In the realm of enhanced seating solutions, comprehending the various elements that contribute to functionality is essential. These systems are designed to provide support and ease of use for individuals requiring assistance in their daily routines. A clear grasp of the intricate mechanisms involved can significantly enhance the user experience, ensuring safety and reliability.

Each segment of these supportive structures plays a vital role in their overall performance. From the foundational supports to the electronic mechanisms, every aspect is engineered to work harmoniously. Recognizing how these components interconnect will empower users and caregivers alike to make informed decisions regarding maintenance and troubleshooting.

Furthermore, having a detailed visual representation of these systems can serve as an invaluable resource. It allows for better understanding and communication, facilitating more efficient repairs and adjustments. By delving into the specifics of these essential features, we can enhance both functionality and comfort for those who depend on them.

Pride Lift Chair Overview

This section provides a comprehensive look at a popular mobility solution designed for comfort and support. These devices are crafted to assist individuals in transitioning from a seated position to standing, enhancing independence and safety in everyday life.

Key Features

Modern designs often incorporate various functionalities tailored to meet the needs of users. Many models come equipped with adjustable recline angles, customizable seating options, and user-friendly controls. Durability is a hallmark of these devices, with high-quality materials ensuring longevity.

Benefits of Use

Utilizing such a mobility aid can significantly improve the quality of life for individuals facing mobility challenges. Users experience increased safety while reducing the risk of falls. Moreover, the ergonomic design promotes better posture and overall well-being, making it an invaluable addition to any living space.

Essential Components of Lift Chairs

The effectiveness of reclining seating solutions relies on a combination of key elements that work together to enhance functionality and user comfort. Understanding these vital components can aid in proper maintenance and informed decision-making when selecting a model.

Frame: The framework serves as the foundation, providing stability and durability. A robust construction ensures longevity and supports the weight of the user effectively.

Mechanism: This component is responsible for the reclining and rising functions. Various types of mechanisms offer different movement options, catering to individual preferences and needs.

Motor: The electric motor is essential for powering the mechanism, allowing for smooth transitions between positions. High-quality motors contribute to reliability and quiet operation.

Control System: A user-friendly control interface, often in the form of a remote or built-in buttons, enables effortless adjustments. Ergonomic design enhances accessibility for users of all ages.

Cushioning: Comfort is significantly influenced by the padding and upholstery materials. Quality cushioning supports the body while providing a pleasing tactile experience.

Safety Features: Various safety mechanisms, such as anti-tipping designs and power failure backups, are crucial for ensuring user protection and peace of mind during operation.

In summary, each element plays a significant role in delivering a reliable and enjoyable experience, making it essential to consider them when evaluating options in the market.

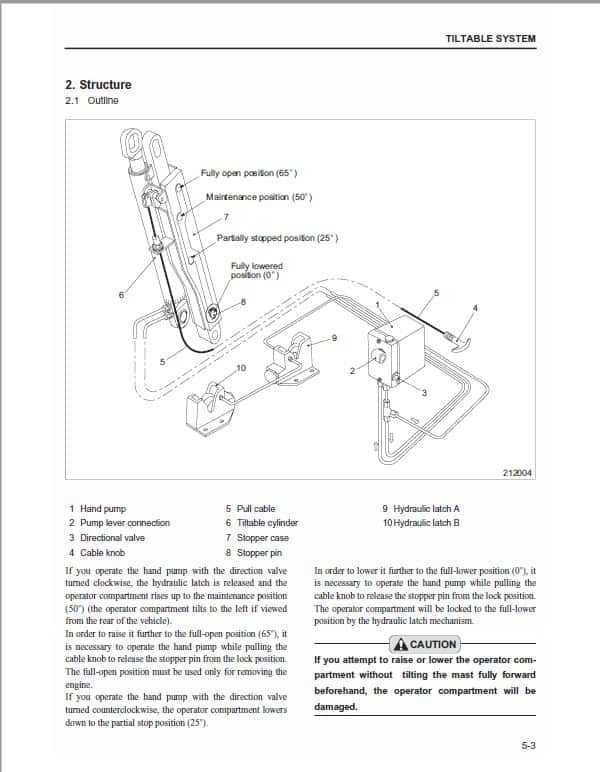

Understanding Chair Mechanisms

In the realm of seating solutions, the intricate systems that facilitate movement and support play a crucial role in user experience. These mechanisms are designed to enhance comfort, accessibility, and functionality, ensuring that users can easily navigate their seating environment. A solid grasp of how these systems operate can greatly aid in maintenance and troubleshooting.

Types of Mechanisms

Various systems exist to provide different functionalities. Some designs utilize hydraulic components, which allow for smooth transitions between positions. Others may employ electric motors, offering a more automated approach. Each type has its own set of advantages, tailored to meet diverse needs.

Importance of Regular Maintenance

To ensure longevity and optimal performance, regular inspection of the mechanisms is essential. Identifying wear and tear early can prevent more significant issues down the line. Understanding how each component interacts not only aids in effective upkeep but also enhances the overall user experience.

Common Issues with Lift Chairs

Individuals who rely on assistive seating solutions may encounter various challenges that can affect usability and comfort. Understanding these common concerns can help users identify issues early and seek appropriate remedies to maintain functionality and safety.

Mechanical Failures

One frequent problem involves mechanical malfunctions. Users may notice that the mechanism does not engage properly, resulting in difficulty transitioning between positions. This can stem from wear and tear, lack of lubrication, or misalignment of components. Regular maintenance is essential to prolong the lifespan of the device and ensure smooth operation.

Electrical Issues

Another area of concern is related to electrical systems. Power supply interruptions, faulty wiring, or issues with the control switch can hinder operation. Users might experience unresponsiveness or erratic movements. Diagnosing electrical faults typically requires careful inspection and, in some cases, professional assistance to ensure safety and functionality.

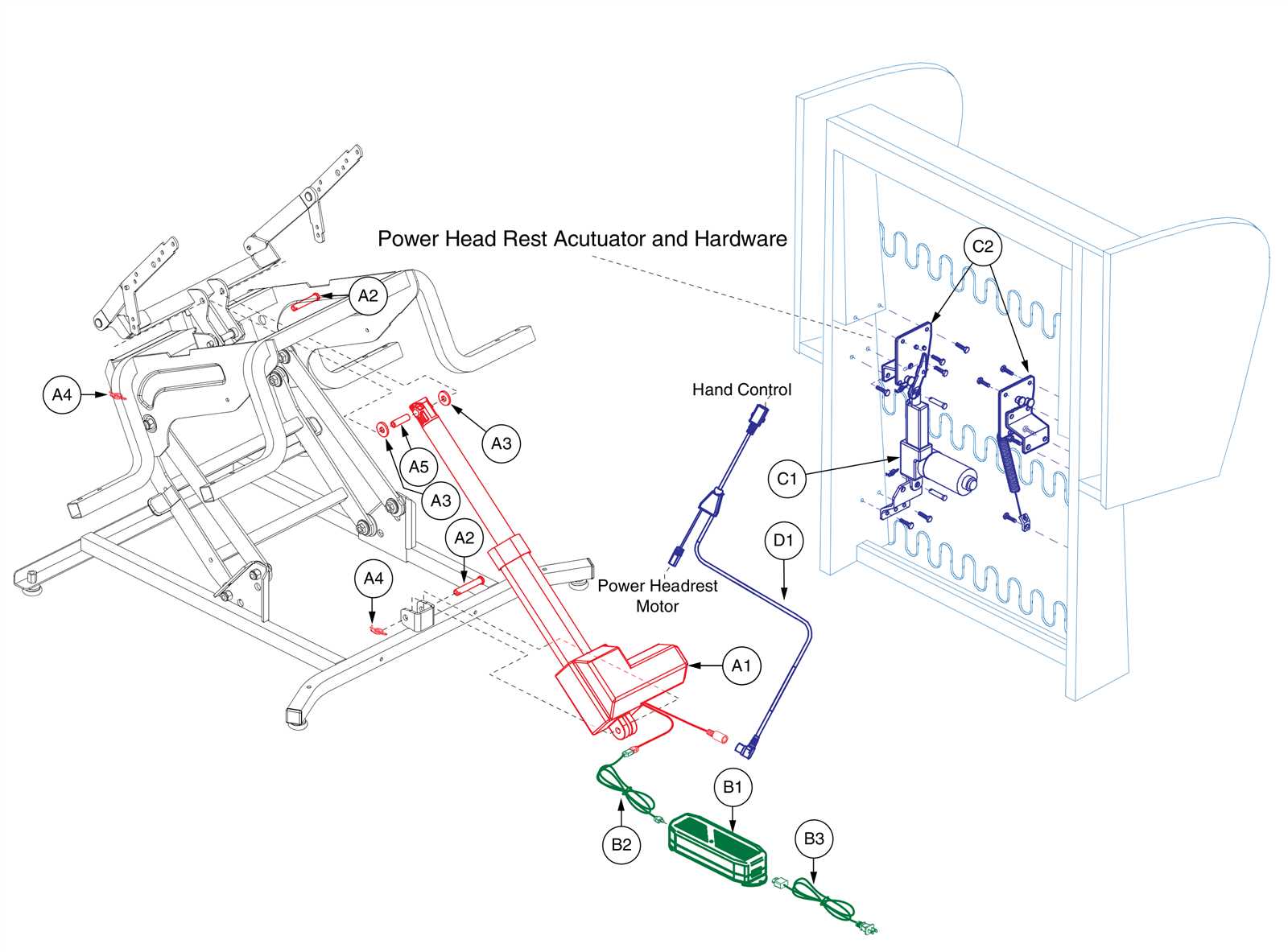

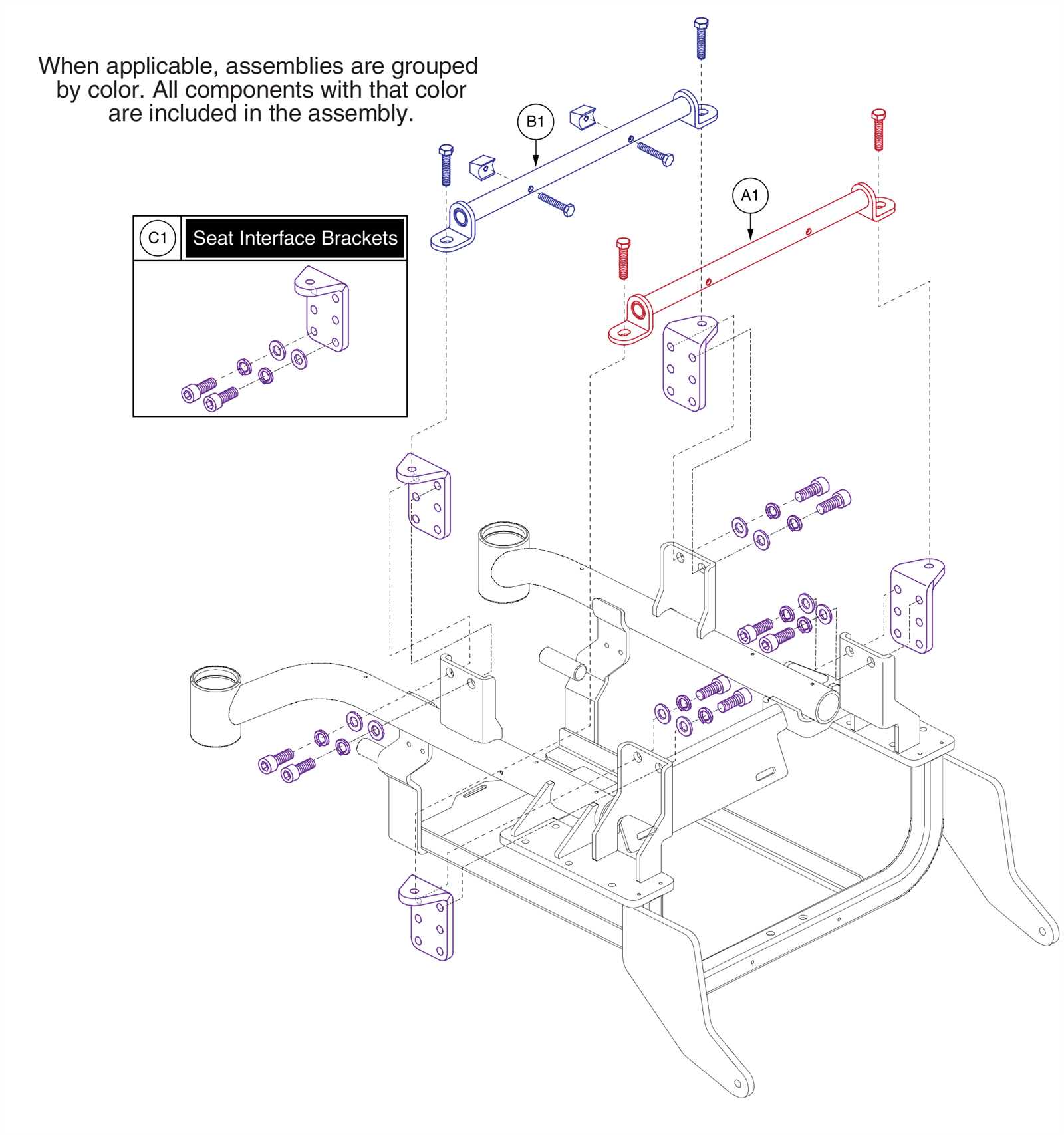

Parts Identification and Functionality

This section delves into the various components of the elevation seating mechanism, emphasizing their roles and importance in ensuring optimal performance. Each element plays a critical role in the overall operation, contributing to user comfort and safety.

| Component | Description |

|---|---|

| Control System | This unit allows the user to operate the elevation mechanism, typically featuring buttons for up and down adjustments. |

| Actuator | The motorized element responsible for moving the seating surface, providing the lifting and reclining functions. |

| Base Frame | The foundational structure that supports the entire assembly, ensuring stability and strength during use. |

| Seat Platform | This is the surface where the user sits, designed to provide comfort while accommodating the elevation features. |

| Armrests | These support the user’s arms and enhance comfort, often adjustable to suit individual preferences. |

| Power Supply | The source of energy that powers the motor and control system, essential for the operation of the elevation functions. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of mobility equipment requires regular attention and care. Proper maintenance not only enhances performance but also guarantees safety for users. By following a few straightforward guidelines, you can keep your device in optimal condition for years to come.

Regular Cleaning: Dust and debris can accumulate, impacting functionality. Use a soft, damp cloth to wipe surfaces regularly, avoiding harsh chemicals that may damage finishes.

Inspect Components: Periodically check all components for wear and tear. Look for loose screws, frayed wires, or any signs of damage. Early detection of issues can prevent costly repairs down the line.

Lubrication: Ensure that moving parts are properly lubricated. Using appropriate lubricants helps reduce friction and wear, enhancing smooth operation. Refer to the manufacturer’s guidelines for specific recommendations.

Batteries and Electrical Systems: For devices with rechargeable power sources, monitor battery health and replace as needed. Avoid overcharging and ensure connections are clean and secure to maintain electrical efficiency.

Professional Servicing: Schedule regular check-ups with a qualified technician. Professional maintenance can address any underlying issues and ensure that your equipment remains safe and reliable.

By adhering to these practices, you can significantly extend the life of your mobility device, ensuring it remains a dependable asset for its users.

Finding Replacement Parts

Locating suitable components for mobility assistance devices can be essential for maintaining their functionality and safety. Whether due to wear and tear or unforeseen damage, ensuring that your equipment is equipped with the right elements is crucial for optimal performance.

Identifying the Specific Component is the first step in this process. Take the time to determine which element requires replacement, noting any model numbers or identifying features. This information will greatly facilitate your search.

Researching Reliable Suppliers can save time and effort. Many manufacturers provide official retailers or authorized service centers where you can purchase genuine replacements. Additionally, online marketplaces often have a range of options, but it’s important to verify the credibility of the seller to ensure quality.

Consulting the User Manual is another effective strategy. Manuals typically include valuable information about compatible elements and their specifications, guiding you in making informed choices.

Lastly, considering Professional Assistance can be beneficial if you’re unsure about the replacement process. Technicians can provide expertise, ensuring that the right components are used and installed correctly, thus extending the lifespan of your mobility equipment.

Diagram Analysis for Troubleshooting

Understanding a visual representation of components can significantly aid in identifying issues and streamlining the repair process. This section will explore how to interpret these visuals effectively, enabling users to pinpoint faults and facilitate maintenance.

Key Elements to Examine

When analyzing the illustration, focus on critical elements such as connections, mechanical structures, and electronic circuits. Identifying discrepancies in these areas can lead to faster resolution of problems. Ensure all components are intact and functioning as intended.

Troubleshooting Steps

Begin by cross-referencing the visual guide with the actual assembly. Look for misalignments or wear that may not be immediately obvious. By systematically checking each segment, users can ultimately achieve a more efficient and effective troubleshooting experience.