In the realm of water distribution systems, comprehending the individual elements and their interactions is crucial for ensuring optimal functionality. Each component plays a significant role in the overall performance, influencing efficiency and reliability.

By examining the arrangement and connections of these elements, users can gain insights into the operational mechanics involved. This understanding not only aids in effective troubleshooting but also enhances maintenance practices, ensuring longevity and smooth operation of the entire system.

Delving into the specifics of these components enables individuals to appreciate the intricacies of design and engineering behind modern water dispensing solutions. Familiarity with the layout of these units empowers users to make informed decisions regarding repairs, replacements, and upgrades.

This section aims to provide a comprehensive overview of the various elements that constitute a typical water dispensing mechanism. By breaking down the essential components, readers can gain a better understanding of how each part contributes to the overall functionality of the system.

Key Elements of a Water Dispensing System

In any liquid distribution setup, specific components play crucial roles in ensuring efficiency and reliability. Recognizing these elements allows for more informed choices during maintenance or upgrades.

| Component | Function |

|---|---|

| Handle | Controls the flow of liquid. |

| Spout | Directs the liquid to the desired location. |

| Cartridge | Regulates the temperature and pressure. |

| Base | Supports and stabilizes the entire assembly. |

Understanding Functionality and Design

Examining the design of each element reveals how they work together to create a seamless operation. A clear understanding of these functionalities can aid in troubleshooting issues or enhancing the system’s performance.

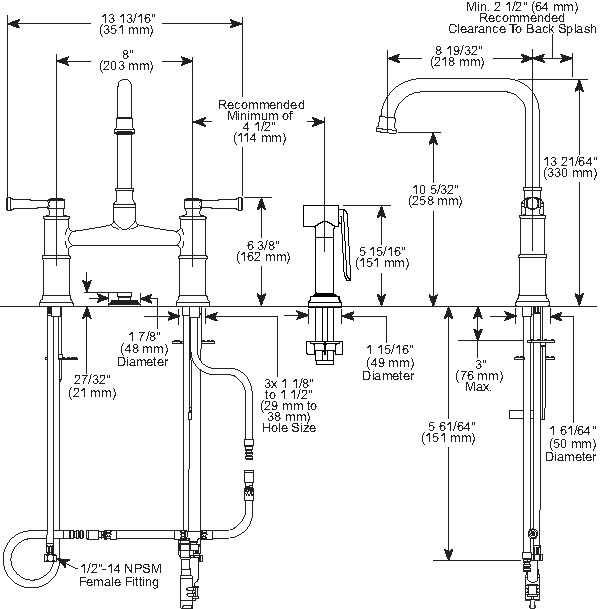

Diagram Overview and Importance

Understanding the visual representation of components is essential in any technical field. These illustrations serve as a blueprint, detailing the arrangement and functionality of various elements within a system. By grasping the layout and connections, individuals can efficiently analyze, troubleshoot, and maintain the apparatus.

Such visual aids play a critical role in enhancing comprehension and communication among professionals. They facilitate collaboration, ensuring that all stakeholders have a clear understanding of the configuration and operation of the system.

| Component | Description | Function |

|---|---|---|

| Element A | Main unit responsible for… | Controls flow and operation |

| Element B | Secondary unit aiding in… | Regulates pressure and efficiency |

| Element C | Connector linking different parts | Ensures seamless interaction |

Types of Faucet Parts Explained

Understanding the various components that make up a water dispensing fixture is essential for effective maintenance and repair. Each element plays a significant role in the overall functionality and efficiency of the system. Familiarity with these components enables better decision-making when it comes to repairs or upgrades.

Handle: The control mechanism that allows users to regulate the flow and temperature of water. Handles can vary in design, from lever types to knobs, and their ease of use is crucial for everyday interactions.

Spout: This is the visible section that directs water from the unit. Spouts come in different heights and shapes, influencing both functionality and aesthetic appeal. A well-designed spout can enhance the user experience while providing the necessary reach for various tasks.

Cartridge: A vital internal component that regulates water flow. The cartridge type can affect the durability and performance of the fixture. Common types include compression, cartridge, and ceramic disc cartridges, each with unique advantages.

Base: The part that secures the fixture to the sink or countertop. A sturdy base ensures stability and prevents leaks. Its design may also contribute to the overall look of the installation.

Seal: Often made from rubber or silicone, seals prevent water from leaking where different components connect. Ensuring seals are in good condition is crucial for preventing water wastage and maintaining efficiency.

Common Issues with Faucet Components

Understanding frequent problems associated with plumbing fixtures can enhance maintenance and repair efforts. Identifying these issues early helps prevent further damage and ensures smooth operation.

- Leaking Seals: Over time, seals may wear out, leading to water leaks. Regular inspection can help detect these issues before they escalate.

- Corroded Valves: Exposure to moisture can cause valves to corrode, affecting their functionality. Replacing corroded components is essential for proper operation.

- Clogged Aerators: Debris buildup in aerators can restrict water flow. Cleaning or replacing aerators ensures optimal performance.

- Loose Handles: Handles can become loose due to frequent use. Tightening them can prevent further issues and enhance user experience.

- Unresponsive Cartridge: A malfunctioning cartridge can lead to inconsistent water flow or temperature. Regular checks can help identify and address these concerns.

Regular maintenance and timely repairs can significantly prolong the lifespan of plumbing fixtures and improve overall efficiency.

Maintenance Tips for Longevity

Ensuring the durability of your installation requires regular upkeep and attention to detail. By implementing a few essential maintenance practices, you can significantly extend the lifespan of your system, minimizing the need for repairs and replacements.

Regular Inspections

Frequent evaluations can help identify potential issues before they escalate. Consider the following steps:

- Check for leaks around connections and joints.

- Inspect seals and gaskets for wear and tear.

- Ensure that all components are securely fastened.

Cleaning and Care

Proper cleaning not only enhances performance but also prevents buildup that can lead to malfunctions. Follow these guidelines:

- Use gentle cleaning agents to avoid damaging surfaces.

- Remove any debris that may obstruct functionality.

- Wipe down all accessible parts to maintain a pristine appearance.

Tools Required for Faucet Repairs

Effective maintenance of water fixtures necessitates specific instruments to ensure proper functionality and avoid leaks. Familiarity with these tools enhances the repair process, making it more efficient and successful.

- Adjustable Wrench: Essential for loosening and tightening nuts and bolts.

- Screwdriver Set: A variety of screwdrivers, including flathead and Phillips, is needed for removing screws.

- Pliers: Useful for gripping and turning small components.

- Utility Knife: Helps in cutting through any tape or seals that may need to be replaced.

- Tape Measure: Important for measuring lengths to ensure proper fit of replacement parts.

- Plumber’s Putty: A sealing compound that helps prevent leaks around fittings.

- Bucket or Towels: Handy for catching any water that may leak during the repair.

Having these tools at hand can significantly streamline the repair process, allowing for swift and effective interventions when issues arise.

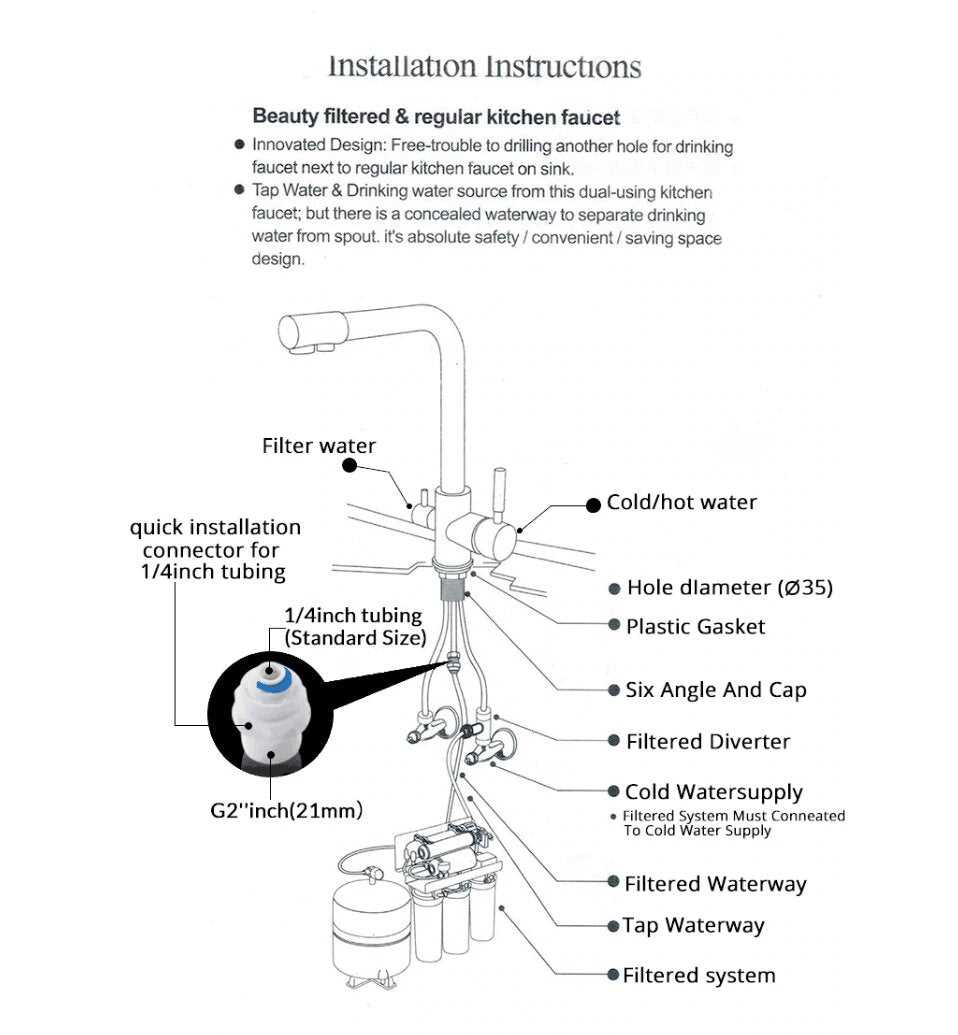

Step-by-Step Assembly Process

This section outlines the comprehensive procedure for assembling the components of a water dispensing system. The following steps ensure that each element is correctly fitted to achieve optimal functionality and efficiency.

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools required for the assembly. |

| 2 | Begin by connecting the main body to the base, ensuring a secure fit. |

| 3 | Attach the spout to the main assembly, making sure it aligns correctly. |

| 4 | Install the control mechanism, ensuring it operates smoothly without obstruction. |

| 5 | Connect any additional features, such as sensors or water filtration units, if applicable. |

| 6 | Perform a final inspection of all connections to verify they are tight and leak-free. |

| 7 | Conduct a test run to ensure the assembly operates as intended. |

Upgrading Faucet Parts for Efficiency

Improving the functionality and performance of water delivery systems can significantly enhance daily usage. By implementing modern components, one can achieve better flow rates, reduce leaks, and conserve resources. This section explores various enhancements that promote efficiency and sustainability.

1. Selecting High-Quality Components is crucial for optimal performance. Investing in durable materials can minimize wear and tear, resulting in fewer replacements and maintenance needs. Consider options made from corrosion-resistant substances that ensure longevity.

2. Incorporating Water-Saving Technologies can dramatically reduce consumption. Devices such as aerators mix air with water, maintaining pressure while using less fluid. Installing these can lead to noticeable savings on water bills and contribute to environmental conservation.

3. Regular Maintenance plays a vital role in ensuring efficiency. Periodic checks and timely replacements of worn-out components can prevent minor issues from escalating into costly repairs. Routine upkeep not only prolongs the lifespan of the system but also optimizes its functionality.

By focusing on these improvements, individuals can create a more efficient and sustainable water management system in their homes, ultimately benefiting both the user and the environment.

Frequently Asked Questions

This section aims to address common inquiries related to the components and mechanisms involved in water dispensing systems. The goal is to provide clarity and support for users seeking information about assembly, maintenance, and troubleshooting.

General Inquiries

Many users often have questions regarding the functionality and setup of various fixtures. Understanding these systems can enhance user experience and prevent common issues.

Maintenance and Troubleshooting

Regular upkeep is crucial for optimal performance. Users frequently encounter specific challenges that require immediate attention. Below is a table outlining common problems and their solutions:

| Issue | Solution |

|---|---|

| Leaking from the base | Check for loose connections or worn-out seals. |

| Low water flow | Inspect for blockages in the aerator or supply line. |

| Unusual noises | Ensure all components are securely attached and free of debris. |