Backpack blowers are essential tools for maintaining outdoor spaces, offering powerful performance and user-friendly operation. An effective understanding of the individual elements that make up this equipment is crucial for ensuring optimal functionality and longevity. Each component plays a significant role, contributing to the overall efficiency and effectiveness of the machine.

By examining the intricate layout of these devices, users can gain insights into the various mechanisms involved in their operation. This knowledge not only aids in troubleshooting but also enhances the ability to perform routine maintenance. With a clear grasp of the essential elements, operators can confidently tackle repairs or upgrades, ensuring their blower remains in peak condition.

Moreover, familiarity with the specific components empowers users to make informed decisions when sourcing replacements or accessories. A comprehensive look at the individual parts allows for a deeper appreciation of how they interact, ultimately enhancing the user experience. Proper maintenance and timely replacement of worn elements can significantly extend the lifespan of the equipment.

Understanding Husqvarna 570BTS Components

The functionality of any machine relies heavily on its individual elements, each serving a unique purpose that contributes to the overall efficiency and performance. A comprehensive grasp of these components is essential for optimal operation and maintenance, ensuring longevity and reliability.

In this context, the various sections of the equipment are intricately designed to work in harmony. The engine, which serves as the powerhouse, is complemented by a series of attachments and systems that enhance functionality. Recognizing the roles of each component helps users make informed decisions regarding repairs and upgrades.

Moreover, understanding how these elements interact can aid in troubleshooting issues effectively. For example, the fuel delivery system plays a critical role in ensuring the engine runs smoothly, while the air filtration system protects internal mechanisms from debris. Each part’s efficiency directly impacts the machine’s performance, making knowledge of their functions invaluable for users.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations facilitate the identification of each element, ensuring users can navigate their equipment effectively. By providing a clear overview, such visuals enhance maintenance and repair processes, ultimately contributing to the longevity of the machinery.

Enhanced Understanding

Illustrative guides offer a simplified way to comprehend complex assemblies. They allow users to visualize how various components fit together, making it easier to troubleshoot issues and execute repairs. This clarity is especially beneficial for those unfamiliar with the specific workings of their equipment.

Efficient Maintenance

Utilizing detailed visuals not only aids in repairs but also supports routine upkeep. By referring to these representations, users can quickly identify wear and tear, ensuring timely replacements of crucial elements. This proactive approach minimizes downtime and enhances operational efficiency.

| Benefit | Description |

|---|---|

| Clear Identification | Facilitates easy recognition of components. |

| Improved Troubleshooting | Helps users diagnose and resolve issues quickly. |

| Streamlined Maintenance | Encourages proactive replacements to avoid breakdowns. |

| Increased Longevity | Enhances the lifespan of equipment through better care. |

Identifying Key Assembly Parts

Understanding the essential components of a powerful outdoor tool is crucial for effective maintenance and operation. Each assembly plays a significant role in ensuring optimal performance and durability. By recognizing these key elements, users can better appreciate the intricacies of their equipment and address any potential issues more efficiently.

Within the assembly, several vital components contribute to the overall functionality. These include the engine unit, which serves as the heart of the machine, delivering the necessary power. The fuel system, responsible for proper energy supply, works in tandem with the ignition system to ensure reliable starting and operation. Additionally, various filters and housing elements play a critical role in maintaining cleanliness and efficiency.

Furthermore, understanding the cooling and exhaust systems is essential for preventing overheating and ensuring proper emission levels. Each component must be carefully examined for wear and tear, allowing for timely replacements and adjustments. Familiarizing oneself with these key assembly elements enhances both the longevity and performance of the tool.

Common Issues with 570BTS Parts

When dealing with power equipment, understanding the frequent challenges associated with components is essential for optimal performance. Various factors can lead to malfunctions, affecting the overall functionality and longevity of the machine. Being aware of these common problems can help users address them promptly and maintain their equipment effectively.

One prevalent issue is wear and tear on essential components due to prolonged usage. This can lead to reduced efficiency and operational difficulties. Additionally, improper installation or lack of maintenance can exacerbate these issues, resulting in more significant malfunctions over time.

Another common concern is the accumulation of debris and dirt within the system, which can obstruct airflow and cooling mechanisms. Regular cleaning and inspections can mitigate these risks, ensuring smooth operation. Moreover, ensuring that all components are compatible and correctly aligned is crucial to prevent unnecessary strain on the machinery.

Finally, monitoring for signs of damage, such as cracks or leaks, is vital for maintaining equipment health. Addressing these concerns quickly can prevent further complications and extend the lifespan of the machinery.

Finding Replacement Parts Online

Locating necessary components for your equipment can be a straightforward process if you know where to look. The internet offers a variety of resources that facilitate the search for suitable items, ensuring you can keep your machinery running efficiently.

When searching for replacements, consider the following strategies:

- Official Websites: Manufacturer websites often have sections dedicated to spare components, where you can find specific listings based on your equipment model.

- Online Marketplaces: Platforms like eBay and Amazon frequently have a wide selection of components, often at competitive prices.

- Specialty Retailers: Many online stores specialize in specific types of machinery and their respective components, providing detailed catalogs and user support.

- Forums and Communities: Engaging with online communities related to your equipment can lead to valuable recommendations for where to purchase necessary items.

To ensure you’re purchasing the correct components, keep the following tips in mind:

- Verify the compatibility of the component with your specific equipment model.

- Check reviews and ratings of the seller to gauge reliability.

- Look for return policies in case the item does not meet your expectations.

By utilizing these resources and strategies, you can easily find the components you need to maintain your equipment in optimal condition.

Maintenance Tips for Husqvarna Equipment

Proper upkeep is essential for ensuring the longevity and optimal performance of outdoor machinery. Regular maintenance not only extends the lifespan of the equipment but also enhances efficiency and safety during operation. Implementing a systematic care routine can help prevent unexpected failures and costly repairs.

Routine Maintenance Practices

- Clean the Equipment: Remove dirt, debris, and other contaminants after each use to prevent wear and tear.

- Check Fluids: Regularly inspect and refill necessary fluids, including oil and fuel, to ensure smooth operation.

- Inspect Filters: Clean or replace air and fuel filters to maintain optimal airflow and performance.

- Sharpen Blades: Regularly sharpen cutting edges for better efficiency and cleaner cuts.

- Inspect Belts and Cables: Regularly check for signs of wear and replace damaged components promptly.

Seasonal Maintenance Considerations

- Winter Preparation: Before storing for winter, drain fuel and clean the machinery thoroughly.

- Spring Check: Inspect all components, check battery health, and refill fluids before the first use of the season.

- Summer Upkeep: Monitor for overheating issues and ensure proper lubrication during peak usage.

- Fall Review: Perform a comprehensive check before the winter season to identify any necessary repairs.

By adhering to these maintenance guidelines, operators can ensure their equipment remains in excellent condition, providing reliable performance throughout its operational life.

Exploring Accessories for Enhanced Performance

Upgrading your equipment with the right add-ons can significantly boost its functionality and efficiency. These enhancements not only improve performance but also make tasks easier and more enjoyable. This section delves into various accessories designed to elevate your machinery’s capabilities, ensuring optimal results in your work.

Here are some essential accessories to consider:

- Performance Filters: Specialized air and fuel filters can improve engine efficiency by ensuring a cleaner airflow and fuel delivery, which translates to better power output.

- Enhanced Nozzles: Different nozzle types can be used for various applications, allowing for precise control of output and optimizing work efficiency.

- Vibration Dampeners: These accessories help reduce operator fatigue by minimizing vibrations during use, making it more comfortable for prolonged operations.

- Protective Gear: Safety should always be a priority. High-quality protective gear ensures that operators remain safe while maximizing their equipment’s potential.

Incorporating these accessories not only enhances performance but also prolongs the life of your machinery, making it a wise investment for any serious user.

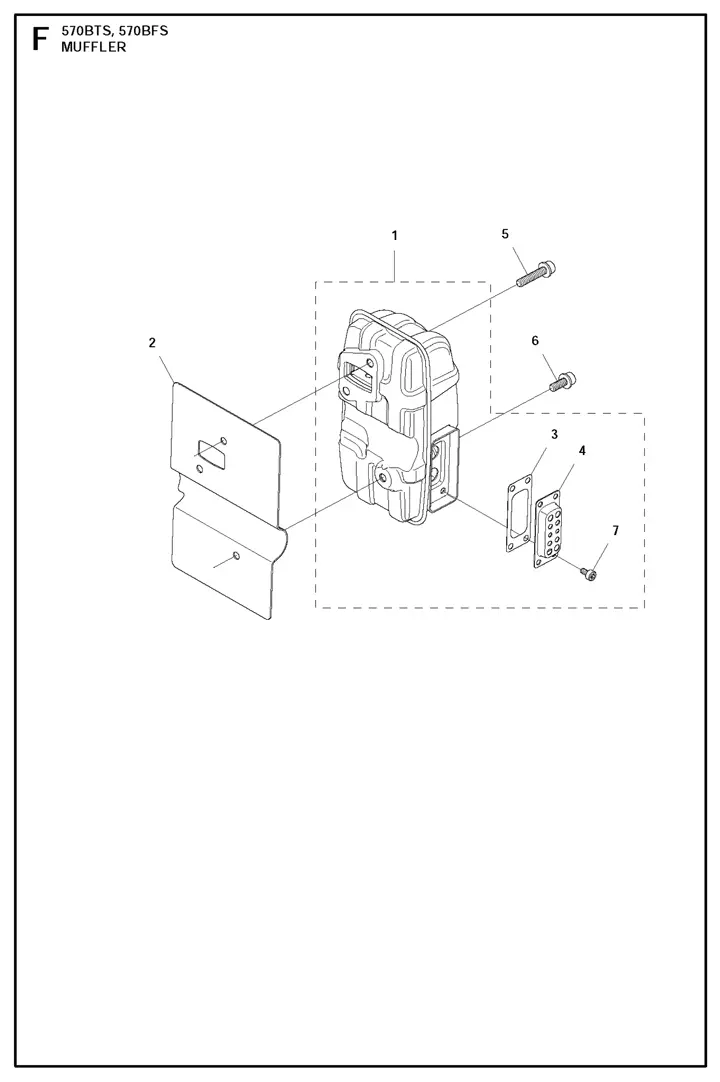

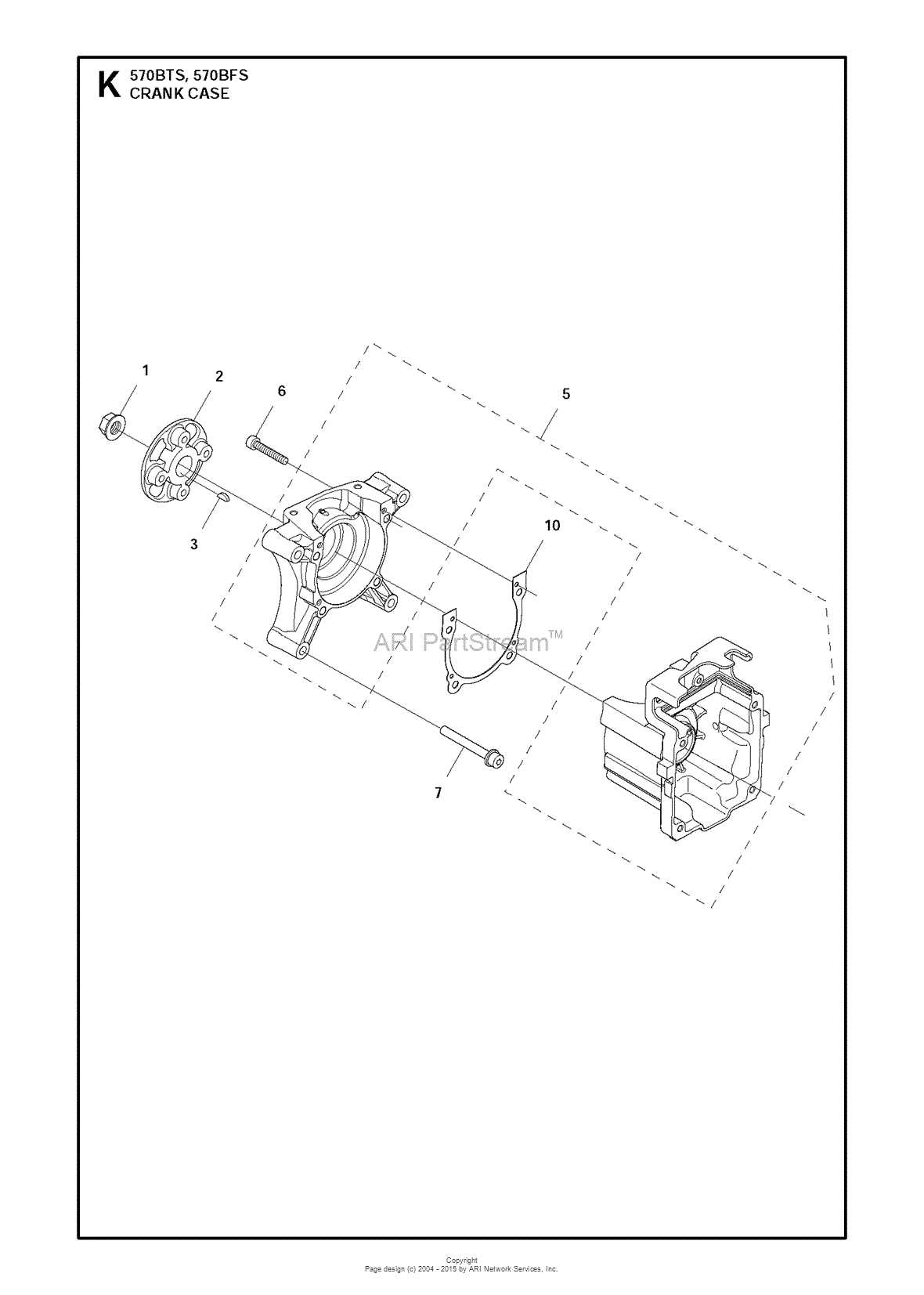

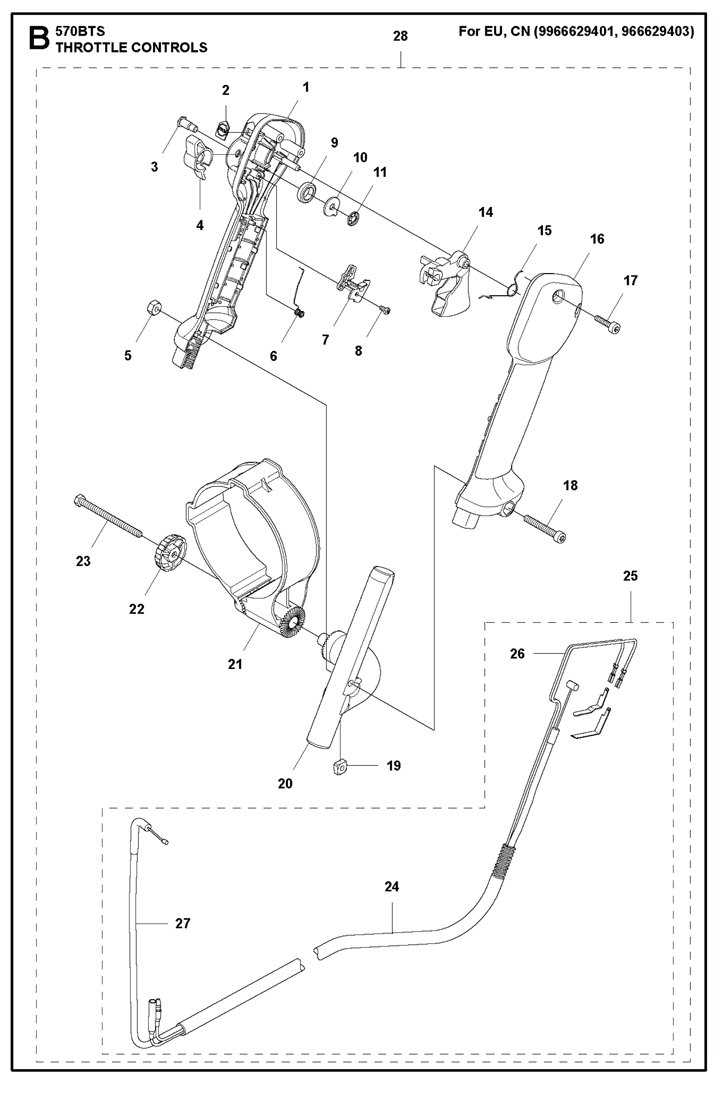

Visual Guide to 570BTS Parts

This section provides an informative overview of the essential components that comprise the powerful equipment, designed for effective performance in various applications. Understanding these elements is crucial for maintenance, troubleshooting, and replacement, ensuring that the machine operates smoothly and efficiently.

Key Components Overview

Familiarity with the critical elements allows users to identify and manage each part effectively. Below is a breakdown of the primary components that contribute to the functionality of the equipment:

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation. |

| Fuel Tank | Stores the fuel needed for the engine to function. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Starter Assembly | Facilitates the initiation of engine operation. |

| Throttle Control | Regulates engine speed and power output. |

| Exhaust System | Channels away harmful gases produced during combustion. |

Maintenance and Care

Regular inspection and care of these components are vital for longevity and performance. Ensuring that each part is in optimal condition will enhance the overall efficiency of the equipment.