In the realm of machinery maintenance, having a comprehensive grasp of the various elements that constitute a piece of equipment is essential. This knowledge empowers users to make informed decisions regarding repairs and upgrades. Whether you’re a seasoned mechanic or a passionate hobbyist, being able to visualize how each component fits together can significantly enhance your understanding and efficiency.

Delving into the intricate design of these machines reveals not only the functionality of individual elements but also their interdependence. Recognizing how these parts interact can streamline the troubleshooting process and facilitate effective maintenance strategies. A well-organized visual representation serves as a valuable tool for anyone looking to deepen their insight into equipment upkeep.

Furthermore, having access to detailed illustrations fosters confidence in addressing potential issues. It equips users with the knowledge necessary to identify wear and tear, ensuring timely interventions and prolonging the lifespan of the machinery. By exploring the layout and relationships between components, one can cultivate a proactive approach to equipment care.

Overview of John Deere 317

This section provides a comprehensive look at a particular model known for its reliability and performance in various agricultural and landscaping tasks. It highlights the essential components and functionalities that make it a preferred choice among users.

Key Features

This model is designed with several noteworthy attributes that enhance its usability. Users can expect a robust engine, efficient transmission, and a user-friendly interface, making operations smoother and more effective.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Gasoline |

| Horsepower | 20 HP |

| Transmission | Hydrostatic |

| Weight | 600 lbs |

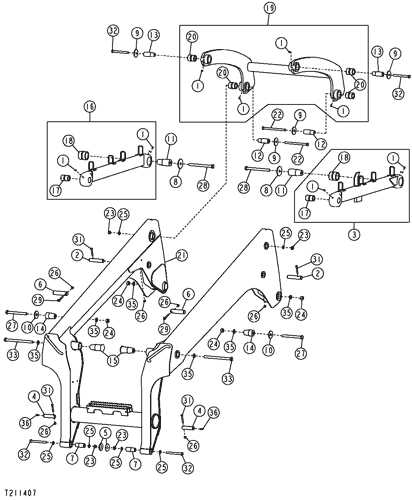

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying and organizing these elements, enabling users to grasp complex systems with ease.

Benefits of Visual Representation

- Clarity: Detailed illustrations provide a clear view of how various components fit together, helping users to comprehend the assembly and disassembly processes.

- Efficiency: Quick reference to schematics reduces downtime during repairs, allowing technicians to locate and replace faulty elements swiftly.

- Accuracy: Visual aids minimize the risk of errors in identification and installation, ensuring that the correct components are used.

Enhancing Knowledge and Skills

- Studying these representations fosters a deeper understanding of machinery operation.

- It aids in troubleshooting by clearly outlining the relationship between different components.

- Technicians can develop better diagnostic skills, leading to improved overall performance of equipment.

In summary, utilizing these visual guides not only streamlines maintenance tasks but also empowers users with the knowledge needed to optimize the longevity and functionality of their machinery.

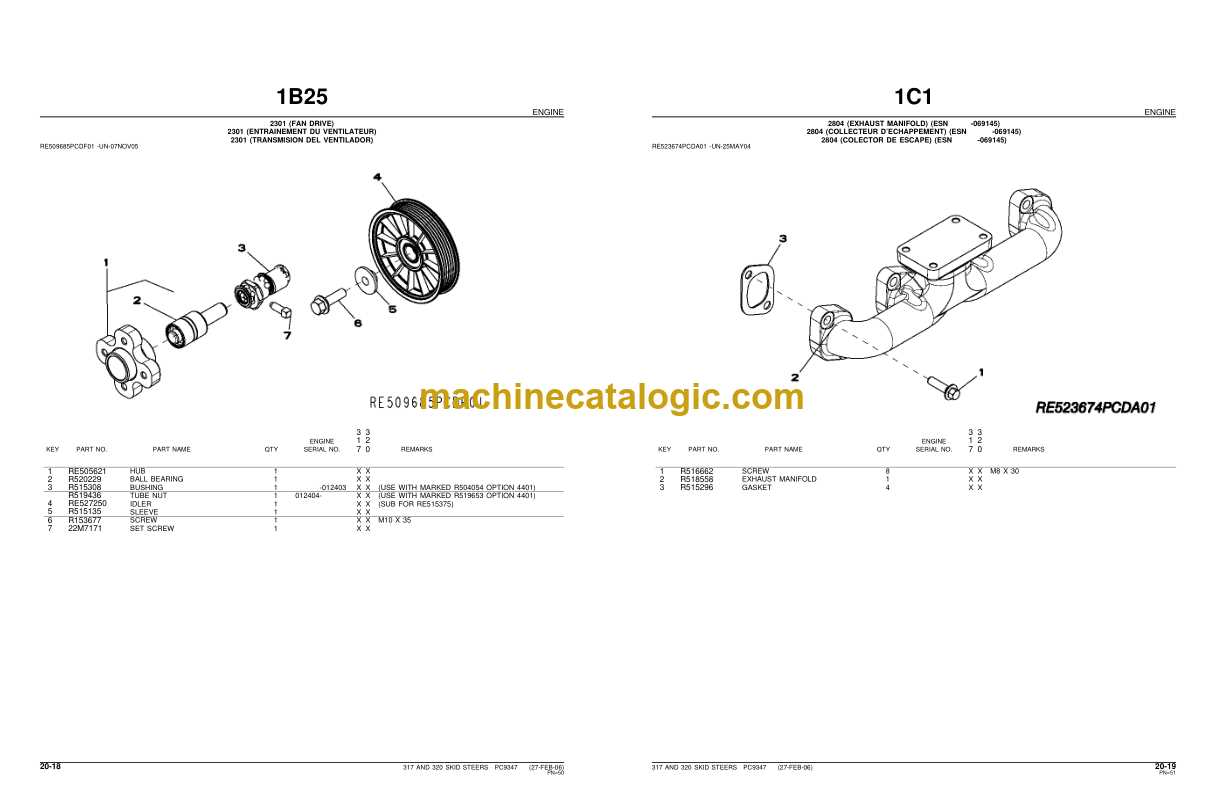

Key Components of the 317 Model

The model features several vital elements that contribute to its functionality and efficiency. Understanding these components is essential for maintenance and optimal performance.

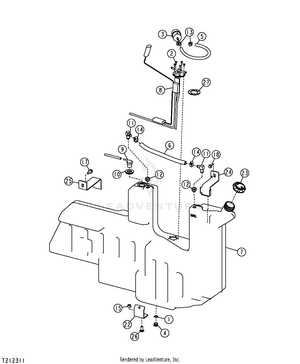

Engine and Transmission

- Power unit: Provides the necessary energy for operation.

- Gear system: Facilitates speed control and torque application.

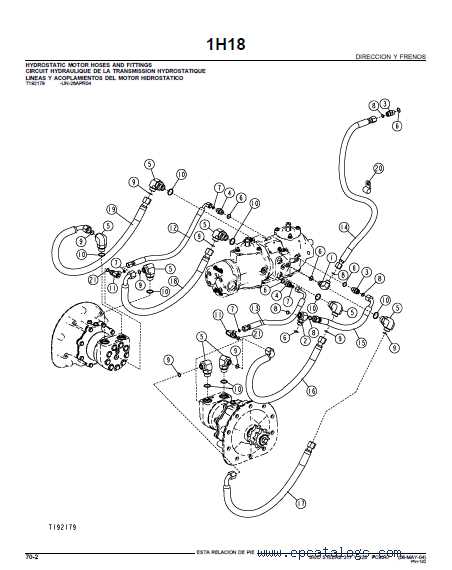

Chassis and Hydraulic System

- Frame: Offers structural integrity and stability during use.

- Hydraulic components: Enable smooth operation of attachments and steering.

These key aspects work in unison to ensure the overall effectiveness of the machine, allowing users to tackle various tasks with ease.

How to Read Parts Diagrams

Understanding illustrations for components is essential for effective maintenance and repair. These visuals provide a clear representation of various elements and their relationships within a machine.

Here are some key steps to help you interpret these illustrations:

- Familiarize Yourself with Symbols: Each component has a specific symbol. Learning these will make navigation easier.

- Identify Sections: Most illustrations are divided into sections. Focus on the relevant area to avoid confusion.

- Reference Numbers: Components are often labeled with reference numbers. Cross-check these with the accompanying list for details.

- Understand Orientation: Pay attention to the orientation of parts. This is crucial for accurate assembly or disassembly.

By mastering these techniques, you’ll ultimately enhance your ability to tackle repairs efficiently.

Common Repairs for John Deere 317

Regular maintenance and timely repairs are essential for ensuring the longevity and optimal performance of your equipment. Familiarizing yourself with typical issues can save time and money, allowing for efficient troubleshooting and upkeep.

Engine Issues

One prevalent concern involves engine performance. Symptoms like difficulty starting or stalling may indicate a need for spark plug replacement or fuel system cleaning. Checking the air filter regularly can also prevent airflow restrictions, ensuring smooth operation.

Transmission Problems

Transmission difficulties often manifest as unusual noises or slipping. Addressing these issues might require fluid changes or inspections of the drive belts. Ensuring proper alignment and tension of components can significantly enhance functionality and prevent further complications.

Where to Find Replacement Parts

Finding components for your equipment can often feel overwhelming, but several reliable resources can simplify the process. It’s essential to explore both online and offline options to ensure you access the most suitable replacements.

Online Retailers: Numerous websites specialize in machinery components, offering a wide range of selections at competitive prices. These platforms often provide detailed descriptions and user reviews, making it easier to choose the right item.

Local Dealerships: Visiting local distributors can be beneficial, as they often have a good inventory and can provide expert advice tailored to your needs. Establishing a relationship with these professionals can lead to valuable insights and support.

Salvage Yards: For those seeking budget-friendly options, salvage yards may offer used items at a fraction of the cost. While these may require more inspection, they can yield excellent finds.

Always ensure that the components you choose meet the necessary specifications to maintain the efficiency and safety of your machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your machinery requires a proactive approach to maintenance. Regular care not only extends the lifespan of your equipment but also enhances its performance, saving you time and money in the long run. Here are some essential tips to keep your machinery running smoothly.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Pay attention to signs of wear and tear, and address them promptly. Create a checklist to cover critical components and systems during each inspection.

Proper Lubrication

Keeping moving parts adequately lubricated reduces friction and prevents premature wear. Use the recommended lubricants for your specific equipment and ensure that all necessary areas are serviced regularly.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 100 hours |

| Filter Replacement | Every 200 hours |

| Belt Inspection | Monthly |

| Battery Check | Every 6 months |

By following these maintenance practices, you can significantly improve the reliability and longevity of your machinery, ensuring it remains in optimal condition for years to come.

Frequently Asked Questions About 317

This section aims to address common inquiries related to a popular model of machinery, providing insights for both new and experienced users. Here are some frequently asked questions that can help enhance your understanding and experience.

- What are the main features of this model?

This equipment is designed for durability, efficiency, and versatility, making it suitable for various tasks.

- How can I maintain my machine effectively?

Regular maintenance includes checking fluid levels, inspecting belts, and cleaning air filters.

- Where can I find replacement components?

Replacement parts are typically available through authorized dealers, online retailers, and specialty shops.

- What are common issues users face?

Common concerns include engine performance problems, hydraulic leaks, and electrical failures.

If you have further questions, feel free to consult user manuals or reach out to support services for detailed assistance.