In the realm of outdoor maintenance, the effective functioning of various cleaning tools is paramount. A thorough grasp of their intricate assemblies can significantly enhance the user experience and efficiency of these machines. Knowing the arrangement of each segment not only aids in troubleshooting but also empowers users to perform necessary repairs and upgrades.

When examining the internal structure of these devices, it becomes essential to identify how each element interacts within the overall system. This knowledge is invaluable, particularly when seeking to resolve operational issues or optimize performance. An organized representation of these components serves as a reliable reference for both novices and seasoned users alike.

Moreover, understanding the configuration of these mechanisms allows for better maintenance practices. Regular upkeep can prolong the lifespan of the equipment and ensure consistent results. By familiarizing oneself with the layout, users can approach their cleaning tasks with greater confidence and effectiveness.

Understanding Mi-T-M Pressure Washers

This section delves into the intricacies of high-performance cleaning machines that are widely recognized for their efficiency and reliability. These devices are designed to tackle a variety of cleaning tasks, making them essential for both professional and personal use.

Key Features

- Powerful motor for enhanced cleaning capabilities

- Diverse nozzle options for different applications

- Durable construction ensuring longevity

- User-friendly controls for easy operation

- Portability for convenience in various settings

Applications

- Residential cleaning tasks, such as driveways and patios

- Commercial uses, including vehicle maintenance and equipment cleaning

- Industrial applications for large-scale maintenance projects

- Outdoor cleaning for decks, fences, and siding

Understanding the design and functionality of these machines can significantly enhance their effectiveness and extend their service life. Knowledge of the various components and their roles is crucial for optimal performance.

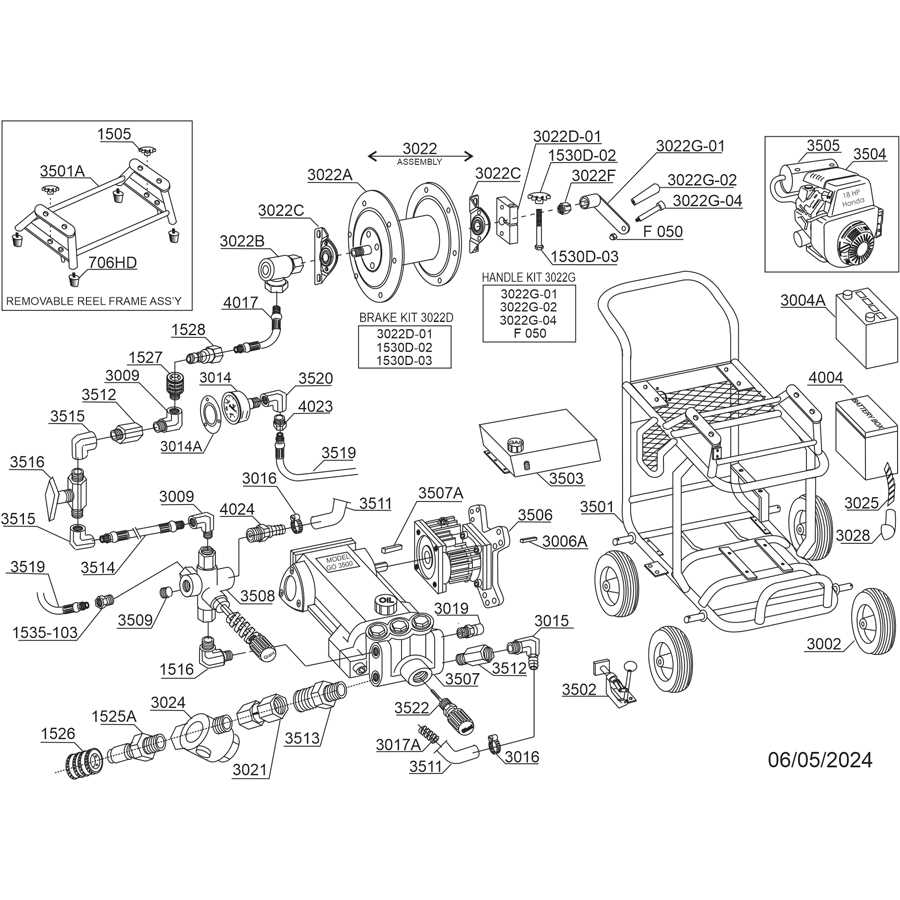

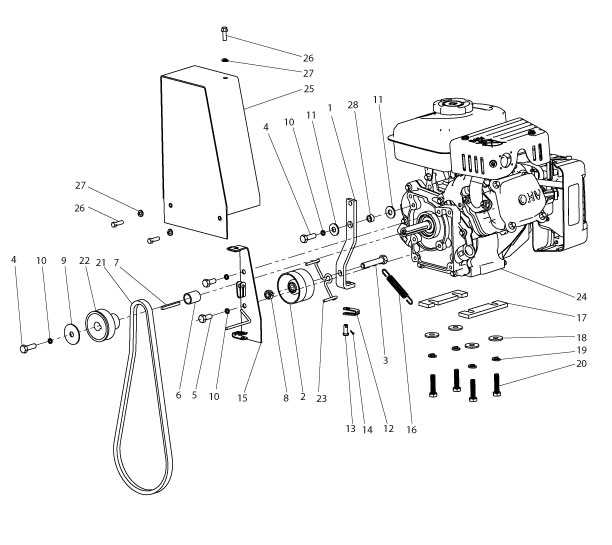

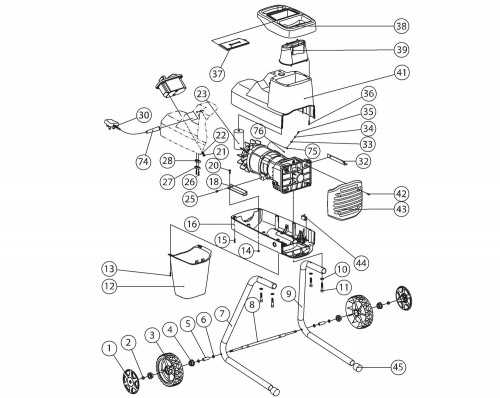

Essential Components of Pressure Washers

Understanding the fundamental elements of cleaning devices is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity, making it important to familiarize oneself with their functions and interactions.

Main Assembly

The main assembly serves as the backbone of the equipment. It houses critical elements that work together to generate high-velocity streams of water. A sturdy frame is essential to support these components while providing stability during use.

Water Supply System

This system includes hoses and connectors that transport water to the main assembly. Filters are often integrated to prevent debris from entering the mechanism, ensuring a clean flow and reducing wear and tear on internal parts. Additionally, valves regulate the water flow, allowing for precise control during operation.

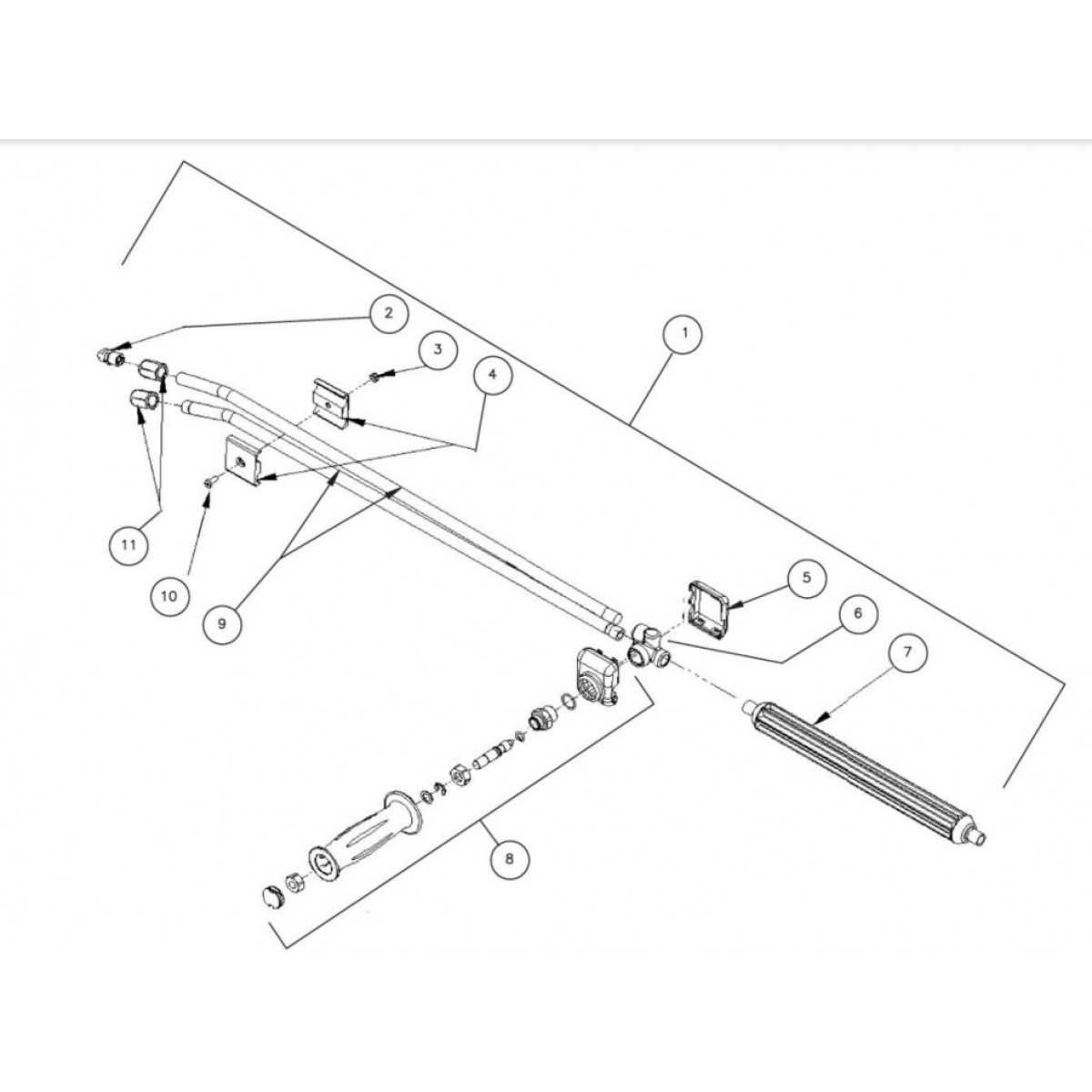

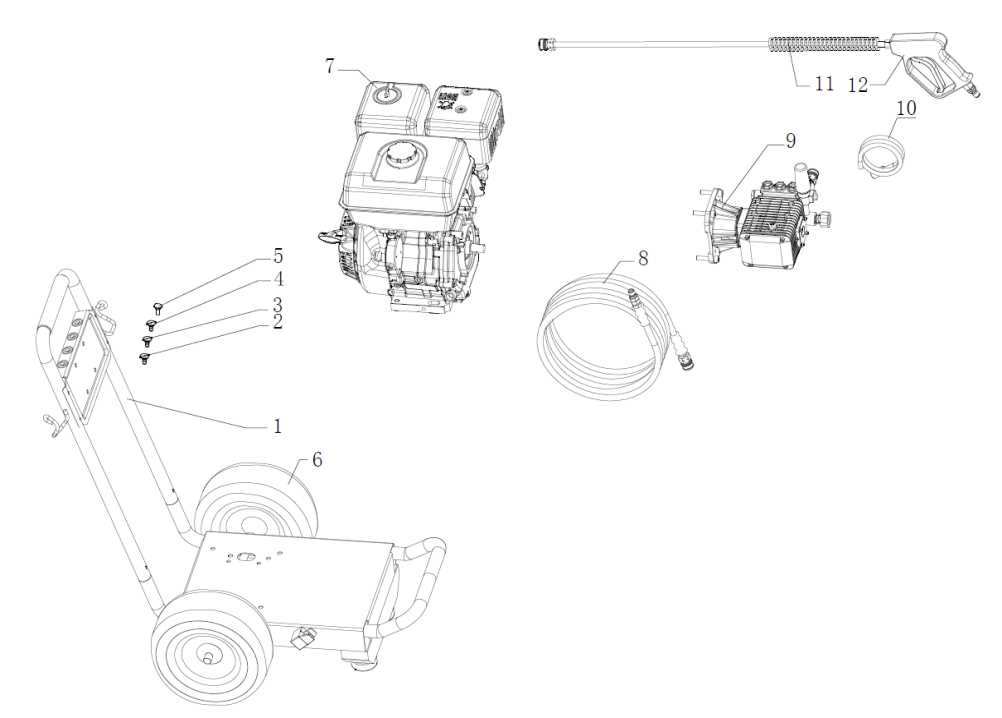

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding users through the various elements and their functions within a machine. Familiarizing yourself with these visuals can enhance your ability to troubleshoot issues and streamline the repair process.

Key Components to Identify

Start by locating the main sections within the illustration. Each area typically represents a distinct part of the system. Pay attention to labels and numbering, as these often correlate with a list of components. This correlation helps in identifying each piece and its corresponding role in the overall operation.

Decoding Symbols and Lines

Examine the symbols and lines used in the illustration. Solid lines usually indicate direct connections, while dashed lines might represent optional or alternate pathways. Understanding these visual cues is crucial for grasping how the elements interact with one another and ensuring proper assembly or disassembly.

Common Issues with Mi-T-M Models

Users of these cleaning machines may encounter several recurring challenges that can affect performance and efficiency. Understanding these common problems can help in maintaining the equipment and ensuring optimal operation.

- Inconsistent Water Flow:

Intermittent or weak flow can be caused by:

- Clogged filters or nozzles

- Damaged hoses

- Low water supply pressure

- Engine Start Issues:

Difficulty starting the motor may arise from:

- Old or contaminated fuel

- Faulty spark plugs

- Blocked air filters

- Overheating:

Excessive heat can lead to operational failures, often due to:

- Insufficient coolant flow

- Dirty or clogged components

- Extended periods of use without breaks

- Leaks:

Fluid leaks can occur from various sources, including:

- Worn seals or gaskets

- Cracked hoses

- Loose fittings

Addressing these common challenges proactively can extend the lifespan of the equipment and enhance user satisfaction. Regular maintenance and timely repairs are essential for optimal functionality.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular care and attention. By following specific maintenance practices, you can enhance performance and reduce the likelihood of costly repairs. Here are some essential tips to keep your device in optimal condition.

- Regular Cleaning: After each use, remove dirt and debris. This prevents buildup that can affect functionality.

- Check Fluid Levels: Regularly inspect and top up necessary fluids to ensure smooth operation.

- Inspect Hoses and Connections: Look for cracks or wear. Replacing damaged hoses promptly can prevent leaks and enhance safety.

- Store Properly: Keep your equipment in a dry, sheltered location to protect it from environmental damage.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule for servicing and part replacements.

By implementing these practices, you can significantly increase the durability and reliability of your equipment, ensuring it remains a valuable tool for years to come.

Finding Replacement Parts Easily

Locating suitable components for your equipment can sometimes feel daunting, but with the right approach, it becomes a manageable task. Understanding where to search and how to identify what you need is essential for maintaining the functionality and longevity of your device.

Utilizing Online Resources

The internet is a treasure trove of information. Many websites specialize in offering detailed catalogs of components, complete with images and descriptions. Search engines can direct you to manufacturer sites or reputable retailers that provide the necessary details to help you make an informed choice. Additionally, user forums often feature discussions that can lead you to hard-to-find items or alternative solutions.

Consulting User Manuals

Another invaluable resource is the user manual of your equipment. These documents usually contain comprehensive information, including specifications and part numbers. By referencing the manual, you can ensure that you are selecting the correct replacements, minimizing the risk of purchasing incompatible items.

In summary, with the right strategies and tools at your disposal, finding the necessary components for your equipment can be a straightforward process. Embrace the resources available to you and ensure your device remains in top condition.

DIY Repairs for Pressure Washers

Taking on repairs for your cleaning equipment can be a rewarding endeavor. Not only can it save you money, but it also enhances your understanding of how these machines operate. With the right tools and knowledge, many common issues can be resolved without professional assistance.

Common Issues and Solutions

- Water Leakage: Inspect hoses and connections for wear or damage. Replacing faulty seals can often remedy this problem.

- Low Water Flow: Check for clogs in the inlet filter or nozzle. Cleaning these components may restore optimal performance.

- Engine Problems: If the motor won’t start, examine the fuel supply, spark plug, and air filter. These are frequent culprits in operational failures.

- Noise Issues: Unusual sounds may indicate loose parts. Tightening bolts or screws can mitigate this issue.

Tools and Supplies

Before you start, gather essential tools:

- Wrenches and sockets

- Screwdrivers

- Replacement seals and filters

- Cleaning brushes

- Lubricating oil

By understanding these common challenges and having the right equipment, you can maintain and enhance the efficiency of your cleaning device effectively.

Benefits of Using Mi-T-M Equipment

Utilizing high-quality cleaning machinery offers numerous advantages for both professional and personal use. These tools are designed to enhance efficiency and effectiveness in various cleaning tasks, making them a valuable addition to any toolkit.

- Durability: Equipment is built to withstand rigorous use, ensuring longevity and reliability over time.

- Power: Designed to tackle tough grime and stains, these machines provide strong performance for heavy-duty cleaning.

- Versatility: Suitable for a range of applications, from residential to commercial, accommodating diverse cleaning needs.

- User-Friendly: Features intuitive controls and designs that simplify operation, making them accessible for users of all skill levels.

- Efficiency: Optimized for quick and thorough results, reducing the time and effort required to achieve a clean surface.

Investing in superior equipment not only enhances cleaning capabilities but also contributes to overall satisfaction and productivity. With the right tools at hand, tasks become less daunting and more efficient.

Upgrading Your Pressure Washer System

Enhancing your cleaning setup can significantly improve efficiency and performance. Whether you are a professional or a home user, investing in superior components can make a noticeable difference in your tasks. This section explores various ways to elevate your system, ensuring you achieve optimal results with every use.

Key Components to Consider

When upgrading, it’s essential to focus on several crucial elements. Each component plays a role in the overall effectiveness of your setup. Below is a summary of key upgrades that can lead to improved functionality:

| Component | Benefits |

|---|---|

| Motor | Increased power and efficiency |

| Hose | Enhanced flexibility and durability |

| Nozzle | Variety of spray patterns for different tasks |

| Accessories | Specialized tools for specific cleaning needs |

Choosing the Right Upgrades

Selecting the right components depends on your individual cleaning requirements. Consider the surfaces you will be working on and the types of jobs you perform most often. Investing in quality upgrades not only extends the life of your equipment but also enhances your overall cleaning experience.