The exploration of mechanical components is essential for anyone engaged in maintenance and repair. Having a clear visual representation of how various elements interact can significantly aid in troubleshooting and assembling machinery. This section delves into the intricate layout that showcases the essential parts of the equipment.

By examining the arrangement of these components, users can gain insights into their functions and relationships. Whether you are an experienced technician or a novice, familiarizing yourself with this comprehensive layout will enhance your understanding of the overall system. Proper knowledge is key to ensuring efficiency and longevity in operation.

Furthermore, an in-depth look at this visual aid not only simplifies repairs but also aids in identifying any potential issues that may arise during operation. Understanding each element and its role can empower users to tackle problems effectively, ensuring a seamless workflow in any mechanical endeavor.

This section aims to clarify the layout and components of the equipment, providing insights into its construction and functionality. Recognizing each element’s role enhances maintenance and repair processes, ensuring optimal performance.

Importance of Knowing Components

Familiarity with the individual elements of the machinery offers several advantages:

- Facilitates accurate troubleshooting.

- Assists in efficient repairs and replacements.

- Enhances overall operational efficiency.

How to Interpret the Layout

When examining the illustration, consider the following aspects:

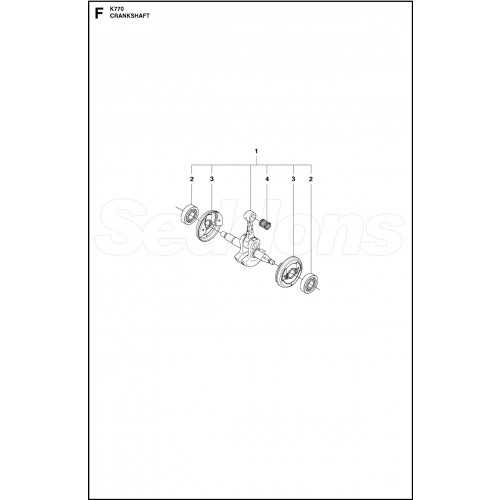

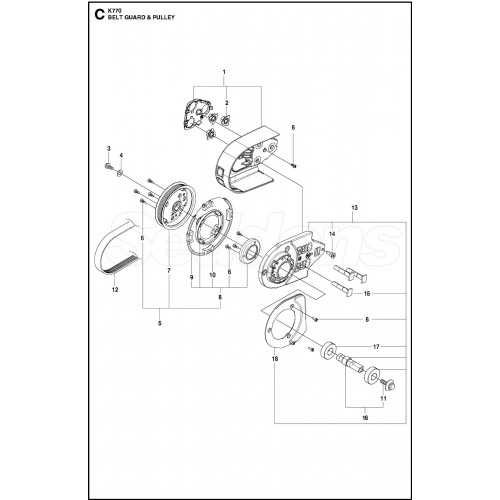

- Identify major assemblies and their connections.

- Note the positioning of smaller components.

- Understand the flow of operation through the system.

By grasping these elements, users can ensure proper handling and maintenance, prolonging the lifespan of the equipment.

Key Components of the K770

This section explores the essential elements that contribute to the effective functioning of the equipment. Understanding these components is crucial for maintenance and optimal performance.

- Engine: The heart of the machine, responsible for providing the necessary power.

- Cutting Head: Designed for precision, this component allows for accurate cuts in various materials.

- Handle: Ergonomically designed to ensure comfort and control during operation.

- Fuel System: Facilitates the supply of fuel to the engine, ensuring smooth performance.

- Cooling System: Prevents overheating, maintaining efficiency and prolonging the lifespan of the equipment.

- Safety Features: Includes mechanisms that protect the user and enhance operational safety.

Each of these elements plays a vital role in ensuring that the machinery operates efficiently and safely, making it important to regularly check and maintain them.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the processes involved in putting together and taking apart the equipment efficiently. Understanding these procedures is essential for maintenance, repair, and ensuring the longevity of the machinery. Proper techniques will help prevent damage to components and ensure a seamless experience during reassembly.

Preparation Steps

Before starting the assembly or disassembly process, gather the necessary tools and workspace. Ensure that all components are clean and free from debris. Familiarize yourself with the assembly sequence to avoid confusion during the procedure.

Disassembly Procedure

Follow these steps to safely disassemble the equipment:

| Step | Description |

|---|---|

| 1 | Remove any protective covers or guards to access the main components. |

| 2 | Loosen and detach any screws, bolts, or fasteners securing the parts together. |

| 3 | Carefully take apart each component, keeping them organized to ensure easy reassembly. |

| 4 | Inspect the components for wear or damage during the disassembly process. |

Common Issues and Solutions

In any machinery, operational difficulties may arise, impacting performance and efficiency. Identifying these challenges promptly is crucial for maintaining functionality. This section addresses prevalent problems and their corresponding solutions, enabling users to troubleshoot effectively and ensure optimal operation.

Engine Starting Problems

Issue: A common concern is difficulty in initiating the engine. This can stem from various factors, including fuel supply issues or ignition system failures.

Solution: Begin by checking the fuel levels and ensuring that the fuel lines are clear. If the fuel system is functioning correctly, inspect the ignition components for any wear or damage, and replace as necessary.

Overheating

Issue: Overheating can lead to severe damage, often caused by insufficient cooling or blocked airflow.

Solution: Regularly clean the cooling system and ensure that the air intake is free from obstructions. Additionally, check the coolant levels and top up if needed, ensuring the system operates within safe temperature ranges.

Maintenance Tips for K770

Proper upkeep of your equipment is essential to ensure its longevity and optimal performance. Regular maintenance can help prevent issues and enhance functionality, providing a smoother operation.

Here are some key practices to consider:

- Regular Inspections: Conduct routine checks to identify any wear or damage. This includes examining the exterior, engine components, and operational parts.

- Cleaning: Keep the machinery clean by removing debris and dust. Regularly clean filters and air intakes to maintain airflow.

- Lubrication: Ensure all moving parts are adequately lubricated. Use the recommended lubricant to reduce friction and wear.

- Check Fluids: Regularly check and top up essential fluids such as fuel, oil, and coolant. Maintaining proper fluid levels is critical for efficient operation.

- Replace Worn Components: Monitor the condition of key components and replace any that show significant wear. This proactive approach can prevent more severe issues down the line.

- Follow the Manual: Refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Adhering to these recommendations will help keep your machine in peak condition.

By following these maintenance tips, you can ensure the reliability and efficiency of your equipment, ultimately extending its operational lifespan.

Replacement Parts Availability

The accessibility of components is crucial for maintaining equipment efficiency and ensuring longevity. Users often seek reliable sources for procuring essential items that may require substitution over time. Having readily available replacements contributes significantly to uninterrupted operation and optimal performance.

Various suppliers offer an extensive selection of essential items that facilitate quick repairs and replacements. These sources provide both original and aftermarket options, catering to different budgetary needs while ensuring compatibility. Additionally, online marketplaces have become increasingly popular, providing convenient access to a vast array of components.

It is advisable to verify the authenticity and quality of the items before making a purchase. Checking reviews and ratings can help in identifying trustworthy vendors. Moreover, ensuring that the replacements meet the specified requirements of the machinery will enhance functionality and safety.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential to prevent accidents and injuries. Proper precautions help create a secure working environment and enhance overall efficiency. By following specific guidelines, individuals can minimize risks and effectively manage potential hazards.

Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection. This gear protects against various risks, including chemical exposure and physical injuries. Additionally, ensure that your workspace is well-ventilated and free from clutter, which can contribute to accidents.

Before beginning any repair, disconnect power sources and allow machinery to cool down if applicable. This step significantly reduces the chance of electrical shocks or burns. Familiarize yourself with the equipment and its components, as understanding their function can help prevent mishandling.

When using tools, make sure they are in good condition and suitable for the task at hand. Regularly inspect equipment for wear and tear to avoid malfunctions that could lead to accidents. Always follow the manufacturer’s guidelines for maintenance and repairs.

In case of any uncertainty regarding a procedure, do not hesitate to seek professional assistance. It is better to consult an expert than to risk injury or damage to the equipment. By prioritizing safety, you can ensure a successful and accident-free repair experience.