The inner workings of any landscaping machinery can be complex yet fascinating. Familiarity with the various elements that contribute to its functionality enhances maintenance and repair efficiency. Grasping these components empowers users to optimize their equipment’s performance.

In this section, we will explore the intricate relationships between individual parts, highlighting their roles and interdependencies. A comprehensive overview will not only assist in troubleshooting but also foster a deeper appreciation for the craftsmanship involved in creating robust outdoor machinery.

For enthusiasts and professionals alike, diving into the specifics of these mechanisms is crucial. By identifying and understanding each element, one can ensure longevity and reliability in their equipment, ultimately leading to a more successful landscaping experience.

Understanding the John Deere Z225

This section delves into the intricacies of a popular lawn care machine, highlighting its components and functionality. Recognizing how each element contributes to overall performance is essential for maintenance and efficient operation.

At the heart of this machine lies a powerful engine that ensures optimal performance in various mowing conditions. Proper care and understanding of its features can lead to better longevity and reliability.

- Engine: The powerhouse responsible for driving the mower, it is crucial to keep it in top shape.

- Cutting Deck: This element determines the quality of the cut and can be adjusted for different grass types.

- Wheels: The choice of tires impacts maneuverability and traction, especially on uneven terrain.

- Controls: User-friendly controls enhance the mowing experience, allowing for precise navigation.

Understanding these components not only aids in efficient operation but also empowers users to perform necessary repairs and maintenance tasks. Familiarity with each part ensures that any issues can be addressed promptly, minimizing downtime.

- Regularly check the engine oil level and change it as needed.

- Inspect the cutting blades for sharpness and damage.

- Clean the undercarriage to prevent grass buildup.

- Ensure tire pressure is within the recommended range for optimal performance.

By staying informed about the machine’s features and upkeep, operators can enhance their mowing experience and extend the life of their equipment.

Key Features of Z225 Model

This section explores the notable characteristics of a popular mowing machine, highlighting its design and performance aspects that contribute to efficient lawn care. The combination of innovative engineering and user-friendly features makes this model a preferred choice for many homeowners.

Performance and Efficiency

- Powerful engine offering reliable performance for various lawn conditions.

- Efficient cutting system that ensures a clean and even finish.

- Compact design allows for easy maneuverability in tight spaces.

User-Friendly Design

- Ergonomically designed controls for comfortable operation.

- Adjustable cutting heights to suit different grass types and preferences.

- Easy-access maintenance points for quick servicing and upkeep.

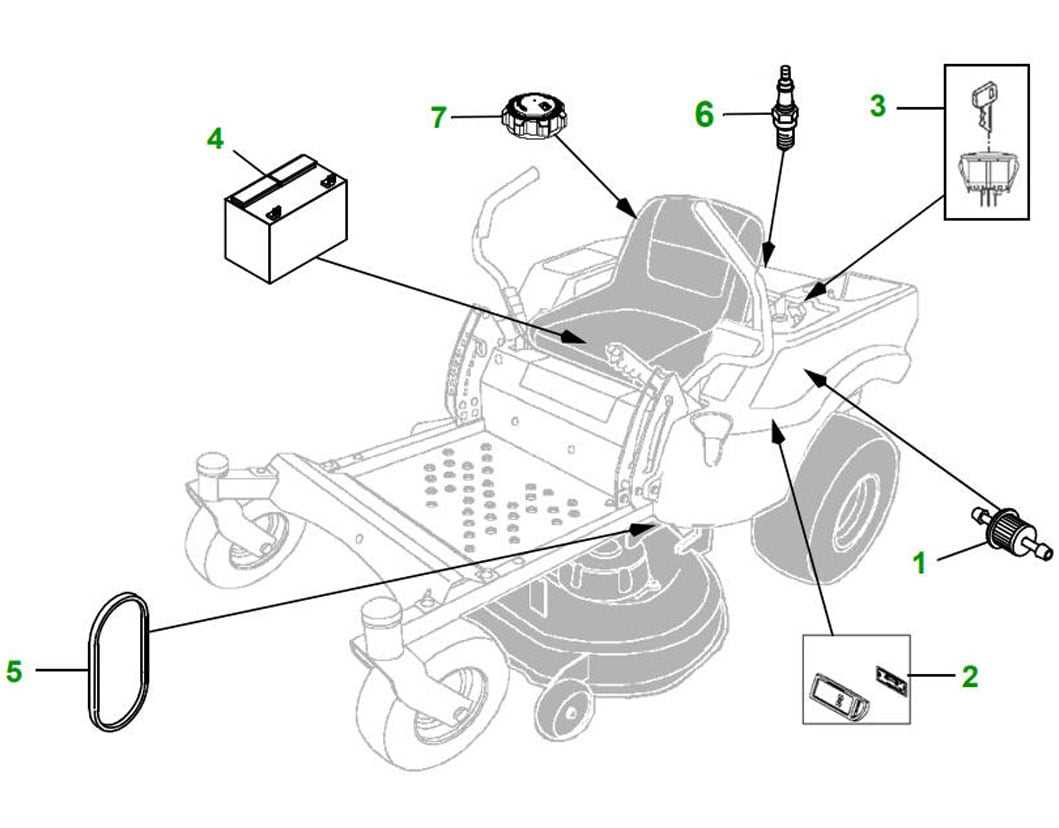

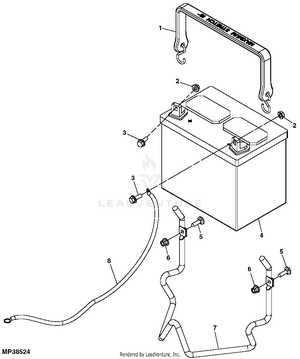

Importance of Parts Diagrams

Understanding the intricacies of machinery requires clear visual aids that illustrate each component and its placement. These representations serve as essential tools for maintenance, repair, and assembly, enabling users to navigate complex systems effectively.

Enhancing Maintenance Efficiency

Visual guides facilitate quicker identification of components, allowing technicians to address issues promptly. By having a detailed visual reference, the likelihood of errors during maintenance tasks diminishes significantly, leading to improved overall efficiency.

Aiding in Accurate Repairs

Accurate repairs rely on a thorough understanding of how individual elements interact within a system. Visual aids provide clarity, ensuring that each piece is correctly understood and positioned, thus preventing potential damage and ensuring longevity.

| Benefits | Description |

|---|---|

| Clarity | Offers a clear view of each component’s location and function. |

| Speed | Accelerates the troubleshooting process by allowing quick reference. |

| Accuracy | Ensures correct placement of components during repairs. |

| Training | Serves as a valuable educational resource for new technicians. |

Common Parts in the Z225

This section explores the essential components of the model, highlighting their functions and significance in ensuring optimal performance. Understanding these elements can aid in maintenance and troubleshooting.

Key Components

- Engine

- Transmission

- Blades

- Wheels

- Deck

Maintenance Tips

- Regularly check the engine oil levels.

- Inspect blades for wear and replace as needed.

- Ensure wheels are properly inflated.

- Clean the deck after each use to prevent grass buildup.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These visual representations help users identify components, their locations, and how they interact within the system. By grasping the layout and symbols used in these illustrations, one can navigate through complex assemblies with confidence.

Familiarize Yourself with Symbols

Each schematic uses specific symbols to denote various elements. It’s crucial to review the legend or key that accompanies the illustration. This will provide clarity on what each icon represents, such as fasteners, bearings, or electrical parts. Recognizing these symbols will streamline the troubleshooting process.

Follow the Flow of the Assembly

Start from a central point and trace the assembly outward. Many schematics are organized in a logical flow that reflects the assembly process. This method not only aids in understanding how parts fit together but also highlights any potential weak points or areas requiring special attention during disassembly or reassembly.

Practice Makes Perfect: The more you engage with these visual tools, the easier it becomes to interpret them quickly and accurately. Whether you are performing routine maintenance or troubleshooting an issue, mastering this skill is invaluable.

Where to Find Replacement Parts

Locating components for outdoor equipment can be a daunting task, yet understanding where to look can simplify the process significantly. There are numerous resources available that cater to enthusiasts and professionals alike, ensuring that the necessary elements for maintenance and repair are easily accessible.

Authorized Dealers

One of the most reliable sources for acquiring components is through certified distributors. These vendors not only offer genuine items but also provide expertise and guidance. Purchasing from authorized sellers guarantees that you receive parts that meet quality standards, which can enhance the performance and longevity of your equipment.

Online Retailers and Marketplaces

In today’s digital age, various online platforms have emerged as valuable resources for finding components. Websites specializing in equipment supplies often feature extensive catalogs and detailed descriptions. Additionally, popular e-commerce sites provide user reviews and ratings, allowing buyers to make informed decisions. Search for specific item numbers or descriptions to find exactly what you need, ensuring compatibility with your machinery.

Maintenance Tips for Z225 Owners

Proper upkeep is essential for the longevity and performance of your equipment. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. By implementing a consistent care routine, you can ensure optimal operation and extend the lifespan of your machinery.

Regular Inspections

Conduct frequent checks on key components to identify any signs of wear or damage. Look for loose connections, leaks, and worn belts. Addressing these issues promptly can save you from major breakdowns later.

Lubrication and Cleaning

Keep moving parts well-lubricated to minimize friction and wear. Additionally, regularly clean the machine to remove debris and dirt, which can hinder performance. A clean and lubricated unit operates more smoothly and efficiently.

Diagnosing Issues with Parts Diagrams

Understanding the layout and components of machinery is essential for effective troubleshooting. Visual representations can significantly aid in identifying discrepancies and malfunctions. By carefully analyzing these illustrations, one can pinpoint issues that may arise during operation.

Common Problems to Look For

- Misalignment of components

- Worn or damaged parts

- Improper assembly

- Missing elements

Steps for Effective Diagnosis

- Review the visual representation to familiarize yourself with the overall structure.

- Cross-check each component against the actual machine.

- Identify any discrepancies between the illustration and the physical parts.

- Document any findings to facilitate repairs or replacements.

By employing these strategies, operators can enhance their ability to address issues promptly, ensuring smooth functioning of their equipment.