Maintaining machinery requires a clear understanding of its components and how they fit together. Having a visual reference is essential for both troubleshooting and routine maintenance. This resource aims to provide insight into the various elements of your equipment, ensuring you can effectively identify and address any issues that may arise.

Whether you are a professional or a hobbyist, familiarity with the internal structure of your tools can enhance their performance and longevity. By examining a detailed representation, users can easily locate specific parts, understand their functions, and make informed decisions regarding repairs and replacements.

Armed with this knowledge, you can approach maintenance tasks with confidence. Understanding how each element works in harmony not only prevents mishaps but also fosters a deeper appreciation for the craftsmanship involved in your equipment. Dive into the intricacies of your machinery and empower yourself to keep it running smoothly.

Understanding the 026 Stihl Chainsaw

This section aims to provide an insightful overview of a widely-used cutting tool, emphasizing its design, functionality, and key components. Knowing the essential features and mechanics can significantly enhance the user experience, making tasks more efficient and effective.

Key Features

This model is known for its robust engine and ergonomic design, which allows for extended use without excessive fatigue. Its lightweight construction does not compromise durability, making it suitable for both professional and amateur users. Understanding its capabilities can help in selecting the right applications, whether for landscaping or forestry tasks.

Maintenance and Care

Common Issues with Stihl 026 Models

When it comes to chainsaw performance, certain challenges frequently arise, impacting functionality and user experience. These issues can stem from various factors, including wear and tear, improper maintenance, or environmental conditions. Understanding these common problems is essential for ensuring optimal operation and longevity.

Starting Difficulties: Many users report struggles when attempting to ignite their machines. This can often be attributed to fuel quality or issues with the ignition system.

Fuel Leaks: Leaking fuel not only poses a safety hazard but can also indicate problems with the fuel lines or gaskets, requiring prompt attention.

Chain Tension Problems: Improper chain tension can lead to inefficient cutting and increased wear. Regular checks and adjustments are necessary to maintain performance.

Overheating: Overheating can occur due to various reasons, including dull blades or clogged air filters, which impede airflow and cooling.

By recognizing these frequent challenges, users can take proactive measures to enhance performance and extend the lifespan of their equipment.

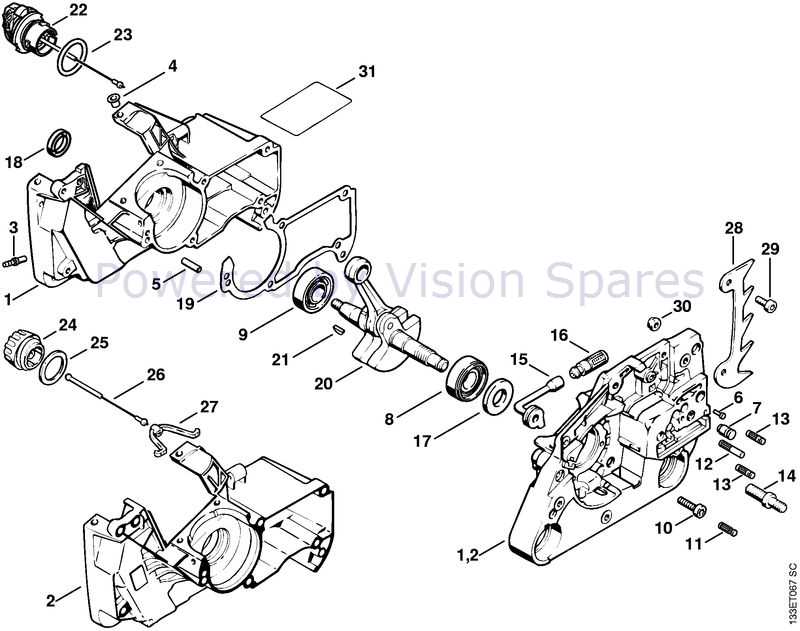

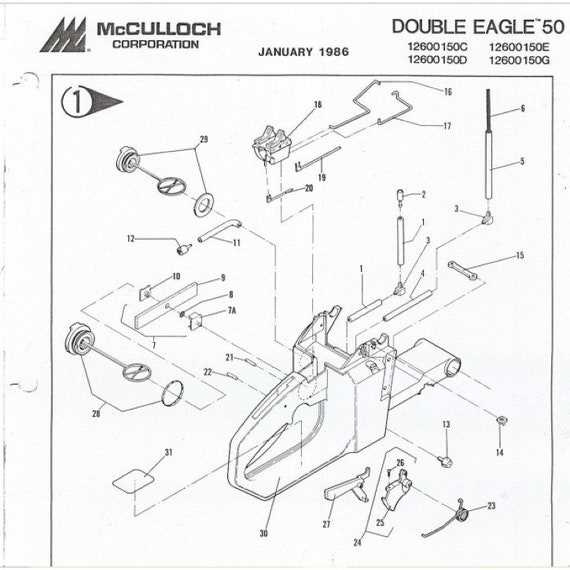

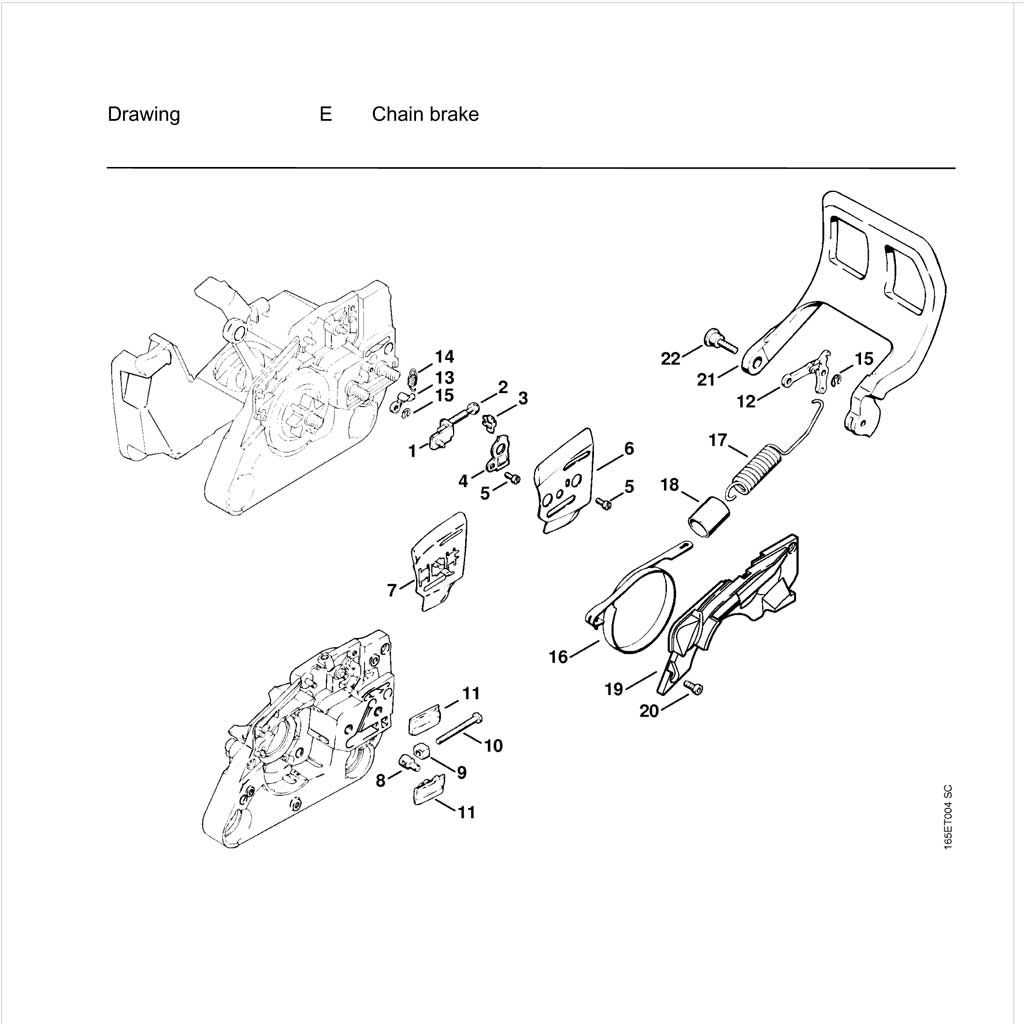

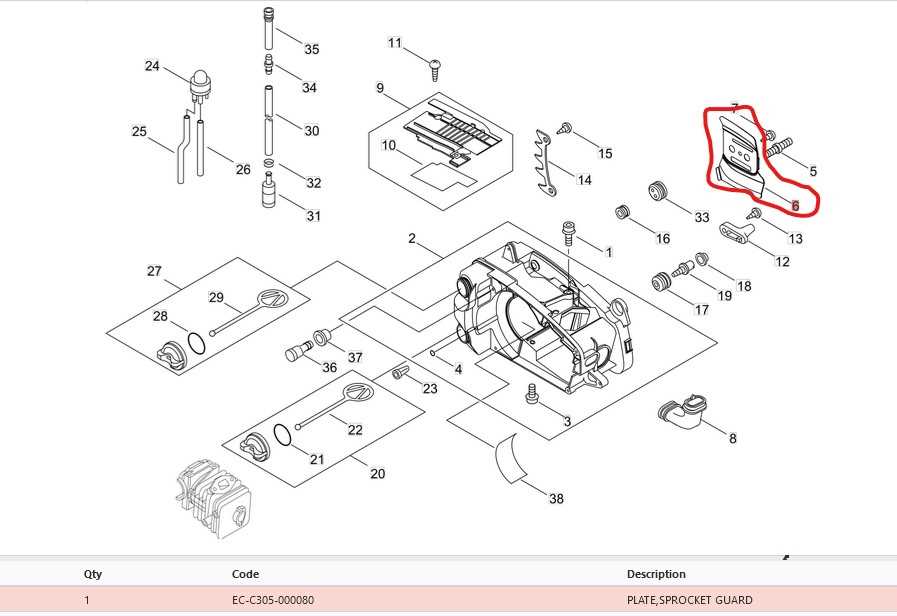

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, enabling users to identify, locate, and comprehend the various elements involved in the assembly and functionality of equipment.

Clear visualization aids in troubleshooting, allowing technicians to quickly pinpoint issues and determine the necessary interventions. Additionally, these illustrations facilitate efficient communication among team members, ensuring everyone is on the same page regarding repairs and replacements.

Moreover, such resources enhance the learning experience for newcomers, providing a foundational understanding of how different components interact. Ultimately, these visual aids are invaluable in promoting longevity and optimal performance of machinery.

How to Use the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair of equipment. This guide will help you navigate the schematic illustration, enabling you to identify and order the necessary elements for your machine.

First, familiarize yourself with the layout. Each part is labeled with a unique identifier, making it easier to find specific components. Pay attention to the grouping of similar items, which can provide insights into assembly and functionality.

Next, use the accompanying reference table to match identifiers from the illustration to their descriptions. This will streamline the ordering process and ensure you receive the correct replacements.

| Identifier | Description | Quantity Needed |

|---|---|---|

| A1 | Fuel Tank | 1 |

| B2 | Air Filter | 1 |

| C3 | Ignition Module | 1 |

Finally, cross-reference any details with the user manual for additional context on installation and maintenance. Utilizing these tools effectively will enhance your repair skills and prolong the lifespan of your equipment.

Identifying Key Components of 026

Understanding the essential elements of a particular equipment model is crucial for effective maintenance and troubleshooting. Each component plays a vital role in the overall functionality and performance.

Main Elements to Consider

- Power Unit

- Fuel System

- Ignition Assembly

- Guide Bar

- Chain Mechanism

Importance of Each Component

- Power Unit: The heart of the machine, providing the necessary energy for operation.

- Fuel System: Responsible for delivering the mixture needed for combustion.

- Ignition Assembly: Initiates the combustion process, crucial for starting the device.

- Guide Bar: Supports the cutting chain, influencing cutting efficiency.

- Chain Mechanism: Engages the cutting action, directly affecting performance.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is essential for optimal performance. Various sources offer a range of options, ensuring you can find what you need for repairs or upgrades.

Authorized Dealers: Visiting an authorized dealer is one of the most reliable ways to acquire authentic components. These establishments typically stock a comprehensive selection and can provide expert advice on compatibility and installation.

Online Retailers: The internet is a valuable resource for sourcing replacements. Numerous websites specialize in equipment accessories, often providing detailed descriptions and customer reviews to help you make informed decisions. Look for reputable platforms to ensure quality.

Local Repair Shops: Many local repair shops can assist with sourcing components. These businesses often have connections with suppliers and may even carry certain items in stock, allowing for quicker repairs.

Salvage Yards: For those seeking budget-friendly alternatives, salvage yards can be a treasure trove. Here, you might find gently used components at a fraction of the retail price, but be sure to assess their condition before purchase.

Community Forums: Engaging with online communities can also be beneficial. Forums and social media groups dedicated to equipment maintenance often feature members who can recommend sources or even sell items directly.

By exploring these avenues, you can ensure your machinery remains in peak condition without breaking the bank.

Tips for Maintaining Your Chainsaw

Regular upkeep of your cutting tool is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also ensures safety during use. Here are some key practices to keep in mind.

1. Clean After Use: Always remove debris and sawdust after each operation. This prevents buildup and keeps components in good condition.

2. Check the Chain Tension: Maintaining the correct tension is crucial. A loose chain can derail, while a tight one may cause damage. Adjust it according to the manufacturer’s guidelines.

3. Sharpen the Chain: A sharp chain cuts more efficiently and safely. Regularly inspect and sharpen it to avoid unnecessary strain on the motor.

4. Inspect the Air Filter: A clean air filter ensures optimal airflow. Replace or clean it as needed to maintain performance.

5. Use Quality Fuel: Always use the recommended fuel type. High-quality fuel can reduce engine wear and improve performance.

6. Store Properly: When not in use, store your tool in a dry place. Consider using a protective cover to prevent dust accumulation.

By following these tips, you can significantly extend the life of your cutting tool and enhance its functionality.

Advantages of Using Original Parts

Utilizing components from the original manufacturer offers numerous benefits that enhance the performance and longevity of equipment. These parts are designed to meet strict quality standards, ensuring that your machinery operates efficiently and safely.

- Quality Assurance: Original components undergo rigorous testing and quality control, guaranteeing durability and reliability.

- Perfect Fit: They are engineered specifically for your equipment, ensuring compatibility and optimal function.

- Enhanced Performance: Using original parts helps maintain the intended performance levels, allowing the equipment to work as designed.

- Warranty Protection: Many manufacturers provide warranty coverage when original parts are used, offering peace of mind.

- Safety: Authentic components are designed with safety in mind, reducing the risk of malfunctions and accidents.

In conclusion, opting for genuine components not only supports the efficient operation of your machinery but also contributes to its overall longevity and safety, making it a wise investment for any user.