In the realm of off-road machinery, understanding the intricate network of elements that constitute a utility vehicle is essential for enthusiasts and mechanics alike. This analysis delves into the various segments and assemblies that contribute to the robust functionality and versatility of a specific model, emphasizing the significance of each component in ensuring optimal performance.

The interplay of various mechanical parts creates a seamless operation, allowing for the handling of diverse terrains and tasks. By examining these elements closely, users can gain valuable insights into maintenance and potential upgrades that enhance both efficiency and durability.

Furthermore, having a comprehensive overview of the assembly allows owners to troubleshoot issues with greater ease. Knowledge of each segment’s role not only fosters a deeper appreciation for the craftsmanship involved but also empowers individuals to take proactive steps in vehicle care and enhancement.

Understanding the Legacy of the Polaris Utility Vehicle

In exploring the historical narrative of this enduring off-road vehicle, we delve into its foundational design and enduring legacy in the realm of utility vehicles. Highlighting its structural ingenuity and enduring reliability, this section illuminates the essence of its engineering prowess and functional versatility.

Structural Anatomy: Examining the intricate framework of this multipurpose vehicle, we uncover its robust architecture and specialized components. Each element contributes synergistically to its operational efficacy, showcasing a harmonious blend of form and function.

Functional Dynamics: Beyond its static composition, this vehicle exemplifies dynamic utility through its diverse operational capabilities. From rugged terrains to utility-driven tasks, its adaptive functionality underscores its role as a stalwart companion in varied environments.

Economic and Ecological Impact: Beyond its mechanical attributes, this vehicle’s enduring presence resonates through its economic significance and ecological footprint. Its role extends beyond utility, encapsulating a broader impact on industries and environmental stewardship.

Key Features of the 1999 Model

This model stands out due to its innovative design and robust functionality. Engineered for both utility and leisure, it combines performance with versatility, making it a favored choice for various terrains.

Performance Specifications

With a powerful engine and superior handling, this vehicle ensures an impressive ride. Its traction capabilities and durability make it suitable for demanding conditions.

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, high-performance engine |

| Transmission | Automatic with high and low range options |

| Payload Capacity | Significant load handling for work tasks |

Design Aspects

Designed for user comfort, the model features an ergonomic layout and ample storage. Its rugged exterior enhances both aesthetics and functionality, appealing to enthusiasts and professionals alike.

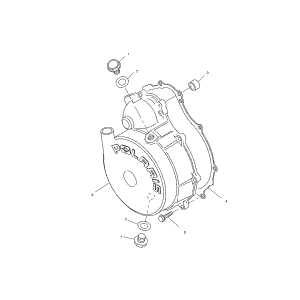

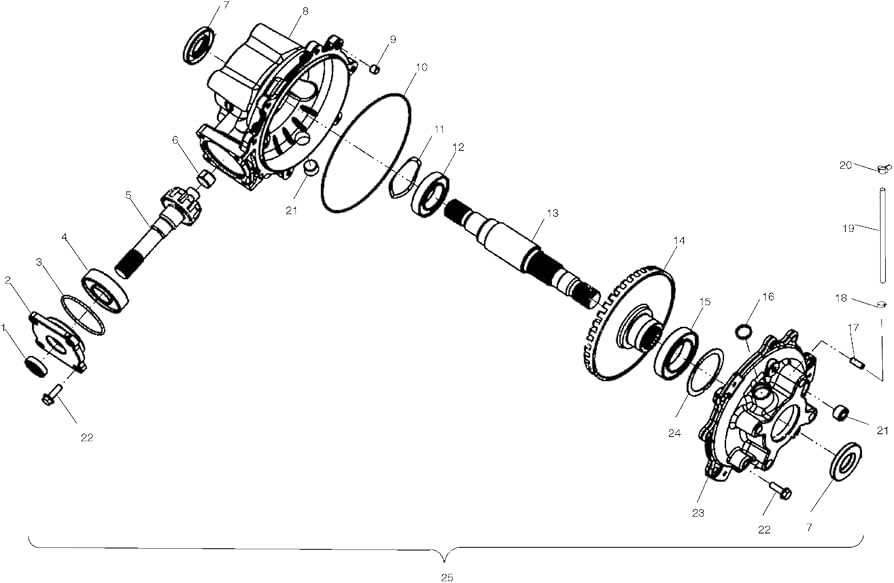

Importance of Parts Diagrams

Understanding the intricacies of machinery and vehicles is crucial for effective maintenance and repairs. Visual representations of components provide a clear overview, facilitating identification and organization. Such illustrations serve as valuable resources for both novice and experienced users, enhancing comprehension and efficiency in the repair process.

Facilitating Repairs and Maintenance

Visual aids simplify the process of troubleshooting and fixing issues by clearly outlining the arrangement and connection of various elements. This clarity allows technicians to quickly locate problems, minimizing downtime and improving overall performance. Moreover, these representations help ensure that replacement items are accurately sourced, reducing the risk of errors during repairs.

Enhancing Understanding and Training

For those new to the field, visual guides are instrumental in learning about complex systems. They provide a foundation for understanding how different components interact, fostering a deeper knowledge of the machinery. This understanding not only boosts confidence but also empowers users to make informed decisions when undertaking maintenance tasks.

Common Replacement Parts for 6×6

Maintaining off-road vehicles often requires attention to specific components that may wear out over time. Knowing which elements typically need replacement can enhance both performance and longevity. Understanding these common items helps enthusiasts keep their machines in top condition, ensuring reliability during use.

Essential Components

Key items that frequently require attention include suspension elements, belts, and filters. Suspension parts, such as bushings and shocks, are critical for a smooth ride and should be inspected regularly. Belts, essential for power transfer, can wear down and affect overall performance. Filters, particularly air and oil, play a significant role in engine efficiency and should be replaced to maintain optimal functioning.

Additional Considerations

Other vital components include brakes, batteries, and tires. Brake systems need to be in good condition for safety, so checking pads and fluid levels is essential. A reliable battery ensures consistent starting power, while tires must be monitored for wear and proper inflation to provide traction in various terrains. Regular maintenance of these elements contributes to a well-functioning vehicle.

Where to Find Parts Diagrams

Locating detailed illustrations for vehicle components can greatly simplify the repair and maintenance process. These visuals not only enhance understanding of assembly but also aid in identifying specific pieces needed for replacement. Here are some effective sources for obtaining these valuable resources.

- Manufacturer Websites: Many manufacturers provide online resources where users can access comprehensive catalogs and technical illustrations specific to their models.

- Online Forums: Enthusiast communities often share resources, including links to diagrams or personal collections of technical information.

- Repair Manuals: Printed or digital service manuals are a reliable source for detailed diagrams and can often be purchased through bookstores or online retailers.

- Parts Retailers: Specialized online retailers may offer access to exploded views and part numbers, which can be helpful in locating the exact item needed.

- YouTube Tutorials: Many users share their repair experiences, often including visual guides that highlight important components and assembly processes.

Utilizing these resources can significantly streamline the process of sourcing necessary components, ensuring that maintenance tasks are completed efficiently and effectively.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. Such illustrations serve as a valuable guide, allowing users to identify individual elements and their relationships within a system. Familiarity with these representations can significantly enhance one’s ability to troubleshoot and replace items accurately.

To effectively interpret these visual aids, one must first recognize the various symbols and labels employed. Each symbol typically corresponds to a specific component, while accompanying annotations provide essential details such as part numbers and descriptions. Familiarizing oneself with the legend or key is an essential step, as it elucidates the meaning behind each symbol.

| Symbol | Description |

|---|---|

| Wrench or tool required for installation/removal | |

| ⚙️ | Gear or moving part |

| Fastener, such as a bolt or screw | |

| Measurement reference |

Next, observe the layout of components within the illustration. Typically, elements are organized in a logical sequence that reflects their arrangement in the physical assembly. This can aid in visualizing the order of disassembly or reassembly, facilitating a smoother workflow.

Additionally, paying attention to connections between parts is vital. Arrows or lines often indicate how components are linked, which can clarify the assembly process and highlight potential points of failure. This understanding allows for more informed decision-making when selecting replacements or upgrades.

In summary, effectively reading these visual representations requires practice and attention to detail. By mastering the symbols, layout, and connections, one can enhance their ability to maintain and repair machinery, ensuring longevity and optimal performance.

Maintenance Tips for Your Ranger

Proper upkeep is essential for enhancing performance and extending the lifespan of your utility vehicle. Regular checks and maintenance routines can prevent issues and ensure smooth operation.

- Regular Inspections: Frequently examine key components such as tires, brakes, and fluids.

- Fluid Changes: Change engine oil and other fluids according to the manufacturer’s recommendations to keep the engine running optimally.

- Clean Air Filter: Keep the air filter clean to ensure proper airflow and engine efficiency.

- Tire Maintenance: Monitor tire pressure and tread to ensure safety and performance.

Implementing these practices will help maintain your vehicle’s functionality and reliability.

Upgrading Components for Better Performance

Enhancing the efficiency and capability of your all-terrain vehicle can significantly elevate your off-road experience. By focusing on key components, you can improve power, handling, and overall functionality. This section will explore various upgrades that can transform your machine into a more robust performer.

One of the primary areas to consider for enhancement is the engine system. Upgrading to a high-performance air intake or exhaust can lead to better airflow, resulting in improved horsepower and torque. Additionally, a tuning module can optimize fuel delivery, further enhancing performance.

Another crucial component is the suspension system. A high-quality aftermarket suspension kit can improve handling and ride quality, allowing for better control on uneven terrain. Adjustable shocks and springs provide versatility, adapting to different conditions and loads.

Wheels and tires are also vital for performance upgrades. Opting for larger, more aggressive tires can increase traction and stability. Pairing these with lightweight wheels can reduce unsprung weight, enhancing responsiveness.

| Component | Upgrade Option | Benefit |

|---|---|---|

| Engine | High-Performance Intake | Increased airflow and horsepower |

| Exhaust | Performance Exhaust System | Improved torque and sound |

| Suspension | Aftermarket Suspension Kit | Enhanced handling and ride comfort |

| Tires | Aggressive Off-Road Tires | Better traction and stability |

| Wheels | Lightweight Alloy Wheels | Reduced weight for improved performance |

By investing in these enhancements, you can unlock the full potential of your vehicle, making it more capable and enjoyable for all your adventures.

Community Resources and Support Groups

Connecting with others who share similar interests can significantly enhance your experience and understanding of maintenance and repair. Communities often provide a wealth of information, resources, and encouragement, making it easier to tackle challenges and improve your skills.

Online Forums: Numerous platforms exist where enthusiasts can exchange tips, seek advice, and share personal experiences. These forums serve as valuable repositories of knowledge and support.

Local Clubs: Joining a local group can foster camaraderie and provide hands-on assistance. Members often organize events, workshops, and group outings, enhancing both learning and enjoyment.

Social Media Groups: Engaging with communities on social media allows for real-time interaction and updates. These platforms are ideal for asking questions and getting quick responses from fellow aficionados.

Workshops and Classes: Many organizations offer educational opportunities that delve into repair techniques and maintenance practices. Participating in these can lead to greater confidence and proficiency.

Ultimately, leveraging these resources can help individuals navigate their projects more effectively while fostering a sense of belonging within the community.