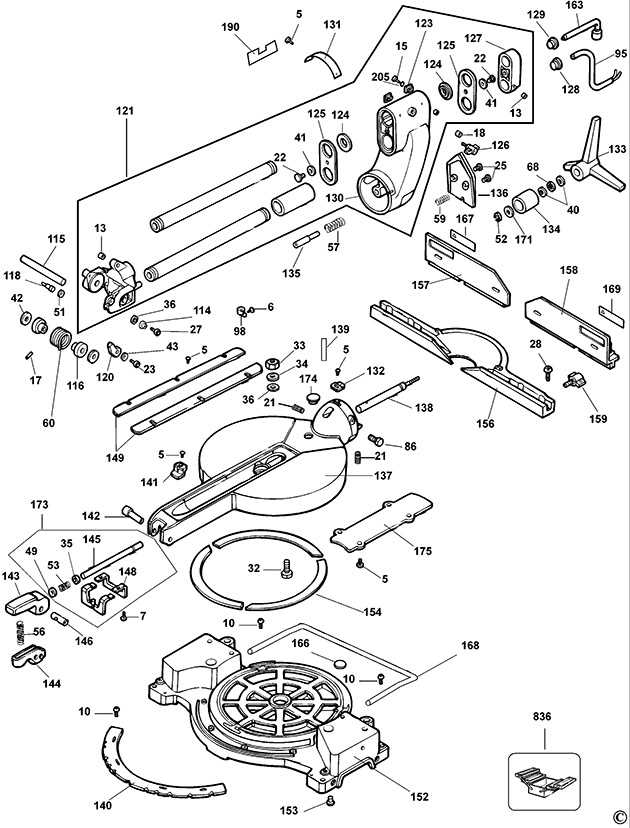

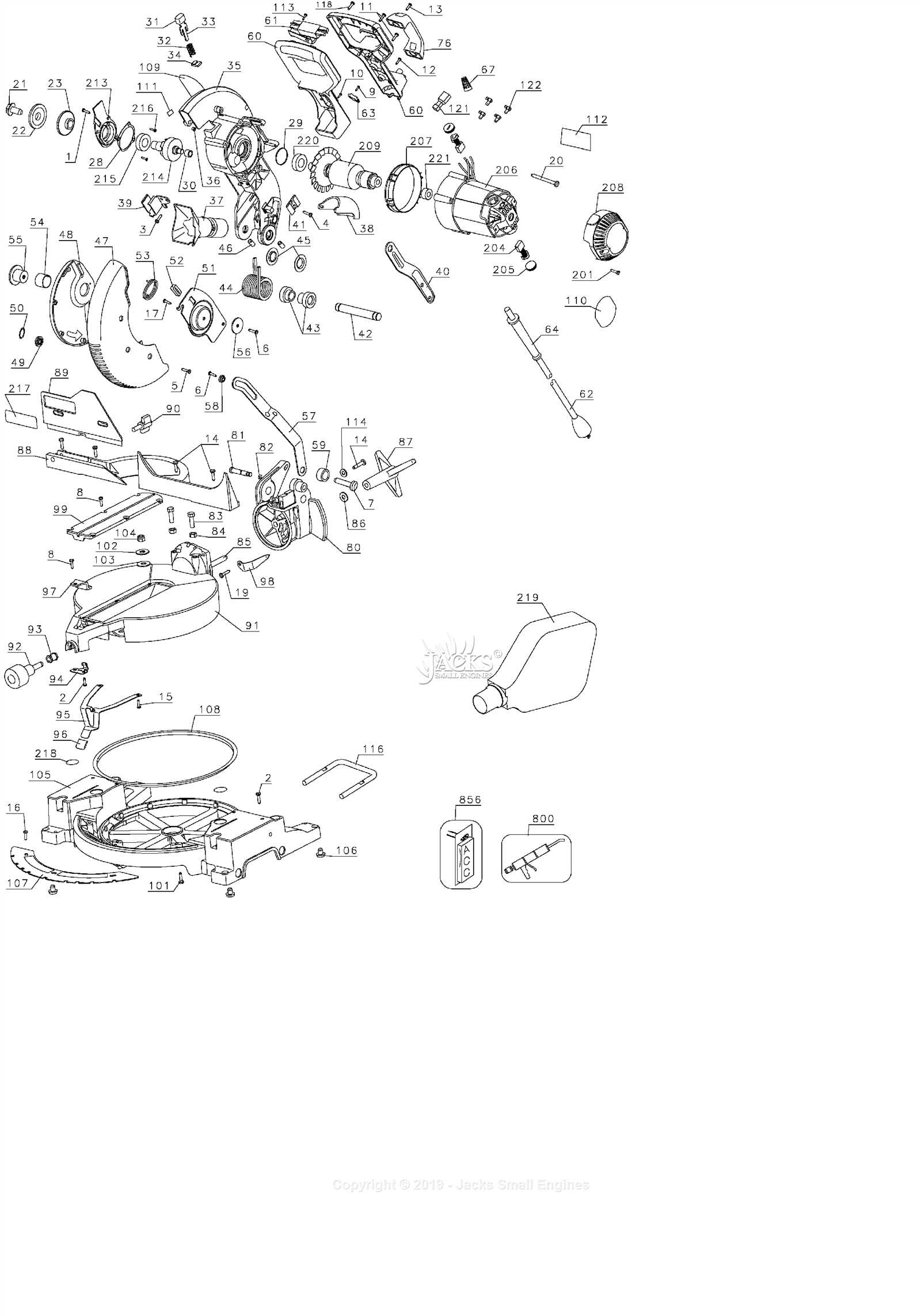

When dealing with complex equipment, it’s essential to have a clear overview of how different elements come together. This helps users in maintaining, repairing, or simply understanding the overall structure of their tools. By focusing on the arrangement and interaction of each element, the process of identifying issues or performing replacements becomes significantly more straightforward.

Visualizing the structure of mechanical systems allows for better navigation through the intricate design. It emphasizes the importance of each individual part and how it connects with others, ensuring the efficiency and longevity of the equipment. Understanding these layouts can make any task involving the tool much easier.

For users seeking detailed insights into how their devices are constructed, having an organized representation of the components is invaluable. It allows for more efficient planning when handling repairs or replacements, offering a clear roadmap to achieve optimal performance.

Essential Components of the Dw708

Understanding the key elements of this tool is vital for ensuring optimal performance and longevity. Each section contributes to its overall functionality, allowing for precise and efficient operation in various applications.

Main Structural Elements

The core framework provides stability and durability, supporting the tool’s various functionalities. Strong materials ensure that the base remains firm during use, enhancing safety and precision during operation.

Movable Mechanisms

Adjustable sections and moving parts allow for flexibility in different cutting angles and depths. These elements are crucial for achieving accurate results across a range of tasks, adapting easily to diverse requirements.

Understanding the Parts Layout

When working with mechanical equipment, it’s essential to have a clear understanding of how various elements are organized. This knowledge not only helps in maintenance but also ensures smooth operation and timely replacement of individual components. Each element plays a specific role, and recognizing their placement can improve the overall efficiency of handling the machine.

- Key components are arranged to work together seamlessly.

- Each section is designed for optimal functionality within the system.

- Identifying specific elements helps streamline repairs and upgrades.

By knowing the layout, you can make informed decisions about handling, upkeep, and enhancing the longevity of the equipment.

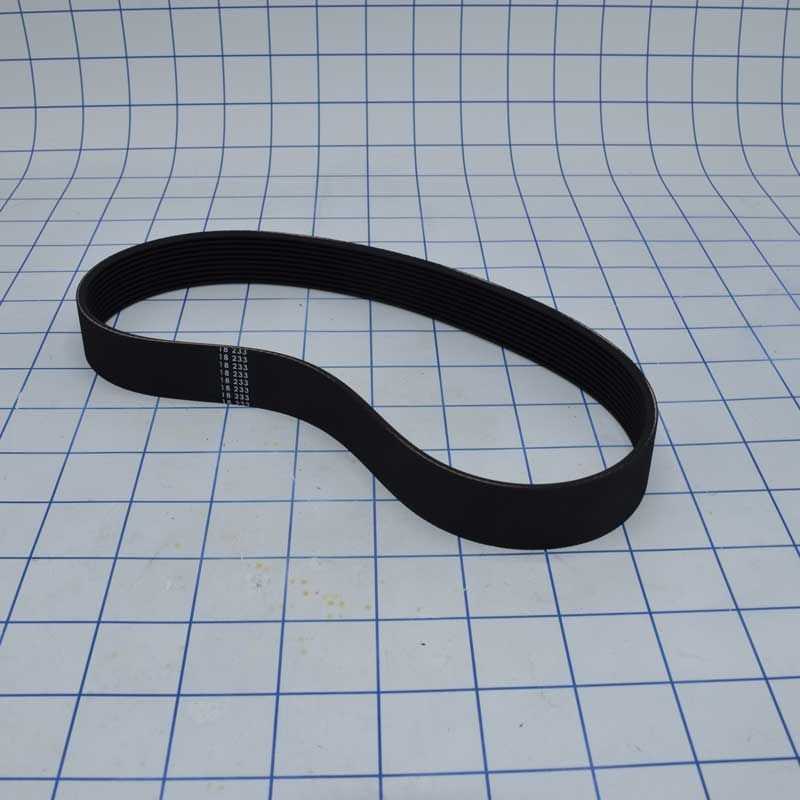

Identifying Replacement Parts Easily

When maintaining your equipment, it’s essential to ensure that all components are in proper condition. Whether you’re dealing with mechanical issues or simply wear and tear, having access to the right pieces for repairs is crucial. Recognizing the correct components quickly can save time and effort, allowing you to get back to work sooner.

Steps to Streamline the Process

First, gather any relevant documentation that came with the tool, such as manuals or guides. These resources often provide detailed breakdowns of each component, which can help you match what you need. Additionally, digital resources and online guides can provide a wealth of information, including images and specifications.

Key Tips for Accuracy

When identifying the correct item, pay attention to dimensions and any unique features that set one piece apart from another. Careful comparison will ensure you select the proper replacement, minimizing the risk of ordering the wrong item and delaying repairs.

Common Issues and Solutions

In mechanical tools, regular wear and tear can lead to various operational problems. Identifying these issues early helps prevent more serious malfunctions and extends the equipment’s lifespan. By understanding frequent problems and knowing how to resolve them, users can maintain their devices efficiently.

One common issue is uneven performance during operation, which can result from improper adjustments or maintenance. To address this, checking the alignment and recalibrating components can often restore smooth functionality.

Another frequent problem is difficulty in maintaining stability during use. This might be caused by loose or worn-out components. Tightening connections and replacing worn elements usually resolves the issue, ensuring consistent operation.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure that your equipment functions efficiently over time. Implementing a few straightforward routines can significantly extend the lifespan of your tools, helping you avoid potential issues and costly repairs in the future.

Begin by keeping all components clean and free from dust or debris, as this can impact performance and lead to wear. Regularly inspect the condition of moving parts, making sure they are well-lubricated to reduce friction. Additionally, storing your equipment in a dry, safe environment prevents unnecessary damage.

Establish a maintenance schedule to check for any signs of deterioration. This proactive approach allows you to address small problems before they become major concerns, ensuring your tools remain in optimal condition for years to come.

Where to Find Authentic Parts

When it comes to replacing components for your tools, ensuring the quality and authenticity of each item is crucial. Obtaining reliable replacements can extend the life of your equipment and prevent future malfunctions.

- Check official retailers or certified distributors for genuine components.

- Manufacturer websites often provide detailed listings and approved sellers.

- Specialized repair shops may offer high-quality, original items tailored to your needs.

- Online marketplaces can be useful, but always verify seller authenticity and reviews before purchasing.

By following these steps, you can ensure you’re getting trustworthy replacements to keep your tools functioning properly for years to come.

Tools Needed for Assembly

To ensure a smooth and efficient assembly process, having the right equipment on hand is essential. Proper preparation minimizes complications and makes the setup more straightforward. Below is a list of items commonly required for most assembly tasks, making the process quicker and easier.

- Phillips screwdriver for securing screws and bolts

- Wrench set for tightening nuts and fasteners

- Measuring tape for precise alignment

- Rubber mallet for gentle adjustments

- Allen keys for tightening hexagonal screws

- Safety gloves to protect hands during handling

Ensure that all these tools are available before starting the assembly to avoid interruptions. Proper organization will streamline the entire process.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of the device. Below are some frequently asked questions that may assist users in understanding its features and maintenance.

- What are the key features of this device?

The primary attributes include durability, ease of use, and efficient performance in various applications.

- How do I identify the required components for repairs?

Consulting a detailed reference guide or contacting customer support can help you determine which parts you need for specific repairs.

- Where can I purchase replacement items?

Replacement components are available through authorized retailers, online marketplaces, or directly from the manufacturer.

- What should I do if I cannot find the specific part?

If a specific item is unavailable, consider reaching out to customer service for assistance or exploring compatible alternatives.

- Are there any maintenance tips for prolonging the lifespan?

Regular cleaning, proper storage, and timely replacements of worn-out parts can significantly enhance longevity.