The efficiency of any outdoor equipment relies heavily on the quality and compatibility of its individual elements. Understanding how each piece fits into the larger mechanism is essential for maintaining performance and ensuring longevity. This section provides a detailed examination of the various components that contribute to the overall functionality of the machine.

Whether you are conducting repairs or routine maintenance, having a clear understanding of the arrangement and role of each part is vital. This information aids in identifying the specific items needed for replacement, facilitating a smoother process when addressing any mechanical issues.

Moreover, recognizing the interplay between different elements enhances your ability to troubleshoot effectively. By gaining insight into how these components interact, users can better anticipate potential challenges and implement proactive solutions.

Understanding the layout and components of a machine is essential for efficient maintenance and repair. A comprehensive illustration showcasing the various elements involved provides clarity and aids in troubleshooting, ensuring that every part is correctly identified and addressed.

Having a visual representation serves several key purposes:

- Facilitates Identification: Easily recognize each component, simplifying the process of locating specific pieces when needed.

- Enhances Communication: A common reference point for technicians and users promotes effective discussions regarding repairs or replacements.

- Improves Maintenance: Regular upkeep becomes more manageable when users can see how parts interact and which areas require attention.

- Aids in Troubleshooting: Quickly pinpoint issues by comparing the existing state of the machine against the reference illustration.

- Streamlines Repair Process: Knowing exactly what is required reduces downtime and increases efficiency during maintenance sessions.

In summary, a well-structured visual representation is a valuable tool for anyone involved in the upkeep of machinery, enabling smoother operations and more effective management of resources.

Commonly Replaced Parts Overview

Maintenance and repair of outdoor power equipment often require the replacement of various components. Understanding which elements are frequently changed can help ensure optimal performance and longevity of the machine. This section will highlight the key components that users typically consider for replacement during servicing.

Frequently Changed Components

One of the most common elements to be replaced is the cutting blade. Over time, blades can become dull or damaged, affecting the efficiency of grass cutting. Regularly inspecting and replacing the blade can enhance the overall performance of the equipment.

Other Key Elements

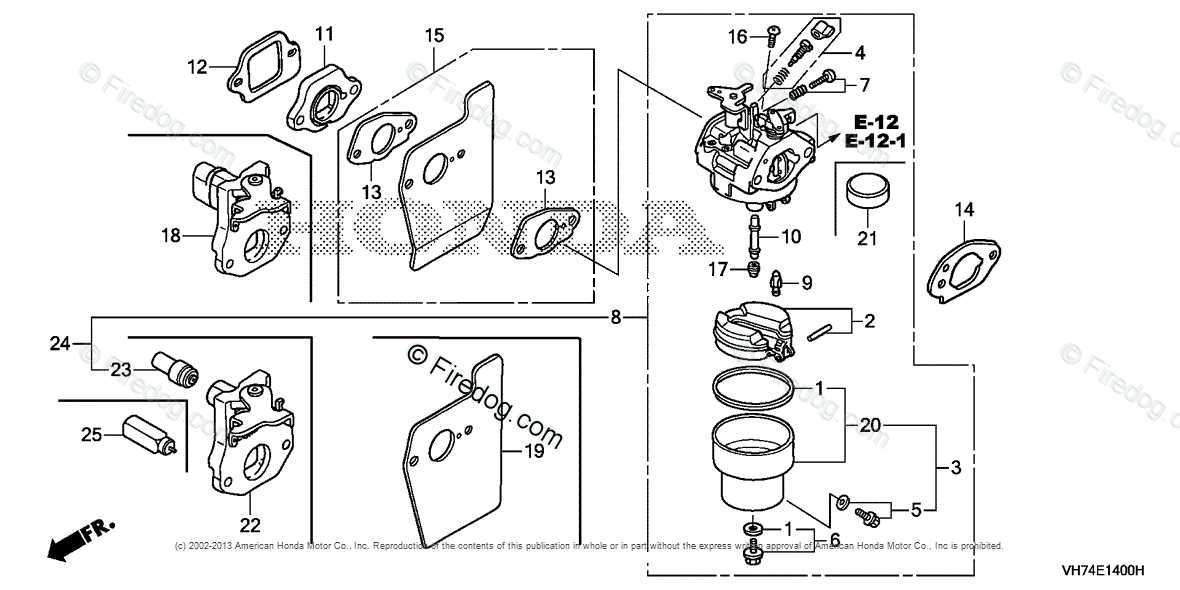

Another essential component often needing replacement is the air filter. A clogged filter can hinder engine performance and fuel efficiency. Ensuring that the air filter is clean or replaced periodically is crucial for maintaining optimal airflow and engine function.

Maintenance Tips for Longevity

To ensure optimal performance and extend the lifespan of your equipment, regular upkeep is essential. Implementing simple maintenance practices can greatly enhance efficiency and prevent costly repairs down the line.

Routine Cleaning

Keeping your equipment clean is vital for its longevity. Dust and debris can accumulate, leading to performance issues. Here are some cleaning tips:

- After each use, wipe down the exterior to remove dirt and grime.

- Inspect and clean the air filters regularly to promote better airflow.

- Ensure that all vents and openings are free of blockages.

Regular Inspections

Conducting frequent inspections helps identify potential issues before they escalate. Follow these guidelines:

- Check for any loose bolts or components and tighten as needed.

- Monitor belts and cables for wear and replace them if necessary.

- Examine fluids and levels; top off or replace as required.

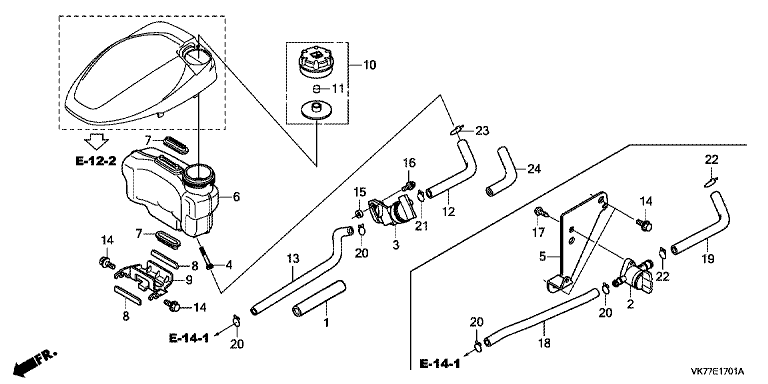

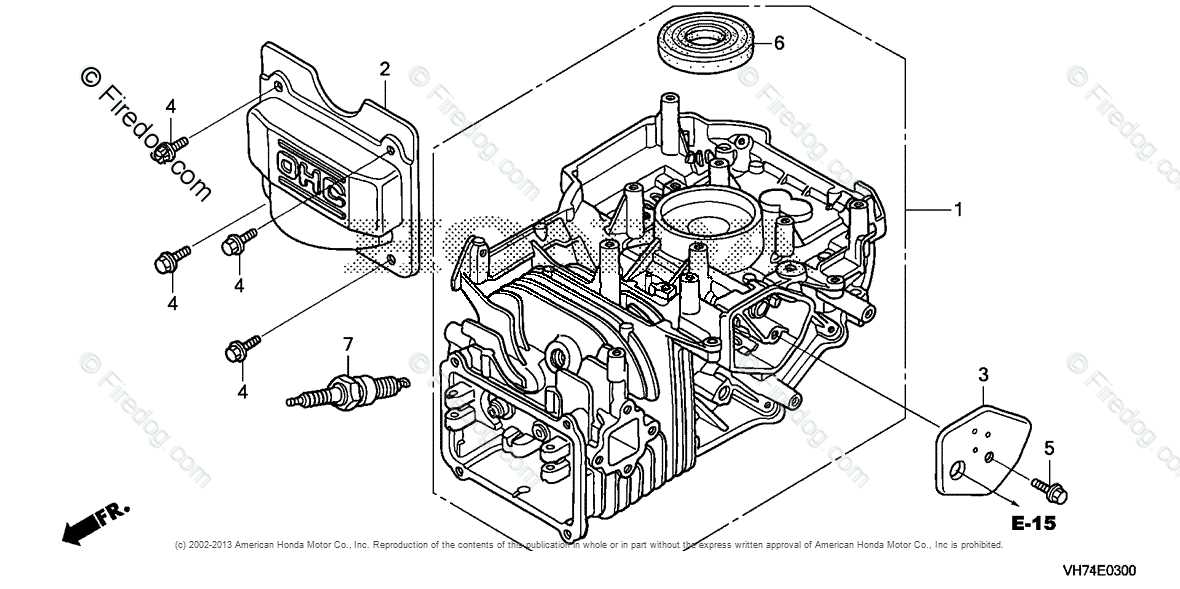

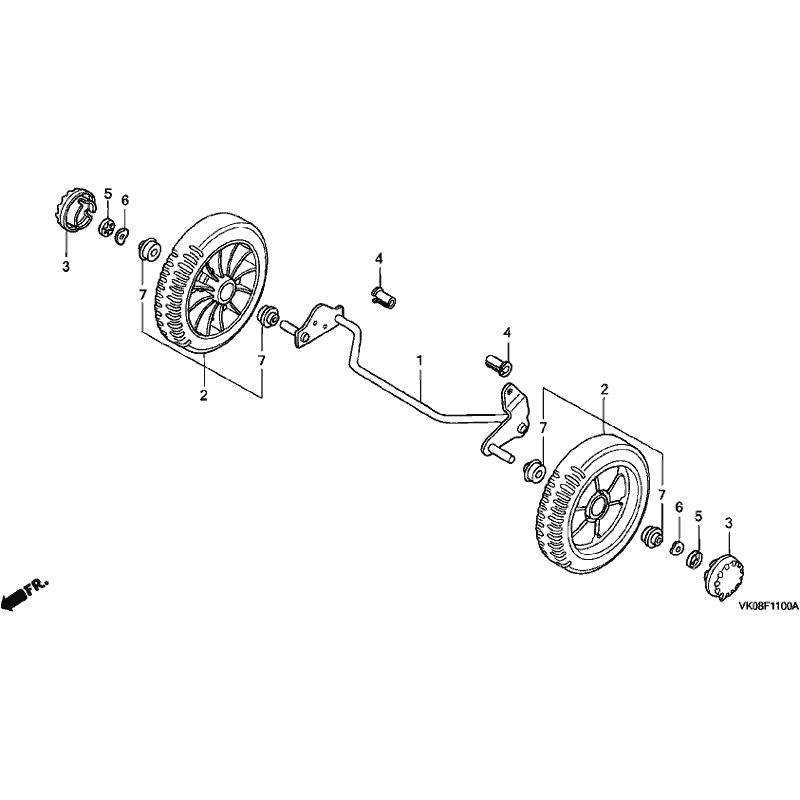

Identifying Parts by Diagrams

Understanding the components of a machine through visual representations is essential for effective maintenance and repairs. These illustrations provide a clear view of each element, allowing users to familiarize themselves with their functions and placements within the overall structure.

Utilizing visual aids can significantly enhance the ability to pinpoint specific elements when troubleshooting or performing replacements. By carefully examining these representations, one can gain insight into how different components interact and contribute to the machinery’s overall performance.

Moreover, such visual guides are invaluable when it comes to locating replacement items. They serve as a reference point, ensuring that the correct elements are selected for any necessary upgrades or repairs. This practice not only saves time but also prevents potential errors that could arise from misidentification.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Various resources are available to assist you in acquiring high-quality replacements that ensure optimal performance.

Online Retailers: Many websites specialize in providing a wide range of components for different types of machinery. These platforms often feature user-friendly search functions, allowing you to easily identify and order the specific items you need. Make sure to read customer reviews to ensure reliability.

Local Dealerships: Visiting a nearby authorized dealer can be beneficial. They usually stock original components and can provide valuable advice regarding installation and compatibility. Additionally, local dealers may offer warranties on the items they sell, providing peace of mind.

Repair Shops: Professional repair services often have access to various suppliers and can assist in sourcing the right components. By consulting with them, you may discover options that are not readily available online or in stores.

Community Forums: Engaging with online communities dedicated to your equipment type can yield useful information. Members often share recommendations for reliable suppliers and may even offer insights based on their own experiences.

Comparing HRX217HXA with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. By examining various features, performance metrics, and user feedback, we can better understand how this particular unit stands out in a competitive market. The focus will be on aspects such as engine efficiency, cutting technology, and overall usability.

Key Features Overview

When comparing various models, it is essential to highlight key attributes that influence user experience. Below is a comparison table that outlines the significant specifications and functionalities across different models.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | Gasoline | Gasoline | Electric |

| Cutting Width | 21 inches | 22 inches | 20 inches |

| Weight | 90 lbs | 85 lbs | 75 lbs |

| Price | $500 | $550 | $400 |

User Experience and Performance

User satisfaction plays a crucial role in determining the effectiveness of any model. Feedback on ease of use, maintenance requirements, and reliability can help potential buyers make informed decisions. Reviews often indicate preferences for specific features, such as self-propulsion or adjustable cutting heights, which can significantly enhance the mowing experience.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components of lawn care machinery. Understanding the various elements can enhance maintenance and ensure optimal performance.

- What should I consider when replacing components?

When looking to replace a component, consider the following:

- Compatibility with your equipment model

- Quality and durability of the material

- Manufacturer recommendations

- How do I identify the correct components for my machine?

To find the right components, you can:

- Consult the user manual for specifications

- Visit a reliable online resource or retailer

- Seek assistance from a local repair shop

- Are there universal components available?

Yes, some components are designed to be universally compatible. However, it’s essential to ensure they meet your equipment’s requirements for proper functionality.

- What are the signs that a component needs replacement?

Common indicators include:

- Unusual noises during operation

- Reduced efficiency or performance

- Visible wear or damage on the component

- How can I ensure the longevity of my equipment?

To maintain your machinery’s longevity:

- Regularly check and replace worn components

- Follow the manufacturer’s maintenance schedule

- Keep the machinery clean and well-lubricated