In the world of small machinery, comprehending the layout of engine elements is crucial for effective maintenance and repair. A thorough grasp of how each component interacts enhances not only functionality but also longevity. This section explores the intricacies of various engine parts, ensuring users can efficiently navigate their specific needs.

Visual representations serve as invaluable tools for mechanics and hobbyists alike, providing a clear guide to assembly and disassembly processes. By delving into the specifics of each piece, individuals can identify potential issues and execute repairs with confidence.

Ultimately, a comprehensive understanding of the inner workings leads to improved performance and reliability. This knowledge empowers users to tackle challenges head-on, transforming what could be daunting tasks into manageable projects.

Understanding Briggs and Stratton 550EX

This section explores a specific engine model known for its reliability and performance in various outdoor equipment. It delves into its components, functionality, and maintenance tips to ensure optimal usage.

Key Features

The engine is designed to deliver efficient power for lawn mowers, pressure washers, and other gardening tools. Its robust construction ensures durability, while the straightforward design allows for easy repairs and servicing.

Maintenance Tips

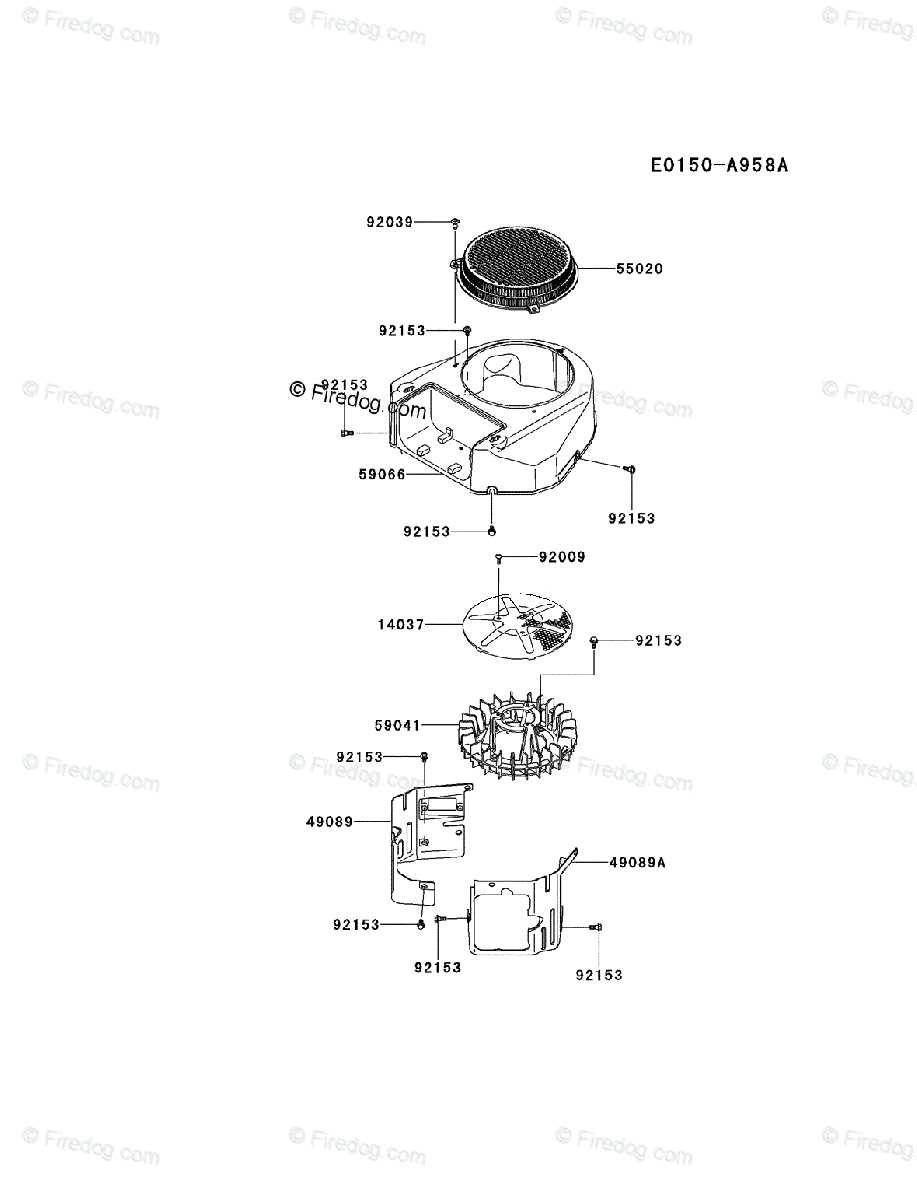

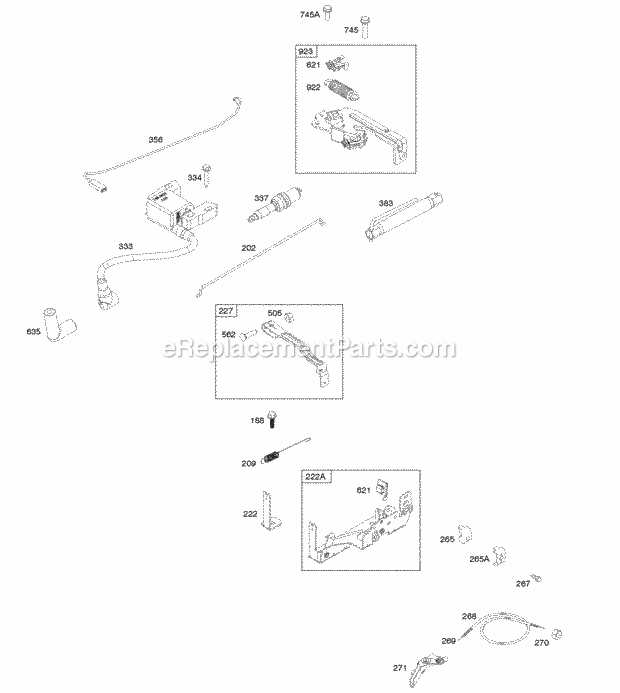

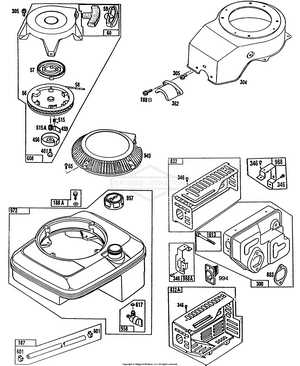

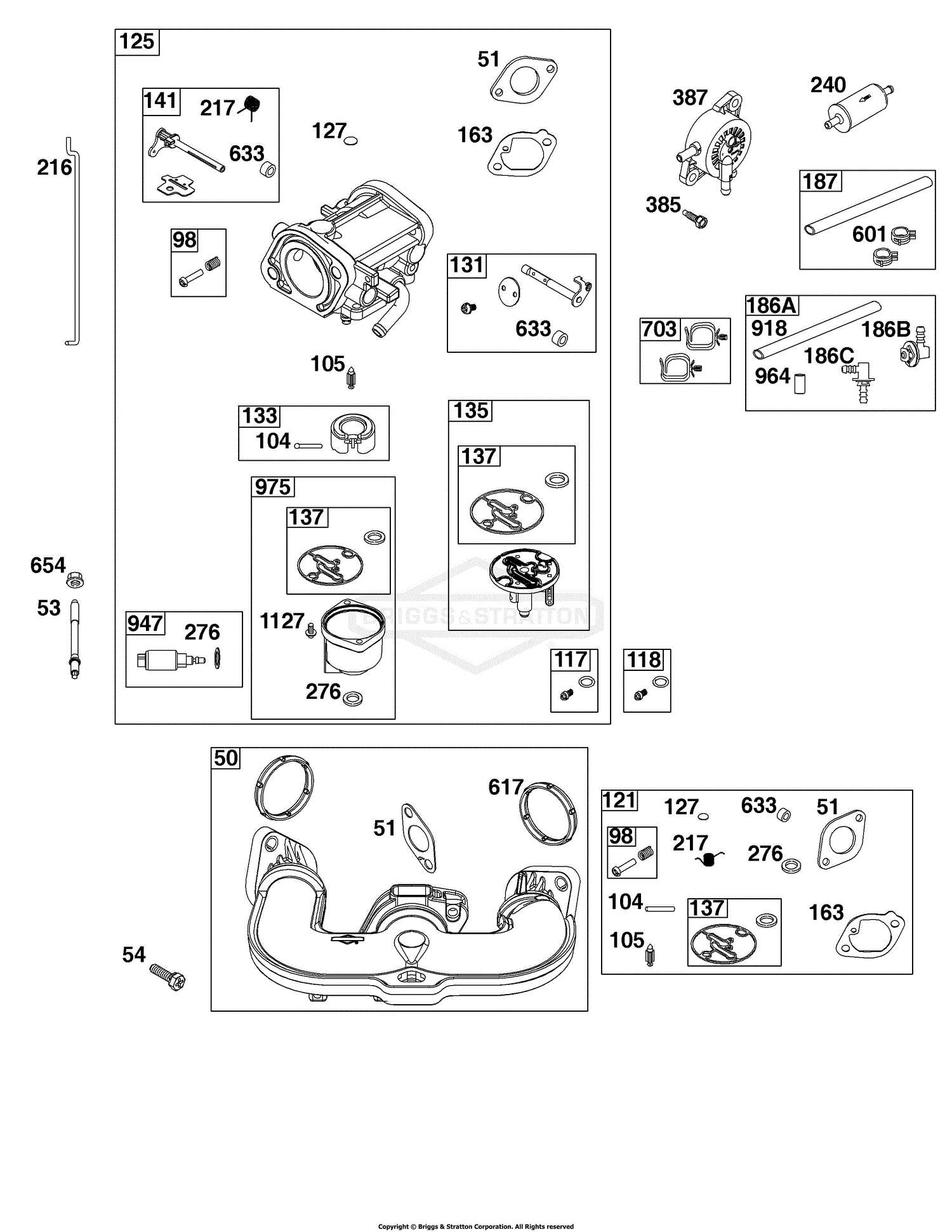

Key Components of 550EX Engines

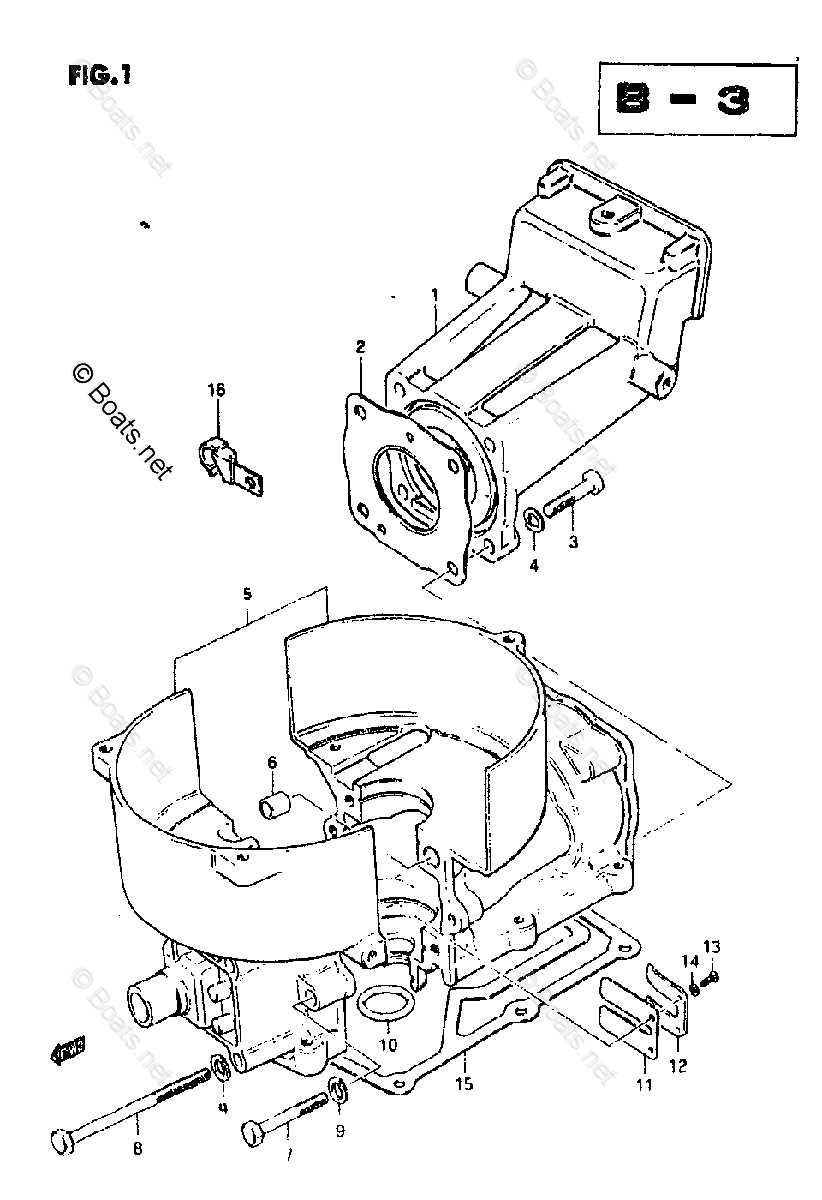

This section explores the essential elements that contribute to the efficient functioning of small engines. Understanding these components is crucial for maintenance and optimal performance, allowing users to delve deeper into their machinery.

Engine Block: The core structure that houses various internal parts, providing stability and support.

Piston: A critical element that converts fuel energy into mechanical movement, driving the crankshaft.

Crankshaft: This component transforms the linear motion of the piston into rotational energy, essential for powering the machine.

Valves: These regulate the intake of air and fuel and the exhaust of gases, ensuring efficient combustion.

Carburetor: A vital part that mixes air and fuel in the correct ratio for optimal combustion, impacting engine efficiency.

Ignition System: This system ignites the air-fuel mixture, ensuring timely combustion for smooth operation.

Cooling System: Designed to dissipate heat generated during operation, preventing overheating and damage to components.

By understanding these key elements, users can enhance their experience and ensure the longevity of their engines.

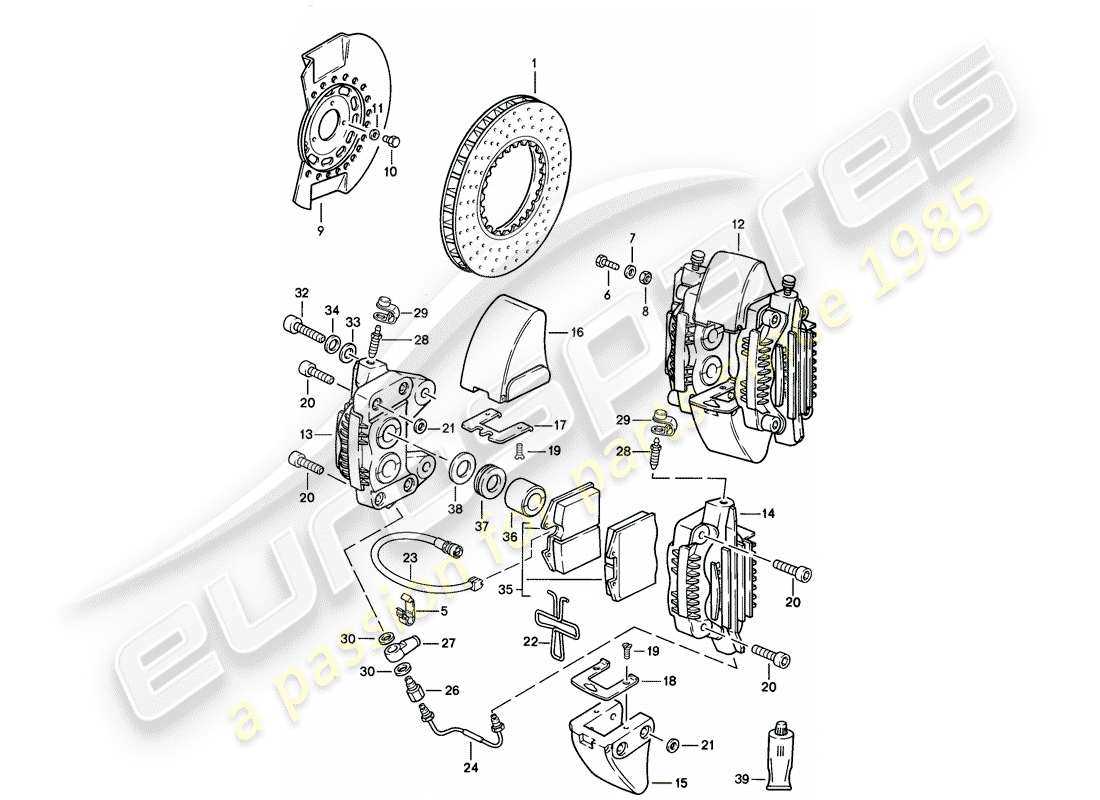

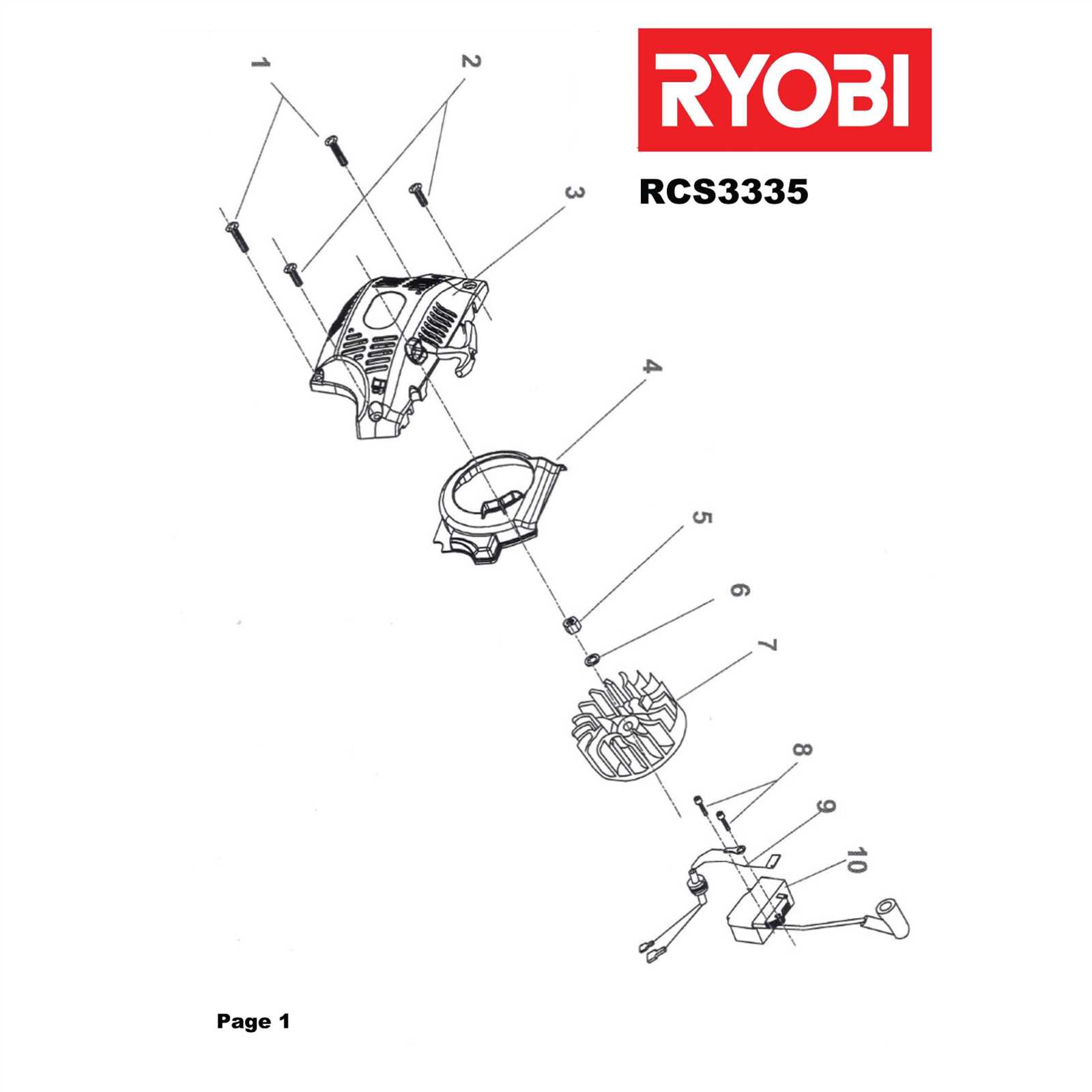

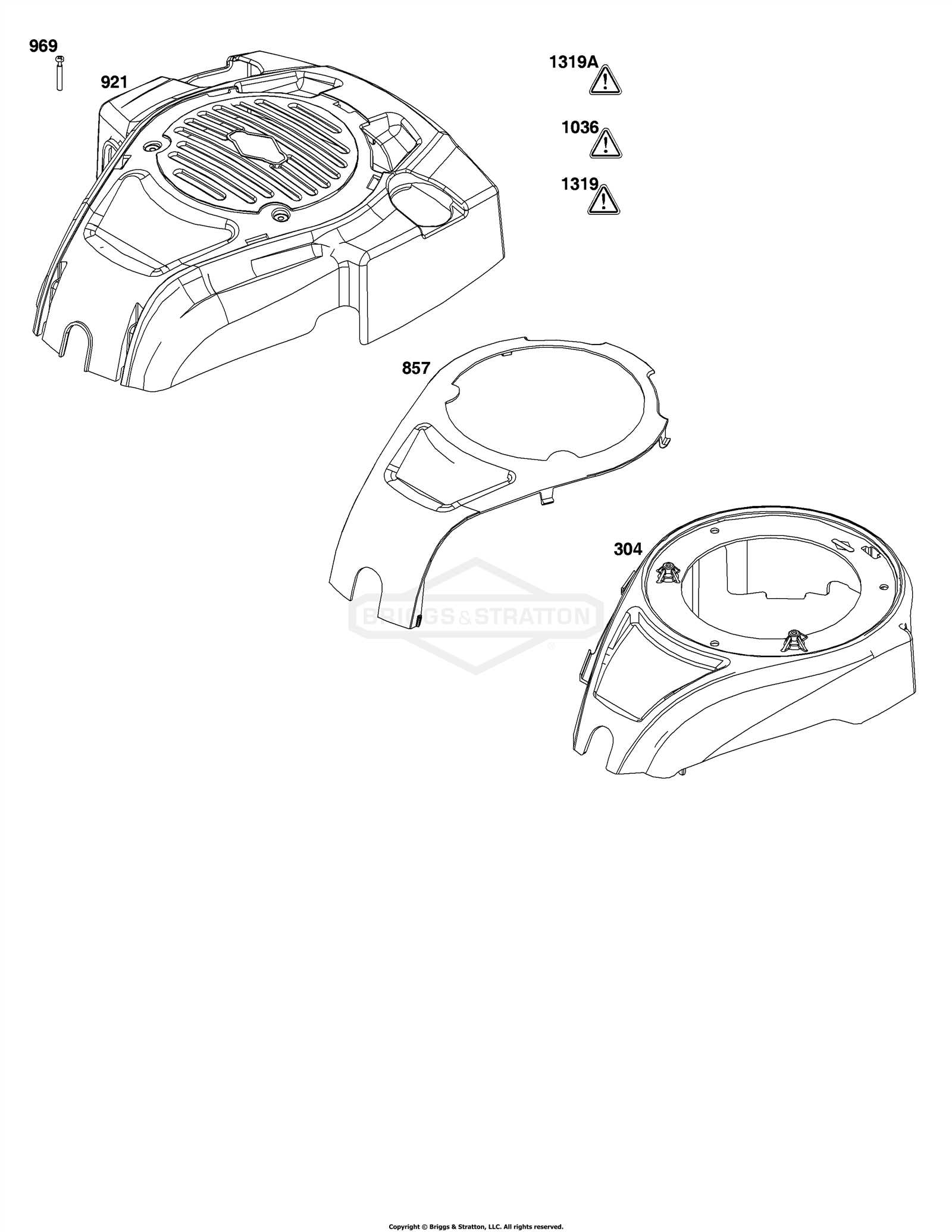

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear layout of each element’s position and connection, enabling users to identify what is needed for assembly or replacement. Familiarity with these visuals can simplify troubleshooting and enhance the overall repair process.

Identify Symbols and Labels

Every illustration uses specific symbols and annotations to indicate various elements. It is crucial to familiarize yourself with these icons, as they often represent different types of components, such as screws, bolts, or larger assemblies. Pay attention to any accompanying labels, which can offer further insight into the function and specifications of each part.

Follow the Flow of Assembly

These visuals typically display the sequence of assembly, helping to understand how each component fits into the whole. Observing the layout can assist in determining the order of disassembly and reassembly. This knowledge can prevent mistakes and ensure that everything is properly aligned during the process.

Common Issues and Solutions

This section explores frequent problems encountered with small engine equipment and offers effective remedies. By understanding these challenges, users can enhance performance and longevity.

Starting Difficulties: If the engine fails to start, check for fuel flow and ensure the spark plug is in good condition. Replacing a worn plug can often resolve this issue.

Overheating: An engine may overheat due to debris blocking airflow. Regularly clean air filters and cooling fins to prevent this problem.

Loss of Power: A noticeable decline in power may stem from clogged fuel lines or filters. Inspecting and cleaning these components can restore efficiency.

Excessive Vibration: If vibrations increase, it could indicate loose bolts or worn mounts. Tightening connections and replacing worn parts can mitigate this issue.

Fuel Leaks: Leaking fuel can be hazardous. Inspect gaskets and seals for damage, replacing them as necessary to ensure safety and functionality.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. Implementing a consistent maintenance routine can significantly extend the lifespan of your machine while optimizing its performance. Here are some practical tips to help you maintain your engine effectively.

- Keep it clean: Regularly remove dirt, debris, and grass clippings from the exterior to prevent overheating and corrosion.

- Change the oil: Regular oil changes improve engine performance. Follow the manufacturer’s recommendations for frequency and type.

- Check air filters: Clean or replace air filters periodically to ensure proper airflow and efficient combustion.

- Inspect spark plugs: Regularly examine spark plugs for wear and replace them as needed to maintain ignition efficiency.

- Sharpen blades: Keep blades sharp for cleaner cuts and reduced strain on the engine, improving overall performance.

Additionally, adhering to a seasonal maintenance schedule can help identify potential issues before they escalate. By investing time in these practices, you can ensure that your equipment remains reliable and performs at its best for years to come.

Where to Find Replacement Parts

Finding the right components for your equipment can seem daunting, but several reliable sources make the process easier. It’s essential to explore various avenues to ensure you get high-quality replacements that fit your specific needs.

Online Retailers

Numerous online stores specialize in outdoor equipment components. Websites like Amazon and eBay often carry a wide range of items. Additionally, manufacturers’ official websites frequently provide a selection of genuine components that guarantee compatibility and performance.

Local Repair Shops

Visiting a nearby repair shop can yield significant benefits. Local experts can offer personalized assistance, helping you identify what you need. Furthermore, they may have an inventory of essential components readily available for purchase, saving you time.

Comparing 550EX to Other Models

When evaluating the performance and features of various small engines, it’s essential to understand how one specific model stands against its peers. This comparison highlights key differences in specifications, usability, and overall efficiency, providing a clearer picture for users seeking the best option for their needs.

Performance Overview

Performance metrics often vary significantly among different engine types. Factors such as power output, fuel efficiency, and ease of maintenance can influence the choice for users. Below is a comparative table outlining these attributes:

| Engine Model | Power Output (HP) | Fuel Efficiency (MPG) | Weight (lbs) |

|---|---|---|---|

| Model A | 5.5 | 30 | 55 |

| Model B | 6.0 | 28 | 60 |

| Model C | 5.0 | 32 | 50 |

| Model D | 5.5 | 29 | 57 |

Usability and Features

In addition to performance, usability plays a crucial role in selecting the right engine. Features such as starting mechanisms, noise levels, and overall design can greatly affect user experience. The following highlights key attributes that distinguish these models:

- Starting Mechanism: Electric vs. Manual

- Noise Level: Decibels during operation

- Ergonomic Design: User-friendly interfaces

DIY Repair Techniques for Homeowners

Home maintenance can be daunting, yet with the right approaches, it becomes manageable and even rewarding. By equipping yourself with basic skills and knowledge, you can tackle common issues around your property, saving time and money while enhancing your home’s functionality.

Essential Tools for DIY Repairs

- Screwdrivers: Various sizes for different screws.

- Wrenches: Useful for tightening and loosening bolts.

- Measuring Tape: For accurate dimensions.

- Utility Knife: Great for cutting various materials.

- Safety Gear: Goggles and gloves for protection.

Common Repair Techniques

- Patching Walls: Use spackle to fill holes and sand for a smooth finish.

- Changing Filters: Regularly replace air and water filters to maintain efficiency.

- Fixing Leaks: Tighten fittings and apply plumber’s tape where necessary.

- Cleaning Gutters: Remove debris to prevent water damage.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, adhering to safety measures is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of the work environment. Implementing the right protocols ensures that both the technician and the equipment remain secure throughout the repair process.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial during any repair task. Ensure you wear gloves to protect your hands from sharp edges and chemicals. Safety goggles are also vital to shield your eyes from debris or harmful substances. Additionally, consider using ear protection if working with loud machinery.

Work Area Organization

Keeping your workspace clean and organized is a key factor in maintaining safety. Remove any unnecessary tools or materials that could create trip hazards. Ensure that all equipment is properly stored and that there is sufficient lighting to clearly see what you are working on. By creating a clutter-free environment, you minimize the risk of accidents and facilitate a more efficient repair process.