In the realm of small engine maintenance, comprehending the arrangement of various components is crucial for effective repairs and enhancements. Familiarity with the intricate layout can significantly streamline the troubleshooting process, ensuring that each element functions harmoniously. A detailed exploration of these layouts not only aids in identifying necessary replacements but also enhances overall operational efficiency.

Every engine has its unique architecture, characterized by a myriad of parts that work together to deliver optimal performance. By delving into a schematic representation, enthusiasts and professionals alike can gain valuable insights into the assembly, making it easier to diagnose issues and implement solutions. This knowledge empowers individuals to tackle repairs with confidence and precision.

Whether you are a seasoned technician or a novice hobbyist, understanding these configurations is essential for anyone looking to maintain or upgrade their machinery. Having access to clear visual guides can be a game changer, allowing for better planning and execution of maintenance tasks. Ultimately, a well-informed approach to engine care can lead to enhanced longevity and functionality.

Understanding the Briggs and Stratton 44P777

This section aims to provide insights into a specific engine model known for its reliability and performance. By exploring its features and components, users can gain a deeper understanding of its functionality and maintenance requirements.

Key Features

This engine variant is designed with a focus on durability and efficiency, making it suitable for various outdoor equipment. Its robust construction allows for prolonged usage, ensuring that tasks are completed without interruptions.

Maintenance Considerations

Key Components of the 44P777 Engine

The engine in question is a robust piece of machinery, featuring a variety of essential elements that work in harmony to ensure optimal performance. Understanding these key components can aid in maintenance, troubleshooting, and enhancement of its functionality.

- Cylinder Head: This critical part houses the valves and spark plugs, playing a vital role in the combustion process.

- Piston: The piston moves up and down within the cylinder, converting combustion energy into mechanical power.

- Crankshaft: The crankshaft transforms the linear motion of the piston into rotational motion, driving the engine’s output.

- Oil Pump: This component circulates oil throughout the engine to lubricate moving parts, reducing friction and wear.

- Fuel System: Comprising the fuel tank, lines, and carburetor, this system ensures a steady supply of fuel for combustion.

- Ignition System: Responsible for starting the engine, it generates a spark that ignites the fuel-air mixture in the combustion chamber.

- Cooling System: This system prevents overheating by dissipating excess heat generated during operation.

By familiarizing oneself with these components, operators can enhance the efficiency and lifespan of the engine, ensuring reliable performance in various applications.

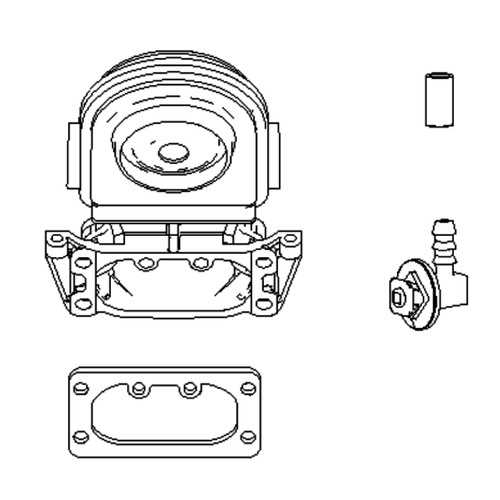

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. These visual representations serve as essential tools, guiding users through the intricate details of assembly and disassembly. They enhance clarity, allowing individuals to identify each element with precision.

Accurate identification of components minimizes the risk of errors during repairs. Users can easily pinpoint specific items, ensuring that replacements are made swiftly and correctly. This ultimately leads to improved efficiency and longevity of equipment.

Furthermore, these illustrations are invaluable in troubleshooting. They provide insights into potential issues, enabling users to delve deeper into problem-solving. By referencing these guides, one can quickly assess which parts may need attention, streamlining the maintenance process.

In summary, visual guides are not merely helpful; they are fundamental for anyone looking to maintain or repair machinery effectively. Their role in enhancing understanding and facilitating successful interventions cannot be overstated.

How to Read the Parts Diagram

Understanding an illustration that details various components is essential for effective maintenance and repair. This visual representation offers a clear view of individual elements and their relationships, enabling users to identify what they need for their specific tasks.

Familiarizing with Symbols

Different symbols and numbers are often used to represent specific elements. It’s important to familiarize yourself with these representations, as they will guide you in locating each component swiftly. Look for keys or legends that explain what each symbol signifies.

Identifying Components

Once you understand the symbols, start by identifying the main sections within the visual guide. Pay attention to the labeled parts, as they will provide you with crucial information for replacements or repairs. This structured approach will ultimately enhance your efficiency in any repair process.

Common Replacement Parts for 44P777

When maintaining small engines, understanding essential components is crucial for optimal performance. Certain items often require replacement due to wear and tear, ensuring longevity and efficiency.

Key Components to Consider

- Air Filter: Vital for clean airflow.

- Fuel Filter: Ensures proper fuel delivery.

- Spark Plug: Essential for ignition efficiency.

- Oil Filter: Maintains engine lubrication.

- Belt: Transfers power effectively.

Benefits of Regular Replacement

- Improved Engine Performance

- Enhanced Fuel Efficiency

- Reduced Emissions

- Extended Lifespan of Equipment

Maintenance Tips for Longevity

Ensuring the durability of your outdoor power equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery, enhancing performance and reliability over time.

Regular Inspections

Conduct frequent checks on your equipment to identify any signs of wear or damage. Look for loose bolts, frayed wires, or leaks. Addressing these issues promptly can prevent more significant problems down the line.

Routine Cleaning

Keeping the machinery clean is vital for optimal function. Remove dirt, grass, and debris from the exterior and any air intake areas. A clean engine runs cooler and more efficiently, reducing the risk of overheating.

Lubrication is equally important; ensure that moving parts are well-greased to minimize friction and wear. Following the manufacturer’s recommendations for oil changes and filter replacements will help maintain peak performance.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential to ensure optimal performance and longevity. Sourcing these items from reliable suppliers guarantees that you receive the quality necessary for effective operation. Here are some reliable options to consider when looking for original replacements.

Authorized Dealers

- Visit local dealerships that specialize in outdoor power equipment.

- Check their websites for inventory availability and pricing.

- Consult with staff for advice on compatibility and installation.

Online Retailers

- Search major e-commerce platforms that offer a wide selection of authentic components.

- Look for dedicated websites focusing on outdoor machinery parts.

- Verify seller ratings and reviews to ensure credibility.

By choosing reputable sources, you can confidently obtain the right components to keep your machinery running smoothly.

Troubleshooting Common Issues

When dealing with small engine malfunctions, identifying the root cause can be challenging yet crucial for effective resolution. Below are some typical problems you may encounter and how to address them.

- Engine Won’t Start:

- Check the fuel level; ensure it’s fresh and free from contaminants.

- Inspect the spark plug for wear and proper connection.

- Examine the air filter; clean or replace if necessary.

- Excessive Smoke:

- Look for oil leaks or overfilled crankcase.

- Inspect the breather for blockages.

- Ensure proper fuel-to-oil ratio is maintained.

- Uneven Running:

- Check for debris in the carburetor; clean as needed.

- Adjust the throttle settings for better control.

- Inspect the ignition system for faults.

By following these steps, you can delve deeper into diagnosing and fixing common engine issues efficiently.

Expert Advice on Engine Repairs

Understanding the intricacies of engine maintenance is crucial for ensuring optimal performance and longevity. Whether dealing with minor adjustments or significant overhauls, having a solid foundation of knowledge can make all the difference. This section provides key insights and tips to help you navigate engine repair challenges effectively.

Common Issues and Solutions

Engines can present various problems, from starting difficulties to unusual noises. Identifying the root cause early can save time and resources. Common issues include fuel blockages, electrical malfunctions, and worn components. Conducting a thorough inspection and using a methodical approach to troubleshooting can lead to effective solutions.

Preventative Measures

Taking proactive steps can significantly reduce the likelihood of major failures. Regular maintenance, such as changing fluids, checking filters, and inspecting belts, is essential. Staying ahead of potential issues not only enhances reliability but also prolongs the lifespan of the engine.