Maintaining machinery in optimal condition is crucial for ensuring longevity and performance. A comprehensive understanding of the various elements that comprise your equipment can significantly enhance troubleshooting and repair processes. This guide aims to provide insights into the essential components and their relationships within a specific model.

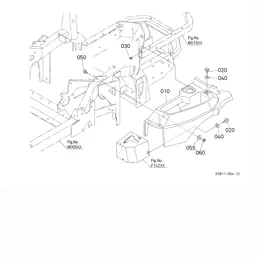

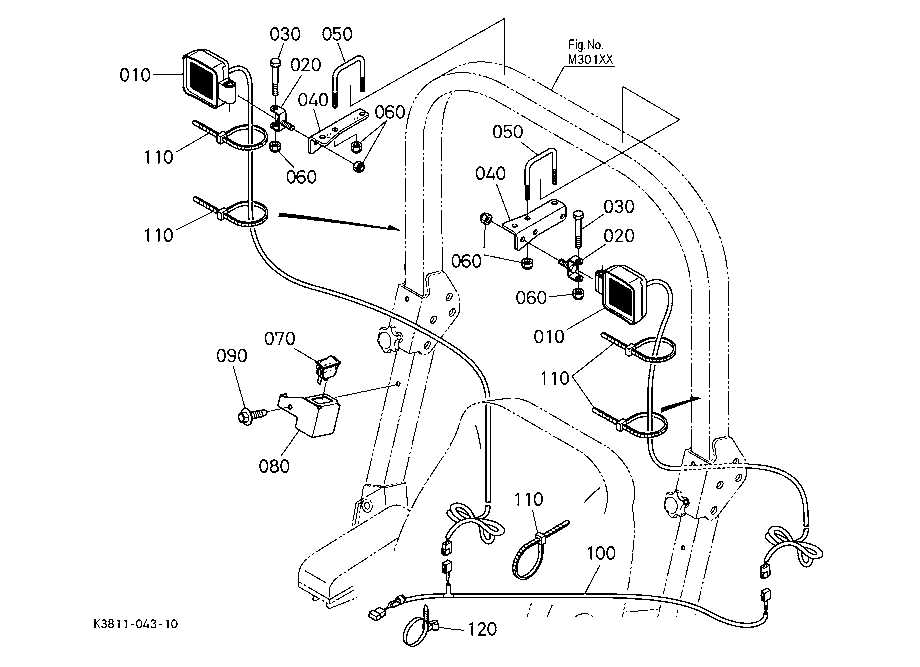

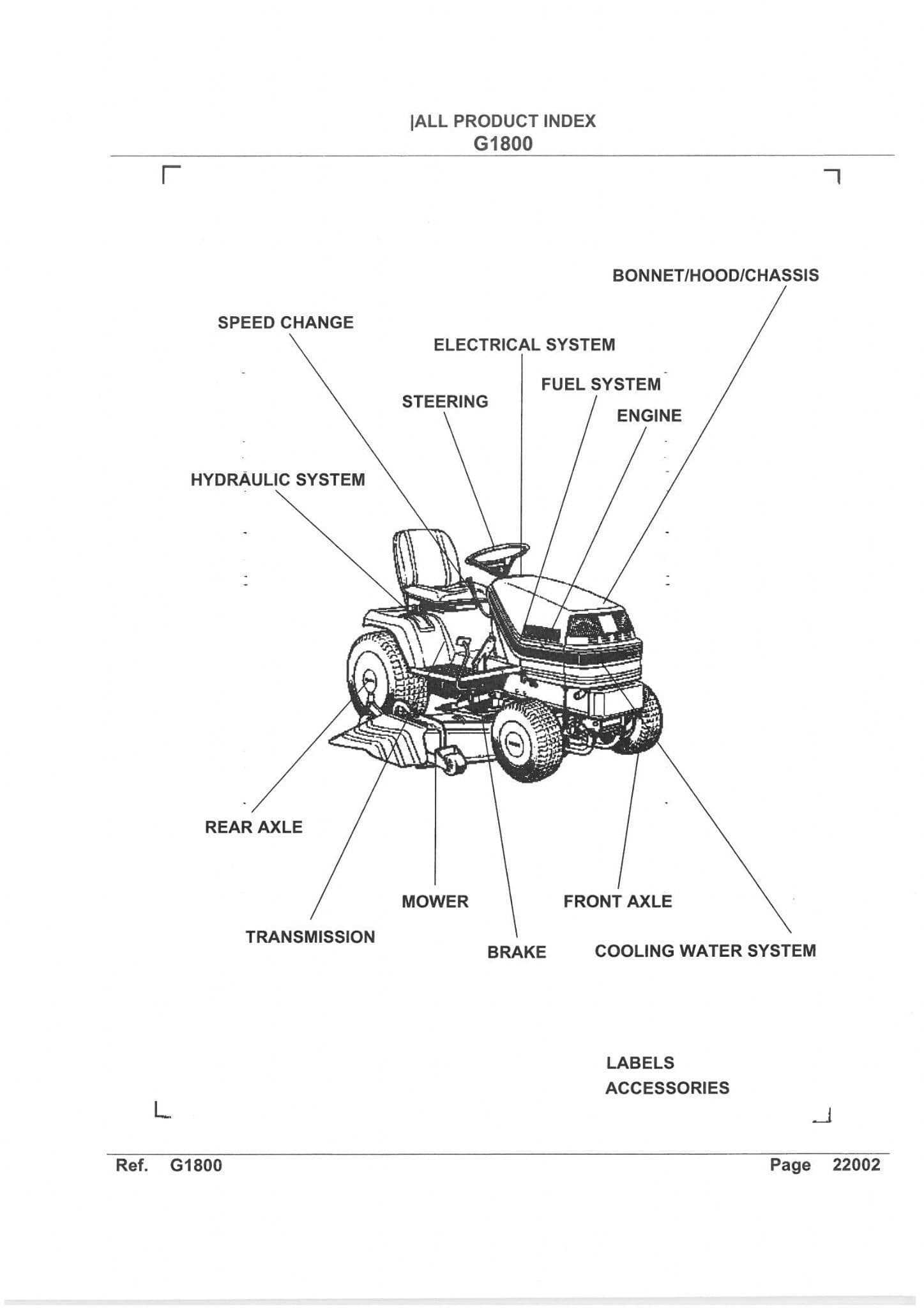

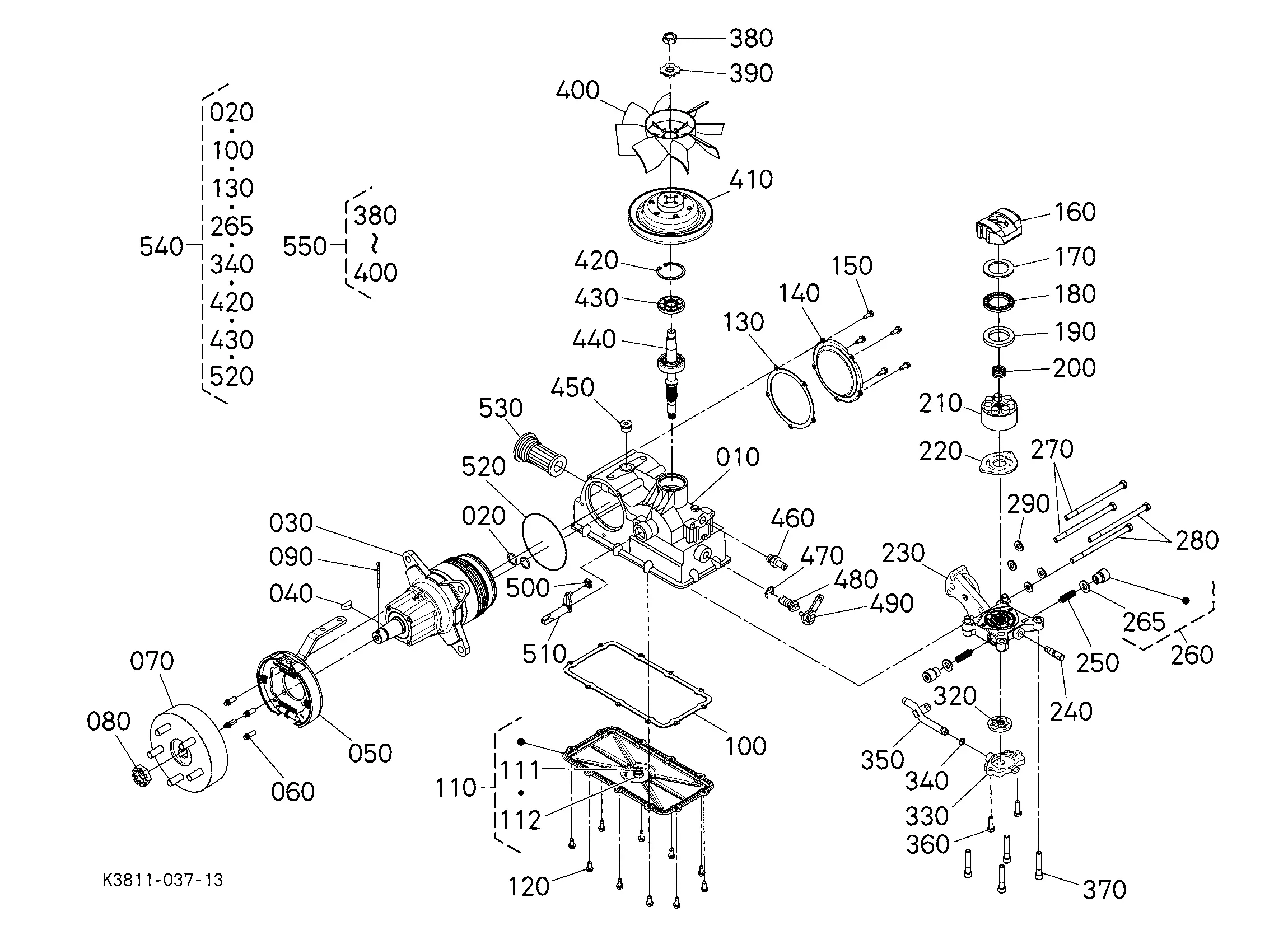

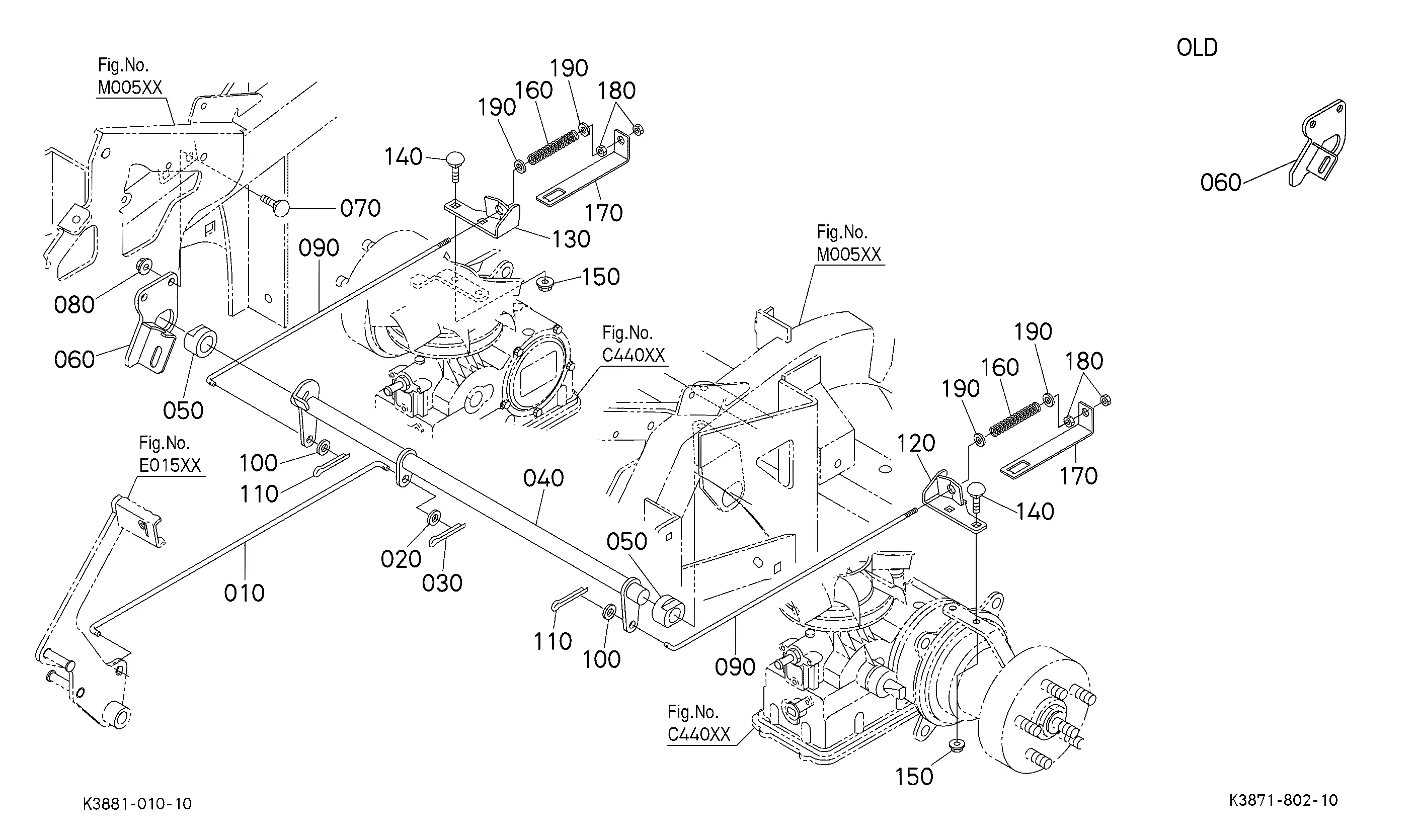

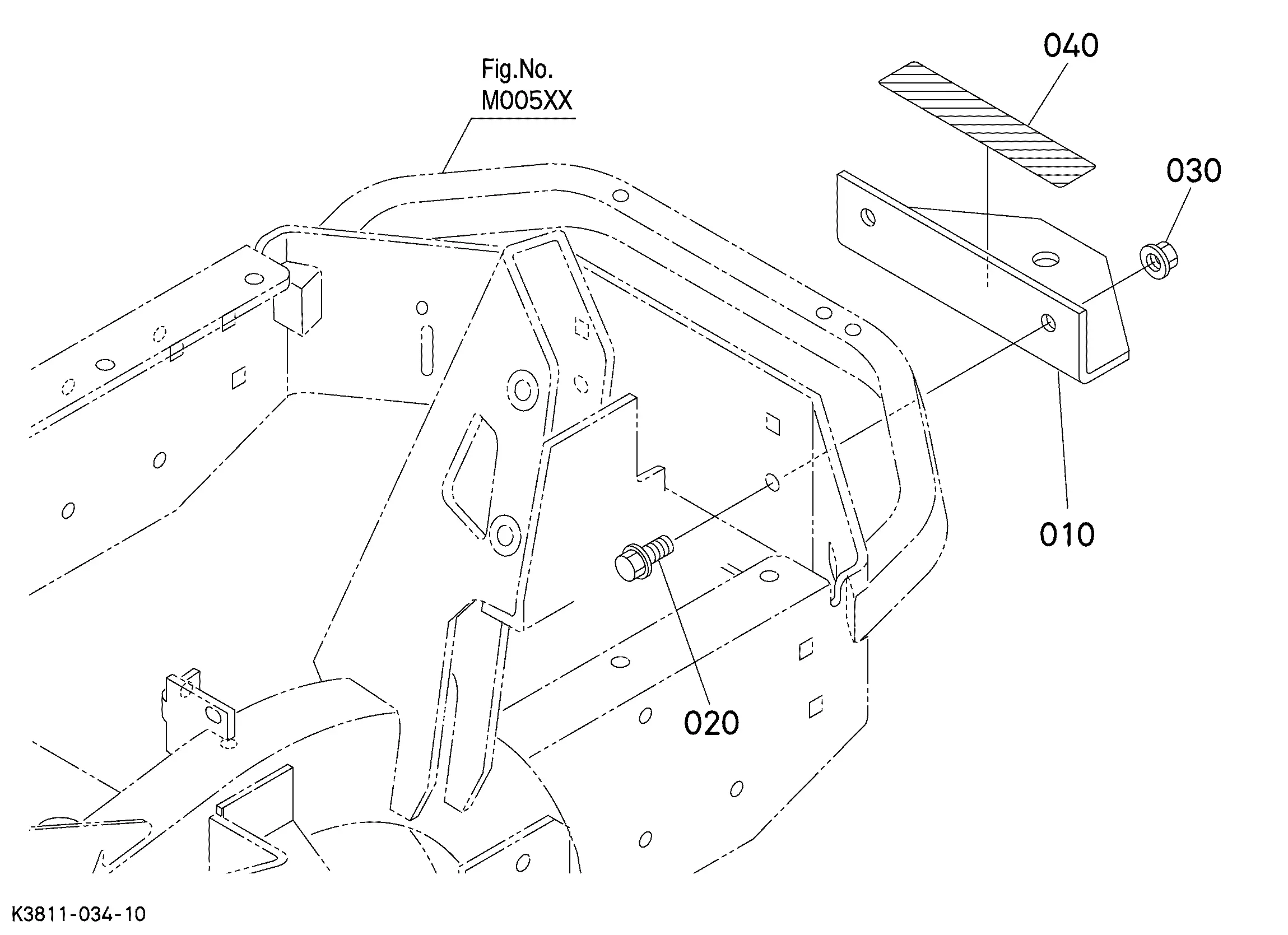

Having access to a visual representation of the internal structure allows operators to quickly identify parts and their functions. This knowledge is invaluable when it comes to maintenance tasks, facilitating timely interventions and minimizing downtime. Knowing where each element is located empowers users to address issues efficiently.

In this article, we will delve into the specifics of component layout, focusing on how different sections interconnect. By exploring these intricate details, operators can gain a deeper appreciation of their machinery, ultimately leading to more effective management and upkeep. Emphasizing clarity and accessibility, our exploration will aid in mastering the intricacies of your equipment.

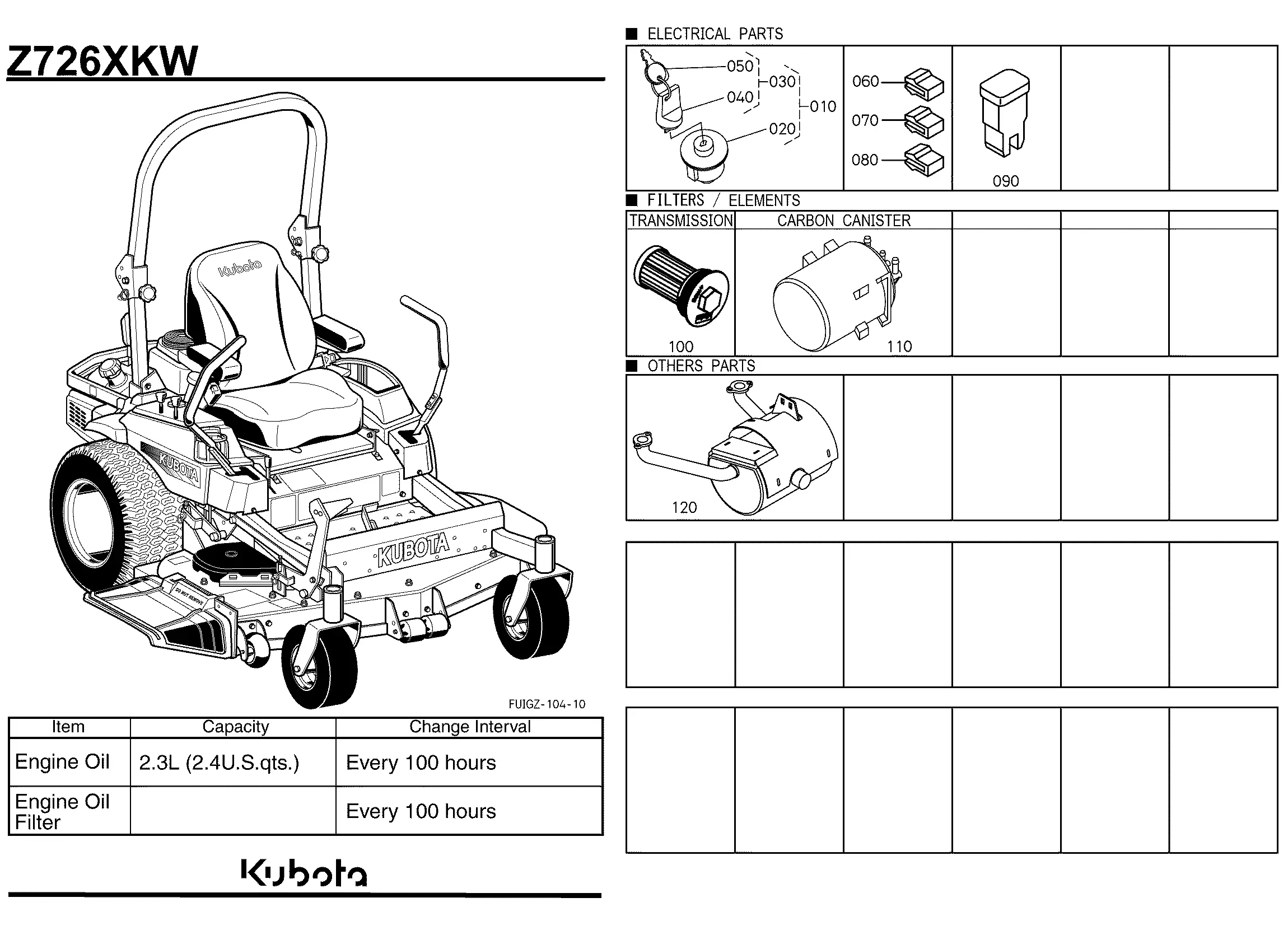

Kubota Z726X Overview

This section provides a comprehensive overview of a particular model known for its efficiency and versatility in various landscaping tasks. With advanced engineering and design, it is tailored to meet the demands of both residential and commercial users.

Featuring a powerful engine and robust construction, this machine offers exceptional performance while ensuring ease of use. The ergonomic controls and adjustable settings enhance user comfort and productivity. Its innovative features make it a reliable choice for maintaining large lawns and expansive green spaces.

| Feature | Description |

|---|---|

| Engine Type | High-performance engine designed for durability and efficiency. |

| Cutting Width | Generous cutting width for faster mowing and improved coverage. |

| Weight | Sturdy construction ensures stability and longevity. |

| Control System | User-friendly interface with intuitive controls for smooth operation. |

| Maintenance | Designed for easy maintenance to prolong the lifespan of the equipment. |

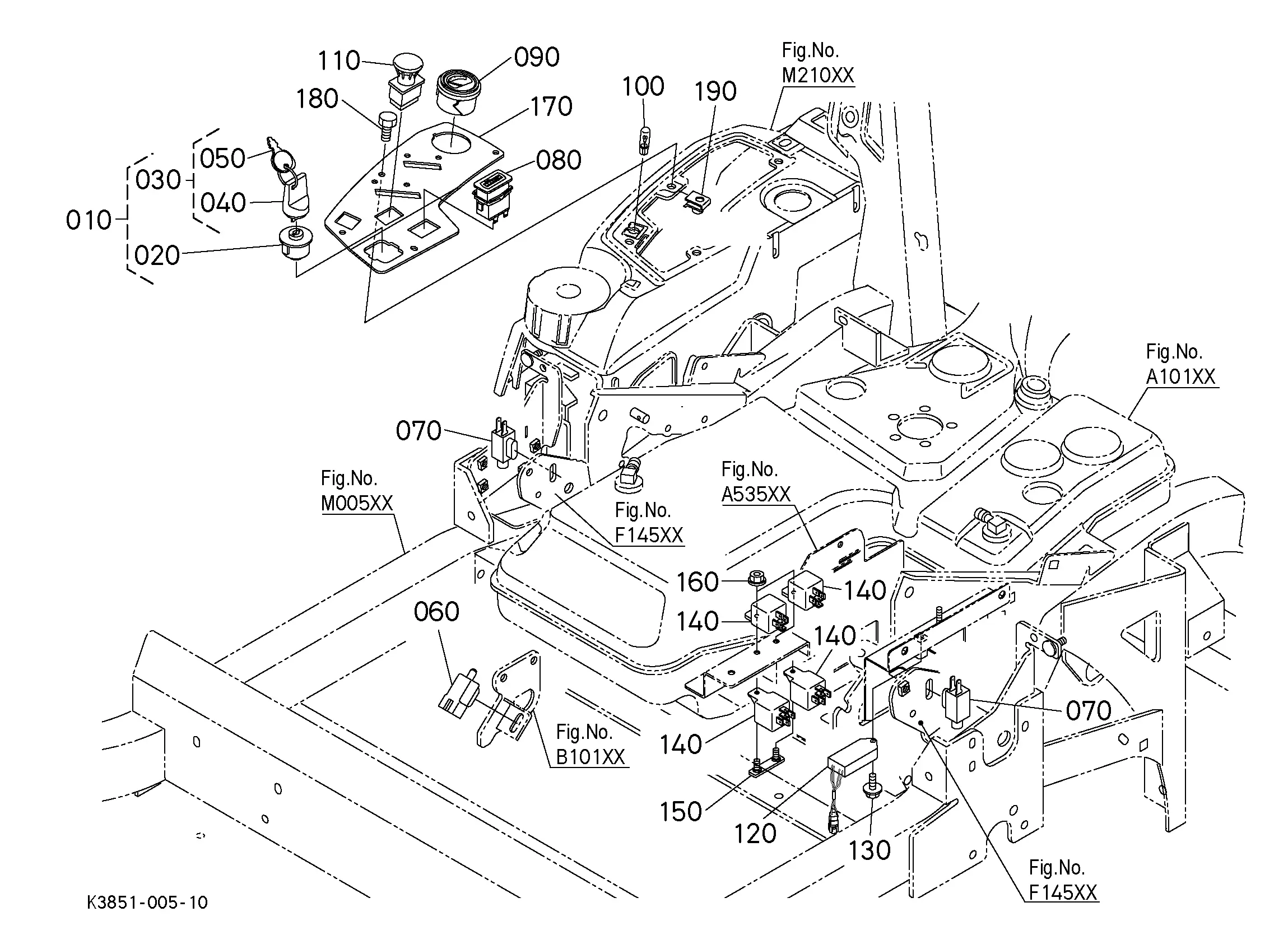

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Clear visual representations enhance comprehension, enabling users to quickly identify and locate individual elements within complex systems. This knowledge is vital for ensuring optimal performance and longevity of equipment.

Benefits of Visual Guides

- Facilitates quick identification of components

- Reduces the risk of errors during repairs

- Enhances communication among technicians

- Streamlines ordering of replacement elements

Enhancing Maintenance Efficiency

- Improves diagnostic processes

- Encourages proactive upkeep strategies

- Supports training for new personnel

Ultimately, investing time in understanding these visual resources pays off by boosting overall productivity and minimizing downtime.

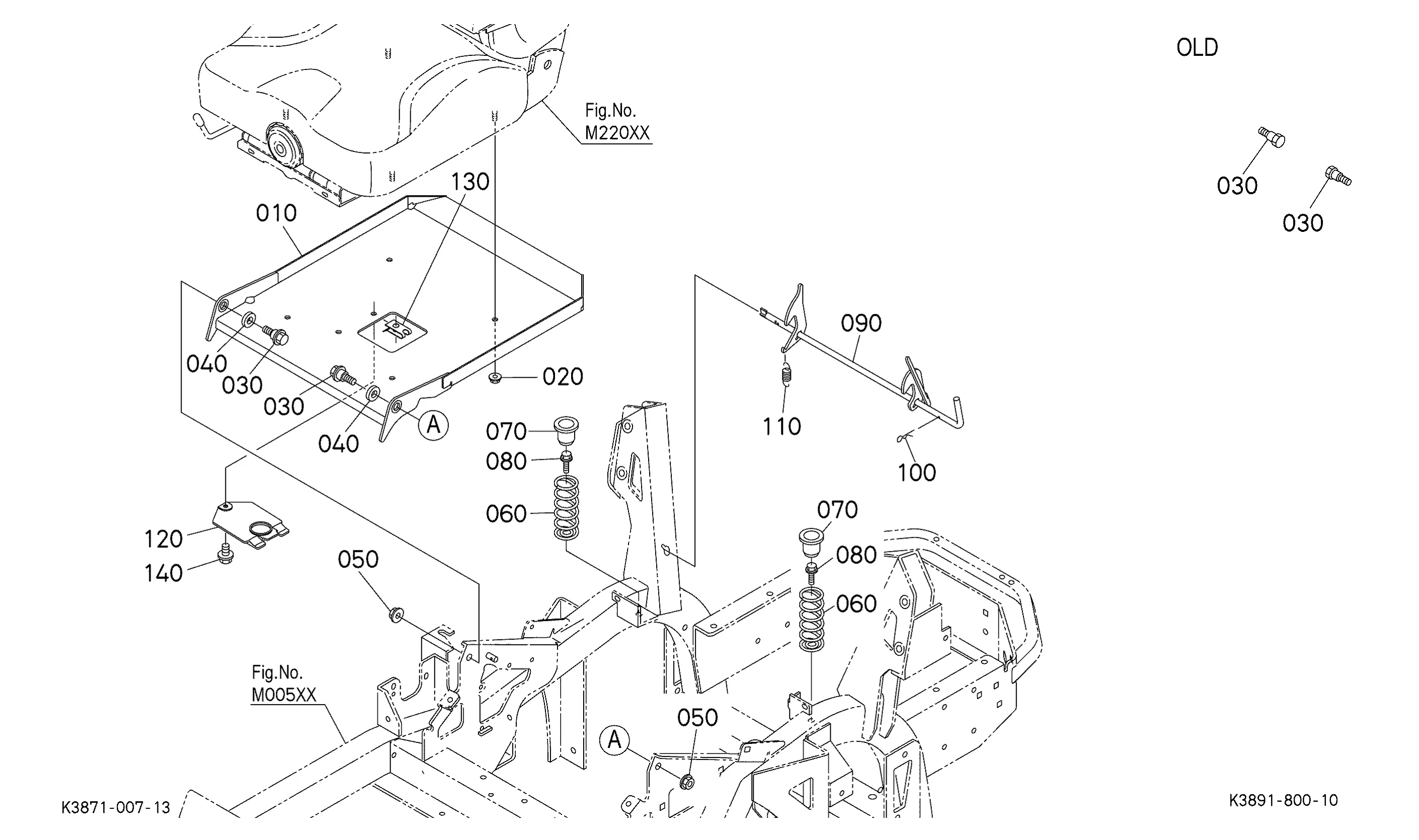

Key Components of the Z726X

This section explores the essential elements that contribute to the functionality and efficiency of this high-performance machine. Understanding these components is crucial for maintenance and optimal operation.

Engine and Power System

- Engine: The heart of the machine, providing the necessary power to drive various functions.

- Transmission: Facilitates the smooth transfer of power from the engine to the wheels.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

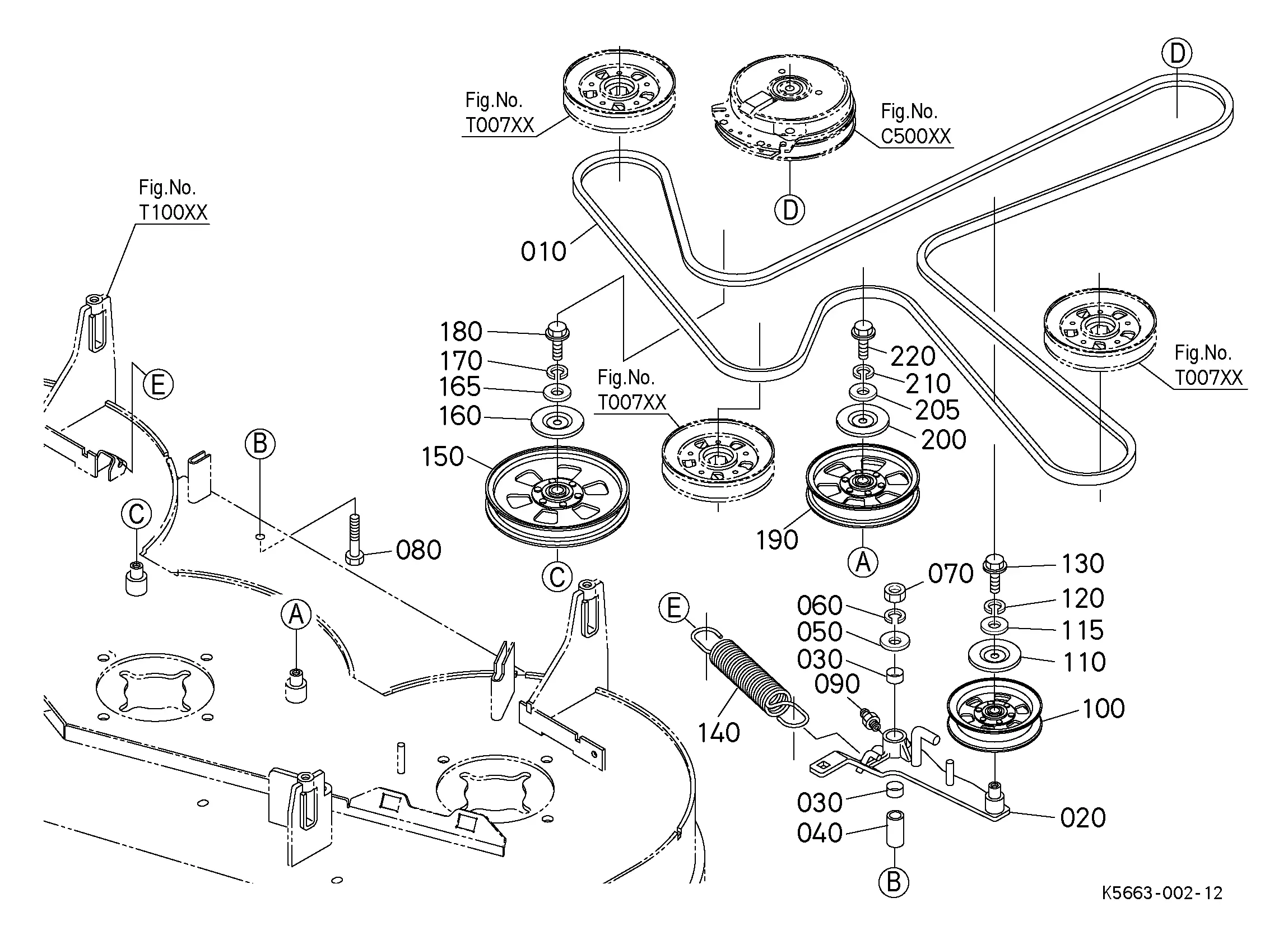

Cutting Deck and Mowing System

- Cutting Blades: Essential for achieving a precise and even cut across different terrains.

- Deck Housing: Protects the blades while ensuring efficient grass discharge.

- Height Adjustment Mechanism: Allows users to customize cutting heights for various grass types.

Each of these components plays a vital role in ensuring reliability and performance, making it important to regularly check and maintain them for continued excellence.

Common Issues with Kubota Mowers

When it comes to maintaining performance and longevity, many users encounter recurring challenges with their mowing equipment. Understanding these common problems can help in troubleshooting and ensuring efficient operation. Whether it’s mechanical failures or maintenance oversights, being aware of these issues can lead to quicker resolutions and improved reliability.

Engine Performance Problems

One frequent concern involves the engine’s ability to start or maintain consistent power during operation. This can stem from various factors, including fuel quality, air filter condition, or spark plug efficiency. Regular checks and replacements can mitigate these issues.

Deck and Blade Issues

The cutting deck and blades often face wear and tear, impacting the mower’s ability to deliver a clean cut. Dull blades, debris buildup, or damage to the deck can all contribute to subpar performance. Routine maintenance and timely blade sharpening are essential for optimal results.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Engine won’t start | No ignition sound, sputtering | Check battery, fuel level, and starter |

| Dull blades | Sharpen or replace blades regularly | |

| Deck vibration | Excessive shaking, noise | Inspect for loose components or debris |

Understanding Maintenance Requirements

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. Regular attention to the various components can prevent unexpected failures and costly repairs. Understanding the specific needs of each part helps in creating a comprehensive maintenance plan that maximizes efficiency.

Routine inspections play a vital role in identifying wear and tear before it leads to significant issues. These assessments should include checking fluid levels, examining belts and hoses, and ensuring that moving parts are well-lubricated. By prioritizing these practices, operators can maintain a high level of reliability.

Additionally, following the manufacturer’s guidelines for service intervals is essential. Each machine has its unique set of requirements, including suggested timelines for oil changes, filter replacements, and other critical tasks. Adhering to these recommendations not only extends the life of the equipment but also enhances its overall performance.

Moreover, keeping detailed records of maintenance activities can provide valuable insights into the operational status of the machinery. This documentation allows for better planning of future service needs and helps track any recurring issues that may arise.

In conclusion, understanding and implementing effective maintenance strategies is key to ensuring that machinery operates smoothly and efficiently throughout its lifespan.

Where to Find Replacement Parts

Finding the right components for your machinery can be a challenging task. However, understanding where to look can simplify the process significantly. Whether you are seeking original items or aftermarket alternatives, numerous sources can help you locate what you need efficiently.

Online Retailers

One of the most convenient ways to search for components is through online platforms. Various e-commerce websites specialize in agricultural and landscaping equipment. These retailers often provide a wide selection and detailed specifications, making it easier to identify the correct items for your machine.

Local Dealers and Distributors

Visiting local dealers can be beneficial for obtaining authentic replacements. They often have knowledgeable staff who can assist with finding the appropriate components and may even offer maintenance services. Building a relationship with a local distributor can also lead to valuable insights about product availability and new arrivals.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, detailed specifications |

| Local Dealers | Expert assistance, authentic items, maintenance services |

| Second-hand Marketplaces | Cost-effective options, unique finds |

| Manufacturer Websites | Direct access to original products, latest updates |

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These items are specifically designed to meet the exact specifications of the equipment, leading to enhanced reliability and efficiency during operation.

One significant advantage of using original items is the assurance of quality. Authentic parts undergo rigorous testing and adhere to strict manufacturing standards, reducing the likelihood of malfunction or premature wear.

Another crucial benefit is the compatibility that comes with using genuine components. These parts fit seamlessly with the existing systems, minimizing the risk of installation issues and ensuring smooth operation.

Moreover, employing original items can result in cost savings in the long run. While aftermarket alternatives may seem less expensive initially, they often lead to increased maintenance costs and more frequent replacements, which can add up over time.

| Benefit | Description |

|---|---|

| Quality Assurance | Meets high manufacturing standards, ensuring durability. |

| Compatibility | Designed for a precise fit, reducing installation issues. |

| Cost Efficiency | Long-term savings through reduced maintenance and replacement frequency. |

| Warranty Protection | Using authentic components often helps maintain warranty coverage. |

In summary, opting for genuine components is a wise choice for anyone looking to maintain their equipment’s efficiency and reliability. The long-term benefits far outweigh the initial cost, leading to a better overall experience in machinery operation.

Tips for Efficient Repairs

When tackling maintenance tasks, efficiency can make all the difference in the outcome. Proper planning, organization, and technique can significantly reduce downtime and enhance the overall quality of repairs. Here are some strategies to help streamline your repair process.

Preparation is Key

Before starting any maintenance work, ensure that you have all necessary tools and components on hand. This includes not just the items you expect to replace, but also the tools that will make the job easier. Creating a checklist can help you avoid interruptions during the repair process. Additionally, familiarizing yourself with the machinery’s manual can provide valuable insights into common issues and solutions.

Work Methodically

Approach each repair task step by step. Documenting your progress can help you track what has been completed and what remains. If you encounter any challenges, take a moment to assess the situation before proceeding. This careful approach can prevent mistakes and ensure a more efficient workflow. Furthermore, consider enlisting a helper when tackling more complex tasks, as an extra set of hands can be invaluable.