When maintaining and repairing outdoor power tools, having a comprehensive view of their structure is essential. Knowing how various elements fit together not only facilitates efficient servicing but also enhances the overall performance of the equipment. This knowledge empowers users to tackle repairs with confidence, ensuring their tools operate at peak efficiency.

Each machine consists of numerous intricate parts that work in harmony to deliver optimal results. Familiarity with these components allows for better troubleshooting and can prevent costly mistakes during maintenance. By examining the relationships between different elements, users can more easily identify issues and understand how to resolve them.

In this section, we will delve into the key components of a specific model, exploring their functions and interconnections. Gaining insight into these details will aid in effective maintenance practices, ensuring that the equipment remains reliable and performs as expected over time.

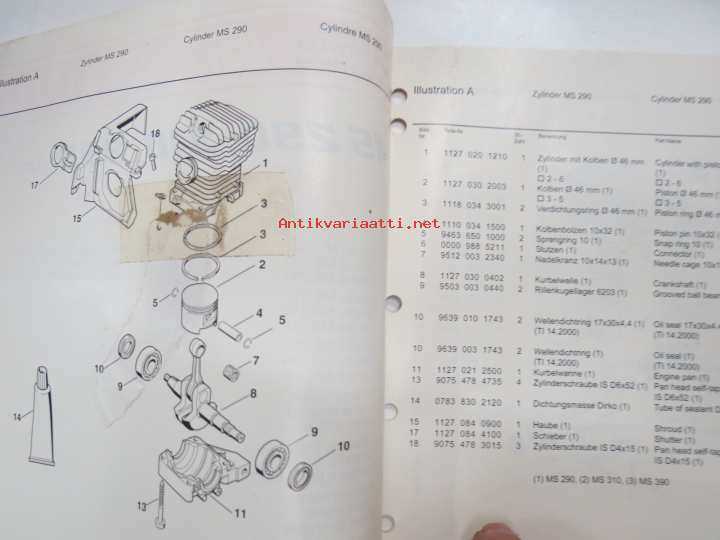

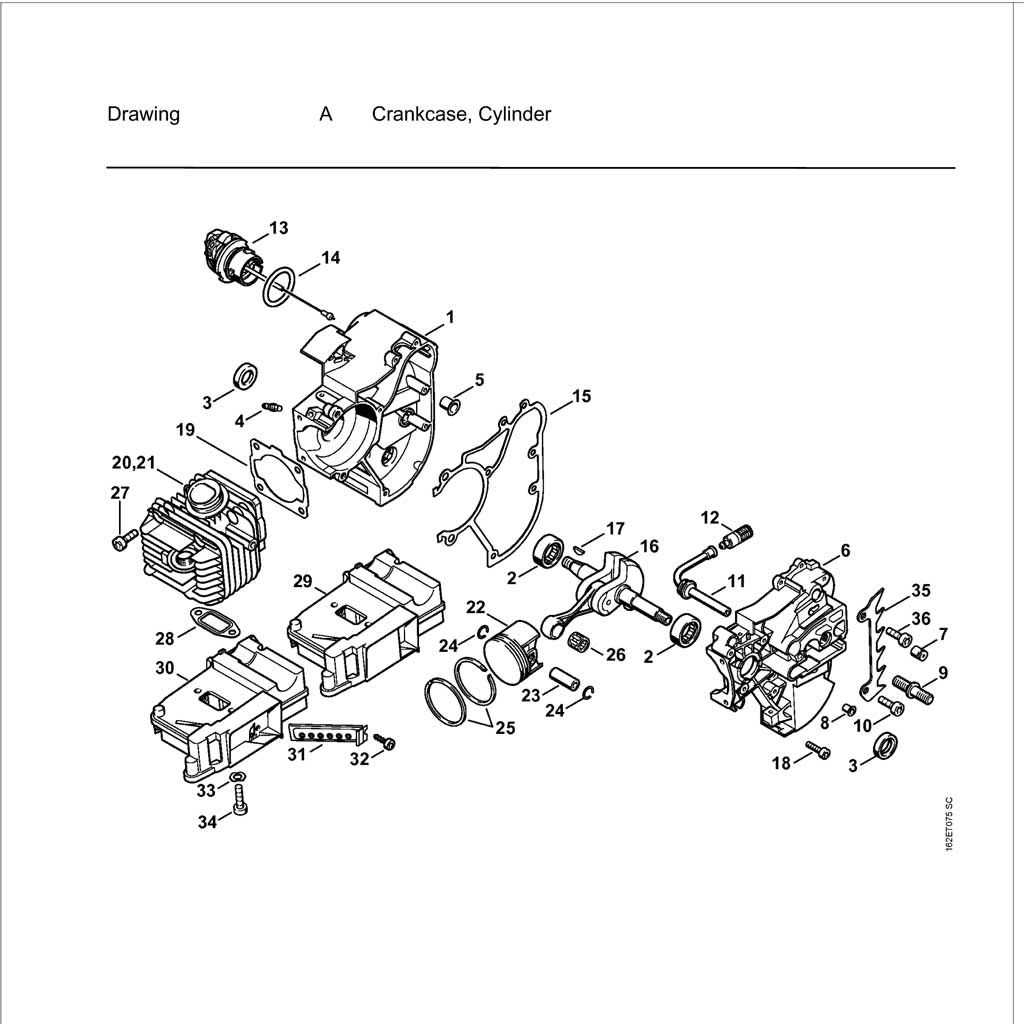

Understanding Stihl MS 290 Parts

Every mechanical device consists of various components that work together to ensure optimal performance. Grasping the function and relationship of each element is crucial for effective maintenance and troubleshooting. This knowledge empowers users to enhance the longevity and efficiency of their equipment.

Critical Elements: Each piece within the machinery has a specific role, contributing to the overall operation. For instance, the engine, housing, and cutting mechanisms interact seamlessly, enabling smooth functionality. Recognizing how these components relate can aid in identifying potential issues.

Maintenance Insight: Familiarity with the different sections allows for more informed decisions during servicing. Regular inspections and timely replacements of worn-out elements can prevent larger malfunctions, ultimately saving time and resources.

In summary, understanding the intricacies of each component not only supports effective repairs but also enhances the overall experience of using the equipment. Knowledge is a vital tool in ensuring that machinery operates at its best.

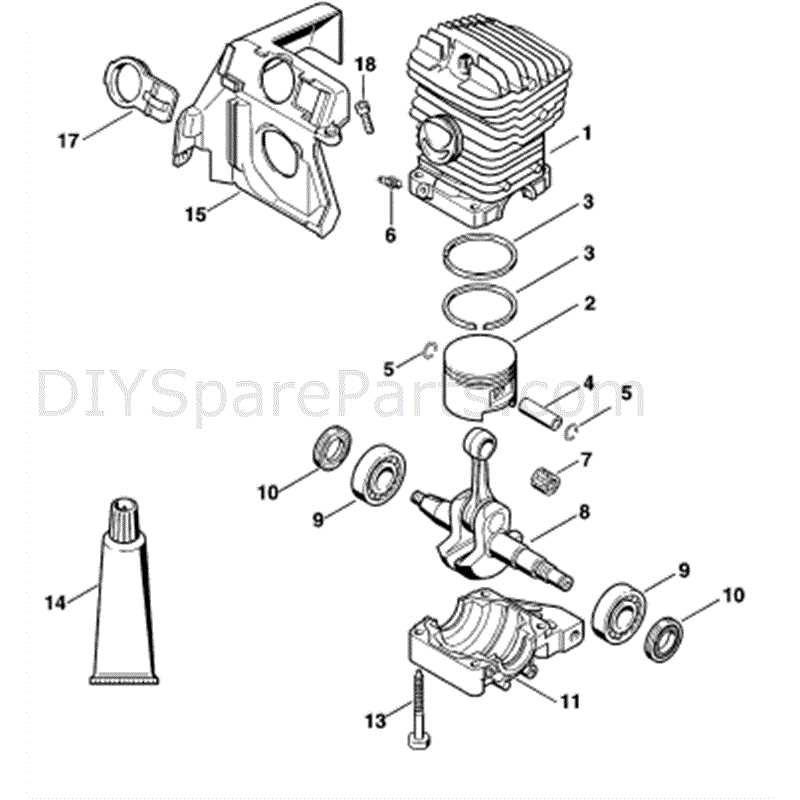

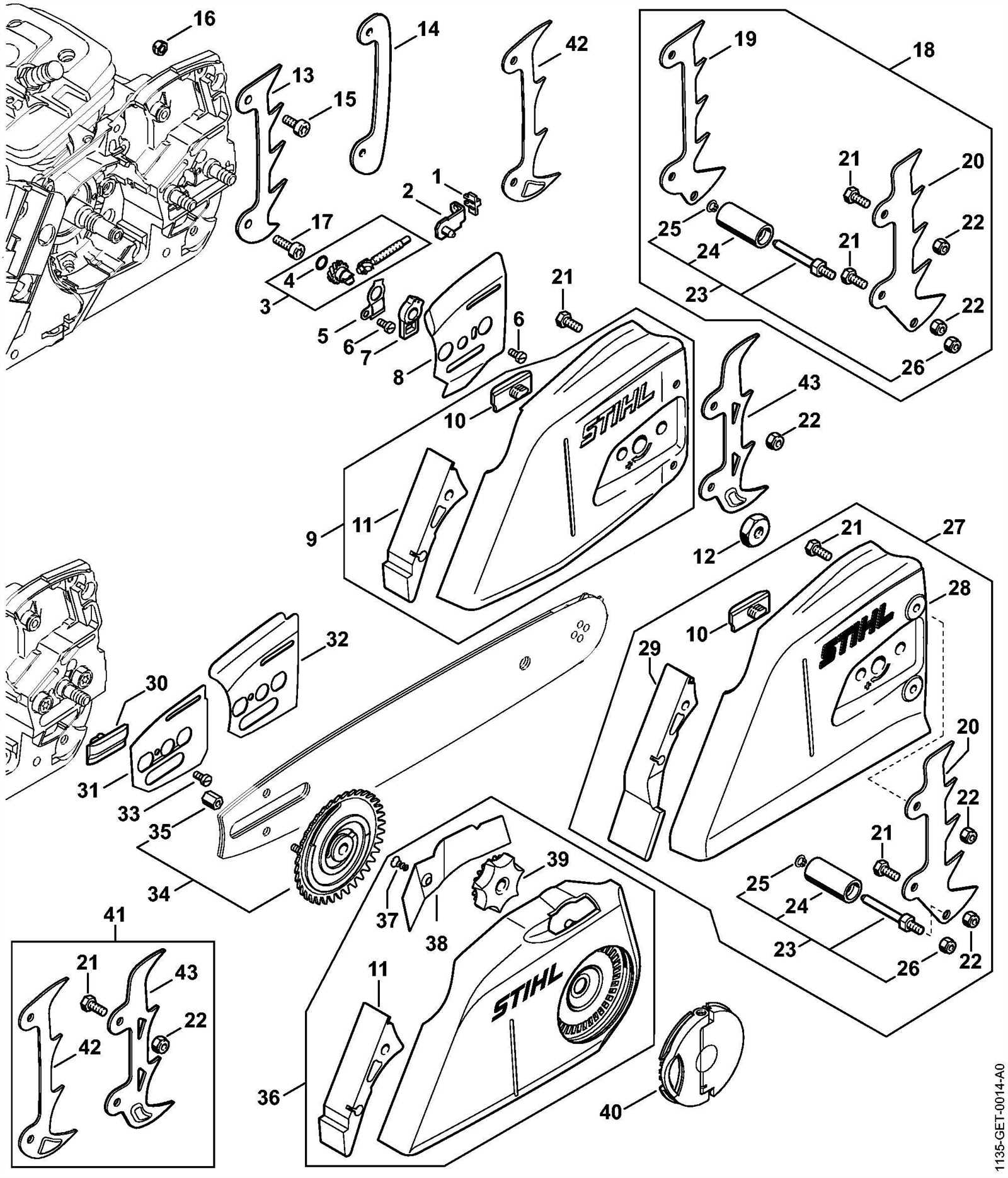

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting through wood efficiently. Understanding its essential elements is crucial for both maintenance and operation. Each component plays a significant role in ensuring the tool functions properly and safely.

- Engine: The heart of the chainsaw, providing the necessary power to drive the chain.

- Bar: The elongated metal piece that supports the cutting chain and determines the length of the cut.

- Chain: A loop of sharp teeth that rotates around the bar, executing the cutting action.

- Throttle: A mechanism that regulates engine speed, allowing the operator to control cutting power.

- Air Filter: Prevents dust and debris from entering the engine, ensuring optimal performance.

- Fuel Tank: Holds the mixture of fuel and oil needed for the engine to operate.

- Chain Brake: A safety feature that stops the chain rapidly in case of kickback.

- Handle: Provides a grip for the operator, allowing for better control during operation.

Each of these components works together to enhance the efficiency and safety of the tool, making it vital to familiarize oneself with their functions for effective use.

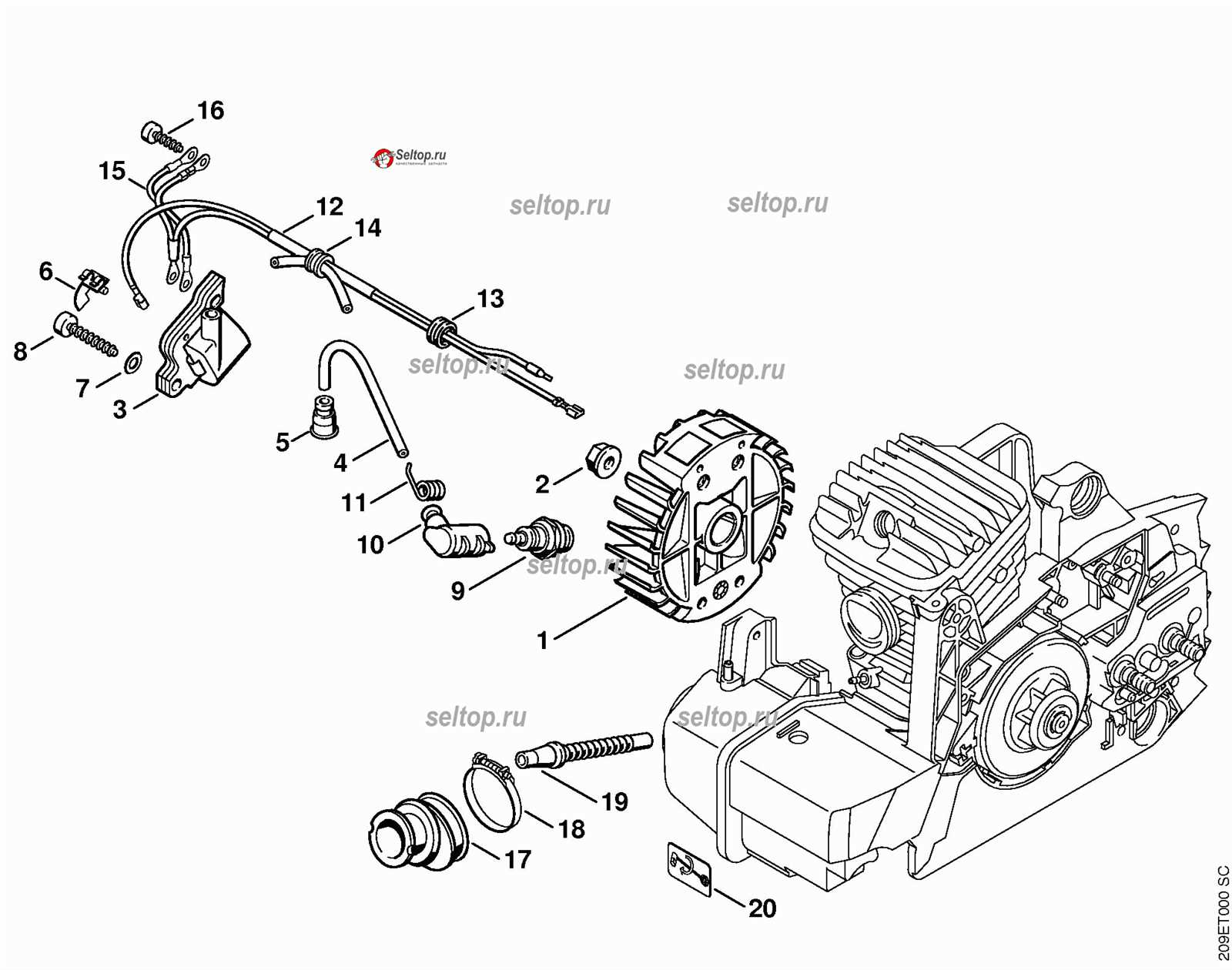

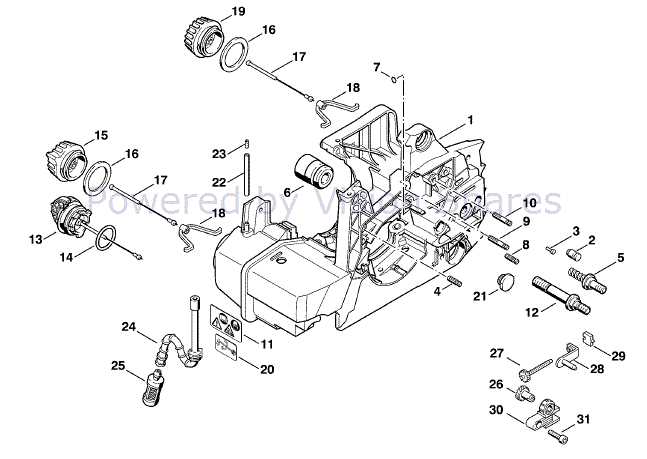

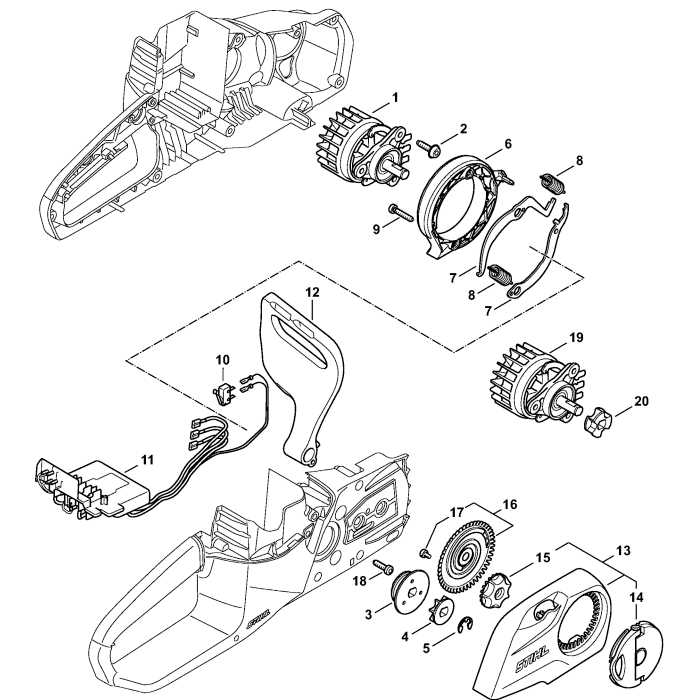

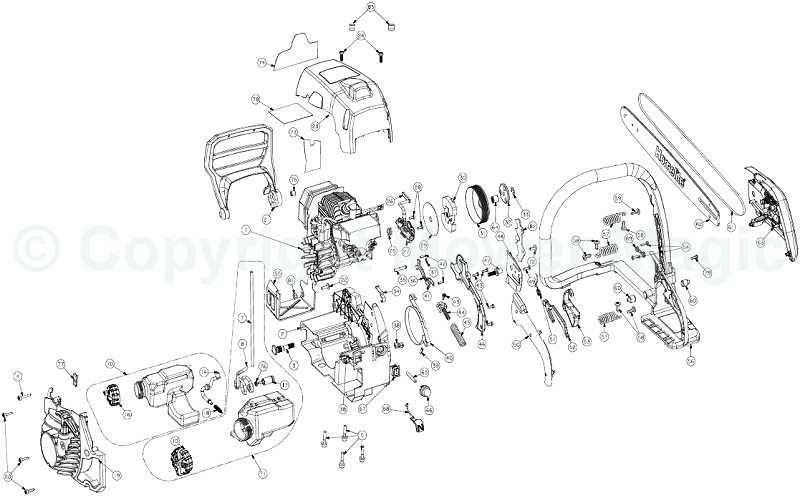

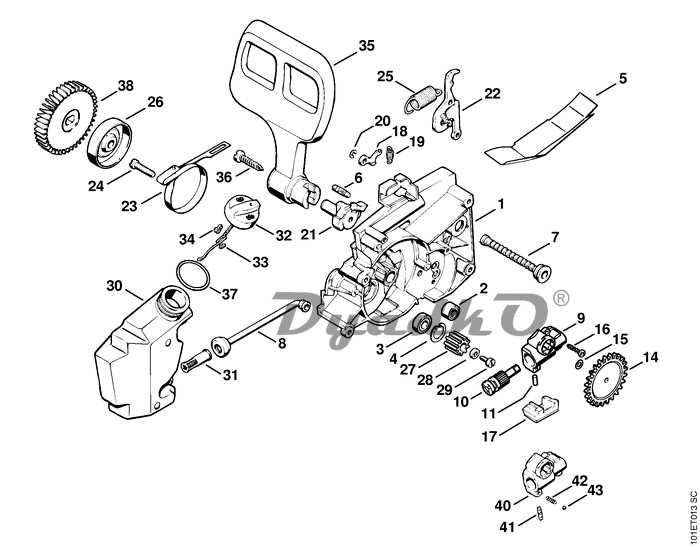

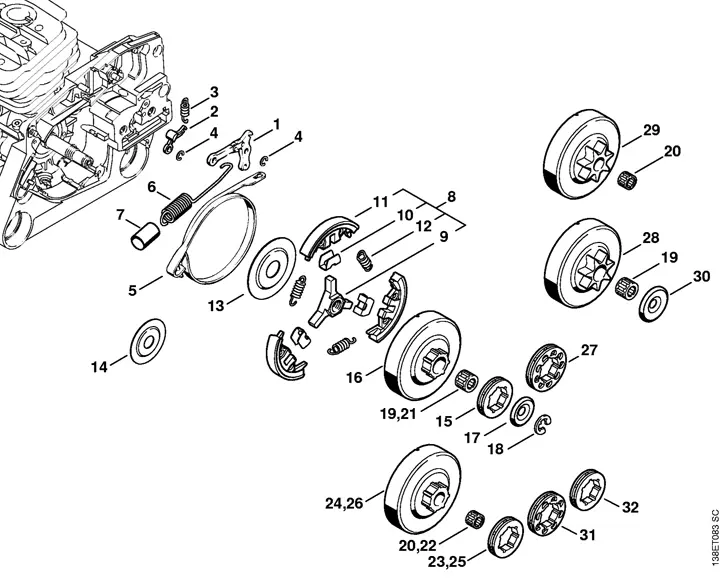

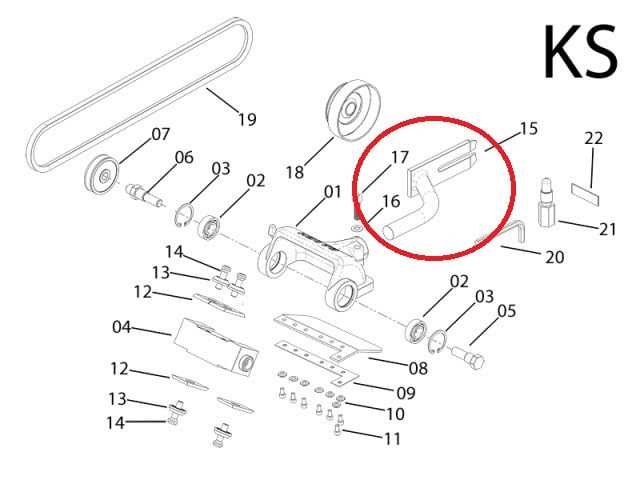

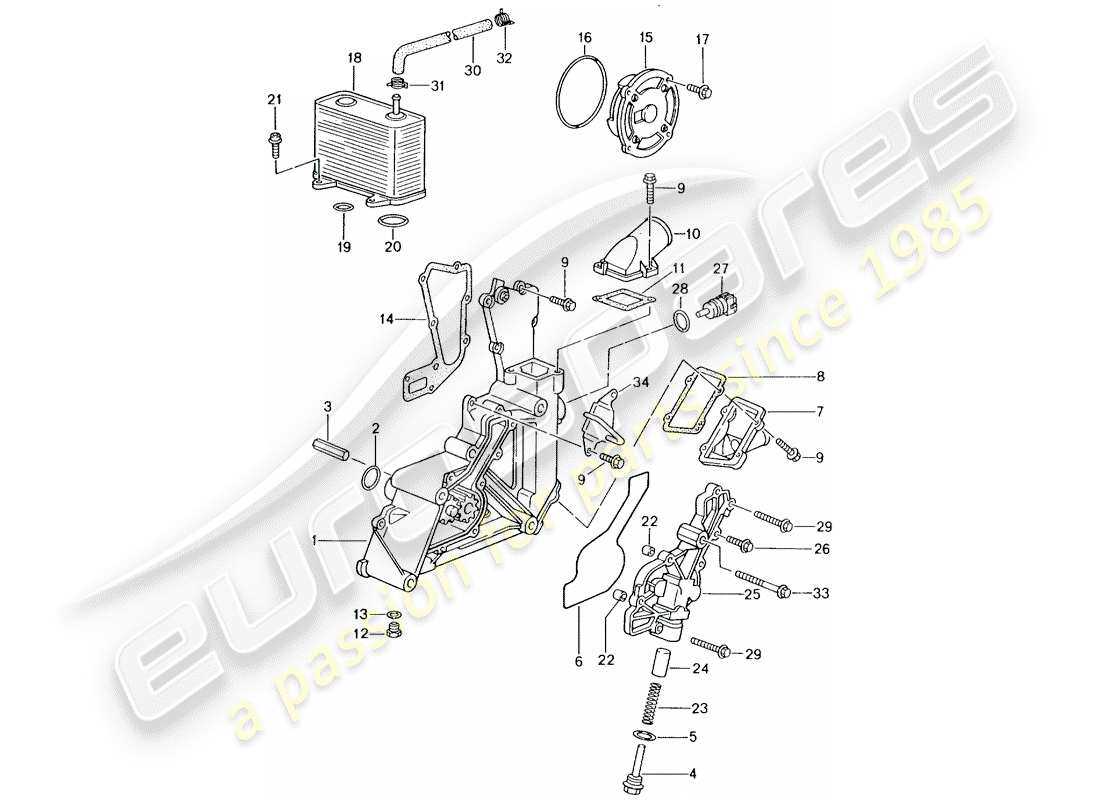

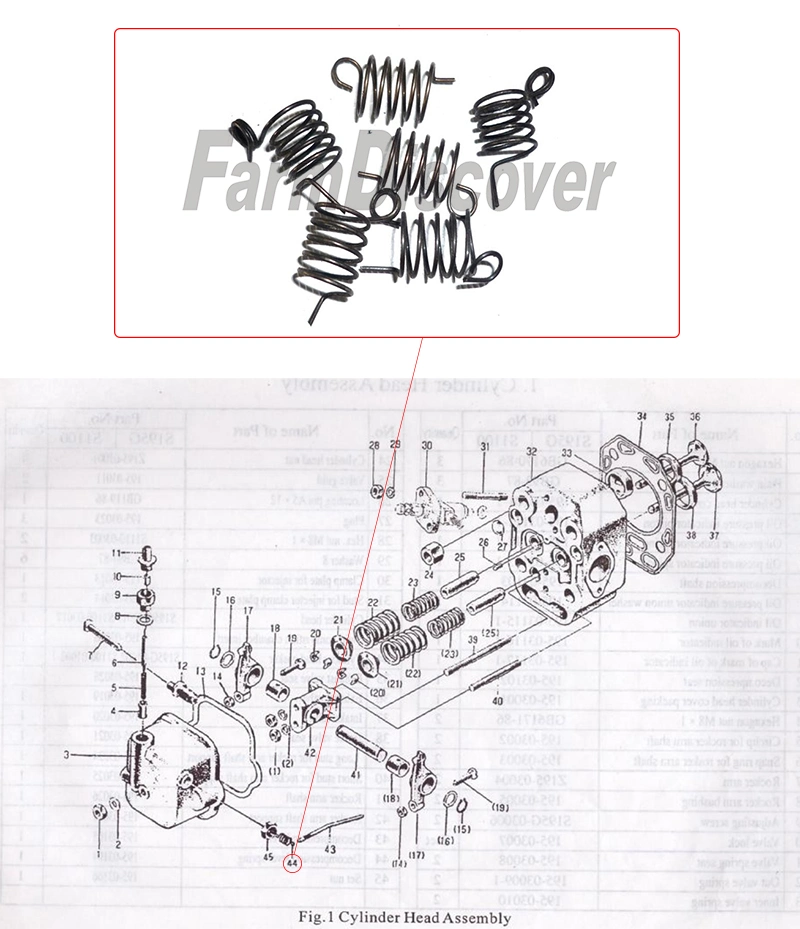

How to Read the Parts Diagram

Understanding the layout of a technical schematic is essential for effective maintenance and repair. By familiarizing yourself with the various components and their relationships, you can ensure a smoother troubleshooting process. This guide will provide you with insights on navigating these illustrations efficiently.

Identify the Key Components

Begin by recognizing the symbols and labels used throughout the schematic. Each item typically has a unique identifier, which allows you to pinpoint specific elements quickly. Pay attention to the numbering system, as it often correlates with a list of parts.

Understand the Relationships

Next, delve into how the various elements connect with each other. Lines often represent connections, and their arrangement can indicate the flow of operation. This knowledge is crucial for diagnosing issues or assembling parts accurately.

Common Issues and Replacement Parts

Every power tool experiences wear and tear over time, leading to potential malfunctions that can affect performance. Understanding the typical problems that may arise, along with the necessary components for resolution, is essential for maintaining optimal functionality.

One frequent issue encountered is difficulty in starting the engine, which can often be traced back to the spark plug or fuel delivery system. Replacing the spark plug or checking the fuel filter can often resolve this problem quickly.

Another common concern is a decrease in cutting efficiency, which may indicate that the cutting chain is dull or damaged. Regular inspection and timely replacement of the chain will ensure that the tool continues to perform effectively.

Overheating during operation can signal that the cooling system needs attention. In such cases, checking the air filter and cleaning any obstructions can help restore proper airflow and prevent overheating.

Lastly, issues with the recoil starter may prevent the tool from engaging properly. This could necessitate the replacement of the starter assembly to ensure reliable operation. Addressing these common challenges with the right components will enhance longevity and reliability.

Maintenance Tips for Longevity

Proper care is essential for enhancing the lifespan of any mechanical tool. Regular maintenance not only ensures optimal performance but also prevents costly repairs and replacements. By following a few simple practices, users can significantly extend the durability and efficiency of their equipment.

Regular Cleaning

Keeping your device clean is crucial. Accumulated debris can lead to overheating and mechanical failures. Make it a habit to clean all accessible areas after each use.

Routine Inspections

Conducting periodic checks helps in identifying potential issues before they escalate. Look for signs of wear and tear, and replace any damaged components promptly.

| Maintenance Task | Frequency |

|---|---|

| Clean the exterior | After each use |

| Inspect parts | Weekly |

| Replace filters | Monthly |

| Oil moving parts | Every 10 uses |

Where to Find Authentic Parts

Ensuring the longevity and performance of your equipment requires sourcing genuine components. When looking for these essential items, it is crucial to navigate through various options to identify reliable suppliers. This will not only help in maintaining optimal functionality but also guarantee safety and durability in the long run.

Authorized Dealers

The first and most reliable option is to visit authorized dealers. These establishments are specifically designated to sell genuine items and often provide a wide selection tailored for specific models. Purchasing from them ensures that you receive high-quality components that meet the manufacturer’s standards.

Online Marketplaces

Another viable avenue is exploring online marketplaces. Websites that focus on outdoor tools often have dedicated sections for genuine replacements. Always verify the seller’s credibility by checking reviews and ratings, as well as confirming that the items are authentic.

In summary, whether opting for local dealers or online platforms, taking the time to ensure authenticity will significantly enhance your equipment’s performance and reliability.

Tools Required for Assembly

When it comes to putting together machinery, having the right tools on hand is essential for a smooth and efficient process. Each component requires specific instruments to ensure that everything fits perfectly and functions as intended. Proper preparation not only saves time but also prevents potential damage to parts during assembly.

Essential Hand Tools

Basic hand tools are vital for the assembly process. A set of screwdrivers, both flathead and Phillips, will help secure various fasteners. Additionally, a wrench set is crucial for tightening nuts and bolts. Pliers can assist in gripping and manipulating components, while a utility knife may be necessary for cutting any packaging or materials that could obstruct the assembly.

Specialized Equipment

For more intricate tasks, certain specialized tools might be required. A torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing loosening or damage. A multi-tool can offer versatility, combining several functions into one device. Lastly, a workbench or sturdy surface provides a stable area to assemble parts efficiently and safely.

Visual Identification of Each Part

Understanding the components of your tool is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and being able to recognize them visually can greatly simplify the troubleshooting process. This section aims to provide clarity on the different sections, enabling you to identify each one confidently.

Key Components and Their Features

Begin by familiarizing yourself with the main sections of the equipment. Look for distinguishing features such as shapes, colors, and markings that can help differentiate similar-looking items. For instance, the cutting assembly often has a specific design that sets it apart from the housing. Paying attention to these details will enhance your understanding of how each piece interacts with the others.

Utilizing Reference Guides

Reference materials can be invaluable when trying to identify components. Many manuals include illustrations that highlight the specific attributes of each element. Use these guides alongside your equipment to cross-reference and ensure accuracy. This practice will not only bolster your repair skills but also increase your overall confidence in managing the tool.

Upgrading Your Stihl MS 290

Enhancing the performance and efficiency of your chainsaw can significantly improve your cutting experience. By focusing on specific upgrades, you can optimize power output, reduce wear and tear, and increase the overall lifespan of your equipment. This section explores various enhancements that can be made to elevate your tool’s capabilities.

Power Enhancements

To boost the engine’s performance, consider upgrading the air filter and muffler system. A high-flow air filter allows for better airflow, leading to improved combustion and power output. Additionally, a performance muffler can enhance exhaust flow, resulting in a more efficient engine operation. These modifications not only improve power but also contribute to a more enjoyable cutting experience.

Safety and Comfort Improvements

Investing in ergonomic handles and anti-vibration systems can greatly enhance user comfort during prolonged use. Upgrading to padded grips reduces strain on your hands, while an advanced vibration damping system minimizes fatigue. Additionally, adding safety features like enhanced chain brakes and kickback protection ensures a safer working environment.

By implementing these upgrades, you can significantly enhance both the performance and safety of your chainsaw, making it a more powerful and reliable tool for any task.