In the fascinating world of homemade beverage production, various elements work in harmony to transform raw ingredients into a refined spirit. Each component plays a crucial role in this intricate process, ensuring the successful extraction of desired flavors and alcohol content.

Every assembly has its unique functions, contributing to the overall efficiency and quality of the final product. From the initial collection of vapor to the eventual condensation into liquid, understanding these crucial sections is essential for both beginners and experienced enthusiasts alike.

By exploring the various segments of this intricate setup, one can delve into the mechanics behind the transformation, gaining insights that lead to better craftsmanship. Ultimately, mastering these components can elevate the art of spirit-making to new heights.

Understanding the Basics of Moonshine Stills

The art of crafting homemade spirits has a rich history, with enthusiasts drawn to the process of fermentation and distillation. This endeavor involves a series of components working in harmony to transform raw ingredients into a desired beverage. Familiarity with the essential elements of this process is crucial for anyone looking to engage in this time-honored tradition.

Core Components of the Distillation Process

At its foundation, the distillation procedure consists of several key components that facilitate the transformation of mash into high-proof liquid. Each element plays a vital role in ensuring efficiency and quality in the final product.

| Component | Function |

|---|---|

| Fermentation Vessel | Where the initial mixture undergoes fermentation, converting sugars into alcohol. |

| Heat Source | Provides the necessary temperature for vaporization of the alcohol. |

| Condensing Unit | Cools vapor back into liquid form, allowing for collection of the final product. |

| Collection Container | Stores the distilled liquid for further processing or consumption. |

Safety Considerations

Engaging in the creation of spirits requires adherence to safety protocols. The use of high temperatures and flammable materials poses risks that must be managed carefully. Proper ventilation, temperature control, and understanding of local regulations are essential to ensure a safe and enjoyable experience.

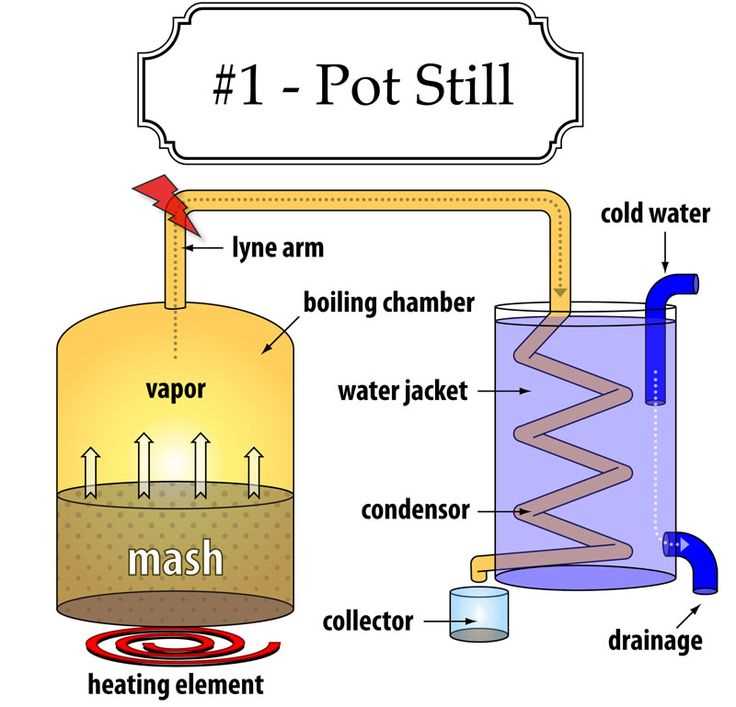

Essential Components of a Still

The process of distillation relies on several key elements that work together to facilitate the separation of alcohol from other substances. Understanding these vital components is crucial for anyone looking to delve into this intricate practice. Each part plays a specific role in ensuring efficiency and effectiveness during the production process.

Primary Elements

At the heart of the operation is the boiler, where the initial mixture is heated. This component must be constructed from materials that can withstand high temperatures and pressure. Adjacent to the boiler is the condensing unit, which cools the vapor back into liquid form. The efficiency of this unit significantly affects the yield of the final product.

Supporting Features

Additional features such as the thermometer and valves are essential for monitoring and controlling the process. The thermometer provides real-time temperature readings, allowing for precise adjustments. Valves enable the operator to manage the flow of the vapor and liquid, ensuring optimal performance throughout the operation.

Common Types of Moonshine Stills

When it comes to creating distilled spirits at home, various designs and configurations can be employed, each serving unique purposes and offering different experiences. Understanding these configurations helps enthusiasts choose the right setup for their brewing endeavors.

Traditional Pot Designs

The most recognized form of apparatus features a simple, yet effective structure. These designs are often favored for their ease of use and historical significance.

- Basic Pot Still: Consists of a boiling vessel and a condenser. Ideal for beginners.

- Single Distillation Units: Focus on simplicity, yielding spirits with robust flavors.

- Double Distillation Units: Offer a more refined product by undergoing two rounds of distillation.

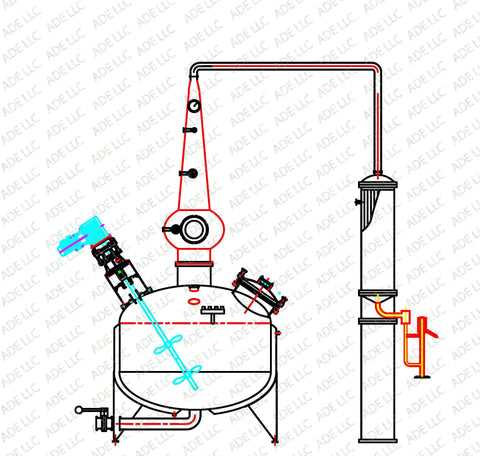

Column Configurations

These setups incorporate a vertical column that enhances the purification process. They are often chosen for producing higher-proof spirits.

- Continuous Column: Allows for an uninterrupted process, making it efficient for large batches.

- Plate Column: Uses several plates to improve separation, resulting in a cleaner final product.

- Hybrid Systems: Combine aspects of both pot and column designs, offering versatility in production.

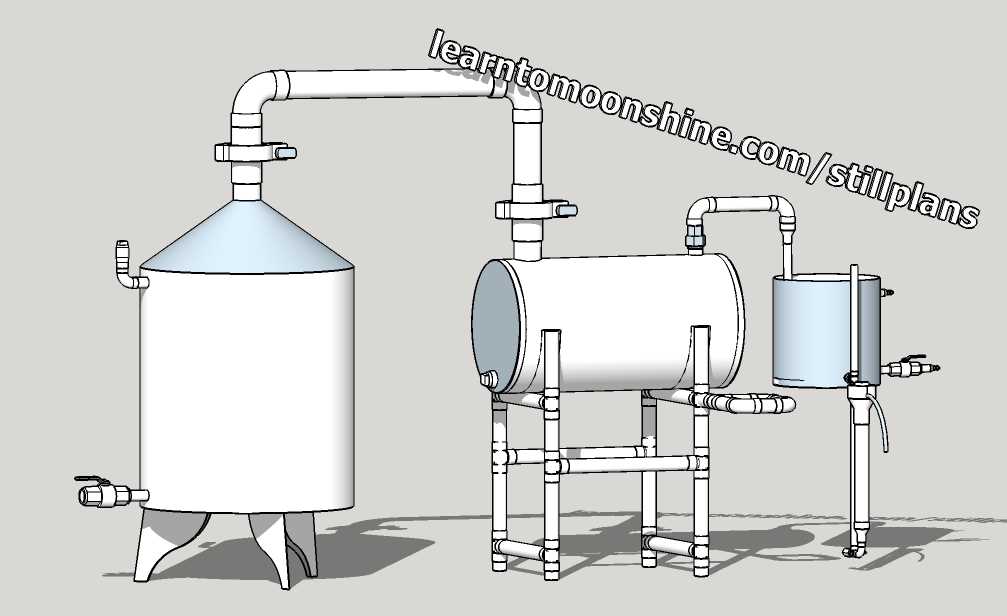

How to Assemble a Distillation Unit

Creating an effective apparatus for the separation of liquids involves a series of carefully arranged components. Each element plays a crucial role in ensuring that the process is efficient and yields high-quality results. Understanding the assembly process is essential for both novices and experienced individuals seeking to enhance their distillation skills.

Necessary Components

Before starting the assembly, gather the following essential elements:

- Boiling vessel

- Condensing unit

- Receiving container

- Heating source

- Thermometer

- Sealing materials

- Connecting tubing

Assembly Steps

- Begin by positioning the boiling vessel securely on the heating source.

- Attach the condensing unit to the top of the boiling vessel. Ensure a tight seal to prevent any vapor from escaping.

- Connect the receiving container to the outlet of the condensing unit using appropriate tubing.

- Install the thermometer in a suitable location to monitor the temperature during the process.

- Double-check all connections and seals to confirm there are no leaks.

- Once everything is in place, power on the heating source and observe the process.

By following these steps, you will successfully assemble a functional unit that allows for effective liquid separation. Careful attention to detail during assembly will enhance the overall performance and safety of the operation.

Safety Considerations When Distilling

Engaging in the art of crafting spirits requires not only skill and knowledge but also a thorough understanding of safety protocols. The process involves handling flammable materials and potentially hazardous substances, making it crucial to take appropriate precautions to ensure a safe environment.

First and foremost, proper ventilation is essential. Working in a well-ventilated area helps prevent the buildup of harmful vapors, reducing the risk of fire or explosion. Ensure that any space used for this activity is equipped with adequate airflow, and avoid closed environments.

Additionally, protective gear should not be overlooked. Wearing gloves, goggles, and a lab coat can provide an extra layer of safety against spills and splashes. It’s also advisable to keep a fire extinguisher nearby, as a precaution against any unexpected incidents.

Understanding the materials involved is another key factor. Familiarize yourself with the substances being used, including their properties and potential risks. This knowledge can help in making informed decisions throughout the process, particularly regarding storage and handling.

Lastly, always prioritize legal compliance. Be aware of the regulations governing the production of alcoholic beverages in your region. Adhering to local laws not only ensures safety but also protects you from potential legal repercussions.

Legal Aspects of Home Distilling

The production of alcoholic beverages at home can be a fascinating hobby, but it is crucial to understand the legal framework surrounding it. Different jurisdictions have varying laws regarding the manufacture and possession of distilled spirits. Awareness of these regulations is essential for anyone considering this activity to avoid potential legal repercussions.

In many regions, the unauthorized production of alcohol is strictly prohibited. This can lead to significant fines or even criminal charges. Therefore, it is important to research and comprehend local laws before engaging in such practices. Compliance with licensing requirements, if applicable, is also necessary to ensure lawful operation.

| Region | Legal Status | Required Licenses |

|---|---|---|

| United States | Illegal without permit | Federal and state licenses |

| Canada | Varies by province | Provincial licenses |

| United Kingdom | Illegal without license | Distiller’s license |

| Australia | Illegal without permit | Federal license |

Understanding these regulations can not only prevent legal troubles but also enhance the overall enjoyment of the craft. It allows enthusiasts to explore their passion within the boundaries of the law, ensuring a safe and responsible approach to home production.

Maintenance Tips for Moonshine Equipment

1. Regular Cleaning: After each use, thoroughly clean all components to prevent residue buildup. Use a mixture of vinegar and water to remove any deposits, ensuring that every part is free from contaminants.

2. Inspect for Damage: Routinely check for cracks, leaks, or any signs of wear and tear. Promptly replacing damaged components can prevent accidents and ensure smooth operation.

3. Check Seals and Gaskets: Ensure that all seals are airtight. Worn or damaged gaskets can lead to inefficient distillation and loss of valuable vapors.

4. Monitor Temperature Controls: Regularly test and calibrate your temperature gauges to ensure accurate readings. This step is vital for maintaining the right distillation conditions.

5. Store Properly: When not in use, store your equipment in a dry, cool place. Covering it with a breathable cloth can prevent dust accumulation while allowing moisture to escape.

6. Keep Documentation: Maintain a log of maintenance activities, including repairs and replacements. This record can help track the condition of your equipment and schedule future maintenance.

By adhering to these maintenance practices, you can ensure that your distillation setup remains efficient, safe, and capable of producing high-quality results for years to come.

Innovative Designs for Modern Stills

In the world of craft distillation, creativity and engineering prowess converge to produce groundbreaking apparatuses. These modern designs prioritize efficiency, sustainability, and user-friendliness, transforming the way enthusiasts engage with the craft. The latest advancements not only enhance the quality of the output but also streamline the overall process, making it more accessible to hobbyists and professionals alike.

Modular Systems have emerged as a popular trend, allowing users to customize their setup according to specific needs. By integrating interchangeable components, distillers can easily modify their equipment for different types of spirits or to experiment with unique flavor profiles. This flexibility encourages innovation and personal expression in the craft.

Energy Efficiency is another crucial aspect of contemporary designs. Many new models utilize cutting-edge technology to minimize energy consumption while maximizing performance. Heat exchangers and advanced insulation techniques are commonly employed to ensure that every drop of liquid is processed with minimal waste, contributing to a more environmentally friendly approach.

Moreover, smart technology has begun to play a significant role in the evolution of distillation equipment. Devices equipped with sensors and connectivity features allow users to monitor and control the process remotely, providing real-time data on temperature and pressure. This integration of technology ensures precision and consistency, elevating the craft to new heights.

As the landscape of distillation continues to evolve, these innovative designs reflect a growing trend towards personalization, efficiency, and technological integration, shaping the future of this ancient art form.