The functionality of restroom equipment relies heavily on the intricate assembly of various mechanisms. Each component plays a crucial role in ensuring efficient operation, from regulating water flow to maintaining optimal performance under various conditions.

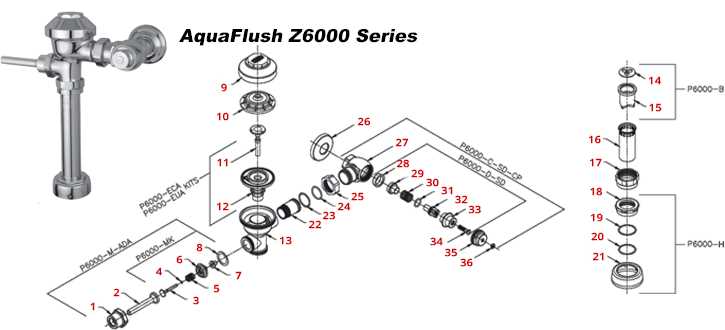

In this section, we will explore a visual representation that illustrates the arrangement and interaction of these essential elements. By examining this illustration, one can gain valuable insights into how each segment contributes to the overall efficiency of the system.

Familiarity with these components is vital for maintenance and troubleshooting. A comprehensive understanding will empower users to address issues effectively, ensuring prolonged reliability and performance of their installations.

This section aims to provide a comprehensive overview of the essential elements involved in the operation of a toilet mechanism. By delving into the various components, readers will gain insights into their functionalities and significance in ensuring efficient performance.

Introduction to Essential Elements

The critical components of a toilet mechanism play a vital role in its overall operation. Understanding these elements helps in identifying issues and performing maintenance effectively.

Key Functional Components

- Overview of each component’s role

- Importance of material quality

- Common issues related to component wear

Maintenance and Troubleshooting

- Regular inspection recommendations

- Identifying signs of wear or malfunction

- Steps for effective maintenance

In summary, exploring the different components associated with the toilet mechanism enhances understanding and promotes efficient operation. Knowledge of these elements not only aids in maintenance but also helps troubleshoot common issues.

Functionality of Flush Valve Systems

In modern restroom facilities, effective systems are essential for managing the flow of water during the flushing process. These mechanisms ensure that toilets operate efficiently, providing a clean and sanitary environment for users. Understanding how these systems function can lead to better maintenance practices and improved performance.

Key Components and Their Roles

The efficiency of the flushing mechanism relies on several critical elements that work together harmoniously. Each component serves a distinct purpose, contributing to the overall functionality:

- Control Mechanism: Regulates the release of water, ensuring optimal flow during the operation.

- Sealing Elements: Prevent leaks and maintain pressure, essential for effective flushing.

- Water Supply Connection: Facilitates the intake of water from the plumbing system, ensuring consistent availability.

- Overflow Features: Prevents excessive water buildup, protecting against potential flooding.

Operational Process

The process begins when a user activates the system, triggering the control mechanism. This action allows water to flow into the toilet bowl, efficiently removing waste. After the process, sealing elements close to retain the water and prevent leaks. The entire cycle is designed to be quick and reliable, ensuring a pleasant experience for the user.

Regular maintenance of these components is crucial for optimal functionality, reducing the likelihood of issues and ensuring longevity.

Common Issues with Flush Valves

Many individuals encounter problems with their toilet systems, which can lead to inefficiencies and inconveniences. Understanding typical complications that may arise can assist in prompt identification and resolution.

Leaking Mechanisms: One prevalent issue is the presence of leaks within the mechanism, often resulting from wear and tear. This can cause excess water usage and contribute to higher utility bills.

Inconsistent Operation: Users may notice that the system does not operate consistently, leading to insufficient clearing or, conversely, over-clearing. This erratic behavior can stem from various factors, including obstructions or malfunctions.

Noise Disruptions: Unusual noises during operation, such as hissing or gurgling, often indicate underlying problems. These sounds may signal air leaks or internal conflicts that require attention.

Slow Refilling: A sluggish refill process can be frustrating and inconvenient. This can result from sediment buildup or issues with the incoming water supply, affecting overall performance.

Corrosion Issues: Components may suffer from corrosion over time, impacting their functionality. Regular inspection can help identify signs of deterioration early, preventing more significant issues down the line.

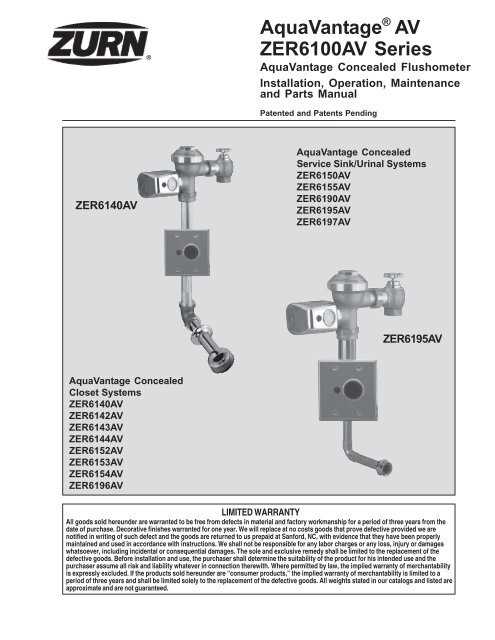

Identifying Zurn Valve Replacement Parts

Understanding the components of your water control mechanism is crucial for efficient maintenance and repairs. Recognizing each element and its function allows for quick identification when replacement is necessary. Properly assessing these components ensures a seamless repair process and helps maintain optimal performance.

Common Components

The primary elements typically found in water control systems include seals, levers, and float mechanisms. Each of these plays a significant role in the functionality of the entire assembly. Familiarity with these common components aids in determining which parts may need to be replaced during maintenance or repairs.

Tools for Identification

To accurately identify components for replacement, having the right tools is essential. A detailed manual or guide can provide illustrations and specifications that assist in recognizing the necessary elements. Additionally, using measurement tools can help ensure that replacements fit perfectly, enhancing the system’s longevity and reliability.

Maintenance Tips for Flush Valves

Regular upkeep of your toilet’s flushing mechanism is essential for ensuring optimal performance and longevity. Proper maintenance can help prevent leaks, reduce water waste, and enhance efficiency. By following a few simple guidelines, you can keep your system functioning smoothly.

Routine Inspection

Perform periodic checks to identify any signs of wear or damage. Look for leaks around connections and inspect the rubber components for cracks or deterioration. Early detection can prevent more significant issues down the line.

Cleaning and Replacement

Regular cleaning of the components is crucial to avoid buildup that can impair function. Use mild cleaners and avoid abrasive materials. Additionally, consider replacing worn-out parts as needed to maintain peak performance. Staying proactive with these tasks will help extend the lifespan of your toilet system.

Installation Guidelines for Zurn Valves

Proper setup of these components is essential for achieving optimal performance in restroom facilities. Following precise instructions ensures that the system operates efficiently, reducing the risk of malfunctions and extending the lifespan of the equipment.

To ensure a smooth installation process, adhere to the following steps:

- Gather all necessary tools and components before beginning.

- Turn off the water supply to prevent any leaks or water damage.

- Carefully read the manufacturer’s instructions specific to your model.

- Begin by removing any old components, ensuring that the area is clean and clear.

- Install the new assembly according to the specified guidelines, paying attention to alignment and secure fittings.

- Reconnect the water supply and check for leaks during initial operation.

Regular maintenance is also crucial for long-term functionality. Consider the following upkeep tasks:

- Inspect for any signs of wear or damage periodically.

- Clean components to prevent buildup that could impair function.

- Test functionality regularly to ensure reliable operation.

Comparing Zurn Valves with Other Brands

When evaluating different manufacturers of toilet components, it is essential to assess the overall performance, reliability, and value offered by each brand. This comparison highlights how various options stand against one another, particularly focusing on functionality and user satisfaction.

Performance and Durability

Manufacturers differ significantly in terms of durability and efficiency. While some brands prioritize advanced technology for enhanced performance, others may focus on traditional designs that have proven effective over the years. Understanding these differences can help consumers make informed decisions regarding their plumbing fixtures.

Cost-effectiveness and Warranty

Another vital aspect to consider is the cost-effectiveness of the products. Some companies offer competitive pricing along with extended warranties, ensuring customers receive quality service and peace of mind. Evaluating the warranty options alongside the initial investment can provide insights into long-term savings and potential repairs.

In summary, comparing various manufacturers allows consumers to choose products that best suit their needs, balancing quality, efficiency, and affordability.

Frequently Asked Questions on Valves

This section addresses common inquiries regarding various mechanisms that control the flow of liquids and gases. Understanding these components can enhance functionality and performance in various systems, ensuring optimal operation and maintenance.

What are the main types of flow control mechanisms?

There are several primary categories, including gate, globe, ball, and butterfly types. Each serves a unique purpose, allowing for precise control of the flow based on the specific needs of the application.

How can I troubleshoot common issues with flow control devices?

Identifying problems typically involves checking for leaks, unusual noises, or failures to operate. Regular maintenance and inspection can prevent these issues and extend the lifespan of the device.

Resources for Further Learning

For those interested in expanding their knowledge in the realm of plumbing fixtures and their components, there are a variety of valuable resources available. Exploring these materials can enhance understanding of the mechanisms involved and facilitate better maintenance practices.

Online platforms offer tutorials and guides that delve into various systems, providing insights into functionality and troubleshooting techniques. Websites dedicated to home improvement frequently feature articles and videos, enabling users to visualize processes and learn at their own pace.

Additionally, manufacturers often provide comprehensive manuals and technical documentation, which can be invaluable for grasping the specifics of different systems. Engaging in forums and community discussions allows enthusiasts to share experiences, ask questions, and gain practical advice from others in the field.