In the world of lawn maintenance, the efficiency of cutting equipment is paramount. Whether for professional landscaping or personal yard care, understanding the individual elements that comprise these machines can significantly enhance their performance. A thorough grasp of how each segment functions allows operators to optimize usage and extend the lifespan of their tools.

Exploring the intricate layout of these devices reveals a complex interplay of mechanisms designed for precision and durability. By dissecting these elements, users can better identify wear and tear, facilitating timely maintenance and repair. This knowledge empowers individuals to tackle issues proactively, ensuring their equipment remains in peak condition.

Delving into the specifics of these assemblies not only aids in maintenance but also fosters a deeper appreciation for the engineering involved. Familiarity with the layout encourages informed decision-making when it comes to replacements or upgrades, ultimately leading to enhanced efficiency in lawn care routines.

Kubota RCK60 Mower Overview

This segment offers a comprehensive insight into a popular grass-cutting machine designed for efficiency and performance. Known for its robust construction and reliability, this equipment is ideal for maintaining lawns and larger green spaces. Users appreciate its versatility and ease of use, making it a preferred choice for both residential and commercial landscaping tasks.

The innovative design ensures effective operation, allowing for precise trimming and excellent grass handling. Its features cater to various mowing needs, ensuring that users can achieve optimal results in diverse environments.

| Feature | Description |

|---|---|

| Cutting Width | Designed for efficient coverage, ideal for larger areas. |

| Height Adjustment | Easy-to-use mechanism for varying grass lengths. |

| Durability | Manufactured with high-quality materials to withstand wear. |

| Ease of Maintenance | Accessible components for simple servicing and upkeep. |

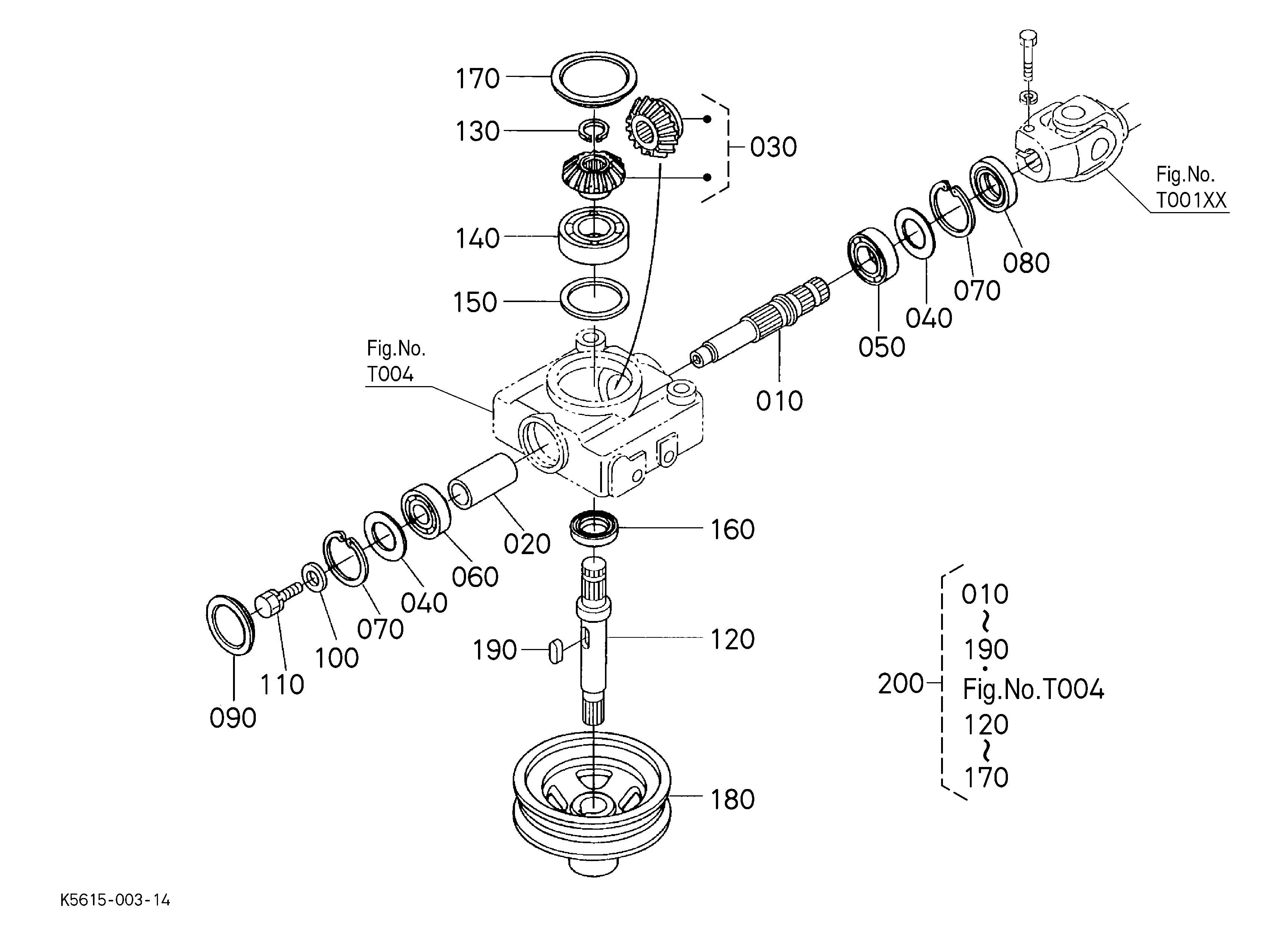

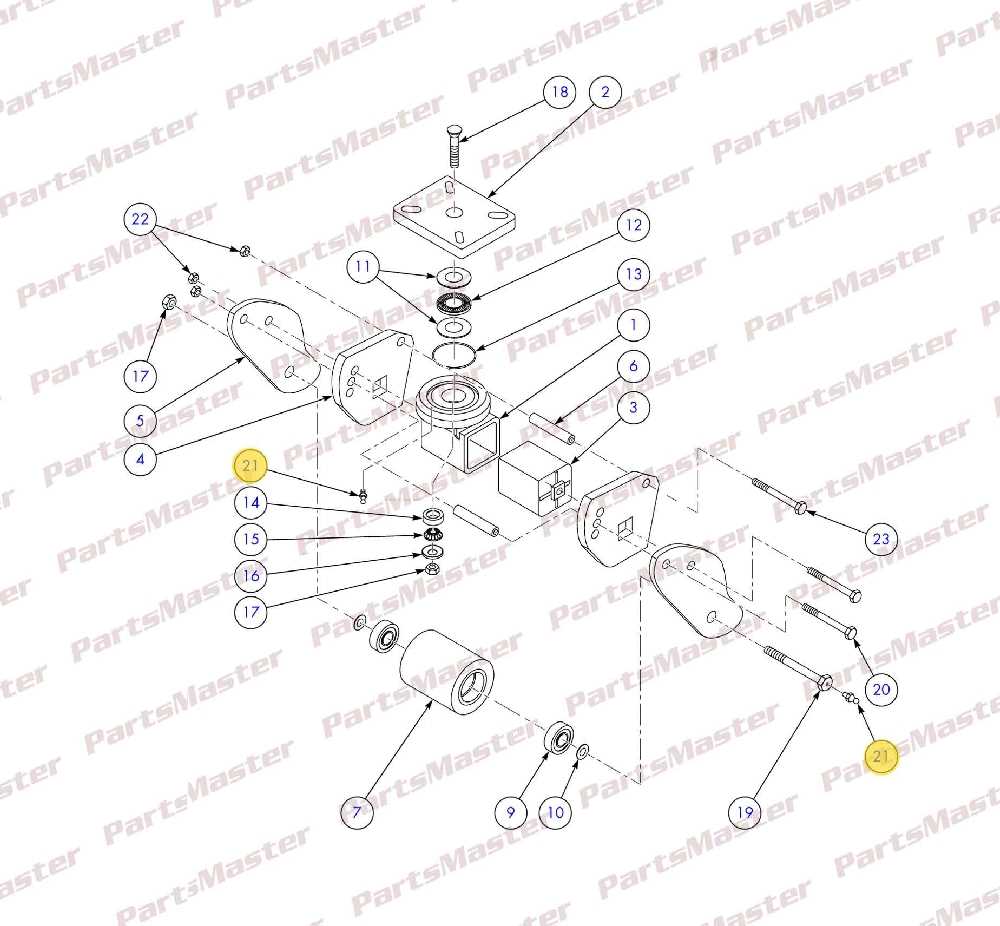

Key Components of the Mower Deck

The essential elements that contribute to the functionality and efficiency of a cutting mechanism play a crucial role in achieving optimal performance. Understanding these key components helps users maintain and troubleshoot their equipment effectively.

Primary Elements

- Blades: The sharp edges responsible for cutting grass and other vegetation, ensuring a clean finish.

- Spindles: These are the rotating shafts that drive the blades, crucial for their effective operation.

- Housing: The protective casing that encases the blades and spindles, designed to withstand impact and prevent debris from escaping.

- Wheels: Often found on the underside, these support the entire assembly and help in maneuvering over various terrains.

Support Structures

- Frame: The backbone of the setup, providing stability and strength to the entire assembly.

- Lift Mechanism: A system that allows users to adjust the height of the cutting apparatus, enhancing versatility.

- Belts: These transfer power from the engine to the spindles, ensuring smooth operation of the cutting elements.

- Guards: Safety features designed to protect users from accidental contact with moving parts.

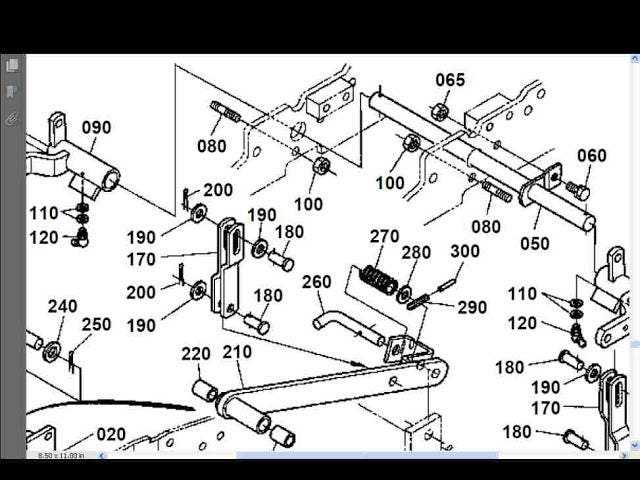

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and troubleshooting. A visual representation not only simplifies identification but also enhances your ability to recognize how various elements interact within the system.

Familiarizing yourself with each section enables you to pinpoint issues swiftly, ensuring optimal performance. Additionally, knowing the relationships between parts aids in understanding the overall function of the equipment.

By taking the time to explore this schematic, you will ultimately become more proficient in managing your machinery, resulting in improved longevity and reliability.

Common Issues with Mower Deck Parts

When it comes to maintaining lawn equipment, various components can face challenges that affect performance. Understanding these common problems can help in ensuring smooth operation and longevity.

- Wear and Tear: Over time, certain elements may degrade due to constant use.

- Misalignment: Components can shift from their original positions, leading to uneven cutting.

- Corrosion: Exposure to moisture can cause rust, impacting functionality.

- Clogging: Debris buildup can hinder efficiency and lead to overheating.

Addressing these issues promptly can prevent further damage and enhance the overall effectiveness of the equipment.

Replacement Parts for Kubota RCK60

Ensuring the efficiency and longevity of your equipment requires regular maintenance and timely replacement of essential components. When certain elements wear out or become damaged, it’s crucial to identify the appropriate alternatives to maintain optimal performance. This section provides a comprehensive overview of the essential components that may need replacement over time.

Commonly Replaced Components

Several key elements are frequently replaced to ensure the equipment operates smoothly. Understanding these components can help in making informed decisions when repairs are necessary.

| Component Name | Description | Replacement Frequency |

|---|---|---|

| Blades | Essential for cutting, these may become dull or chipped over time. | Every 25 hours of use |

| Belts | Power transmission elements that can wear due to friction and heat. | Annually or as needed |

| Spindles | Support the rotating blades and may need replacement if they become noisy or loose. | Every 100 hours of use |

| Washers | Small components that prevent wear and tear on larger parts, often overlooked. | As needed |

Where to Find Quality Replacements

When sourcing new components, it’s essential to choose reliable suppliers who offer high-quality alternatives. Authorized dealers and trusted online retailers often provide genuine replacements that ensure compatibility and durability. Always verify the specifications to match your specific requirements for optimal functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your lawn care equipment. By following a few simple guidelines, you can extend the lifespan of your machine and enhance its performance. Regular maintenance not only helps in preventing unexpected breakdowns but also promotes a healthier lawn, ultimately providing a better return on your investment.

Regular Inspections

Cleaning and Care

After each use, clean the equipment to remove grass clippings, dirt, and debris. This prevents corrosion and buildup that can hinder performance. Additionally, lubricate moving parts regularly to ensure smooth operation. A clean machine not only performs better but also lasts longer.

How to Troubleshoot Deck Problems

Addressing issues with your cutting apparatus can often be straightforward if approached systematically. Recognizing the signs of malfunction is the first step towards efficient resolution. By methodically examining various components, you can identify the root cause of performance problems.

1. Examine the Blades

Start by checking the sharpness and alignment of the blades. Dull or misaligned blades can lead to uneven cutting and excessive wear. If necessary, sharpen or replace them to restore optimal function.

2. Inspect the Drive System

Evaluate the drive mechanism for any signs of wear or damage. Listen for unusual noises during operation, which may indicate that components like belts or pulleys require attention. Ensure that all connections are secure.

3. Check for Obstructions

Look for any debris or buildup that could be obstructing movement. Grass clippings and dirt can accumulate, affecting performance. Regular cleaning can prevent these issues from arising.

4. Review Height Settings

Ensure that the cutting height is set appropriately for the terrain and type of grass. Incorrect height settings can lead to poor cutting results. Adjust as needed for the best outcome.

5. Consult the Manual

Refer to the manufacturer’s manual for specific troubleshooting tips and maintenance recommendations. It often contains valuable information tailored to your equipment, assisting in pinpointing issues effectively.

By following these steps, you can effectively diagnose and address common issues, ensuring your cutting equipment remains in peak condition for a longer lifespan.

Where to Buy Replacement Parts

Finding high-quality components for your equipment can greatly enhance its performance and longevity. Several options exist for sourcing these essential items, ensuring that you can maintain your machine in optimal condition.

Online Retailers: Numerous e-commerce platforms specialize in machinery components, offering a vast selection that often includes user reviews and competitive pricing. These sites frequently provide detailed descriptions and compatibility information, making it easier to find the right items.

Local Dealerships: Authorized dealers can be a reliable source for authentic components. Visiting a local dealership allows you to consult with knowledgeable staff who can assist in identifying the necessary items and provide guidance on installation.

Aftermarket Suppliers: Alternative vendors may offer cost-effective solutions, including refurbished or compatible components. While these options can save money, it’s crucial to verify the quality and compatibility of these products to avoid future issues.

Before purchasing, always check reviews and ratings to ensure you’re making an informed decision.