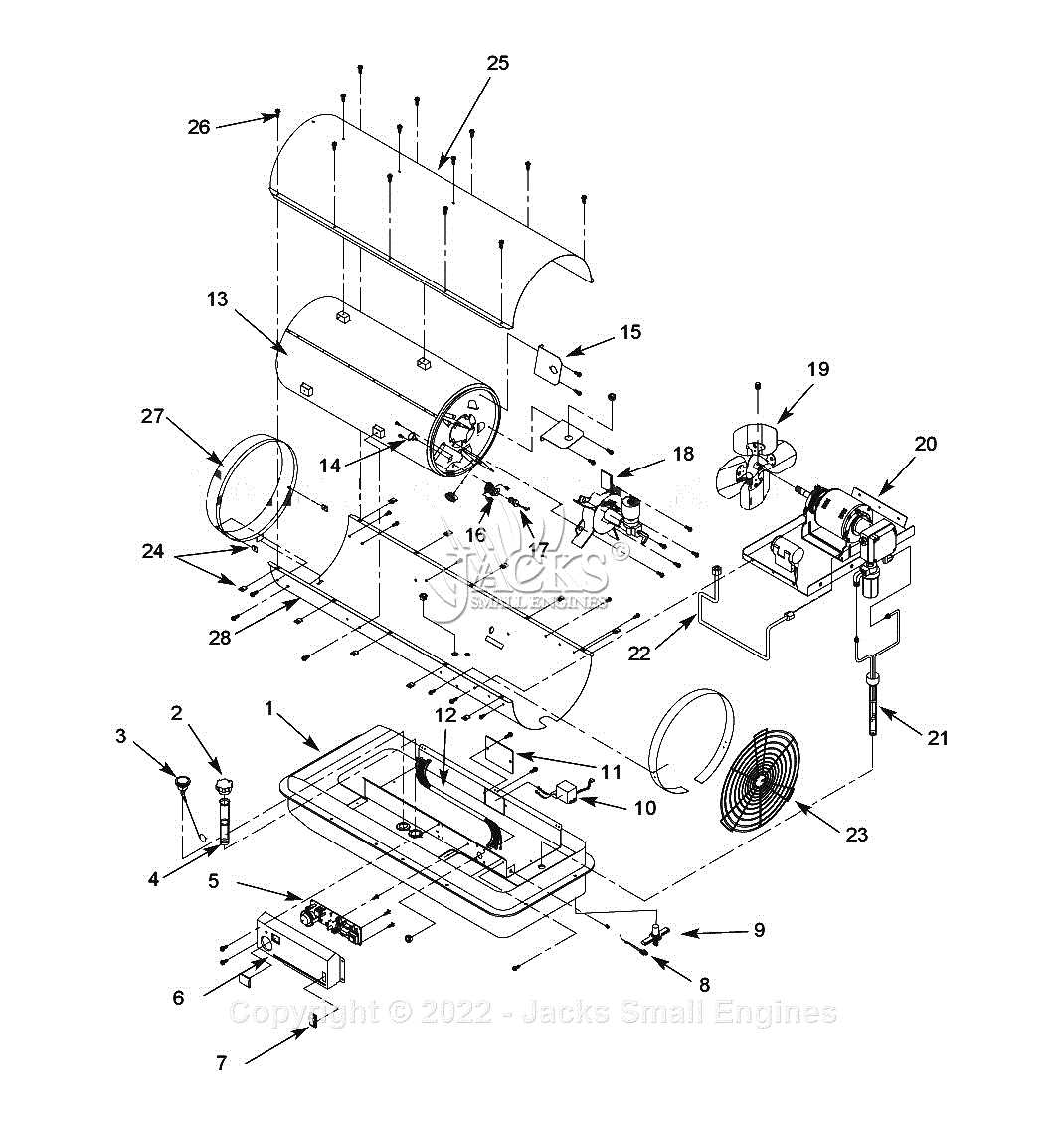

In the realm of temperature control, a thorough comprehension of the essential elements involved is crucial for optimal performance. Each component plays a pivotal role in ensuring efficiency and reliability, contributing to the overall functionality of the system. By exploring these individual elements, users can enhance their knowledge and facilitate better maintenance.

Visual aids can significantly improve one’s understanding of how these components interact and function together. A well-organized representation allows for quick identification and troubleshooting, ultimately leading to a more informed approach to repairs and upkeep. This knowledge empowers users to tackle potential issues before they escalate.

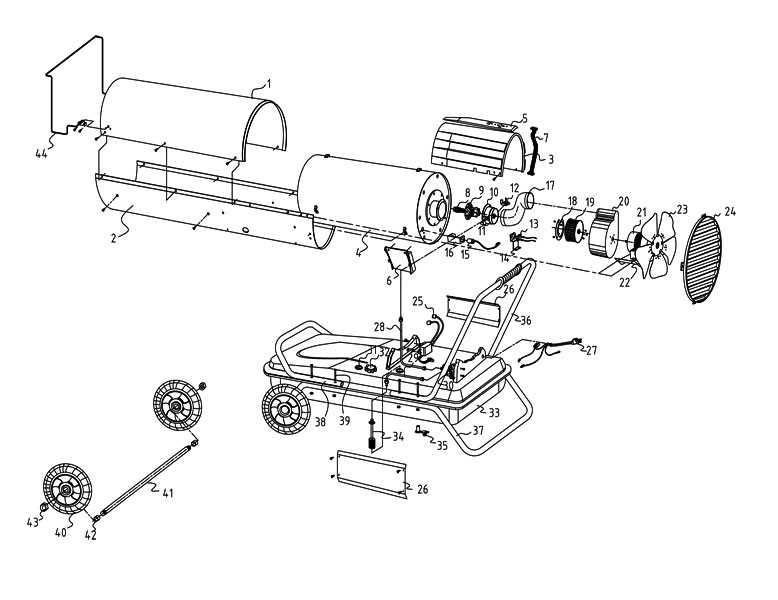

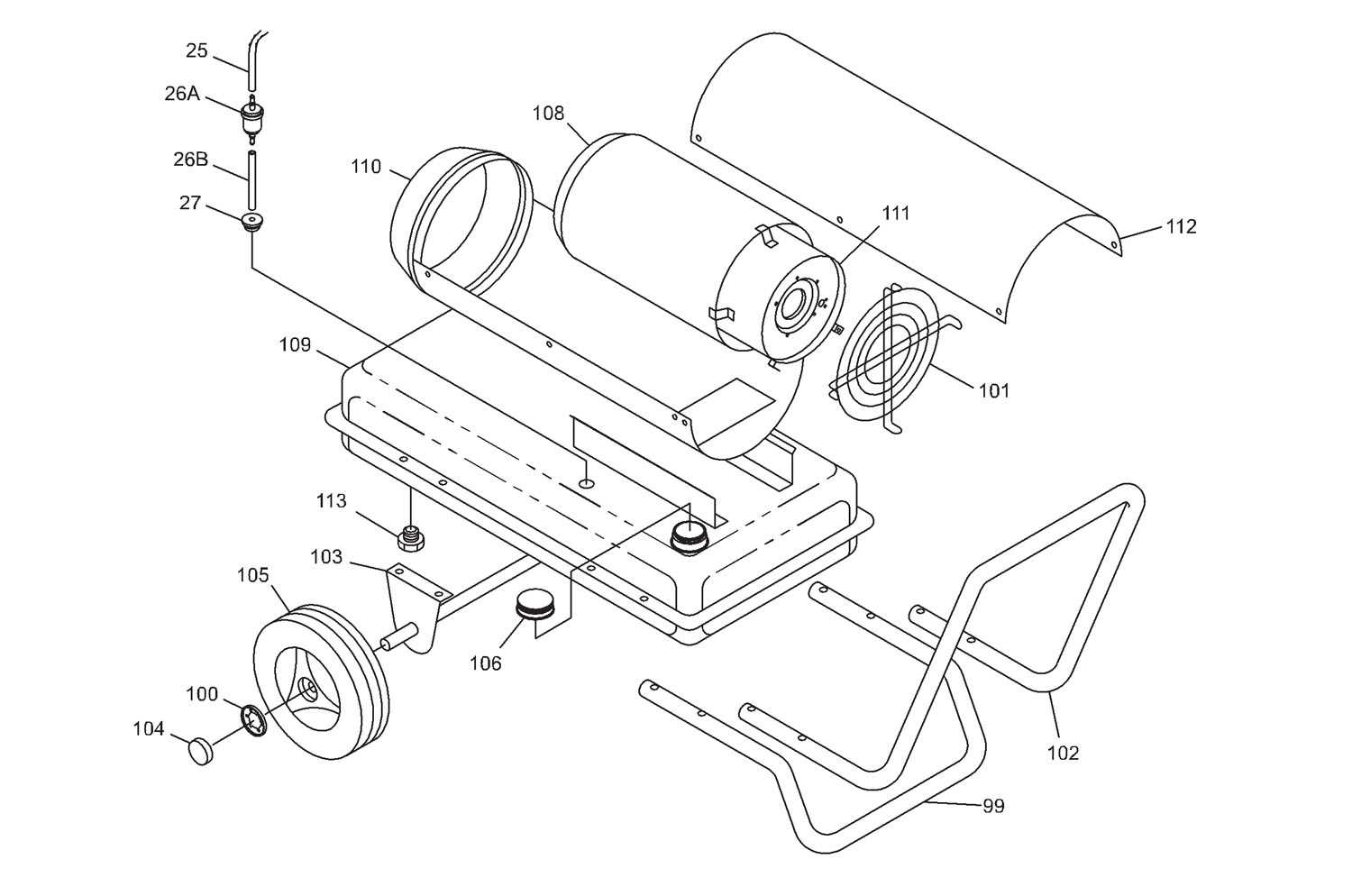

To delve deeper into the inner workings of your heating apparatus, examining the layout of these vital parts becomes essential. Understanding their arrangement and connections provides insight into the ultimate operation of the unit, ensuring that it runs smoothly and efficiently throughout its lifespan.

Understanding Reddy Heater Components

Familiarity with the various elements that contribute to the operation of portable warmth appliances is essential for effective maintenance and troubleshooting. Each component plays a vital role in ensuring optimal functionality and efficiency.

Key elements include:

- Ignition System: Responsible for initiating combustion, ensuring reliable start-up.

- Fuel Tank: Stores the necessary energy source, impacting run time and performance.

- Fan Mechanism: Circulates warm air, enhancing heat distribution within the environment.

- Thermostat: Regulates temperature, allowing for user comfort and energy conservation.

- Exhaust System: Safely directs combustion byproducts away from the appliance, ensuring safe operation.

Each of these components interacts with the others to create a seamless heating experience. Understanding their functions can aid in identifying issues and prolonging the lifespan of the unit.

Common Issues with Heater Parts

Understanding the typical challenges that arise with heating appliances can significantly enhance their longevity and efficiency. Regular maintenance and awareness of potential malfunctions can prevent costly repairs and ensure optimal performance. Below are some common complications that users may encounter.

Frequent Problems

- Insufficient warmth being produced.

- Unusual noises during operation.

- Unresponsive controls or settings.

- Foul odors emanating from the unit.

Possible Causes

- Clogged filters leading to reduced airflow.

- Electrical faults affecting power supply.

- Worn-out components causing inefficiency.

- Improper assembly or installation issues.

Identifying these challenges early can help in taking appropriate actions to maintain functionality and comfort.

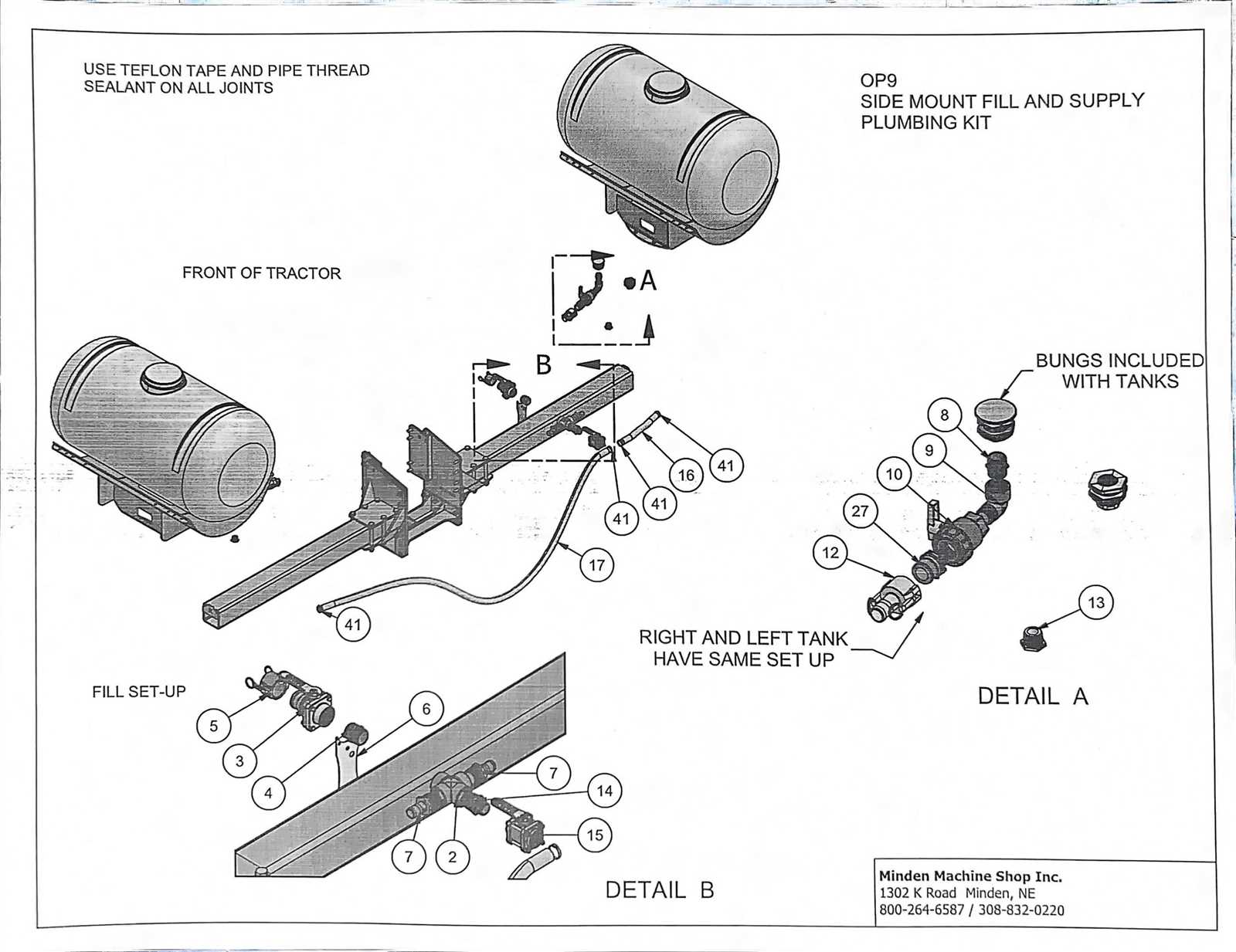

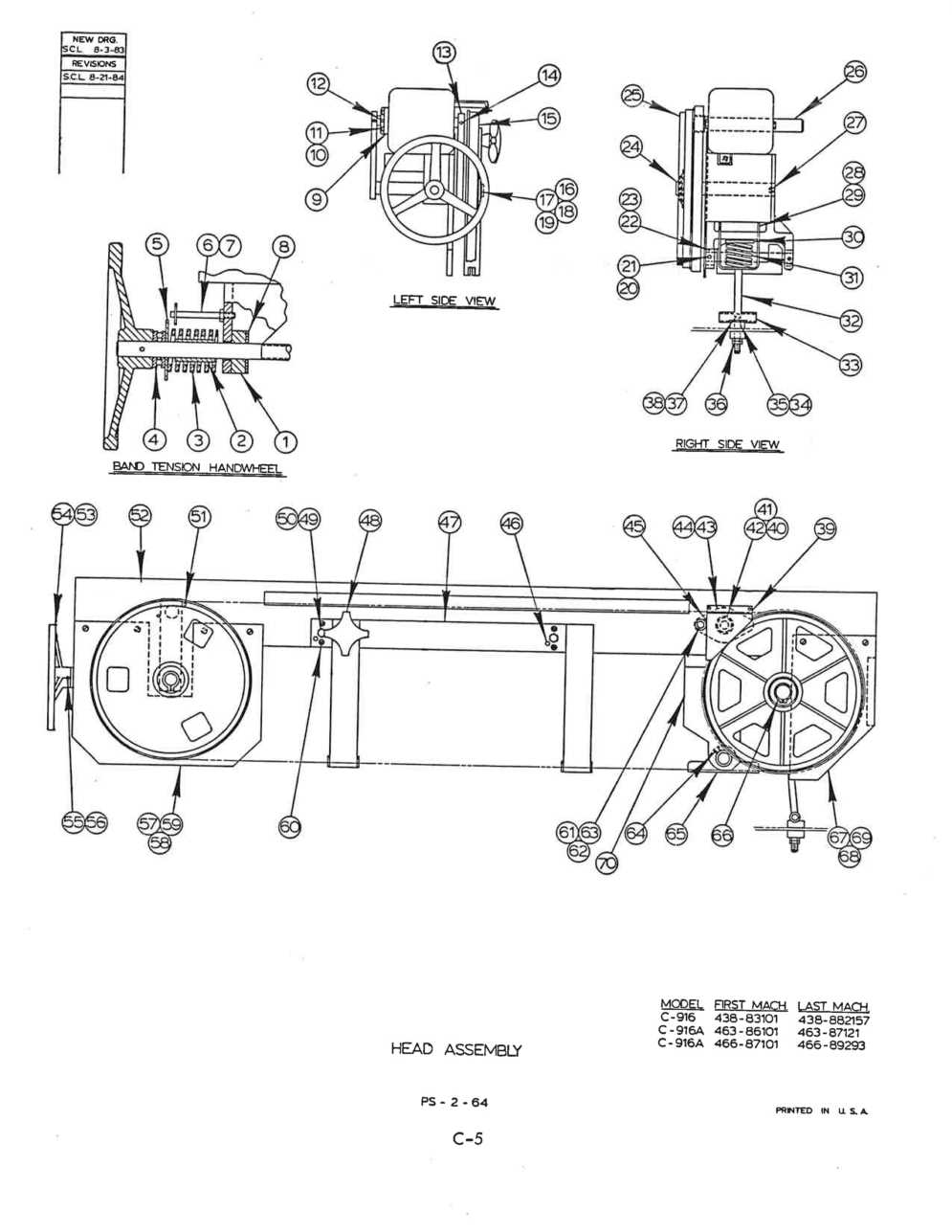

Importance of a Parts Diagram

Understanding the assembly of complex systems is crucial for maintenance and repair. Visual representations provide clarity, ensuring that users can identify components effectively. This understanding enhances efficiency and reduces the likelihood of errors during servicing.

| Benefits | Description |

|---|---|

| Clarity | Visual aids help simplify intricate structures, making them easier to comprehend. |

| Efficiency | Streamlined identification of elements speeds up the repair process. |

| Accuracy | Reduces mistakes by providing a reference for correct assembly and disassembly. |

| Training | Serves as a valuable tool for educating new technicians about the system. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. This guide provides clear instructions to help you maintain your system effectively. By following these steps, you can prevent potential issues and enhance performance.

Preparation

- Gather necessary tools: screwdrivers, wrenches, and cleaning supplies.

- Ensure the unit is powered off and disconnected from any electrical sources.

- Review the manufacturer’s manual for specific guidelines related to your model.

Maintenance Steps

- Inspect external surfaces for any signs of wear or damage.

- Clean the exterior using a soft cloth to remove dust and debris.

- Check all connections and fasteners to ensure they are secure.

- Examine internal components for signs of corrosion or buildup.

- Replace any worn or damaged parts as necessary.

- Test the system by powering it on and observing its operation.

By adhering to this maintenance routine, you can keep your equipment running smoothly and efficiently, ultimately saving time and resources in the long run.

Identifying Faulty Components

Recognizing malfunctioning elements in a heating system is crucial for ensuring efficient operation and safety. Identifying these issues early can prevent further damage and costly repairs. Here are some common indicators of defective components.

- Unusual Noises: Listen for grinding, popping, or hissing sounds, which may indicate wear or malfunction.

- Inconsistent Performance: Fluctuations in temperature or an inability to maintain desired levels can signal underlying problems.

- Visible Damage: Inspect for signs of corrosion, cracks, or burned areas on components.

- Odors: A burning smell or unusual scents may suggest overheating or electrical issues.

- Electrical Malfunctions: Check for tripped breakers or blown fuses, which can indicate electrical component failures.

After identifying symptoms, it’s essential to conduct a thorough examination of the system. Below are steps to systematically assess each element:

- Power off the unit to ensure safety during inspection.

- Remove access panels to expose internal components.

- Conduct visual inspections for any physical damage.

- Use a multimeter to test electrical components for continuity.

- Replace any faulty parts as needed, following manufacturer guidelines.

By diligently assessing and addressing issues, you can maintain optimal functionality and extend the life of your system.

Where to Find Replacement Parts

Locating components for your heating device can be essential for maintaining its efficiency and prolonging its lifespan. Several avenues exist for sourcing these crucial items, whether through direct manufacturers, local retailers, or online platforms. Understanding where to search can save you time and ensure you obtain the correct items for your specific model.

Online Retailers

One of the most convenient options is to explore online marketplaces. These platforms often feature a vast selection of components, catering to various models and brands. Popular websites provide user-friendly interfaces, making it easy to compare prices and read customer reviews.

Local Supply Stores

Your neighborhood supply stores may also stock essential components. Visiting these locations allows you to consult with knowledgeable staff who can assist in finding the right items and offer valuable advice on installation.

| Source Type | Examples | Pros | Cons |

|---|---|---|---|

| Online Marketplaces | Amazon, eBay | Wide selection, convenience | Shipping times, potential for incorrect items |

| Local Stores | Home Depot, Lowe’s | Immediate availability, expert assistance | Limited stock, higher prices |

DIY Repairs for Reddy Heaters

Taking on maintenance and fixes for your heating equipment can be both rewarding and cost-effective. Understanding the components and how they function will empower you to address common issues without the need for professional help. This section covers essential tips and tricks for performing repairs effectively and safely.

Common Issues and Solutions

Many issues arise due to wear and tear or improper usage. Here are some frequent problems along with their potential solutions:

| Problem | Solution |

|---|---|

| Unit fails to ignite | Check the fuel supply and ensure all connections are secure. Clean the ignition components if necessary. |

| Inconsistent heating | Inspect the airflow and clear any obstructions. Ensure that the fan is functioning properly. |

| Unusual noises | Examine the unit for loose screws or components. Tighten or replace as needed. |

Safety Precautions

Before starting any repairs, always prioritize safety. Disconnect the power source and allow the unit to cool down. Use protective gear and consult the user manual for specific instructions related to your model. Following these precautions will ensure a safe and successful repair process.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance tasks is crucial to prevent accidents and injuries. Following established guidelines can significantly reduce risks associated with handling equipment and performing repairs. Always prioritize safety to protect yourself and others involved.

Personal Protective Equipment

Utilizing personal protective gear is essential. Items such as gloves, goggles, and masks can shield you from potential hazards. Make sure to wear the appropriate attire to mitigate exposure to harmful substances and sharp components.

Work Environment

Maintaining a clean and organized workspace contributes to safety. Remove any unnecessary items and ensure good lighting to avoid tripping hazards. Additionally, proper ventilation is vital when working with chemicals or fuels to prevent inhalation of harmful fumes.