In the realm of outdoor adventure and rugged terrain navigation, the functionality of specialized equipment plays a pivotal role. These mechanisms are engineered to provide assistance in challenging situations, ensuring safety and efficiency during operations. A thorough understanding of their construction is essential for optimal performance and longevity.

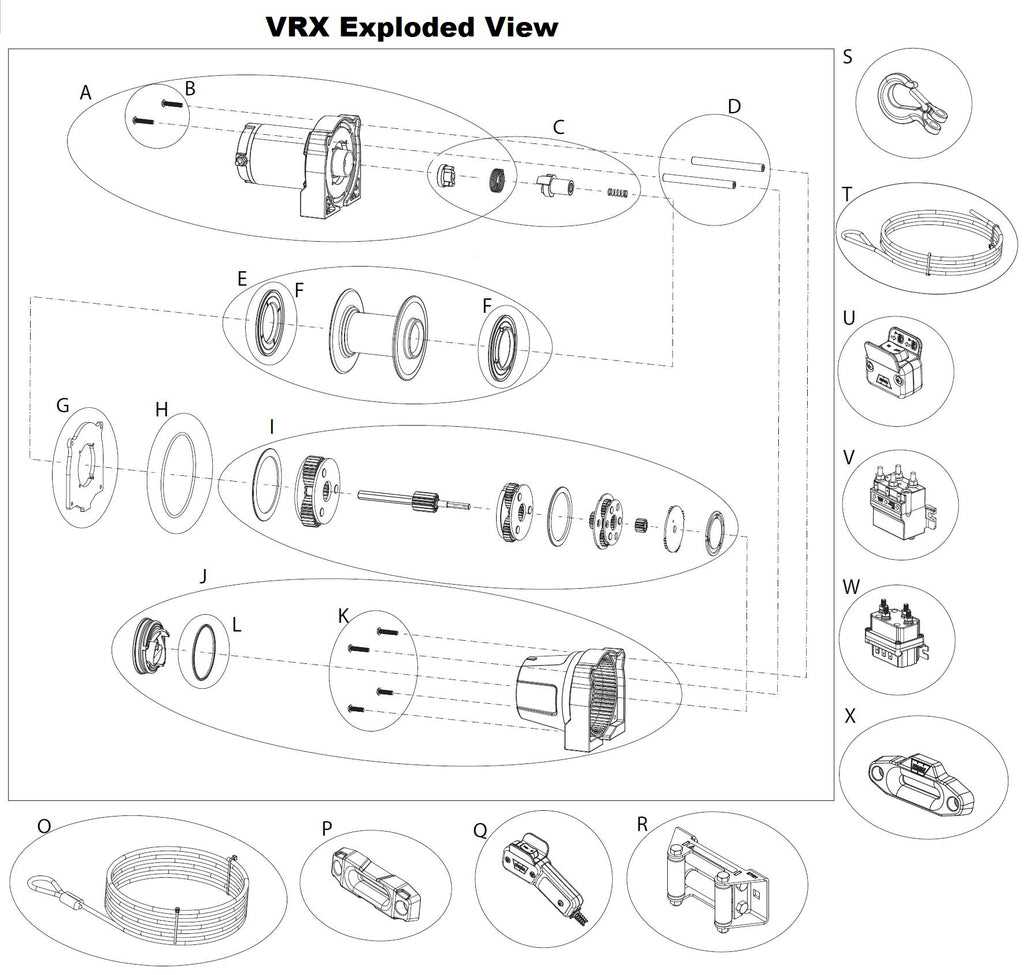

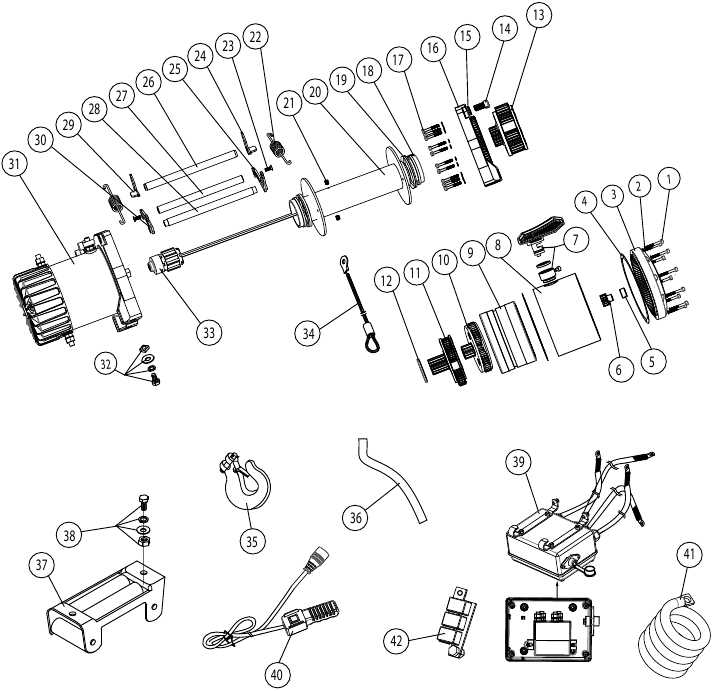

Every assembly consists of various elements, each contributing to the overall efficiency and effectiveness of the system. By familiarizing oneself with these individual components, users can better appreciate the intricate design and the importance of each piece in facilitating powerful traction.

To achieve the ultimate reliability, it is crucial to recognize the interrelationship between these segments. A comprehensive exploration of their arrangement not only enhances operational knowledge but also empowers users to make informed decisions regarding maintenance and upgrades.

Understanding Badlands Winch Components

When engaging in off-road activities or recovery tasks, understanding the essential elements of a recovery system can make all the difference. The intricate components work together to ensure efficiency and safety in various scenarios. From heavy-duty motors to durable cables, every element plays a vital role in the overall functionality. In this section, we’ll break down the individual elements that contribute to the system’s operation, helping you to grasp how each part works in harmony.

- Motor: The power source behind the operation, converting electrical energy into mechanical force to drive the entire mechanism.

- Drum: The cylindrical component that holds the rope or cable and provides a smooth surface for it to wind and unwind during recovery tasks.

- Rope or Cable: A high-strength line that is crucial for securing and pulling objects. It is typically made from synthetic fibers or steel, depending on the desired strength and flexibility.

- Gearbox: The mechanism responsible for transmitting the motor’s energy to the drum, enabling efficient speed and torque control.

- Control System: Allows the operator to manage the speed and direction of the line, usually through wired or wireless remotes for user convenience.

- Brake: Ensures that the load remains secure when the recovery is in progress, preventing unwanted slack and allowing the operator to maintain control.

- Clutch: A key element for disengaging the motor from the drum, allowing manual operation of the cable or rope when necessary.

Each of these components interacts with others to form a cohesive, reliable recovery system. By understanding how these elements function individually and together, users can operate their equipment more effectively, ensuring safer and more successful recovery efforts.

Key Parts of Badlands Winches

Understanding the essential components of a heavy-duty pulling system is crucial for optimal performance and maintenance. Each element plays a specific role in ensuring the mechanism operates efficiently, allowing users to tackle various challenges with ease. By exploring these crucial elements, one can appreciate the engineering behind effective towing solutions.

The first vital component is the motor, which provides the necessary power to drive the entire assembly. Coupled with a sturdy gear system, it ensures that torque is effectively transmitted, facilitating smooth operation. Additionally, the drum serves as the storage unit for the cable, making its design critical for preventing tangling and wear over time.

Another significant aspect is the braking system, which secures loads during use, offering safety and reliability. Control mechanisms, whether wired or wireless, are also essential, as they provide users with the ability to manage operations from a distance. Finally, the housing must be durable and resistant to environmental elements, ensuring longevity and consistent performance in various conditions.

How to Read Winch Diagrams

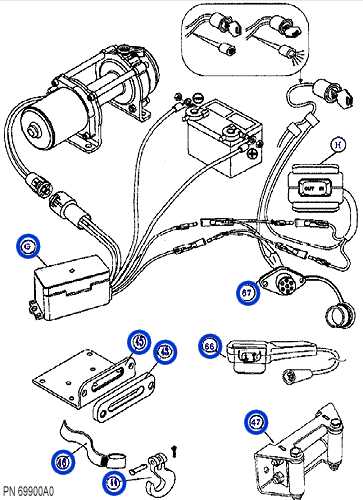

Understanding the layout of mechanical systems is essential for effective maintenance and repairs. When dealing with complex tools, it’s important to be able to interpret visual representations that show how various components interact. These illustrations provide a clear overview of connections, orientations, and the correct assembly process. Mastering the art of reading these schematics ensures smoother troubleshooting and efficient upgrades.

Start by identifying the key elements. Look for symbols, labels, and color codes that indicate the specific functions of each part. This helps in determining where each component fits within the system. Pay attention to the flow of movement and how energy is transmitted between the elements.

Next, follow the lines and connections. These often represent mechanical linkages or electrical pathways. Understanding how they are routed can prevent errors during reassembly or upgrades. Be cautious of any additional notes, as they often contain essential information for proper handling and usage.

Lastly, refer to the legend or guide, if available. This will provide clarification on any unfamiliar symbols or abbreviations, helping you fully grasp the meaning behind the schematic. With practice, reading these visuals becomes an intuitive skill that enhances your ability to maintain and repair equipment.

Importance of Winch Maintenance

Regular upkeep of essential equipment is crucial for optimal performance and longevity. Neglecting this aspect can lead to decreased efficiency and potential failures, which may pose safety risks. Ensuring that all components are in top condition is vital for reliable operation.

Routine inspections help identify wear and tear, allowing for timely interventions. Lubrication and cleaning of mechanical parts prevent buildup that could hinder functionality. Furthermore, a well-maintained system enhances overall productivity, minimizing downtime.

Ultimately, prioritizing maintenance not only protects your investment but also ensures readiness for demanding tasks. Staying proactive can save time and resources while maximizing effectiveness in various applications.

Common Issues with Winch Parts

When operating recovery equipment, users often encounter a range of challenges that can hinder performance and safety. Understanding these common issues is essential for maintaining reliability and effectiveness. Proper identification of problems can lead to timely repairs and optimal functionality.

Mechanical Failures

One prevalent concern involves mechanical breakdowns, which can stem from wear and tear over time. Components such as gears and bearings are particularly vulnerable to degradation, leading to reduced efficiency or complete failure. Regular inspections and maintenance can help mitigate these risks and extend the lifespan of the machinery.

Electrical Malfunctions

Another significant issue pertains to electrical failures, which can affect the operation of the device. Faulty wiring or connections can lead to power loss or erratic performance. Ensuring that all electrical components are properly maintained and replaced when necessary is crucial for reliable operation and safety during use.

Upgrading Your Badlands Winch

Enhancing the performance and durability of your recovery system can significantly improve your ability to tackle challenging terrains. By upgrading specific components, you can increase the efficiency, reliability, and overall power of your equipment. Whether you’re looking to boost pulling strength, reduce wear and tear, or improve control, upgrading is a valuable investment for both recreational and professional use.

Choosing the Right Components for Upgrades

When considering upgrades, it’s essential to focus on parts that directly impact performance. Start by evaluating the most frequently used elements of your system and identify where improvements are needed the most. Upgrading certain components can not only increase strength but also enhance your setup’s longevity and ease of use.

- Motor: A higher torque motor will provide more pulling power.

- Rope: Opting for synthetic rope over traditional steel cable can reduce weight and improve safety.

- Control: A wireless remote control can offer better convenience and precision from a distance.

- Brake System: Upgrading the brake system can ensure smoother operation and prevent overheating.

Installation Tips for Improved Performance

Proper installation is crucial to ensure that your new components function optimally. Here are a few helpful tips for getting the best performance out of your upgraded system:

- Follow the manufacturer’s guidelines for installing each component to avoid damaging any parts.

- Ensure that all connections are secure, and use appropriate tools to prevent any loose fittings.

- Test the system thoroughly after installation to ensure everything works smoothly and efficiently.

Upgrading your setup is a straightforward process that can make a substantial difference in how well your equipment performs in tough conditions. With the right enhancements, you can extend the lifespan of your system and ensure that you’re always prepared for any challenge.

Safety Tips for Winch Operation

Operating heavy machinery requires careful attention to safety protocols to prevent accidents and ensure smooth functioning. Understanding proper techniques is crucial for maintaining both personal safety and the integrity of the equipment.

- Always read the user manual before operation.

- Inspect the equipment thoroughly before use.

- Wear appropriate protective gear, including gloves and helmets.

Additionally, follow these guidelines:

- Ensure the area is clear of obstacles and personnel.

- Do not exceed the load limit specified by the manufacturer.

- Use safety features, such as brake systems and emergency stops.

- Maintain a safe distance from the cable during operation.

By adhering to these precautions, operators can delve into their tasks with confidence, knowing they are prioritizing safety above all else.

Comparing Badlands with Other Brands

This section aims to explore the distinctions and similarities between a prominent manufacturer and its competitors in the market. By analyzing various features, quality, and performance, we can gain insights into what sets these brands apart and helps consumers make informed choices.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Durability | High | Medium | High |

| Price Range | $$$ | $$ | $$$$ |

| Performance | Excellent | Good | Very Good |

| Warranty | 5 years | 3 years | 4 years |

Understanding these factors allows potential buyers to delve deeper into their options, ultimately leading to a more satisfying investment.

Resources for Winch Repair Guides

When tackling the challenge of repairing a mechanical pulling device, having the right resources at your fingertips is crucial. These guides can provide detailed insights into troubleshooting, maintenance, and replacement procedures. By utilizing comprehensive materials, you can ensure that your equipment remains in optimal working condition and extends its lifespan.

Online Forums and Communities: Engaging with fellow enthusiasts in online platforms can be invaluable. Many forums feature sections dedicated to sharing experiences, tips, and solutions related to equipment issues. You can often find troubleshooting advice and step-by-step guides from seasoned users who have faced similar challenges.

Manufacturer Websites: Most manufacturers offer an array of resources, including instructional videos, technical manuals, and FAQs. These materials are specifically tailored to their products and often contain detailed schematics and service recommendations that are essential for effective repairs.

Video Tutorials: Platforms like YouTube are filled with visual guides that demonstrate the repair processes in action. Watching these tutorials can provide clarity on complex tasks and help you grasp techniques that might be difficult to understand through text alone.

Specialized Repair Manuals: Investing in dedicated repair manuals can offer comprehensive guidance. These books often cover everything from basic maintenance to advanced troubleshooting techniques, making them a valuable addition to your toolkit.

Local Workshops and Classes: Participating in hands-on workshops can greatly enhance your understanding of repair techniques. Many local organizations offer classes that focus on practical skills, allowing you to learn directly from experienced professionals.