In the world of machinery maintenance, having a clear view of all the essential elements that contribute to the efficient operation of your tools is crucial. Each piece plays a vital role, and comprehending their functions can lead to better performance and longevity.

Exploring the intricacies of these components allows users to troubleshoot issues effectively and undertake repairs with confidence. Visual representations can simplify the understanding of how each part interconnects, enabling smoother operations and maintenance practices.

Ultimately, being knowledgeable about these elements not only enhances your skills but also ensures that your equipment runs optimally. Engaging with the visual guides will provide invaluable insights for both novice users and seasoned professionals alike.

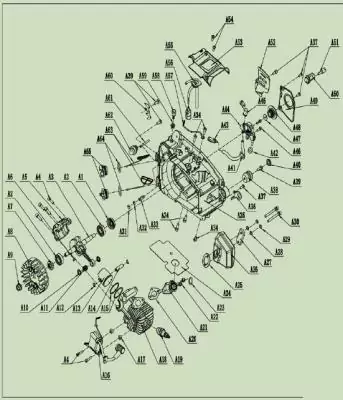

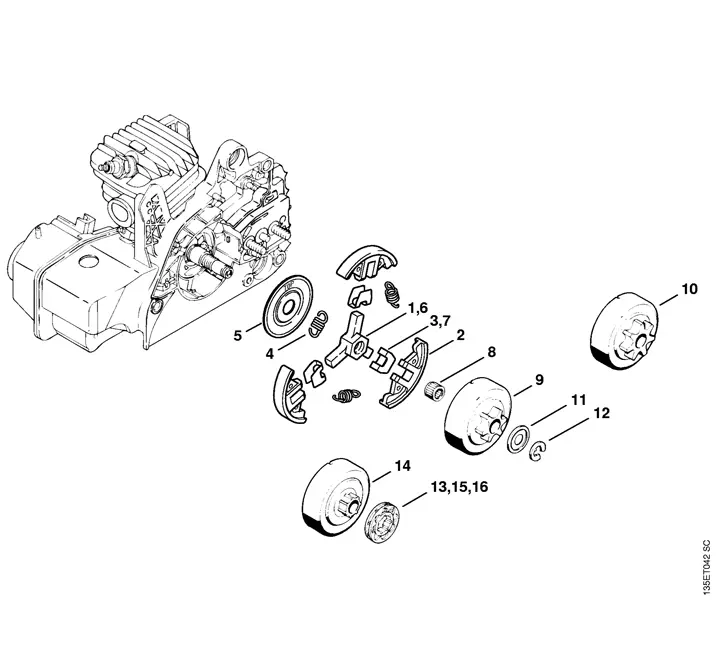

Understanding the 025 Stihl Parts Diagram

Grasping the layout of components in a power tool can greatly enhance maintenance and repair tasks. Familiarity with these schematics allows users to identify and replace worn or damaged elements efficiently, ensuring optimal performance and longevity of the equipment.

Key benefits of understanding the component layout include:

- Improved troubleshooting capabilities.

- Increased knowledge of the machine’s functionality.

- Enhanced ability to source compatible replacements.

- Cost savings by enabling DIY repairs.

When examining the layout, consider the following essential sections:

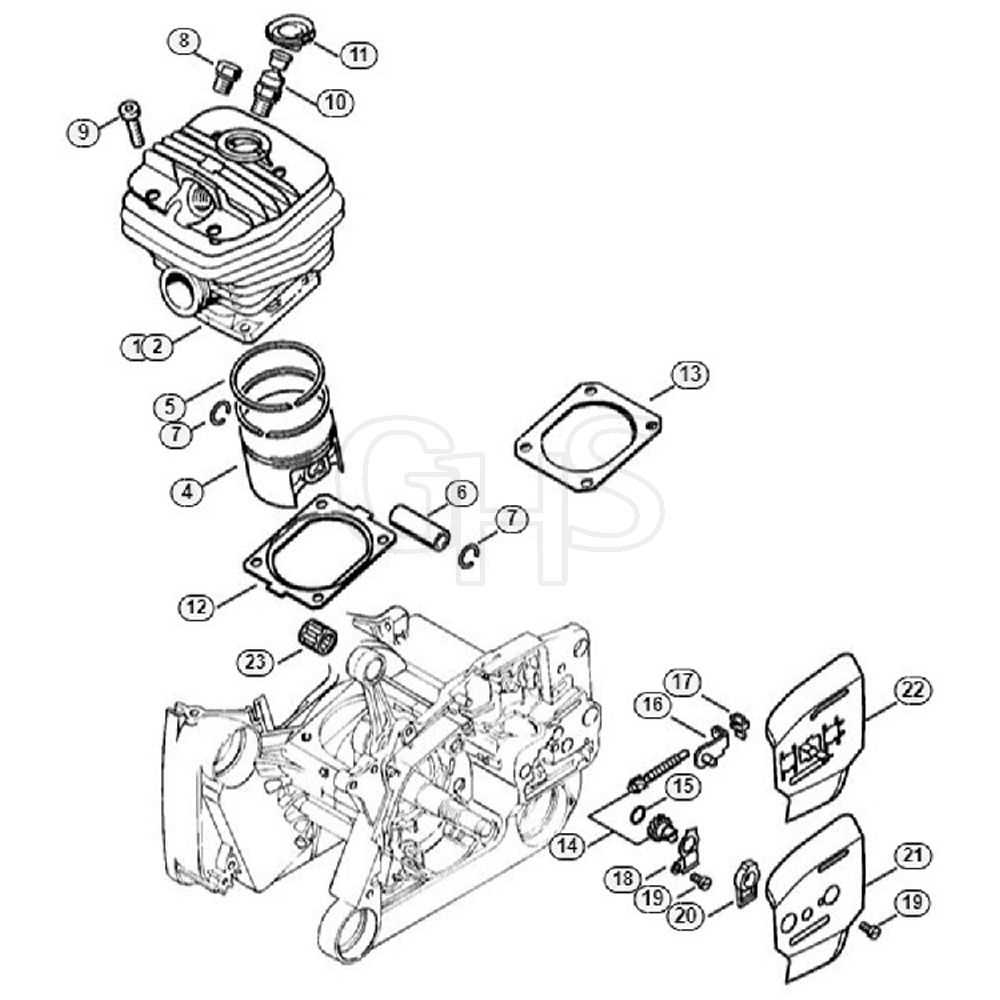

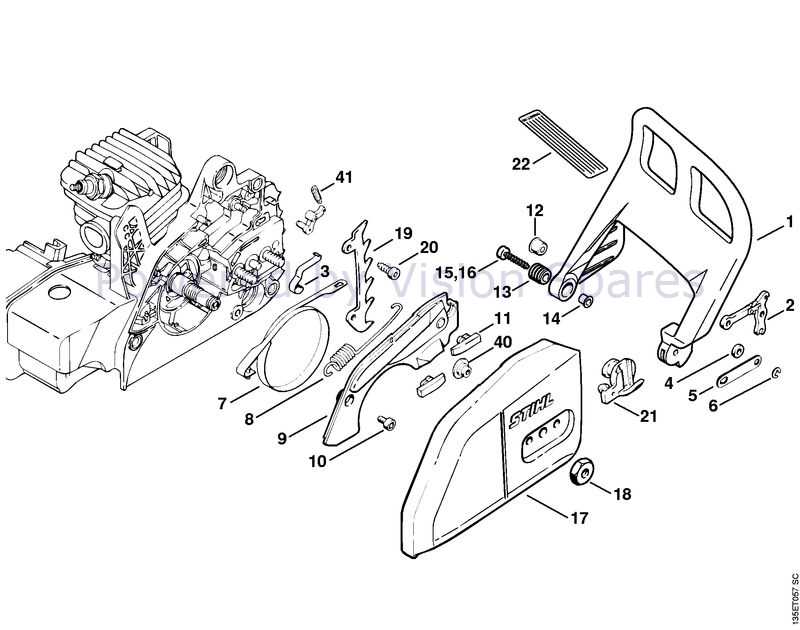

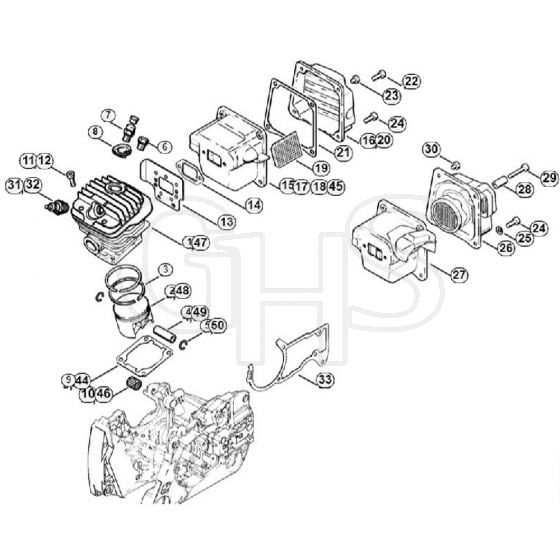

- Engine Assembly: Understand the parts that power the machine and how they interact.

- Fuel System: Familiarize yourself with components responsible for fuel delivery and efficiency.

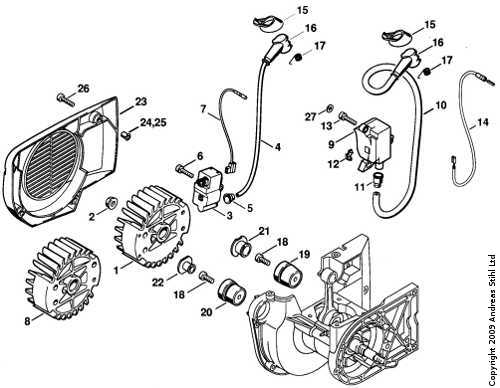

- Ignition System: Learn about the elements that spark the engine into action.

- Cutting Mechanism: Identify the parts that facilitate the tool’s primary function.

By breaking down the structure into these categories, users can better navigate and comprehend the intricacies of their equipment, making repairs and maintenance tasks more manageable and effective.

Importance of Accurate Parts Identification

Correctly identifying components is crucial for ensuring optimal performance and longevity of any machinery. Misidentification can lead to a range of issues, from operational inefficiencies to increased maintenance costs.

Here are several reasons why precise identification is essential:

- Operational Efficiency: Using the right components ensures that equipment functions smoothly, minimizing downtime.

- Cost-Effectiveness: Accurate identification helps avoid unnecessary purchases, reducing overall expenditure on replacements.

- Safety: Correct components are vital for maintaining safety standards, preventing accidents caused by faulty or incompatible parts.

- Compatibility: Ensuring that each element fits well with others is essential for seamless operation and performance.

- Longevity: Properly matched components contribute to the overall durability and lifespan of the equipment.

In summary, meticulous attention to detail in identifying each element plays a significant role in maintaining the functionality and reliability of machinery.

Common Issues with Stihl 025 Models

Many users of these popular outdoor power tools encounter specific challenges that can affect performance and reliability. Understanding these common problems can aid in troubleshooting and maintenance, ensuring smoother operation and longevity of the equipment.

Fuel System Complications

One frequent issue relates to the fuel system. Over time, fuel lines can become clogged or damaged, leading to poor engine performance. Regular inspection and replacement of these components are essential to avoid starting difficulties and inconsistent power delivery. Additionally, using stale or incorrect fuel can exacerbate these issues.

Ignition System Failures

The ignition system may also present challenges. A faulty spark plug or ignition coil can result in hard starting or misfiring during operation. Ensuring that these components are in good condition is vital for reliable performance. Regular maintenance and timely replacements can help prevent these common setbacks.

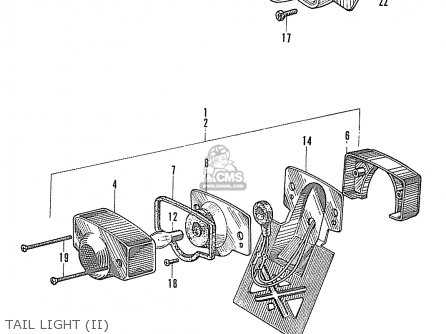

How to Read a Parts Diagram

Understanding a visual representation of components can significantly simplify maintenance and repairs. These illustrations often display various elements, their arrangement, and how they interact within a machine. Familiarity with this type of schematic can enhance your ability to identify parts, order replacements, and perform troubleshooting effectively.

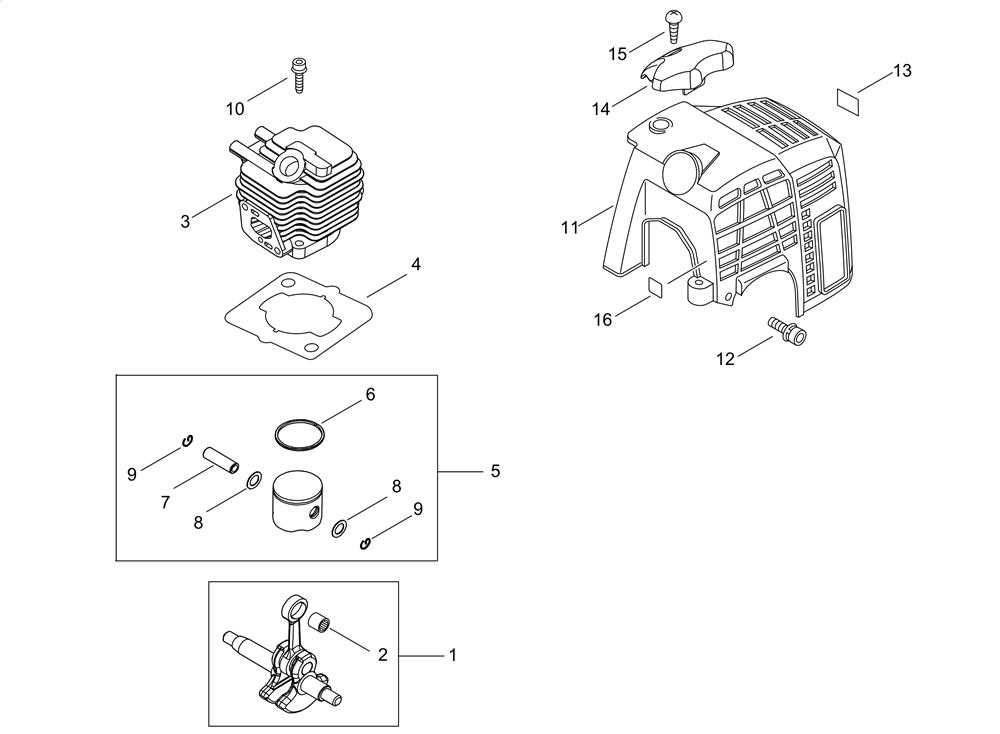

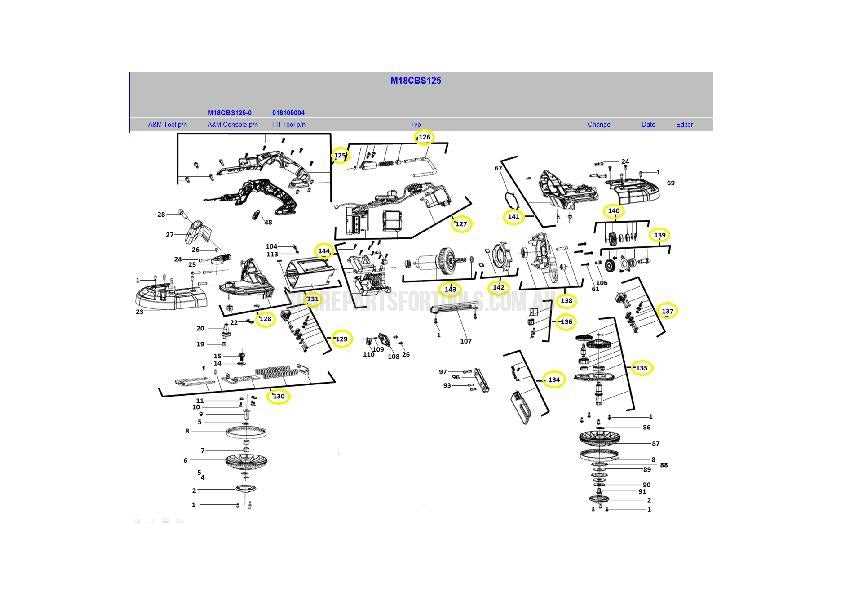

Key Components of the Visual Representation

Each illustration typically features labels and numbers corresponding to individual components. These identifiers make it easier to locate specific items. Often, the parts are categorized into sections, which can help in understanding the assembly’s overall structure. Pay attention to any accompanying legend or key that explains the symbols and notations used in the drawing.

Steps to Effectively Use the Representation

Start by locating the part you need to examine. Use the identifiers to find it on the visual guide and cross-reference it with any available lists that detail specifications and compatibility. Note the arrangement of surrounding elements, as this can provide insight into how to disassemble or reassemble parts without causing damage. Finally, ensure you have the correct information to facilitate any necessary orders for replacements.

Essential Tools for Maintenance Tasks

Regular upkeep of equipment is crucial for optimal performance and longevity. Having the right tools at your disposal can make maintenance tasks more efficient and effective. Below is a list of essential instruments that every technician should consider for routine care and repair activities.

- Wrenches: A variety of sizes is necessary to handle different fasteners. Adjustable wrenches are particularly versatile.

- Screwdrivers: Both flathead and Phillips types are indispensable for loosening and tightening screws.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Ideal for dealing with nuts and bolts, providing better leverage than standard wrenches.

- Cleaning Brushes: Essential for maintaining cleanliness in various parts of the equipment, preventing buildup and ensuring efficiency.

Having these tools readily available can significantly simplify maintenance processes. Regular checks and timely repairs can save time and resources in the long run, enhancing the performance of your equipment.

- Assess the condition of tools regularly to ensure they are in good working order.

- Organize your workspace for easy access to tools, reducing downtime during maintenance.

- Stay informed about specific maintenance requirements for your equipment to tailor your toolkit accordingly.

With the right instruments and a proactive approach, you can ensure that your equipment remains in peak condition, ready to perform whenever needed.

Where to Find Genuine Stihl Parts

Finding authentic components for your equipment is crucial for ensuring its optimal performance and longevity. With numerous options available, it’s essential to identify reliable sources that offer quality items designed specifically for your machinery. This section will guide you through the best avenues to procure original items, ensuring your tools run smoothly and efficiently.

Authorized Dealers

One of the most reliable places to obtain genuine components is through authorized retailers. These establishments often carry a comprehensive selection of items and can provide expert advice on compatibility and installation. Additionally, buying from authorized dealers often guarantees that you receive high-quality components that meet the manufacturer’s standards.

Online Resources

The internet is another valuable resource for sourcing authentic items. Many reputable online platforms specialize in selling original components. When purchasing online, always verify the seller’s credibility and check for customer reviews to ensure a safe transaction.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Quality assurance, expert support | Potentially higher prices |

| Online Retailers | Convenience, wide selection | Risk of counterfeit items |

| Manufacturer’s Website | Direct access to genuine items | Shipping times may vary |

Step-by-Step Repair Guide for 025

This guide provides a comprehensive approach to restoring your outdoor power equipment. Whether you’re facing performance issues or routine maintenance, following these steps will ensure a thorough and effective process.

- Preparation:

- Gather necessary tools and safety gear.

- Ensure the equipment is clean and free of debris.

- Diagnosis:

- Identify the symptoms of malfunction.

- Check fuel levels and quality.

- Inspect for visible damage or wear.

- Disassembly:

- Carefully remove components as per the manufacturer’s instructions.

- Organize parts to avoid confusion during reassembly.

- Inspection:

- Examine each part for signs of damage or excessive wear.

- Replace any faulty components with high-quality replacements.

- Reassembly:

- Follow the reverse order of disassembly.

- Ensure all connections are secure and components are aligned correctly.

- Testing:

- Start the equipment and observe its performance.

- Address any remaining issues as needed.

By following these structured steps, you can effectively restore your equipment to optimal functioning condition.

Upgrades and Modifications for Performance

Enhancing the efficiency and power of your equipment can significantly improve its overall functionality and longevity. By making targeted adjustments and integrating advanced components, users can experience enhanced performance tailored to their specific needs. This section will explore various options that can elevate your machine’s capabilities.

Engine Tuning is one of the most effective ways to boost performance. Adjusting the carburetor settings or optimizing the fuel mixture can lead to improved combustion and, consequently, better power output. This modification can often be achieved with simple tools, making it accessible for most users.

Another essential upgrade involves the air filtration system. Upgrading to a high-flow filter can increase airflow, allowing the engine to breathe better and perform more efficiently. This change can result in noticeable gains in horsepower and throttle response.

Consider also the benefits of a performance exhaust. An aftermarket exhaust system can reduce back pressure, which allows exhaust gases to exit more freely. This modification not only enhances performance but can also contribute to a more robust sound, adding to the overall experience.

Lastly, regular maintenance is crucial. Keeping components such as spark plugs, fuel lines, and filters in top condition ensures that your machine operates at peak performance. Simple routine checks can prevent wear and tear and maintain efficiency over time.

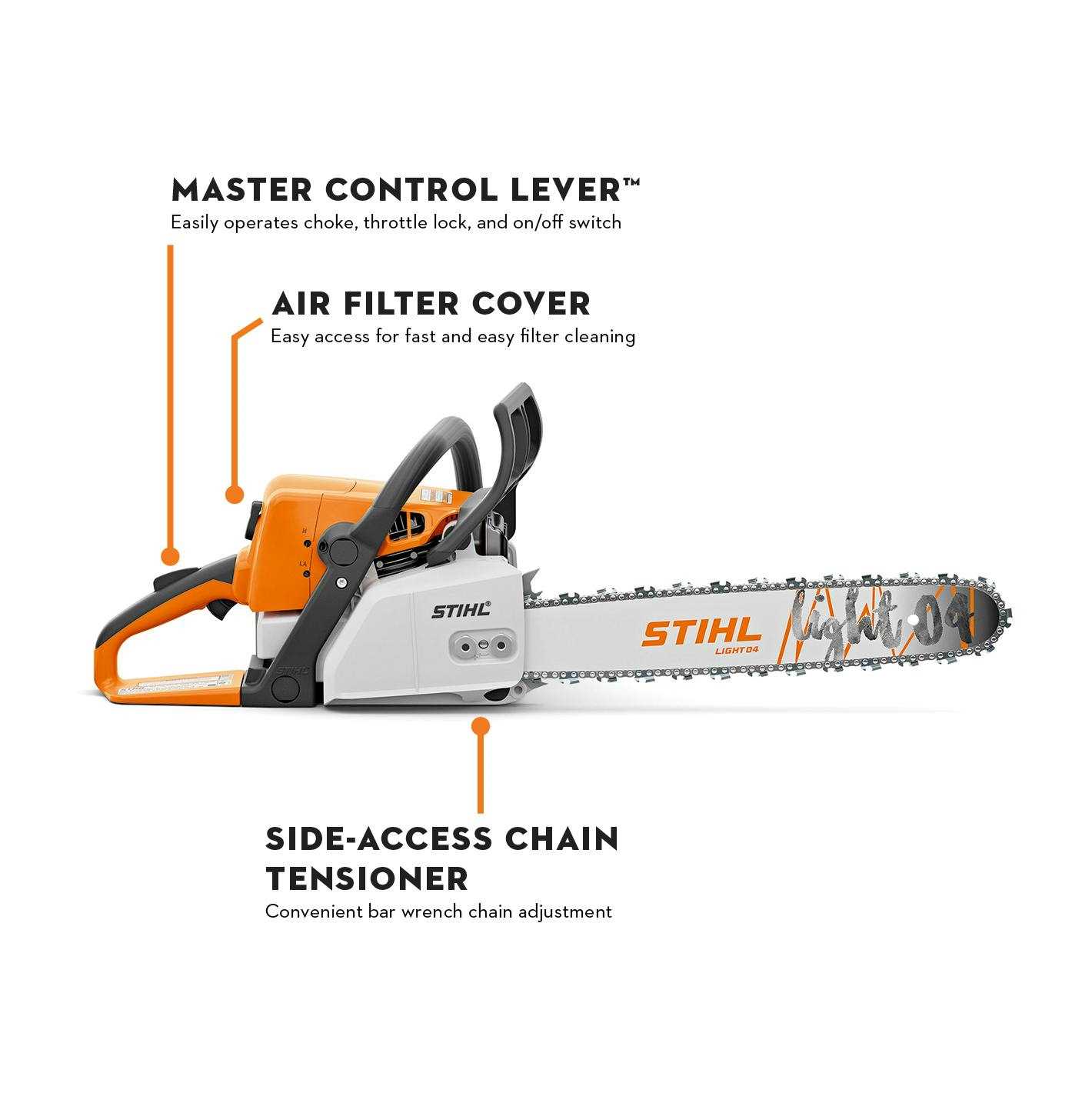

Tips for Maintaining Your Stihl Equipment

Regular upkeep of your tools is essential for ensuring longevity and optimal performance. By following a few straightforward practices, you can enhance the efficiency of your equipment and prevent unnecessary breakdowns. This guide outlines key strategies to keep your machinery in top shape.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean the air filter | Every 10 hours of use | Remove debris and dust to allow proper airflow. |

| Check the fuel system | Before each use | Ensure fuel is fresh and free of contaminants. |

| Sharpen the blades | As needed | Use a sharpening tool to maintain cutting efficiency. |

| Inspect spark plug | Every 25 hours of use | Replace if worn or dirty to ensure smooth operation. |

| Lubricate moving parts | Every 5 hours of use | Use appropriate lubricants to prevent wear. |

Implementing these maintenance practices will not only extend the life of your equipment but also enhance safety during use. Regular attention to detail can make a significant difference in performance and reliability.