The inner workings of small engines can often seem complex, yet they are built from a variety of essential elements that work in harmony to deliver power and efficiency. Gaining familiarity with these components not only aids in maintenance but also enhances overall performance. In this exploration, we will delve into the crucial parts that make up an 18 HP power unit, providing insights into their functions and interrelations.

Whether you’re a seasoned mechanic or a novice user, having access to detailed information about engine elements is invaluable. From the ignition system to fuel delivery, understanding these segments empowers you to troubleshoot issues effectively. This knowledge can also assist in making informed decisions when it comes to repairs or upgrades.

With a comprehensive view of the engine’s structure, you can appreciate how each piece contributes to the machine’s operation. By identifying these components and their roles, you set the stage for more effective maintenance practices, ensuring longevity and reliability in your equipment.

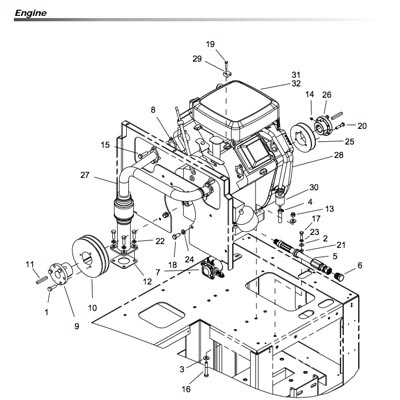

Understanding the 18 HP Engine

The 18 horsepower engine represents a robust and reliable power source, widely utilized in various outdoor equipment and machinery. Its design emphasizes durability and efficiency, making it a favored choice for both residential and commercial applications. This section explores the essential components and functionality of this engine type, shedding light on its operational principles and maintenance requirements.

| Component | Function |

|---|---|

| Cylinder | Houses the piston, facilitating combustion. |

| Piston | Converts fuel energy into mechanical motion. |

| Crankshaft | Transforms linear motion of the piston into rotational force. |

| Fuel System | Delivers fuel to the combustion chamber. |

| Ignition System | Initiates combustion by generating a spark. |

| Cooling System | Regulates temperature to prevent overheating. |

Understanding these key elements is crucial for effective maintenance and operation. Regular checks and servicing of each component can significantly enhance the engine’s lifespan and performance, ensuring reliable operation for years to come.

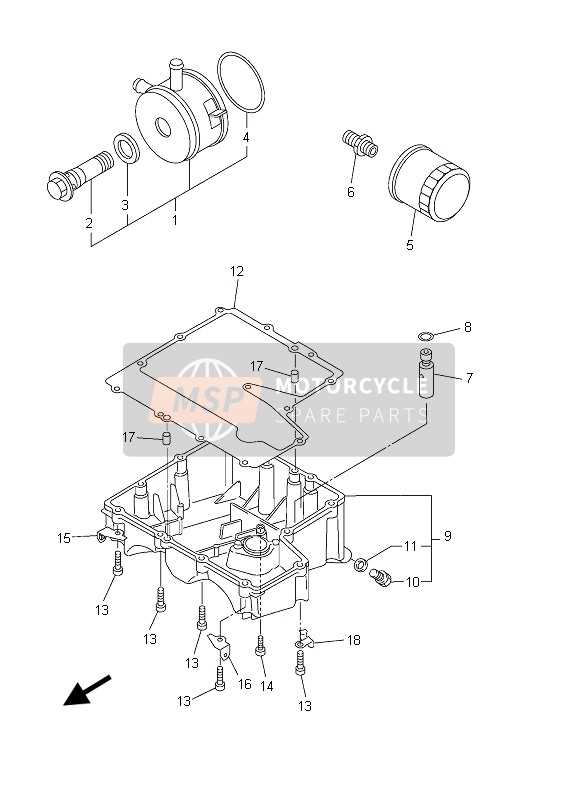

Key Components of Briggs and Stratton

Understanding the essential elements of small engines is crucial for effective maintenance and repair. These components work together to ensure optimal performance and longevity. Each part plays a specific role, contributing to the overall functionality of the engine.

Fuel System is vital for delivering the necessary energy to the engine. It typically consists of a fuel tank, lines, and a carburetor, which work in harmony to mix air and fuel for combustion.

Ignition System is responsible for starting the engine. This system usually includes a spark plug, ignition coil, and a flywheel. A reliable ignition is essential for ensuring smooth operation and quick starts.

Cooling Mechanism prevents overheating during operation. This often involves fins on the cylinder head and a cooling fan, which circulate air around the engine to maintain a safe temperature.

Lubrication System reduces friction between moving parts, enhancing efficiency and durability. It typically features an oil sump and an oil pump to ensure that all necessary components are adequately lubricated.

Crankshaft and Piston are critical for converting fuel energy into mechanical power. The crankshaft transfers rotational energy, while the piston moves up and down within the cylinder, enabling the combustion process.

These elements collectively ensure that the engine runs smoothly and efficiently. Familiarity with these core components allows for better troubleshooting and maintenance practices.

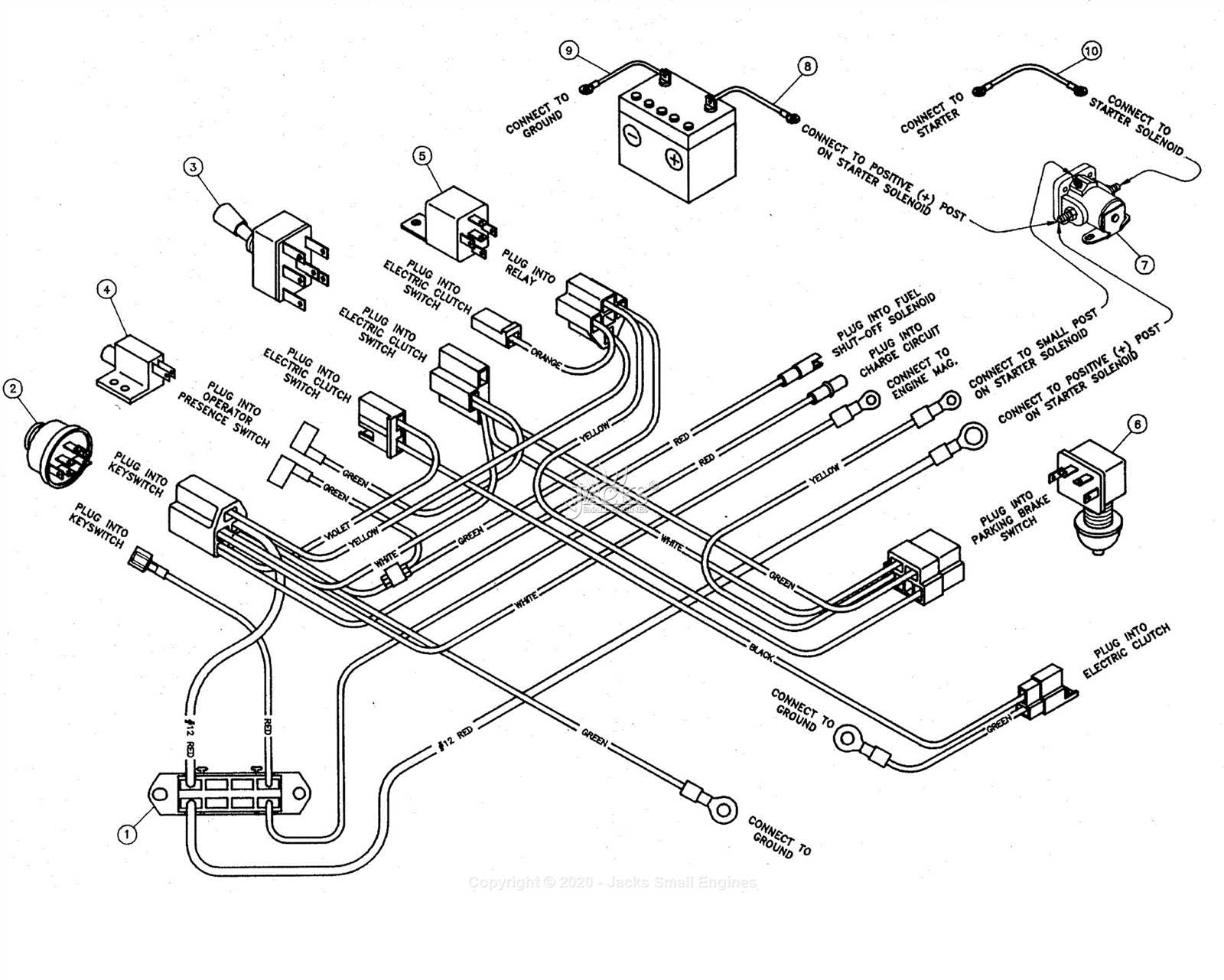

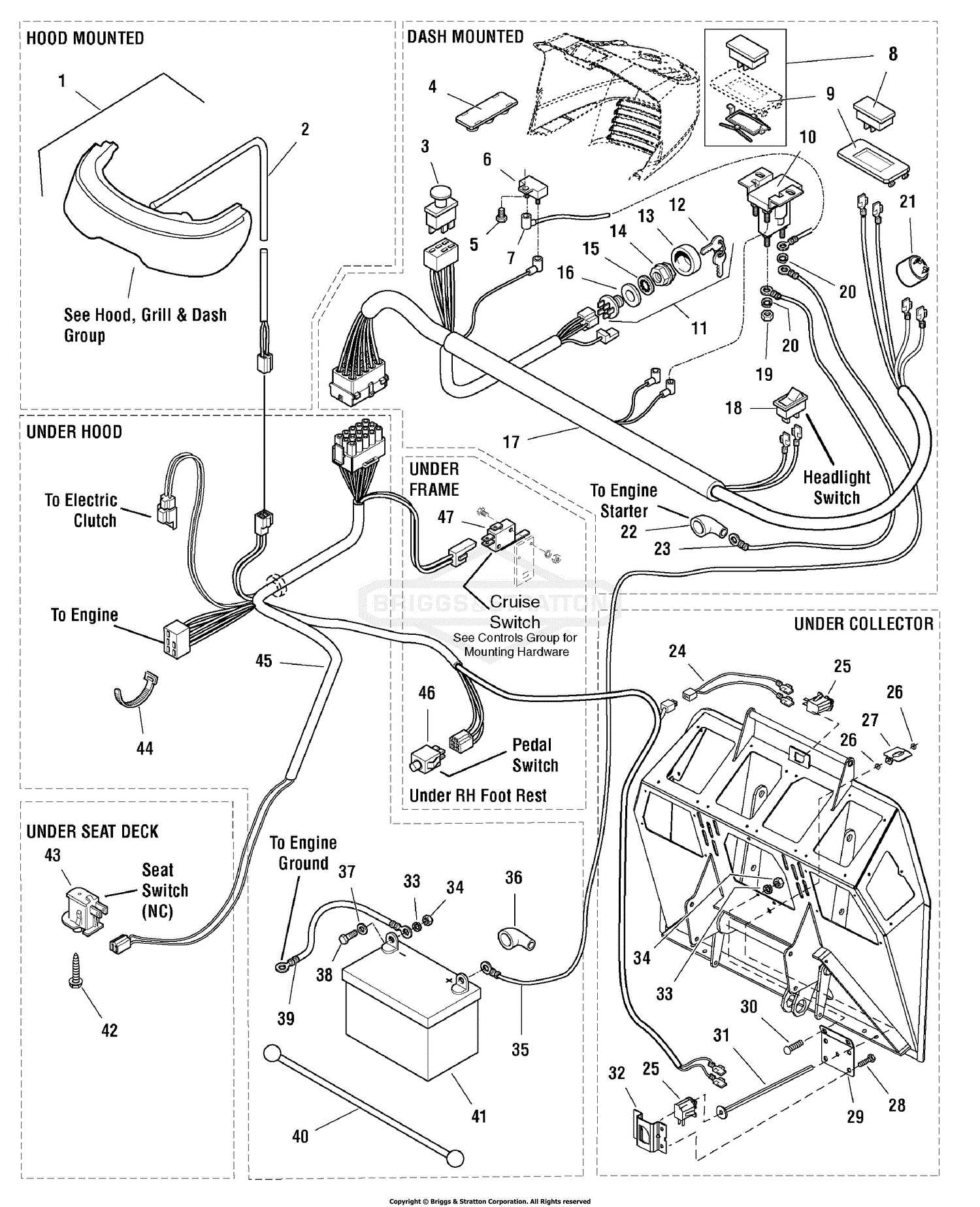

Importance of Parts Diagrams

Understanding the layout of mechanical components is crucial for effective maintenance and repair. Visual representations of individual elements provide clarity on how each piece interacts within a system. Such illustrations serve as valuable resources for technicians and DIY enthusiasts alike, facilitating efficient troubleshooting and assembly.

Clear Guidance: Detailed illustrations offer precise information about component placement, aiding users in identifying the necessary items for repairs. This clarity minimizes the chances of errors during reassembly, ensuring that machinery operates smoothly.

Enhanced Efficiency: By utilizing visual aids, individuals can quickly locate parts and understand their functions. This expedites the repair process, saving both time and effort while reducing the likelihood of miscommunication in collaborative environments.

Learning Tool: For newcomers, these visuals serve as educational resources. They help in grasping the overall structure and functionality of machinery, fostering a deeper understanding of how different elements work together.

In summary, having access to comprehensive visual guides is essential for anyone involved in mechanical maintenance, promoting accuracy and proficiency in handling equipment.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective maintenance and repair tasks. These visuals provide a detailed view of components, helping users identify each piece’s location and function. By mastering this skill, you can simplify the troubleshooting process and enhance your mechanical knowledge.

Identifying Components

Begin by examining the illustration closely. Each element is usually labeled with a specific number or letter, correlating with a list that details their names and functions. This connection is crucial for correctly ordering replacements or making adjustments.

Understanding Connections

Pay attention to how various pieces interact. Lines and arrows may indicate relationships, showing how components fit together or move in relation to one another. Recognizing these links allows for a more comprehensive grasp of the overall assembly.

Common Issues with 18 HP Engines

Small engines of this power rating can encounter several frequent problems that may affect their performance and longevity. Understanding these common issues can help users maintain their machinery effectively and troubleshoot any concerns that arise during operation.

Frequent Problems

Engine owners often face specific challenges that stem from wear and tear, improper maintenance, or external factors. Recognizing these can lead to timely repairs and a smoother operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel System Blockage | Engine stalling, poor acceleration | Clean or replace fuel filter, check fuel lines |

| Ignition Problems | Difficulty starting, misfiring | Inspect spark plug, replace ignition coil if necessary |

| Oil Leaks | Visible oil spots, low oil level | Check gaskets and seals, replace damaged parts |

| Overheating | Unusual noises, engine shutdown | Ensure proper cooling, clean air filter, check coolant levels |

Maintenance Tips

Regular maintenance is key to preventing these issues. Schedule consistent checks on fuel quality, oil levels, and spark plugs to ensure optimal performance and extend the life of the engine.

Finding Replacement Parts Online

Locating suitable components for small engines can often feel overwhelming, especially with the vast array of options available on the internet. However, utilizing a few strategic approaches can simplify the process significantly, ensuring you find the right items quickly and efficiently. This section will guide you through effective methods for sourcing necessary replacements online.

Utilizing Manufacturer Websites

One of the most reliable ways to find quality replacements is by visiting the official websites of manufacturers. These platforms typically offer extensive catalogs that allow you to search for specific models. By entering the engine’s model number, users can access precise specifications and compatible components, ensuring accuracy in their selection.

Online Retailers and Marketplaces

In addition to manufacturer sites, various online retailers and marketplaces provide a wide range of options. Sites like Amazon, eBay, or specialty engine supply stores often have competitive pricing and customer reviews that can guide your purchase decisions. When exploring these platforms, be sure to check seller ratings and product descriptions thoroughly to avoid any mismatches.

| Source | Advantages |

|---|---|

| Manufacturer Websites | Accurate specifications, direct from the source |

| Online Retailers | Wide variety, customer reviews, competitive pricing |

| Forums and Community Groups | Expert advice, user experiences, recommendations |

By combining these resources, you can enhance your search for quality engine components, making the replacement process smoother and more efficient.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your engine. Regular attention to key components can prevent premature wear and tear, ultimately extending the lifespan of your machine. By following a few simple practices, you can enhance performance and reduce the risk of costly repairs.

1. Regular Oil Changes: Changing the oil at recommended intervals is crucial. Fresh oil lubricates moving parts, reducing friction and heat. Always use the appropriate grade for optimal performance.

2. Clean or Replace Air Filters: A clean air filter allows for better airflow, improving combustion efficiency. Inspect and clean or replace filters as needed to maintain optimal engine function.

3. Spark Plug Maintenance: Regularly check the spark plugs for wear and deposits. Replacing worn plugs can enhance starting, fuel efficiency, and overall engine performance.

4. Fuel Quality: Use high-quality fuel and consider adding a fuel stabilizer if your machine will sit unused for extended periods. This helps prevent varnish buildup and keeps the fuel system clean.

5. Inspect Belts and Hoses: Regularly check for signs of wear or cracks in belts and hoses. Replacing damaged components early can prevent more serious issues down the line.

6. Clean the Exterior: Keeping the exterior clean not only enhances aesthetics but also allows for better airflow and cooling. Remove debris from cooling fins and other vital areas regularly.

7. Store Properly: When not in use, store your equipment in a dry place, preferably indoors. This protects it from the elements and extends its overall lifespan.

By incorporating these maintenance practices into your routine, you can ensure that your engine remains reliable and efficient for years to come.

Comparing Similar Engine Models

When evaluating various engine types, understanding the distinctions and similarities among them can be crucial for making informed decisions. Each model often serves specific applications, making it essential to recognize their features and performance metrics.

Here are some key aspects to consider when comparing similar engine models:

- Power Output: Assess the horsepower and torque ratings to determine the suitability for different tasks.

- Fuel Efficiency: Look for models that offer better mileage, as this can significantly impact long-term operational costs.

- Maintenance Requirements: Evaluate how often each model requires servicing and the complexity of upkeep.

- Weight: Consider the weight of the engine, which can influence installation and maneuverability.

- Durability: Investigate the materials used in construction and the expected lifespan under typical operating conditions.

By focusing on these factors, users can select the most appropriate engine for their specific needs, ensuring efficiency and reliability in their applications.

Resources for Engine Repair Guides

Finding reliable resources for engine repair can significantly ease the process of maintenance and restoration. Whether you’re a seasoned mechanic or a DIY enthusiast, having access to comprehensive manuals, instructional videos, and community forums can enhance your understanding and efficiency when working on engines.

Here are some valuable resources to consider:

- Online Manuals: Many manufacturers provide downloadable manuals that offer detailed schematics and troubleshooting tips.

- YouTube Channels: Numerous content creators specialize in engine repairs, showcasing step-by-step procedures that are easy to follow.

- Repair Forums: Engaging with communities where experienced users share insights and solutions can be immensely helpful.

- Books: Comprehensive guides available in bookstores or libraries can provide in-depth knowledge on engine mechanics.

- Manufacturer Websites: Official sites often have sections dedicated to support, offering diagrams and FAQs that clarify common issues.

Utilizing these resources can empower you to tackle engine repairs with confidence and precision, ensuring your machinery runs smoothly for years to come.