Maintaining a well-functioning lawn care machine is essential for achieving optimal performance in your outdoor tasks. Understanding the intricate system of components that comprise your equipment can help you troubleshoot issues and enhance its longevity. Each element plays a vital role in ensuring smooth operation, and having a clear understanding of these can lead to more efficient maintenance practices.

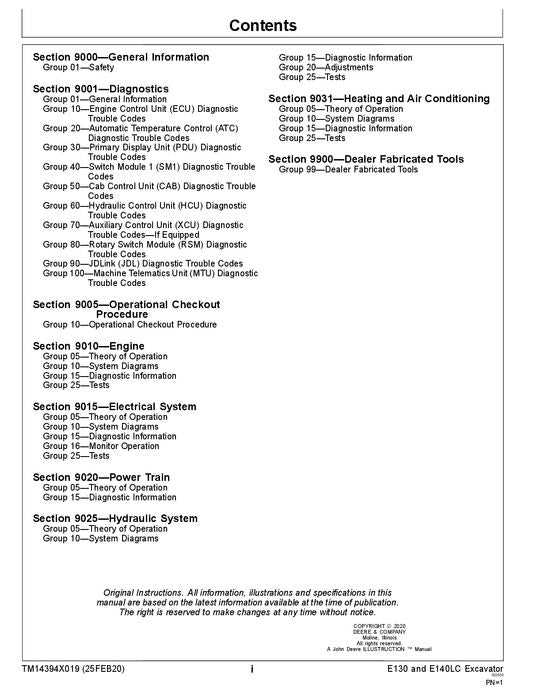

Familiarizing yourself with the various sections and individual pieces can provide insight into how they work together harmoniously. This knowledge allows for easier identification of any malfunctioning parts and the selection of appropriate replacements when necessary. Proper documentation detailing the assembly of these units serves as an invaluable resource for both novice and experienced operators alike.

Moreover, a comprehensive overview of the essential elements can significantly assist in the decision-making process during repairs or upgrades. Being well-informed about each component enables users to make educated choices, ensuring that their machinery remains in peak condition. With the right understanding, you’ll be better equipped to navigate the intricacies of your equipment and maintain its efficiency for years to come.

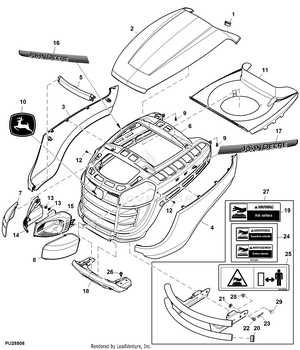

Understanding John Deere E130 Components

The efficient operation of any outdoor equipment relies heavily on its various elements working harmoniously. Each component plays a crucial role in the overall functionality, ensuring smooth performance and reliability. This section delves into the essential components found in a specific model of riding machinery, providing insights into their significance and interrelationships.

Key Features of the Machinery

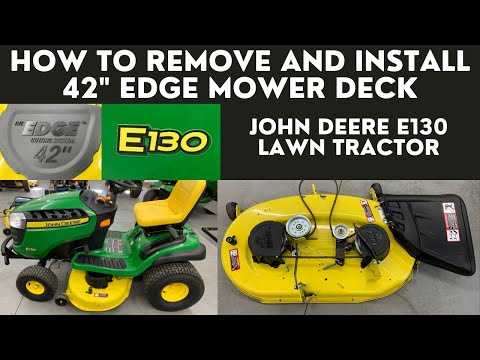

Every piece of equipment includes vital features that contribute to its effectiveness. The engine serves as the powerhouse, providing the necessary energy for operation. Meanwhile, the transmission system is responsible for transferring this power to the wheels, allowing for movement and maneuverability. Additionally, the cutting mechanism is designed to efficiently trim grass and other vegetation, making it a fundamental aspect of this machinery.

Maintenance and Care

Proper maintenance is essential for prolonging the life of any outdoor equipment. Regular checks on the engine’s oil levels, air filters, and spark plugs can prevent potential issues and ensure optimal performance. Furthermore, keeping the cutting blades sharp and clear of debris is vital for achieving clean and efficient cuts. Understanding these components and their maintenance needs will help users keep their machinery in top condition.

Essential Features of E130 Tractor

The E130 model offers a range of capabilities that enhance its utility in various agricultural and landscaping tasks. This versatile machine combines power, efficiency, and user-friendly features to cater to both novice and experienced operators.

- Powerful Engine: The tractor is equipped with a robust engine that ensures reliable performance, making it suitable for a variety of tasks.

- Comfortable Operator Station: The seating arrangement and control layout are designed to provide comfort and ease of use, reducing fatigue during extended operation.

- Efficient Transmission: A smooth transmission system allows for seamless gear shifts, enhancing maneuverability and efficiency on the field.

- Durable Construction: Built with high-quality materials, this machine is designed to withstand the rigors of outdoor work, ensuring longevity and reliability.

- Versatile Attachments: Compatibility with a range of attachments expands the functionality, enabling users to perform diverse tasks with a single machine.

These characteristics make this model a valuable asset for anyone looking to accomplish various outdoor projects with efficiency and ease.

Common Repairs and Maintenance Tips

Regular upkeep and minor fixes can significantly enhance the longevity and performance of your outdoor equipment. Understanding the common issues that may arise and how to address them can save time and resources while ensuring optimal operation.

Here are some essential repair and maintenance recommendations to keep your machinery running smoothly:

| Task | Frequency | Tips |

|---|---|---|

| Check and change oil | Every 50 hours of use | Use the recommended oil type for optimal performance. |

| Inspect and replace air filter | Every 25 hours of use | Keep the filter clean for better engine efficiency. |

| Sharpen blades | Every 10 hours of use | Keep blades sharp for a clean cut and to reduce strain on the engine. |

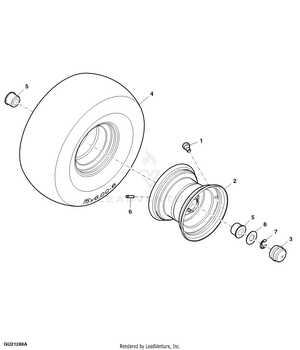

| Check tire pressure | Monthly | Maintain proper tire pressure to ensure stability and efficiency. |

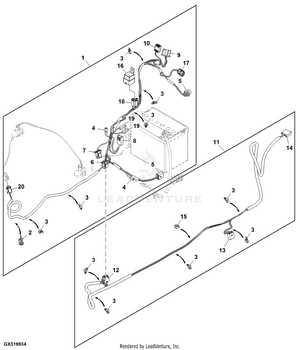

| Inspect battery terminals | Monthly | Clean terminals to prevent corrosion and ensure proper connections. |

By following these maintenance practices, you can avoid many common issues and ensure that your outdoor equipment remains reliable throughout its lifespan.

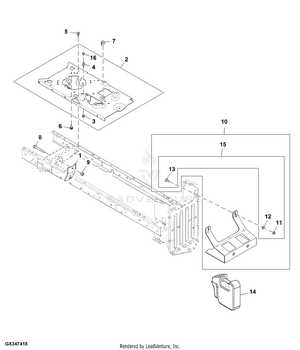

How to Access Parts Diagrams

Locating and understanding the visual representations of component layouts is essential for efficient maintenance and repairs. These resources offer a clear view of how different elements interact, ensuring that users can make informed decisions when it comes to servicing machinery.

Online Resources

Many manufacturers provide access to these visual aids through their official websites. Here’s how to find them:

- Visit the manufacturer’s official website.

- Navigate to the support or resources section.

- Look for a link related to service information or technical documents.

- Utilize the search function to input the specific model number.

User Manuals and Documentation

Another valuable source of information is user manuals. These often contain detailed illustrations. To access them:

- Check the packaging that came with the equipment for any included documentation.

- Search online for downloadable versions of the manual using the model number.

- Visit forums or community pages where users share resources and tips.

Identifying Key Replacement Parts

Understanding the essential components of a lawn care machine is crucial for effective maintenance and repair. Recognizing which elements need replacement can significantly enhance the machine’s performance and longevity. Familiarity with these components empowers users to make informed decisions when sourcing replacements and performing repairs.

Common Components to Monitor

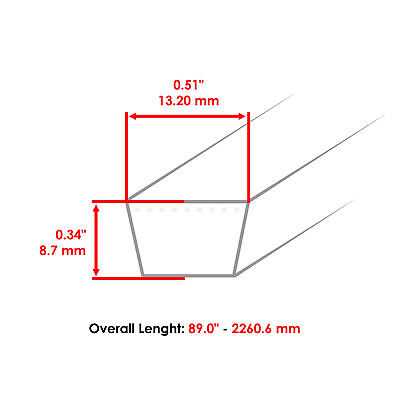

Several vital elements require regular attention and potential replacement over time. Blades are essential for ensuring a clean cut, while the engine filter plays a critical role in maintaining optimal airflow and performance. Additionally, keeping an eye on the batteries and belts can prevent unexpected breakdowns during use.

Where to Find Quality Replacements

When searching for quality replacements, it’s essential to consider reputable suppliers. Authorized dealers often provide components that meet the manufacturer’s standards, ensuring compatibility and reliability. Online marketplaces also offer a wide variety of options, but it is vital to verify the authenticity and quality of the products before making a purchase.

Tools Required for E130 Maintenance

Regular upkeep of your lawn equipment ensures its longevity and optimal performance. To effectively conduct maintenance tasks, having the right set of tools is essential. This section outlines the necessary implements that will aid in the care and servicing of your machinery.

Below is a list of essential tools:

- Wrenches: A variety of socket and open-end wrenches will be necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers will be crucial for adjusting and securing various components.

- Plier Set: Pliers will help grip, twist, and cut wires and other materials during repairs.

- Grease Gun: This tool is vital for lubricating moving parts to reduce friction and wear.

- Oil Filter Wrench: An oil filter wrench is required for easy removal and installation of the oil filter.

- Fuel Stabilizer: This can help maintain fuel quality during storage and prevent engine problems.

In addition to the tools mentioned, having a reliable work surface and safety equipment, such as gloves and goggles, will enhance your maintenance experience and ensure safety. By utilizing these implements, you can effectively maintain your lawn equipment and keep it in peak condition.

Buying Genuine John Deere Parts

When maintaining and repairing your machinery, selecting authentic components is crucial for ensuring optimal performance and longevity. Original elements are designed to fit seamlessly and function reliably, providing peace of mind that your equipment will operate as intended. By choosing these components, users can avoid potential issues associated with counterfeit or generic alternatives.

Investing in legitimate components not only enhances the efficiency of your equipment but also supports its resale value. Authentic parts often come with warranties, offering further protection against unforeseen repairs. Additionally, utilizing original elements can help maintain the manufacturer’s warranty on your machine, safeguarding your investment over time.

Purchasing from authorized dealers or trusted sources guarantees that you are acquiring high-quality components that meet rigorous standards. These suppliers can provide guidance on the right items for your specific model, ensuring you receive the correct replacements. This level of support can prove invaluable for both novice and experienced users alike.

Benefits of Using OEM Components

Choosing original equipment manufacturer components is essential for maintaining the longevity and performance of machinery. These components are designed specifically for particular models, ensuring compatibility and reliability. Utilizing these parts can lead to enhanced functionality, reduced maintenance issues, and greater overall satisfaction for users.

Quality Assurance

OEM components undergo rigorous testing and quality control processes to meet high industry standards. This ensures that every piece functions as intended, minimizing the risk of failure and prolonging the lifespan of the equipment. By opting for these original parts, users can trust in their performance and durability.

Warranty Protection

Using OEM components often helps maintain warranty coverage on machinery. Many manufacturers require the use of original parts to uphold warranty agreements. This protection is vital for users, as it can save significant costs in repairs or replacements if issues arise within the warranty period.

Frequently Asked Questions about E130

This section addresses common inquiries regarding a popular lawn care machine, providing valuable insights for both new and experienced users. Understanding its features, maintenance, and troubleshooting can enhance the overall user experience.

Common Queries

- What is the recommended maintenance schedule?

Regular upkeep is crucial for optimal performance. Key maintenance tasks include:

- Changing the oil and filter every 50 hours or annually.

- Inspecting and replacing the air filter as needed.

- Sharpening the cutting blades after every 25 hours of use.

- Checking tire pressure and condition periodically.

- How can I troubleshoot starting issues?

If the machine does not start, consider these troubleshooting steps:

- Ensure the fuel tank is filled with fresh gasoline.

- Check the battery connections for corrosion and tightness.

- Inspect the ignition switch and safety features to ensure they are engaged.

- Examine the fuse for any signs of damage and replace if necessary.

Parts and Accessories

Many users inquire about compatible components and additional tools to enhance functionality. Here are some recommended items:

- Replacement blades for improved cutting efficiency.

- Mulching kits for better lawn health.

- Tow-behind accessories like carts or spreaders for versatile use.