Understanding the mechanical layout of a modern lawn tractor is essential for maintaining its performance and ensuring a long lifespan. Whether you are performing regular maintenance or replacing specific elements, a clear and detailed look at the internal and external components can be invaluable for both novice and experienced users.

In this guide, we delve into the intricate system that powers this widely-used machine. From the engine to the smallest bolts, every aspect of the equipment plays a crucial role in its operation. By familiarizing yourself with the different sections, you will be better equipped to handle any repairs or replacements that may arise.

For those aiming to enhance their technical know-how, understanding how various mechanisms interact within this equipment is the first step. We will outline the key areas of interest, helping you navigate the system with confidence and ease.

Understanding the Key Components of a Popular Riding Mower

When examining the main elements of a modern riding lawn machine, it’s essential to focus on how each part contributes to overall functionality. Every mechanism, from the engine to the cutting deck, plays a vital role in ensuring smooth and efficient operation. By identifying and understanding these essential components, users can maintain and optimize the machine’s performance.

Engine: The heart of the machine, the engine powers every function, from blade rotation to movement across various terrains. A well-maintained engine ensures longevity and reliability.

Transmission: This part manages speed and torque, providing smooth transitions between gears. Proper care of the transmission is crucial for both handling and fuel efficiency.

Cutting Deck: Responsible for the core task of cutting grass, this area houses the blades. Ensuring the deck is level and the blades sharp guarantees an even cut.

Steering Mechanism: Offering precise control over direction, the steering system allows users to navigate tight spaces and varied landscapes with ease.

Tires:

Engine Layout of the John Deere S120

The engine configuration of this lawn tractor is designed to deliver reliable performance and ease of maintenance. Its structure ensures optimal power distribution and efficient operation, providing users with a well-balanced machine. This section covers the main components and their arrangement, focusing on how they work together to support the vehicle’s functionality.

The engine block serves as the core, housing vital components such as the pistons and crankshaft. Positioned centrally, it connects to various systems that regulate fuel intake and exhaust release, ensuring smooth combustion.

The cooling system surrounds the engine, preventing overheating through the use of a radiator and airflow channels. This layout maximizes heat dissipation, especially during long periods of use.

Another crucial aspect is the fuel system, which is placed strategically to enhance efficiency. This setup guarantees a steady fuel supply while minimizing the risk of clogs or interruptions during operation.

Lastly, the exhaust manifold channels emissions away from the engine, allowing it to maintain optimal pressure and performance. The exhaust path is designed to minimize

Transmission System Breakdown for Efficient Operation

The transmission mechanism is a crucial component that ensures the smooth transfer of power from the engine to the wheels, optimizing overall machine performance. Understanding its structure and how different elements work together can help operators achieve better control, efficiency, and longevity of the equipment. Below, we outline the key sections of the transmission system, providing insights into its functionality and maintenance tips.

| Component |

Function |

Maintenance Tip |

| Clutch |

Engages and disengages the engine from the drivetrain |

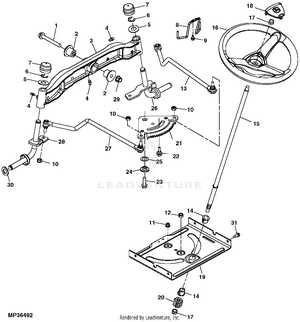

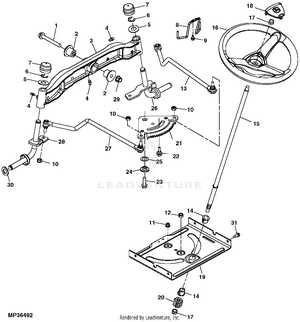

Front Axle and Steering System Overview

The front axle and steering mechanism play a crucial role in ensuring smooth maneuverability and stability during operation. These components are engineered to provide precise control and handle various terrains, making the machine efficient and easy to navigate. In this section, we will examine the key elements that make up this system, focusing on its structure, functionality, and maintenance tips.

- Axle Structure: The front axle is designed to support the weight of the vehicle and to absorb shocks from uneven ground. It provides the necessary strength and flexibility to handle heavy loads while maintaining balance.

- Steering Linkage: The steering system consists of multiple connecting components that ensure accurate directional control. These linkages are responsible for transmitting the driver’s input to the wheels, allowing for responsive turning and adjustment.

- Ball Joints and Tie Rods: Critical to the steering process, ball joints and tie rods connect the axle to the wheels, enabling smooth movement and steering precision. They ensure that the

Hydraulic System Structure for Agricultural Machinery

The hydraulic system plays a crucial role in the operation of modern agricultural machinery, offering precise control over various mechanical functions. It provides the necessary force to move, lift, or adjust parts of the equipment, ensuring smooth and efficient performance in the field. Understanding how this system is constructed helps operators maintain equipment longevity and optimize its use.

Main Components of the Hydraulic System

- Pump: The central element that drives fluid through the system, creating the pressure needed for all hydraulic operations.

- Valves: These components regulate the flow and pressure of the hydraulic fluid, ensuring the system operates efficiently.

- Cylinders: Actuators that convert hydraulic pressure into mechanical force, driving movements like lifting or rotating.

- Reservoir: A tank that stores the hydraulic fluid when not in circulation.

How the System Functions

Electrical System Parts and Connections

The electrical setup of a riding mower is essential for its smooth operation, ensuring all components work in harmony. From the ignition system to the battery and control switches, each element plays a crucial role in powering various functions. Proper understanding of these components and their interconnections is necessary for efficient maintenance and troubleshooting.

The power supply is primarily managed through a high-capacity battery that stores electrical energy. It supplies the ignition system, the lighting system, and other electrical modules. The alternator works in tandem with the battery to recharge it as the engine operates. Switches and relays regulate power flow to ensure all systems are activated and deactivated as needed.

Cables and connectors facilitate the transmission of electrical signals between different components. These connections must be properly secured and insulated to prevent electrical shorts or damage. Regular inspection of wiring harnesses is vital to ensure their integrity and functionality, ensuring seamless power delivery across all systems.

Fuel System Diagram and Key Components

The fuel system plays a crucial role in ensuring smooth operation and efficient performance of outdoor machinery. This system is responsible for delivering the necessary fuel to the engine, allowing it to operate at optimal efficiency. Understanding the key components of this system is essential for proper maintenance and troubleshooting.

The main elements involved in the fuel system include:

- Fuel Tank: Stores the fuel before it is delivered to the engine.

- Fuel Pump: Moves the fuel from the tank to the engine, creating pressure for proper flow.

- Fuel Filter: Removes impurities and debris from the fuel, ensuring clean delivery to the engine.

- Carburetor or Fuel Injectors: Mix the fuel with air to create the proper air-fuel mixture for combustion.

- Fuel Lines: Channels the fuel between the tank, pump, filter, and engine components.

- Fuel Shutoff Valve: Allows control over fuel flow, helping to prevent leaks or unintentional fuel flow.

Each of these components works together to ensure that fuel is properly supplied and mixed with air for combustion, helping to keep the engine running smoothly. Proper maintenance of these elements is crucial for avoiding performance issues and extending the lifespan of the machine.

Blade Assembly and Deck Mechanism Explained

The cutting mechanism of a lawn mower is crucial for achieving a clean and efficient lawn. Understanding how the blade system and deck are structured and interact ensures proper maintenance and operation. This section explores the key components that make up the cutting system, offering insights into their functionality and maintenance practices.

Blade Assembly

The blade assembly is responsible for generating the cutting force that trims the grass. It is typically comprised of several essential components that work together to deliver precise cutting performance. The main parts include:

- Cutting Blades: The sharp edges of the blade are designed to slice through grass with precision, and they are often made from high-strength steel to resist wear and corrosion.

- Blade Spindle: This component holds the blades in place and connects them to the mower’s drive mechanism, allowing them to rotate at high speeds.

- Blade Nuts and Bolts: These secure the blades to the spindle, ensuring they remain fixed during operation.

- Blade Pulleys: In some systems, pulleys are used to transfer power from the engine to the blade, enabling smooth and efficient cutting.

Deck Mechanism

The deck is the housing that surrounds and protects the cutting blades while directing the grass clippings. It is an essential part of the mower’s overall design and plays a role in the quality of the cut. The primary components of the deck include:

- Deck Shell: The outer casing that holds all of the cutting components together and helps funnel the grass clippings out of the chute.

- Anti-Scalping Wheels: These small wheels are attached to the deck and prevent the mower from digging into the ground, maintaining an even cutting height.

- Deck Lift System: The system that allows the deck height to be adjusted, which controls how high or low the blades sit in relation to the ground.

By maintaining the blade assembly and deck properly, users can extend the life of their equipment and ensure a consistently well-trimmed lawn.

Maintenance Points and Replacement Part Guide

Regular upkeep of machinery is crucial to ensure optimal performance and longevity. Proper maintenance and timely replacement of components will help prevent breakdowns and keep equipment running efficiently. This guide outlines key areas to monitor and offers advice on which components are most likely to need replacement over time.

- Engine oil and filter: Regularly check and change the oil and filter to ensure smooth engine operation. Contaminated or low oil levels can lead to overheating and damage.

- Air filter: Clean or replace the air filter as needed. A clogged filter can reduce engine efficiency and performance.

- Fuel filter: Replace the fuel filter periodically to prevent dirt and debris from clogging the fuel system, which can cause engine misfires or power loss.

- Blades: Inspect the cutting blades regularly for signs of wear or damage. Sharpen or replace them if they become dull or chipped to maintain cutting quality.

- Belts: Inspect belts for wear and tension. Replace any cracked, frayed, or loose belts to avoid failure during use.

- Battery: Check the battery’s condition and charge regularly. Replace it if it shows signs of wear or fails to hold a charge.

- Wheels and tires: Check for proper inflation and wear. Replace tires that are worn down or damaged to ensure smooth operation on all surfaces.

- Spindle and deck: Inspect the spindle and deck components regularly for alignment and secure connections. Grease the fittings to prevent rust and keep moving parts functioning properly.

Following a regular maintenance schedule and replacing worn components as needed will ensure that your machine remains reliable and efficient throughout its lifespan. Regularly consulting the user manual for specific maintenance intervals is recommended.