The intricate design of farming machinery plays a crucial role in modern agriculture, enhancing efficiency and productivity. By examining the various elements that constitute these tools, we can gain insight into their functionality and maintenance. This exploration delves into the essential mechanisms that enable effective soil cultivation, illustrating their significance in the agricultural process.

Familiarity with the individual components not only aids in better handling but also fosters an appreciation for the engineering that underpins these devices. Each segment serves a unique purpose, working harmoniously to achieve optimal results in fieldwork. Understanding how these features interact can empower operators to make informed decisions, leading to improved performance and longevity of the equipment.

As we break down the different sections of this machinery, we will highlight key aspects that are vital for both new and seasoned users. Recognizing the specific roles of each element can enhance operational efficiency and minimize downtime. This knowledge is essential for anyone involved in the agricultural sector, ensuring that all aspects of equipment management are covered comprehensively.

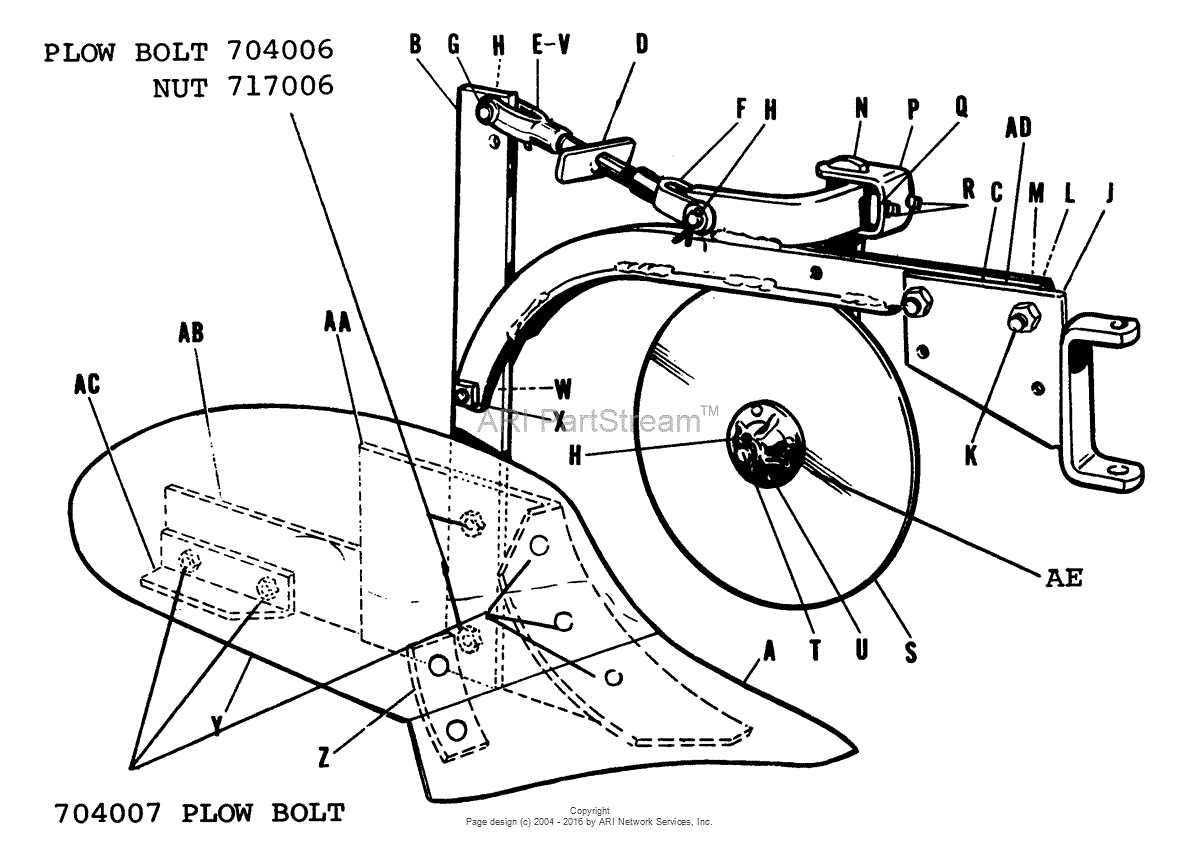

Understanding Cycle Country Plow Components

Comprehending the elements that constitute a snow removal apparatus is essential for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance during winter months. By familiarizing oneself with these integral pieces, users can enhance both efficiency and longevity of the equipment.

The foremost element is the cutting edge, which is responsible for efficiently breaking through snow and ice. Following closely are the frame and mounting brackets, providing the necessary structural integrity and support for the entire setup. Additionally, the hydraulic system facilitates dynamic adjustments, allowing for improved maneuverability across various terrains.

Moreover, the tires or tracks enhance traction and stability, ensuring that the machine can traverse slippery surfaces with ease. Lastly, the control mechanisms, including levers and switches, enable the operator to manage the device effectively, ensuring that each task is executed with precision.

Overview of Plow Functionality

This section explores the essential mechanics behind soil cultivation tools, highlighting their crucial role in agricultural practices. Understanding how these implements operate can enhance efficiency and effectiveness in farming tasks.

Mechanics of Soil Turning

The primary function of these tools involves turning and aerating the earth. By cutting through the soil and lifting it, they prepare the ground for planting by improving drainage and nutrient distribution.

Importance of Design

The design of these implements greatly influences their performance. Features such as blade shape and material impact how well they penetrate the soil, allowing for varying depths and styles of cultivation depending on the task at hand.

Key Parts of Cycle Country Plows

Understanding the essential components of agricultural implements is crucial for optimizing their performance and ensuring longevity. Each element plays a vital role in the overall functionality, influencing efficiency and ease of use in various tasks. Familiarity with these critical features can significantly enhance the user experience.

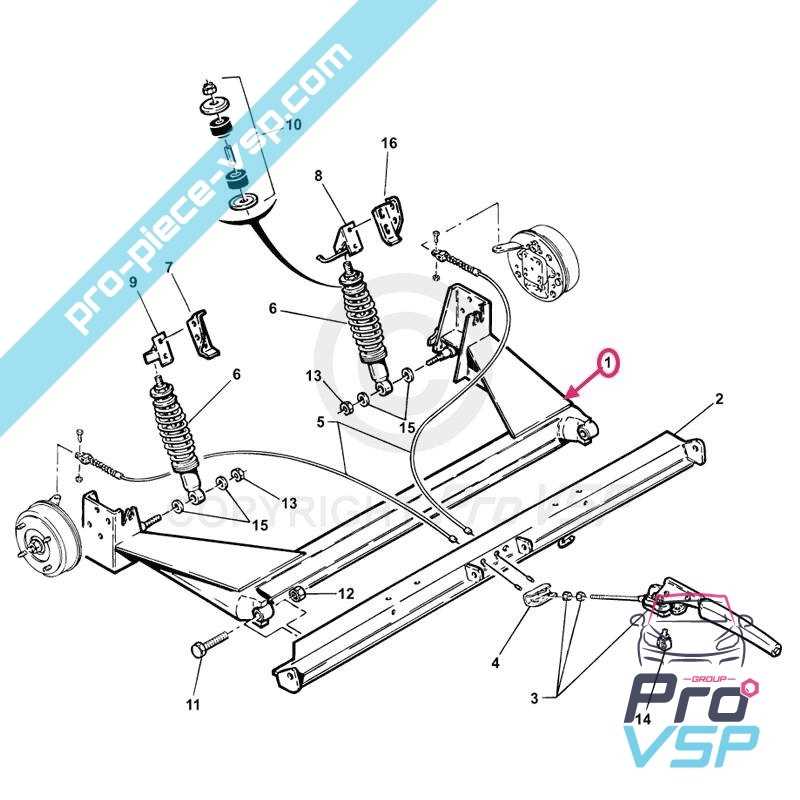

1. Frame: The sturdy structure serves as the backbone, supporting all other elements and providing stability during operation. A well-constructed frame is essential for durability and resilience against wear and tear.

2. Moldboard: This curved surface is instrumental in turning and aerating the soil, creating furrows that facilitate planting. Its design directly impacts the effectiveness of the tilling process.

3. Share: Positioned at the leading edge, this component slices through the earth, allowing for efficient penetration. The quality of the share affects how well the implement engages with different soil types.

4. Hitch: This connection point attaches the implement to the tractor or other vehicles, ensuring secure engagement. A reliable hitch is crucial for safe operation and maneuverability.

5. Adjustments: Features such as depth controls and angle settings allow users to customize the implement for specific tasks, making versatility a key attribute in achieving optimal results.

In summary, comprehending these fundamental elements aids in selecting the right equipment and maintaining it effectively, ultimately enhancing agricultural productivity.

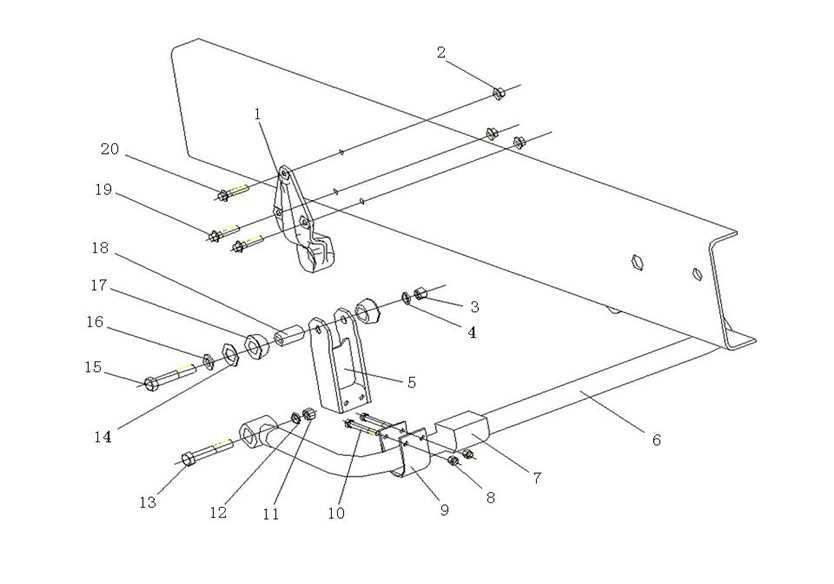

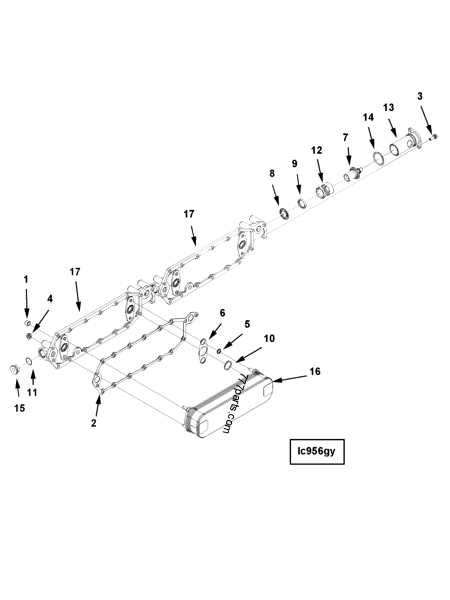

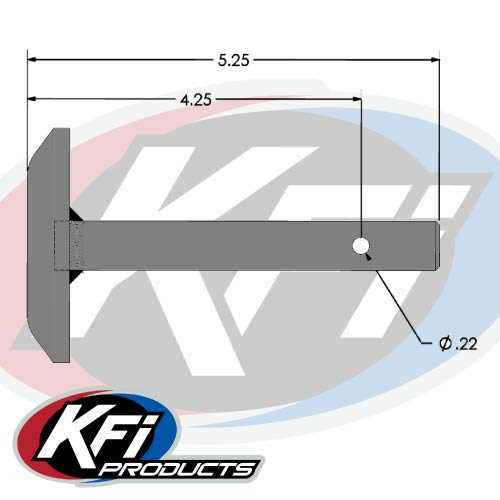

How to Read a Parts Diagram

Understanding a visual representation of components can greatly simplify the process of identifying and assembling equipment. These illustrations serve as valuable guides, allowing users to locate each element effectively and comprehend their interconnections. By familiarizing yourself with the layout and symbols used, you can streamline maintenance and repairs.

Key Components of the Illustration

- Labels: Each item is typically marked with a specific identifier, making it easier to reference in manuals or during discussions.

- Numbers: Frequently, numerical codes are assigned to components, aiding in quick identification when ordering replacements.

- Connections: Arrows or lines often indicate how different parts connect or interact with one another, which is crucial for understanding assembly.

Tips for Effective Interpretation

- Familiarize Yourself: Take time to study the legend or key that accompanies the illustration, as it explains the symbols used.

- Follow a Sequence: Start from one area and move systematically through the diagram to avoid confusion.

- Cross-reference: Use the illustration alongside your user manual or repair guide for clearer context.

Common Issues with Plow Parts

When working with agricultural tools, various challenges can arise that affect their efficiency and longevity. Identifying and addressing these problems early can save both time and resources, ensuring that the equipment remains in optimal working condition. Understanding the frequent malfunctions can aid in effective maintenance and improve overall performance.

Wear and Tear

One of the most prevalent issues is the natural deterioration of components due to continuous use. Elements such as blades and fittings may become worn down, leading to reduced functionality. Regular inspections can help detect these signs early, allowing for timely replacements before more significant damage occurs.

Improper Alignment

Another common problem is misalignment, which can result from rough terrain or improper adjustments. This misalignment can cause uneven operation, affecting the quality of work done. Regularly checking and adjusting the setup can prevent these complications, ensuring smooth and efficient performance.

Maintenance Tips for Plow Components

Proper upkeep of essential farming tools is crucial for ensuring their longevity and performance. Regular attention not only enhances efficiency but also prevents costly repairs down the line.

1. Routine Inspections: Regularly examine each component for wear and tear. Look for signs of rust, cracks, or any unusual wear that may affect functionality.

2. Cleaning: After use, thoroughly clean all elements to remove dirt and debris. This practice helps prevent corrosion and keeps parts operating smoothly.

3. Lubrication: Apply appropriate lubricants to moving parts. This reduces friction, minimizes wear, and contributes to optimal performance.

4. Storage: Store equipment in a dry, sheltered area to protect against the elements. Proper storage significantly extends the lifespan of all components.

5. Replacement: Be proactive about replacing worn or damaged elements. Timely replacements are essential for maintaining operational effectiveness.

By implementing these maintenance strategies, users can ensure their equipment remains in peak condition, ultimately leading to more efficient agricultural practices.

Upgrading Cycle Country Plow Parts

Enhancing your equipment can significantly improve performance and efficiency. By investing in superior components, you can boost productivity and extend the lifespan of your machine. This section outlines essential upgrades that can make a noticeable difference.

Key Upgrades to Consider

- High-Quality Blades: Opt for advanced materials that resist wear and improve cutting efficiency.

- Durable Mounting Systems: Upgrade to reinforced mounts that provide better stability and alignment.

- Enhanced Hydraulic Systems: Consider replacing or improving hydraulic components for smoother operation.

- Adjustable Skids: Install adjustable skids for better depth control and versatility across various terrains.

Benefits of Upgrading

- Improved performance in challenging conditions.

- Reduced maintenance costs due to higher-quality materials.

- Increased operational efficiency and speed.

- Enhanced versatility to handle different tasks.

Investing in these enhancements will not only optimize your machinery’s capabilities but also ensure a more reliable and effective working experience. Consider your specific needs and choose upgrades that align with your operational goals.

Where to Purchase Replacement Parts

Finding the right components for your equipment is essential to maintain its efficiency and performance. Whether you need a specific item for repair or routine maintenance, knowing where to look can save time and ensure quality. Here are some reliable sources to consider when seeking replacements.

| Source | Description | Website |

|---|---|---|

| Authorized Dealers | Official representatives that offer genuine components, often providing warranty and support. | example.com/dealers |

| Online Retailers | Large platforms with a wide selection, often featuring competitive prices and customer reviews. | example.com/retailers |

| Local Hardware Stores | Convenient for quick purchases, these stores may stock essential items and provide personal service. | example.com/hardware |

| Second-Hand Marketplaces | Platforms where you can find used items at lower prices, ideal for budget-conscious buyers. | example.com/marketplaces |

By exploring these options, you can ensure that you acquire the necessary components efficiently and at a fair price. Always verify the compatibility of any item before making a purchase to ensure optimal functionality.

Plow Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in assembling and disassembling a cultivation implement. Understanding these processes is crucial for maintenance, storage, and efficient operation.

Assembly Procedure

To begin the assembly, ensure all components are available and in good condition. Follow these sequential steps to achieve a stable configuration:

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools. |

| 2 | Connect the main frame securely. |

| 3 | Attach the working elements according to the layout. |

| 4 | Ensure all fasteners are tightened properly. |

| 5 | Perform a final inspection before use. |

Disassembly Procedure

When it comes time to disassemble, proper steps should be followed to avoid damage and ensure all components are preserved. The procedure is outlined as follows:

| Step | Description |

|---|---|

| 1 | Ensure the implement is parked on a flat surface. |

| 2 | Loosen all fasteners carefully. |

| 3 | Remove the working elements in reverse order of assembly. |

| 4 | Detach the main frame from the towing vehicle. |

| 5 | Store all components in a dry place for future use. |